A binder with inorganic minerals as the core component

A technology of inorganic minerals and adhesives, applied in the field of building decoration materials, can solve the problems of broken hollow, loose surface of tiles, long initial setting time, etc., and achieve the effects of good adsorption capacity, unique dispersibility and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

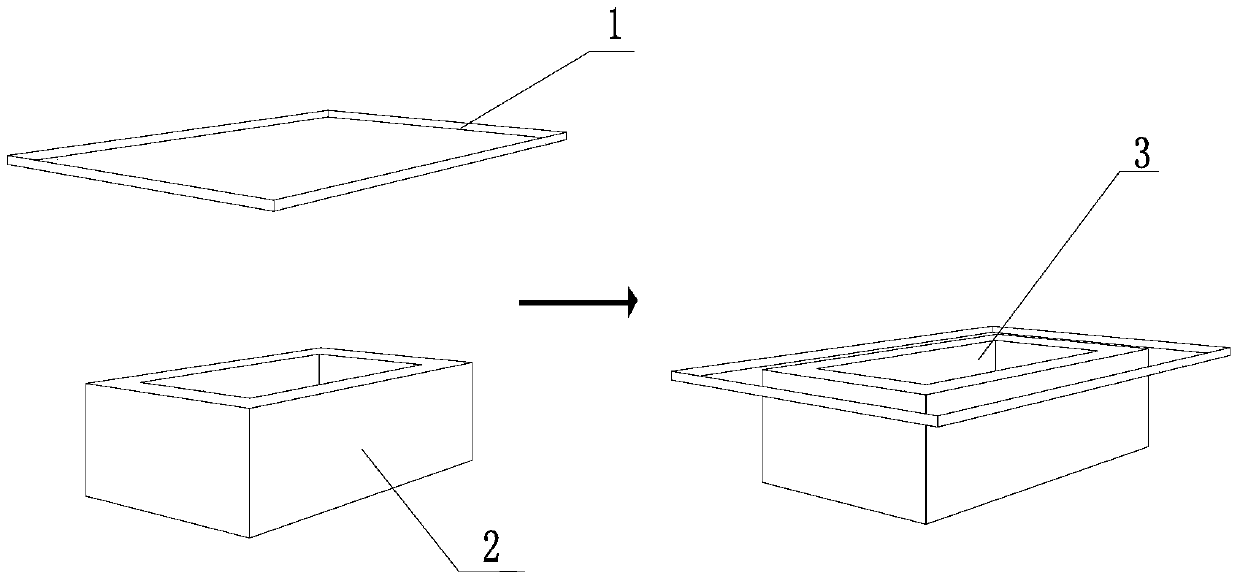

Image

Examples

Embodiment 1

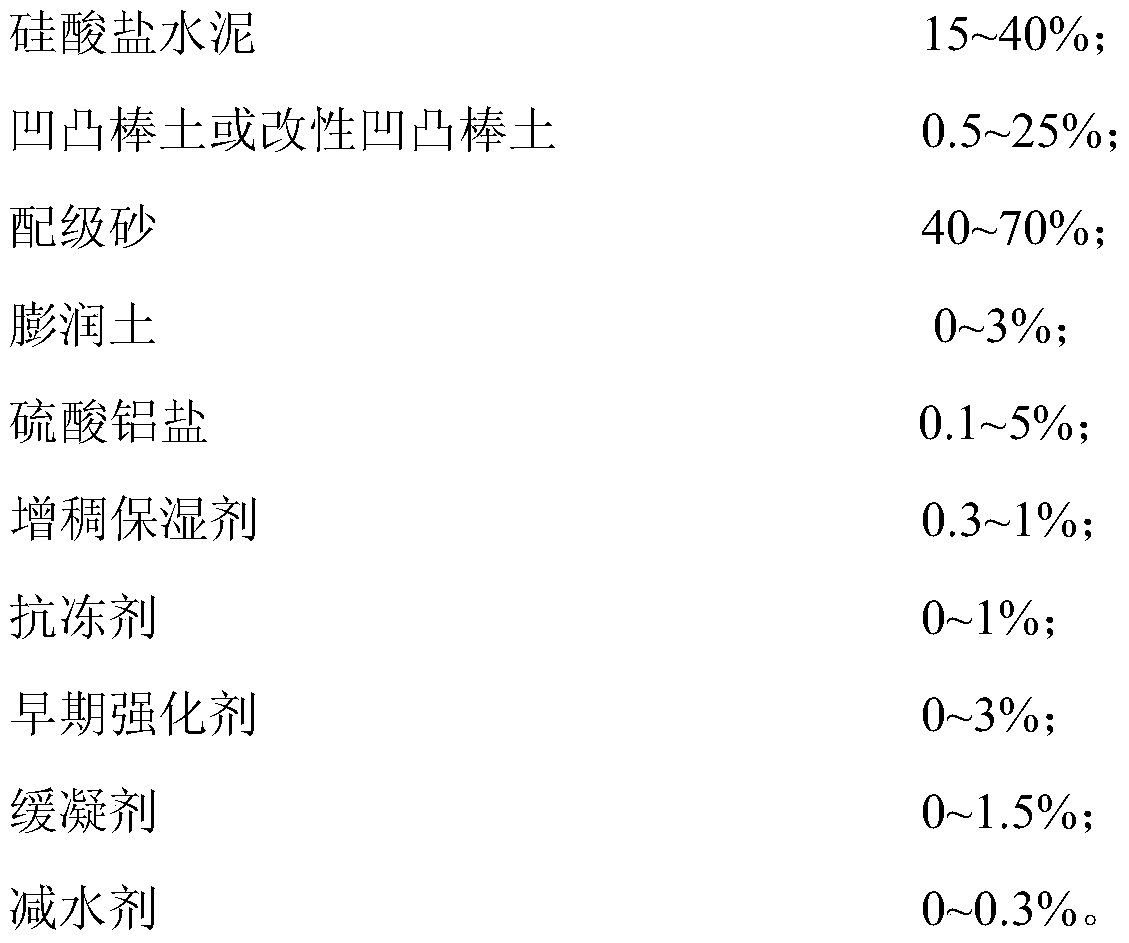

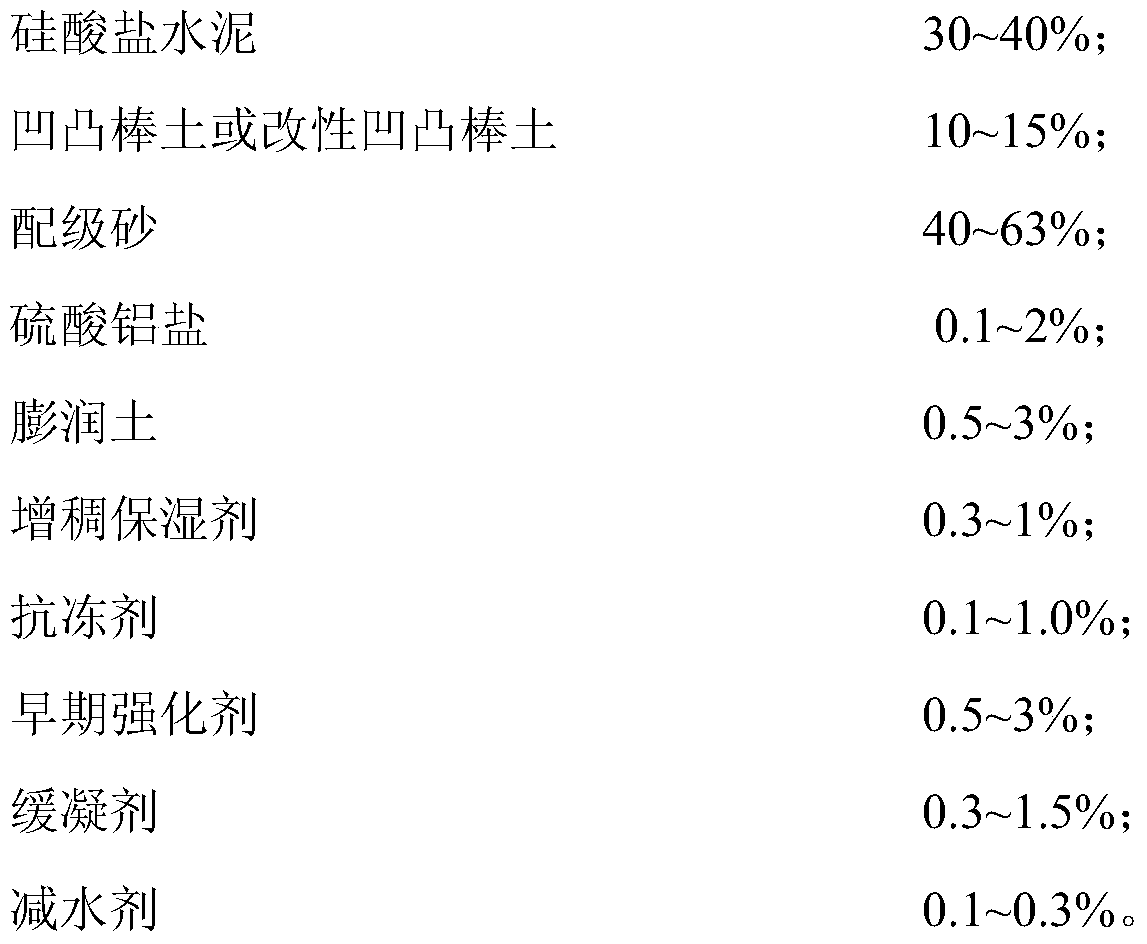

[0043] A binder with inorganic minerals as the core component, its formulation components and content are:

[0044] Ordinary 425 Portland cement 300 kg, graded quartz sand 577 kg, attapulgite 100 kg, calcium-based bentonite 5 kg, early strengthening agent lithium carbonate 3 kg, thickening and moisturizing agent hydroxymethyl cellulose 3 kg, retarding 1 kg of sodium tartrate, 1 kg of antifreeze calcium chloride, 10 kg of aluminum potassium dodecahydrate. Mix 180-250 kg of water.

[0045] The process of above-mentioned adhesive is:

[0046] First grade the quartz sand, 40-80 mesh accounts for 60%, 80-120 mesh accounts for 40%, and the grade is prepared; then the portland cement is passed through the 80-mesh screen to remove the lumps, and then put into the mixing tank respectively ;When adding aluminum potassium sulfate dodecahydrate, it should be ground into powder and passed through a 80 mesh, and then put into the mixing tank together with attapulgite, bentonite, humectant...

Embodiment 2

[0048] A binder with inorganic minerals as the core component, its formulation components and content are:

[0049] 370 kg of ordinary 425 portland cement, 600 kg of graded quartz sand, 10 kg of attapulgite, 2 kg of hydroxymethyl cellulose, 3 kg of naphthalene-based water reducing agent, 15 kg of aluminum potassium sulfate dodecahydrate , with 180-280 kg of water.

[0050] The process of above-mentioned adhesive is:

[0051] First grade the quartz sand, 40-80 mesh accounts for 60%, 80-120 mesh accounts for 40%, and the grade is prepared; then the portland cement is passed through the 80-mesh screen to remove the lumps, and then put into the mixing tank respectively ;When putting in potassium aluminum sulfate dodecahydrate, it should be ground into powder and passed through a 80 sieve, and then put into the mixing tank together with attapulgite, water reducing agent, early strengthening agent, and hydroxymethyl cellulose; after stirring for 20 minutes That is, a uniform fine ...

Embodiment 3

[0053] A binder with inorganic minerals as the core component, its formulation components and content are:

[0054] 400 kg of ordinary 425 Portland cement, 422 kg of graded quartz sand, 150 kg of attapulgite, 3 kg of methyl cellulose, 5 kg of early strengthening agent calcium formate, and 20 kg of potassium aluminum sulfate dodecahydrate.

[0055] The process of above-mentioned adhesive is:

[0056] First grade the quartz sand, 40-80 mesh accounts for 60%, 80-120 mesh accounts for 40%, and the grade is prepared; then the portland cement is passed through the 80-mesh screen to remove the lumps, and then put into the mixing tank respectively ;When putting in potassium aluminum sulfate dodecahydrate, it should be ground into powder and passed through a 80 mesh, and then put into the mixing tank together with attapulgite, early strengthening agent, and hydroxymethyl cellulose; after stirring for 20 minutes, it will be uniform and fine Finished product in powder form.

[0057] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com