Activating solution composition for nonmetallic material electroless plating

A technology of non-metallic materials and compositions, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of destruction, palladium solution decomposition and catalytic failure, so as to maintain stability and improve activation reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

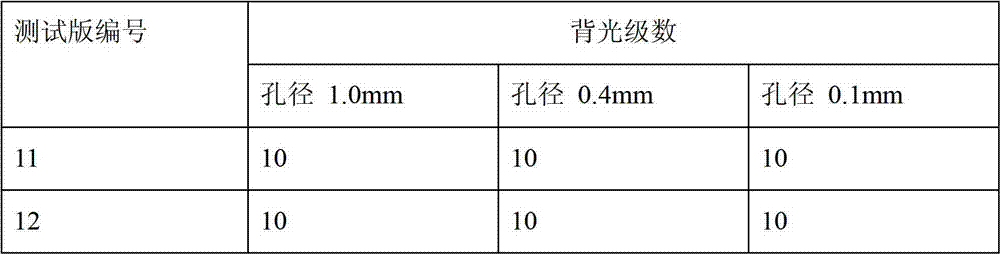

Examples

Embodiment Construction

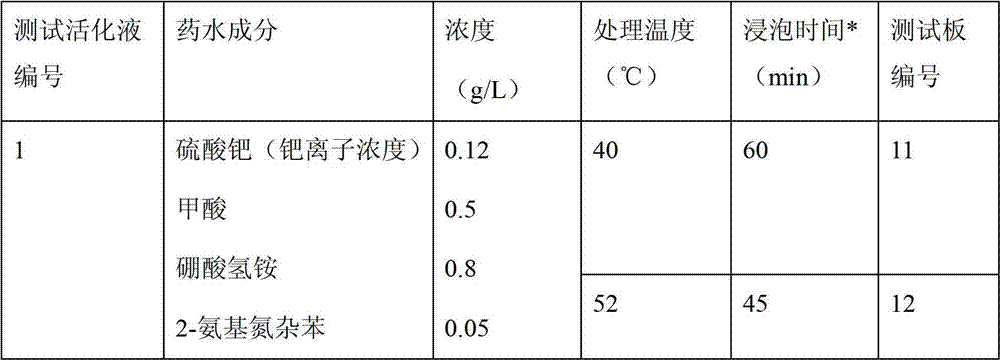

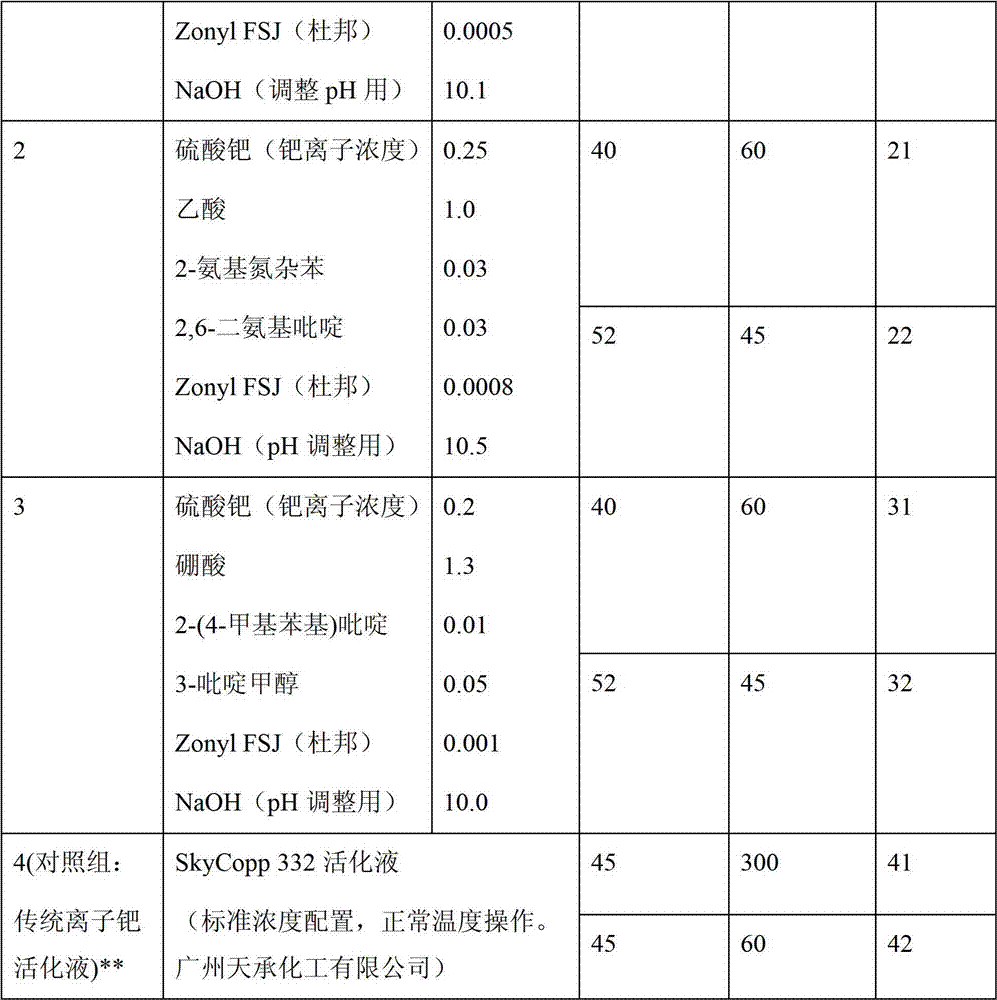

[0017] The invention provides an electroless plating activation solution suitable for non-metallic materials of horizontal line equipment, the activation solution contains palladium sulfate, a stabilizer, a reaction accelerator and a surfactant, and the activation solution is adjusted to a suitable level with a dilute alkaline solution. pH range.

[0018] The palladium sulfate in the activation solution of the present invention is the main active component of the activation solution, and can be adsorbed on the surface of the non-metal material to form a metal catalytic active center, so that the subsequent electroless plating can form a complete metal plating layer on the surface of the non-metal material.

[0019] The stabilizer in the activation solution of the present invention includes formic acid, acetic acid, boric acid and salts thereof, one or a combination of the two, which can maintain the stability of the activation solution under the condition of vigorous stirring o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com