Online continuous production and injection integrating method and device for jelly dispersoid

A jelly dispersion and jelly technology, which are applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of inability to achieve deep profile control or flood control, continuous online injection, and continuous large-scale construction. Difficulties and other problems, to achieve the effect of shortening production time, practical and convenient, and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

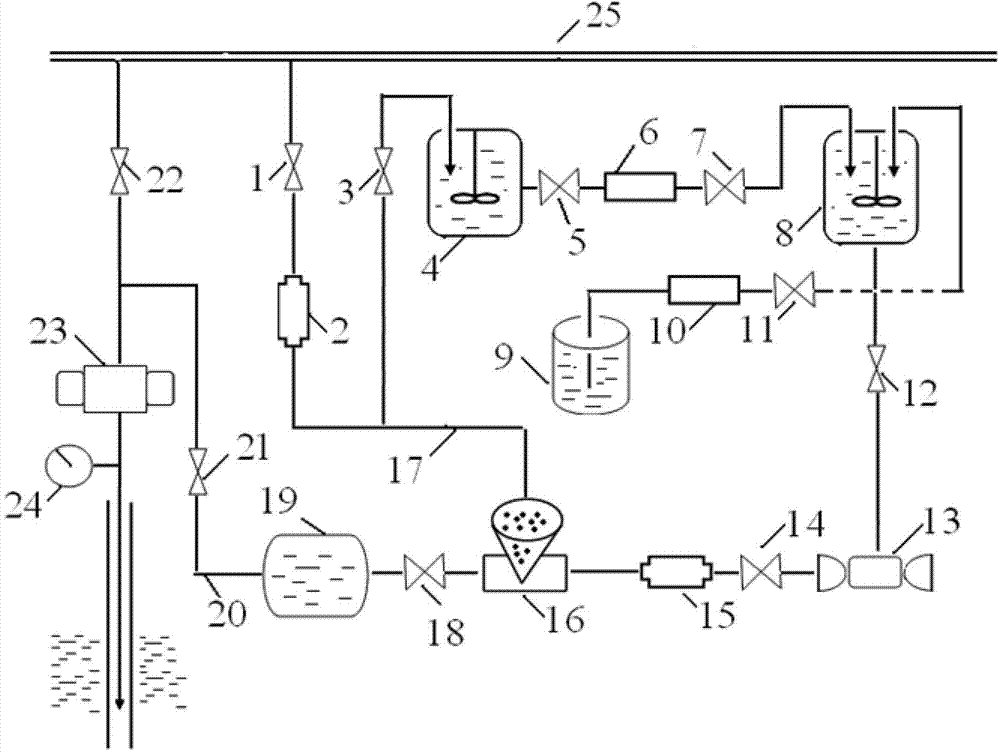

[0038] An integrated device for continuous on-line production and injection of jelly dispersion, the structure is figure 1 Shown, comprise high-pressure plunger pump 23, curing tank 4, cross-linking agent storage tank 9, jelly reaction tank 8, colloid mill 16 and buffer tank 19, high-pressure plunger pump 23 is connected with water injection pipeline 25 by pipeline, ripening The liquid inlet of tank 4 is connected with water injection pipeline 25, and the liquid outlet of ripening tank 4 is connected with the liquid inlet of jelly reaction tank 8, and the liquid inlet of jelly reaction tank 8 is also connected with crosslinking agent storage tank 9, The liquid outlet of the jelly reaction tank 8 is connected with the feeding port of the colloid mill 16 by the rotor pump 13, the water inlet of the colloid mill 16 is connected with the water injection pipeline 25 by the water delivery pipeline 17, and the discharge port of the colloid mill 16 is connected with the buffer The li...

Embodiment 2

[0043] Utilize the device described in embodiment 1 to carry out the method for jelly dispersion continuous on-line production and injection, may further comprise the steps:

[0044] 1. Choose a molecular weight of 9.6×10 6 1. Add non-ionic polyacrylamide with a degree of hydrolysis of 3.6% into the aging tank 4, add water and stir for aging, and prepare a non-ionic polyacrylamide solution with a mass fraction of 0.6%;

[0045] 2. The non-ionic polyacrylamide solution with a mass fraction of 0.6% prepared in step 1 is transported to the jelly reaction tank 8 through the metering pump 6. Deliver zirconium acetate solution in jelly reaction tank 8, the flow rate of metering pump 10 is 32 liters / hour; The mass ratio of metering pump control nonionic polyacrylamide solution and zirconium acetate solution is 62.5: 1, the jelly reaction tank 8. Stir the non-ionic polyacrylamide solution and the zirconium acetate solution for 10 minutes to prepare the jelly system;

[0046] 3. The ...

Embodiment 3

[0050] Utilize the device described in embodiment 1 as described in embodiment 2 to carry out the method for continuous on-line production and injection of jelly dispersion, the difference is:

[0051] Step 2, the metering pump controls the mass ratio of the nonionic polyacrylamide solution to the zirconium acetate solution to be 60:1, and stirs the nonionic polyacrylamide solution and the zirconium acetate solution in the jelly reaction tank 8 for 8 minutes to prepare the jelly system;

[0052] Step 3, the rotor pump 13 sucks the jelly system in the jelly reaction tank 8 into the colloid mill 16 through the flow meter 15, and at the same time, the water delivery pipeline 17 injects water into the colloid mill 16 through the flow meter 2, and the flow meter controls The mass ratio of the jelly system to water is 1:3, adjust the rotation speed of the colloid mill 16 to 1000 rpm, and grind for 3 minutes to obtain a jelly dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com