Intellectualization ceramic tile vacuum ion membrane plating equipment

An ion coating and vacuum technology, applied in ion implantation coating, vacuum evaporation coating, sputtering coating and other directions, can solve the problems of poor coating effect, complicated operation and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

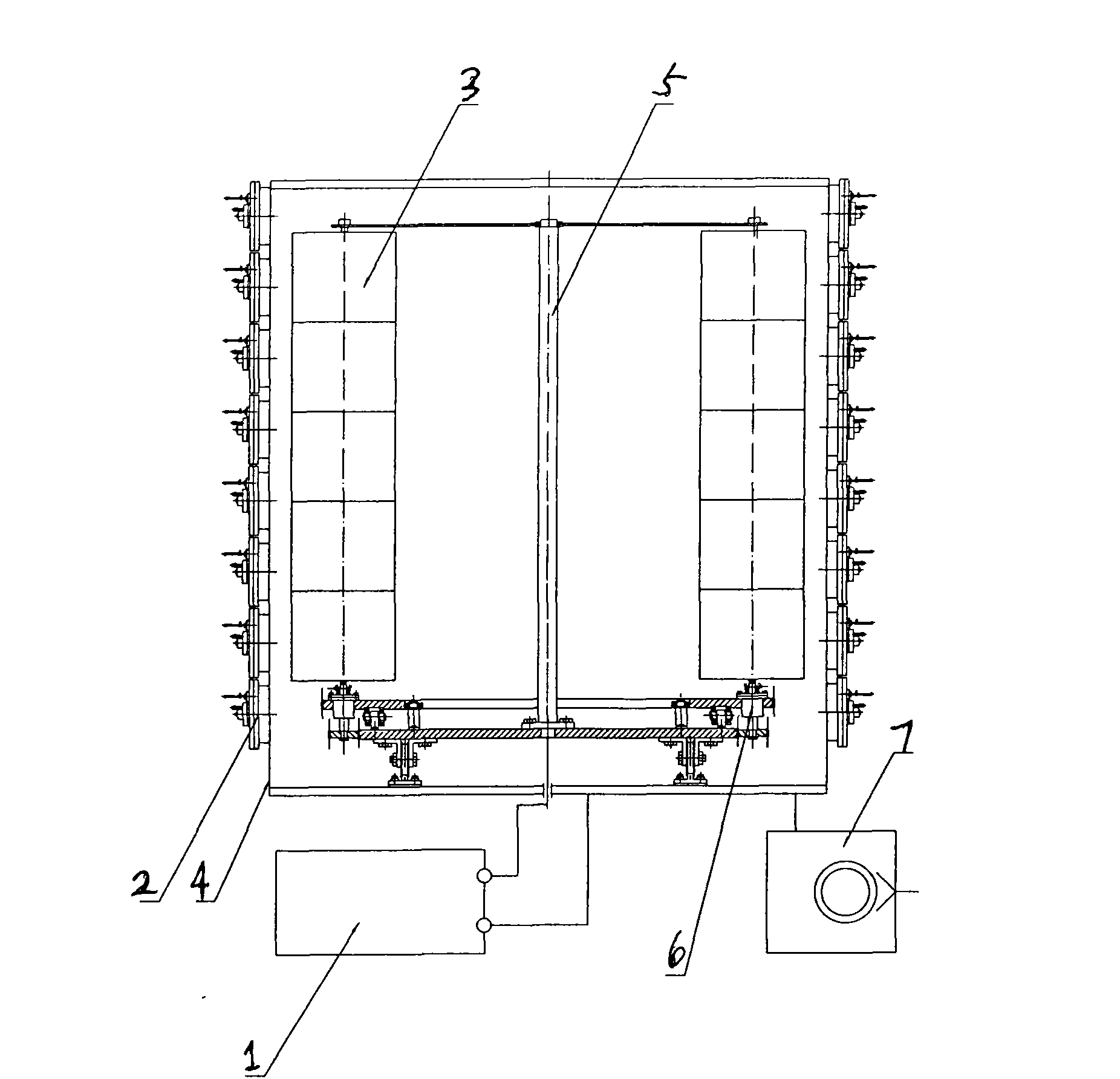

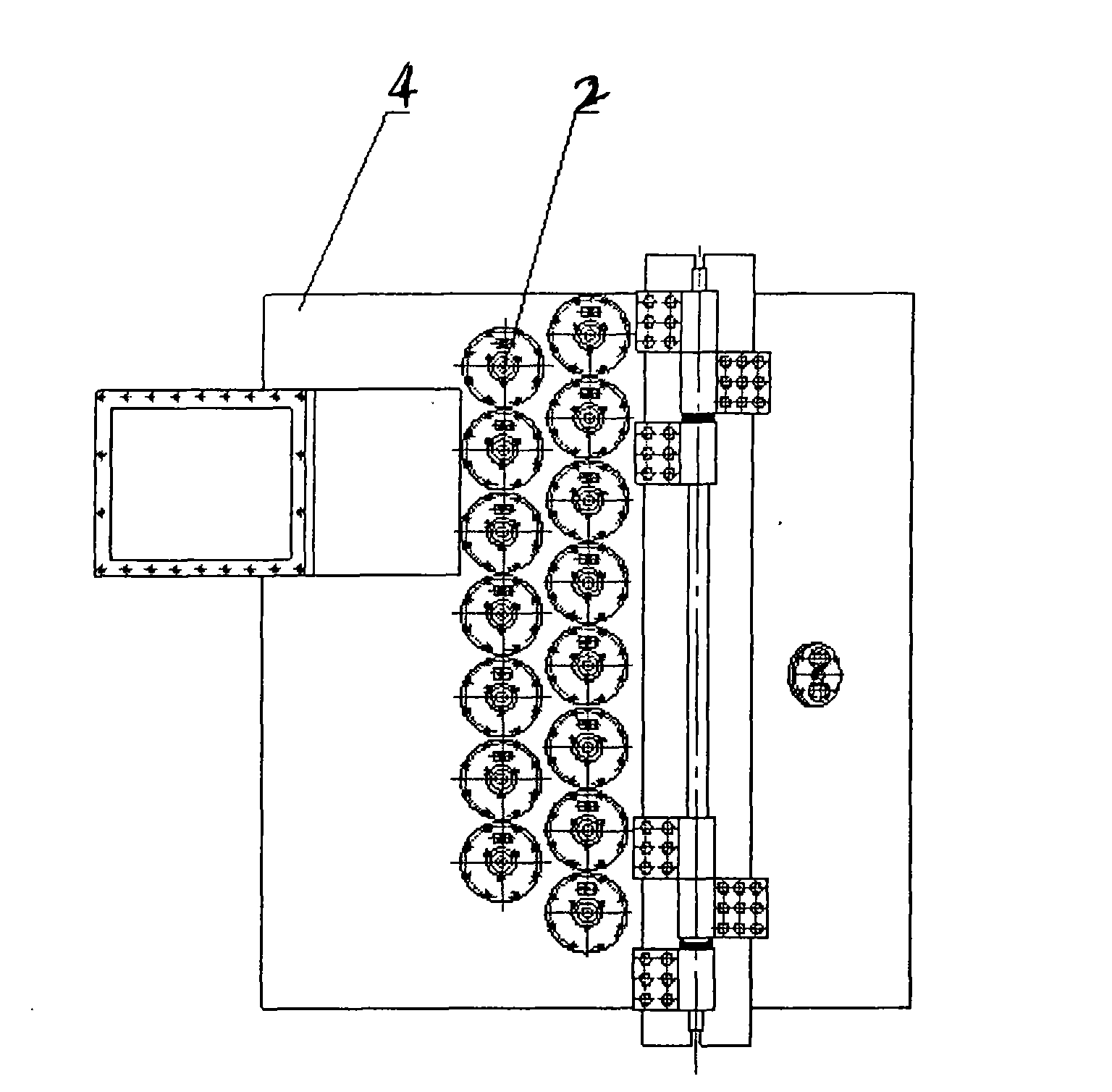

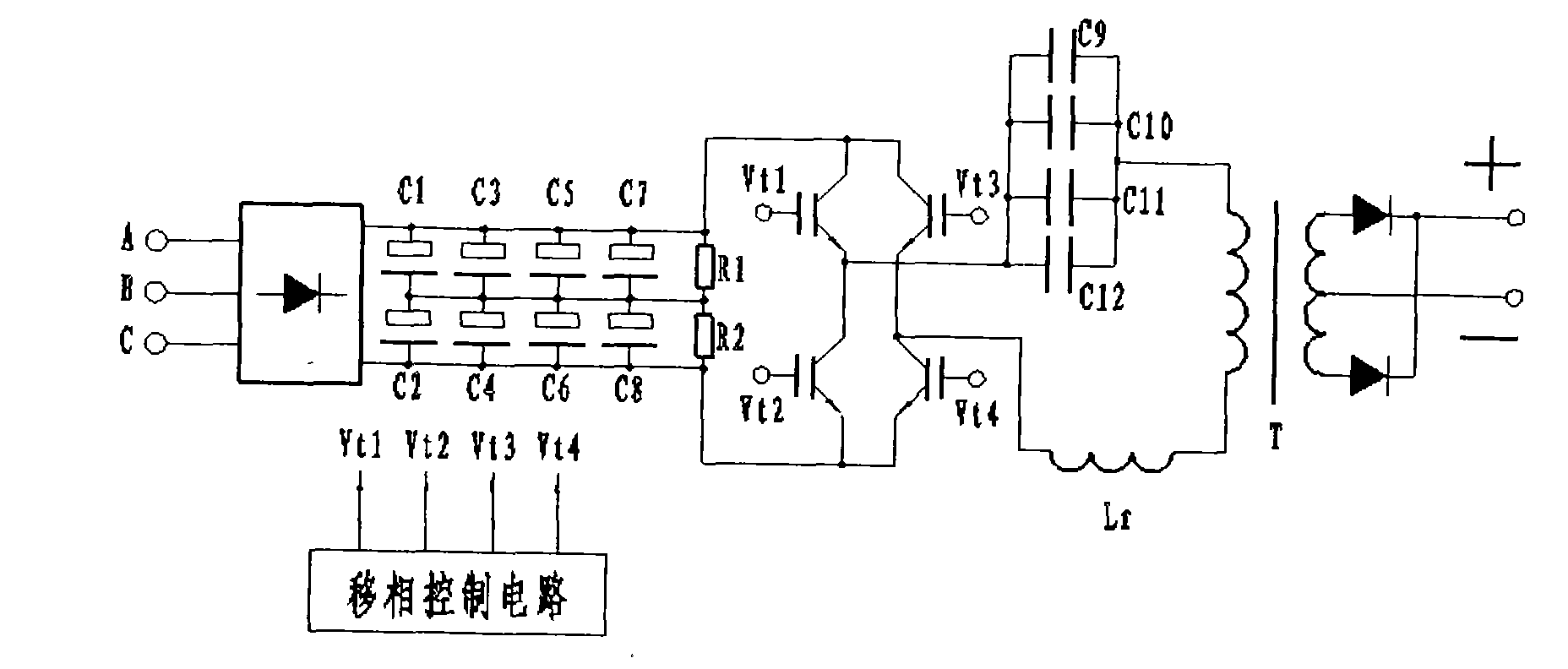

[0012] reference Figure 1-Figure 3 , An intelligent ceramic tile vacuum ion coating equipment, including a vacuum chamber 4 connected with a vacuum pumping system 7, a rotating rack type multifunctional sample stage 5, an arc metal ion source 2 and a PLC capable of being evenly distributed on both sides of the vacuum chamber Programming the centralized controller, the rotating rack type multifunctional sample stage 5 is insulated from the vacuum chamber, and the cleaning electrode 6 of the gas ion cleaning source is located on the rotating rack type multifunctional sample stage 5 and connected to the vacuum outdoor gas ion cleaning power supply 1. There are 30 arc metal ion sources 2 and the distance between the ion source and the plating piece 3 is 150 mm. The power supply of the arc metal ion source adopts an IGBT inverter switching power supply with a working voltage of 20-30V and a working current of 50-150A. The rectifier part of the inverter switching power supply adopts a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com