Assistant absorption agent for removing foreign matter from petroleum product and method of producing the same

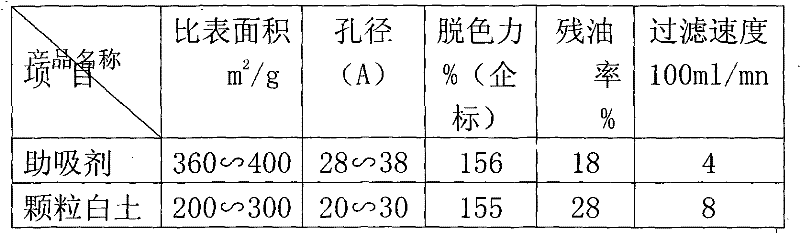

A technology for oil and impurities, applied in the field of chemical products, can solve the problems of poor market competitiveness, low product quality, slow filtration speed, etc., and achieve the effects of low residual oil rate, strong decolorization power, and fast filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. Processing of attapulgite raw ore:

[0014] Attapulgite raw ore with attapulgite content of 20-50% and water content below 20% is selected, put into a reaction kettle, and diluted sulfuric acid is added. The consumption of diluted sulfuric acid is the amount obtained after diluting the 15-50% sulfuric acid (concentration is 98%) of the weight of the raw ore of the convex rod with the water of 50-70% of the raw ore of the convex rod; then heated to 150-200 °C, make it activated for 16 hours to promote the attapulgite cation reaction.

[0015] After the activation reaction, stir evenly at 150-200°C for 10 minutes.

[0016] The material is extruded under a pressure of 250kg into a flake with a thickness of 1-2mm.

[0017] The flakes are baked at a temperature of 370-450°C for 20-60 minutes to make the decolorization power reach 90-170% (enterprise standard).

[0018] After roasting, it is processed into 200-mesh powder with 95% passing rate through grinding, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com