Method for preparing porous carbon material by using magnesium oxide template in cooperation with activation of potassium hydroxide

A potassium hydroxide and magnesium oxide technology, which is applied in the field of preparing porous carbon materials with magnesium oxide template and potassium hydroxide activation, can solve the problems of high cost, high energy consumption, long time consumption, etc., and achieves improved yield, promoted formation, Large and easy-to-get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Porous Carbon PC 4.2-16.8-6 The specific preparation process is as follows:

[0022] (1) Pretreatment of coal tar pitch: The coal tar pitch is ground to a particle size of less than 74 μm to obtain the pretreated coal tar pitch. The air drying base moisture of the obtained coal tar pitch is 1.13%, the ash content is 0.16%, the volatile matter is 57.5%, and the carbon is fixed. is 41.21%, and the softening point is 110°C.

[0023] (2) Grinding of reactants: Weigh 4.2 g of the pretreated coal tar pitch obtained in step (1) into a mortar, add 16.8 g of magnesium oxide with a particle size of 50 nm, add 6 g of solid potassium hydroxide, and grind the mixture of the three. The reaction was obtained after 1 h.

[0024](3) Preparation of porous carbon: move the reactant raw material obtained in step (2) into a corundum crucible, place the corundum crucible in a microwave chemical reactor, and place a nitrogen bottle, quartz protective cover, corundum crucible, the...

Embodiment 2

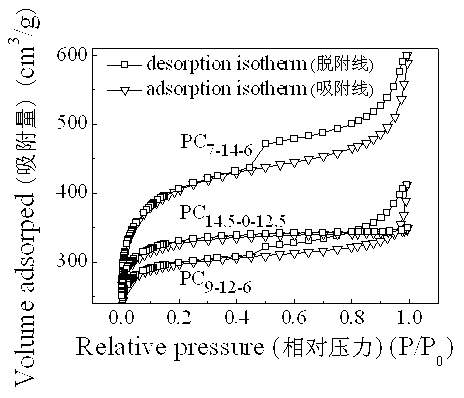

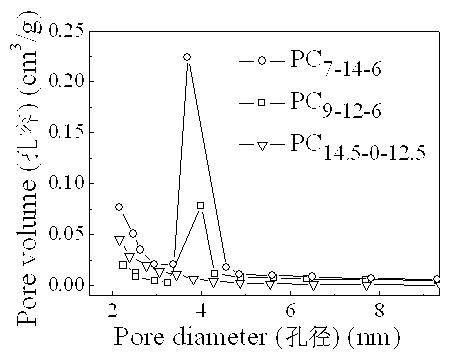

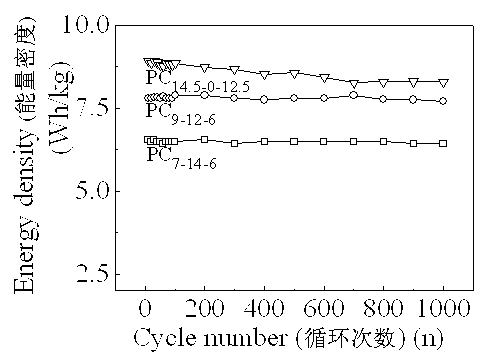

[0026] Example 2: Porous Carbon PC 7-14-6 The specific preparation process is as follows:

[0027] (1) Pretreatment of coal tar pitch: It was implemented by the same method as the step (1) in Example 1.

[0028] (2) Carry out the same method as step (2) in Example 1, except that the weighed coal tar pitch is 7 g, the magnesium oxide is 14 g, and the potassium hydroxide is 6 g.

[0029] (3) The same method as step (3) in Example 1 was carried out.

[0030] (4) Carry out the same method as step (4) in Example 1, except that the amount of 2M dilute sulfuric acid added is 300 mL, and the obtained porous carbon material is marked as PC 7-14-6 .

Embodiment 3

[0031] Example 3: Porous Carbon PC 9-12-6 The specific preparation process is as follows:

[0032] (1) Pretreatment of coal tar pitch: It was implemented by the same method as the step (1) in Example 1.

[0033] (2) Carry out the same method as step (2) in Example 1, except that the weighed coal tar pitch is 9 g, the magnesium oxide is 12 g, and the potassium hydroxide is 6 g.

[0034] (3) The same method as step (3) in Example 1 was carried out.

[0035] (4) Carry out the same method as step (4) in Example 1, except that the amount of 2M dilute sulfuric acid added is 270 mL, and the obtained porous carbon material is marked as PC 9-12-6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com