Copper-zinc-tin sulfide thin film preparation method

A copper-zinc-tin-sulfur and thin-film technology, which can be used in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

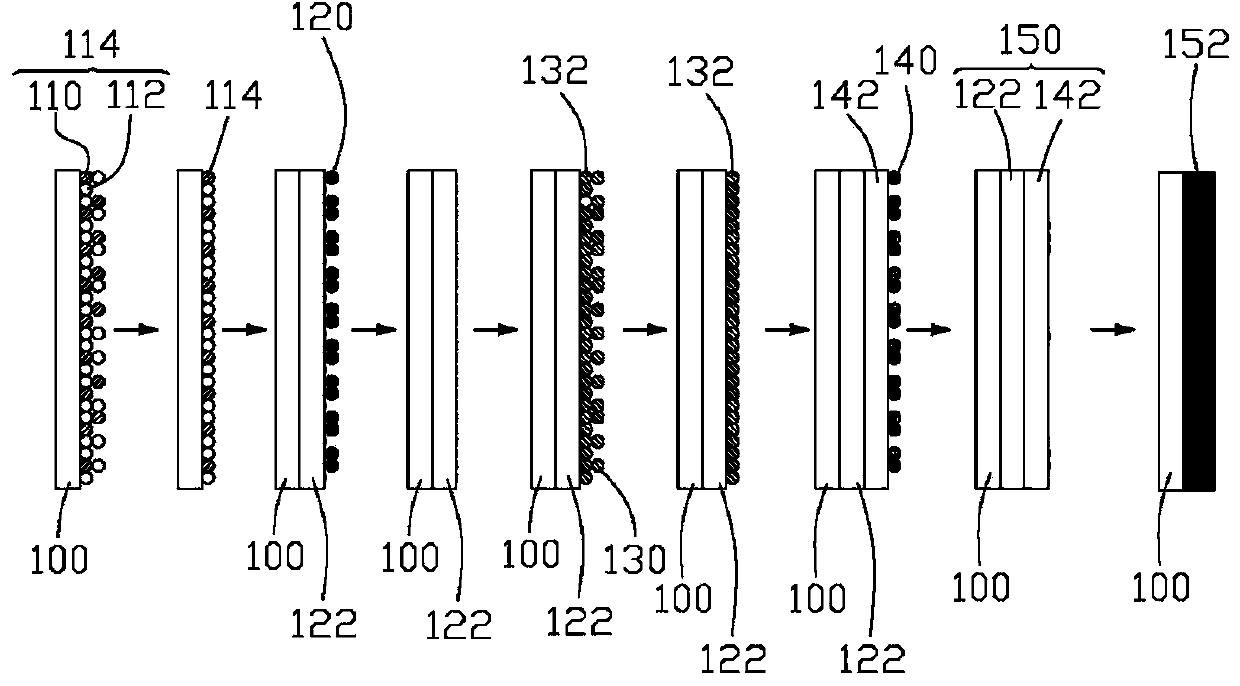

[0026] see figure 1 , the preparation method of the copper-zinc-tin-sulfur thin film 152 provided by the present invention comprises the following steps:

[0027] S10, taking out a substrate 100 after being dipped in a first cationic solution, so that a mixed ion layer 114 of copper ions and tin ions is adsorbed on the surface of the substrate 100;

[0028] S11, cleaning the mixed ion layer 114 of copper ions and tin ions;

[0029] S12, taking out the substrate 100 formed with the mixed ion layer 114 of copper ions and tin ions in a first anion solution, and then taking out the mixed ion layer 114 of copper ions and tin ions to absorb a plurality of first sulfur ions 120, and the plurality of first sulfide ions 120 react with the mixed ion layer 114 of the copper ions and tin ions to form a mixed compound film 122 of copper sulfide and tin sulfide;

[0030] S13, cleaning the copper sulfide and tin sulfide mixed compound film 122;

[0031] S14, taking out the substrate 100 ...

Embodiment 1

[0053] (1), clean the substrate. Soda-lime glass with a length of 70 mm and a width of 30 mm was ultrasonically cleaned with alkaline cleaning solution, acetone, isopropanol and high-purity deionized water for 20 minutes, and dried with nitrogen. Then, use the UV cleaner to clean the soda-lime glass surface ozone for 10 minutes, then put it into a vacuum drying oven for subsequent use.

[0054] (2), solution preparation. Prepare solutions A, B, and C with 99.99% metal salts and high-purity deionized water. A solution is CuSO 4 , SnSO 4 , trisodium citrate and deionized water, in which Cu 2+ The ion concentration is 0.01 mol / L, Sn 2+ The ion concentration is 0.02 mol / L, and the pH of the solution is 5.5. Solution B is ZnSO 4 deionized aqueous solution, where Zn 2+ The ion concentration is 0.5 mol / liter, and the pH of solution B is 5.0. C solution is N 2 Deionized aqueous solution of S salt, wherein, S 2- The ion concentration is 0.05 mol / liter.

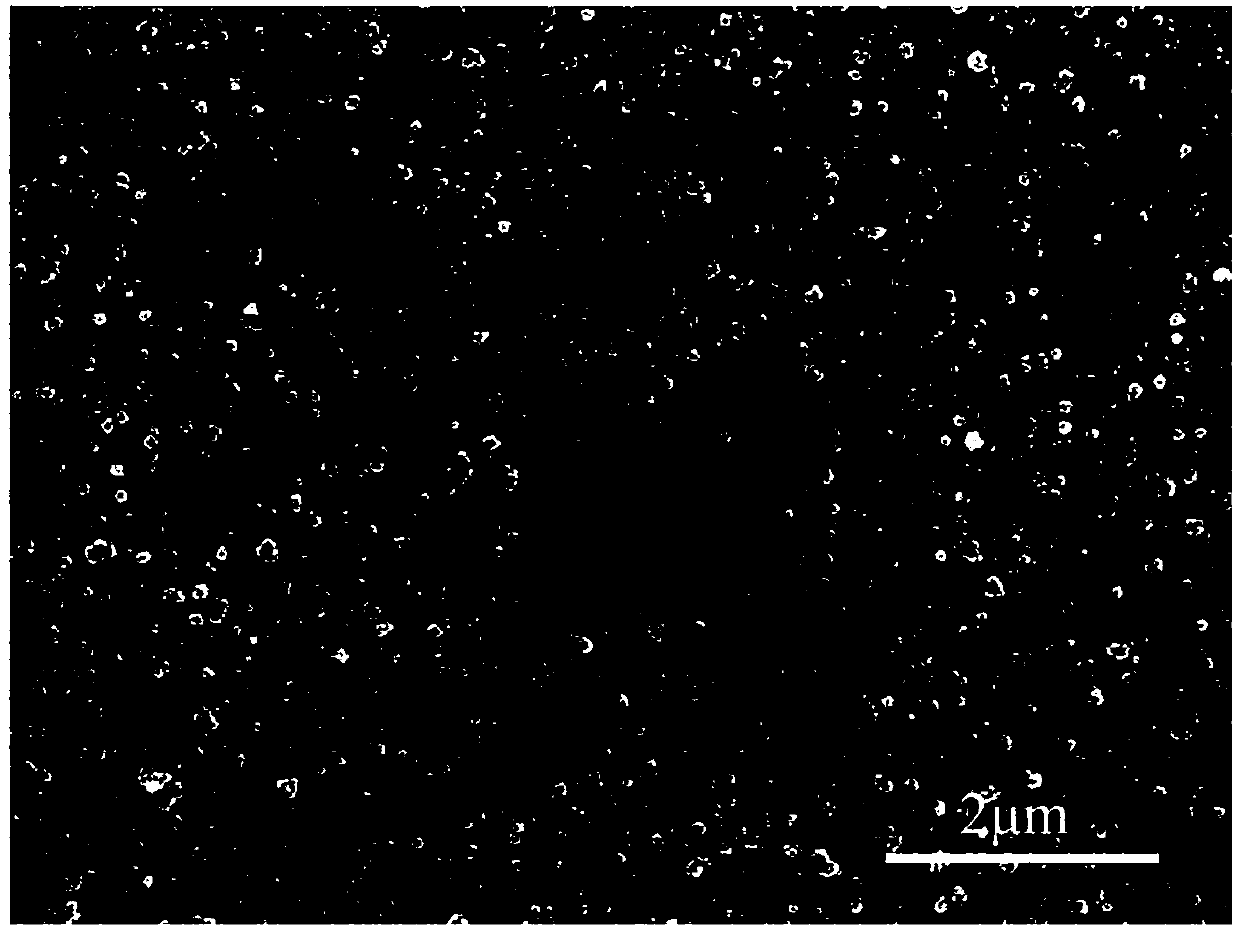

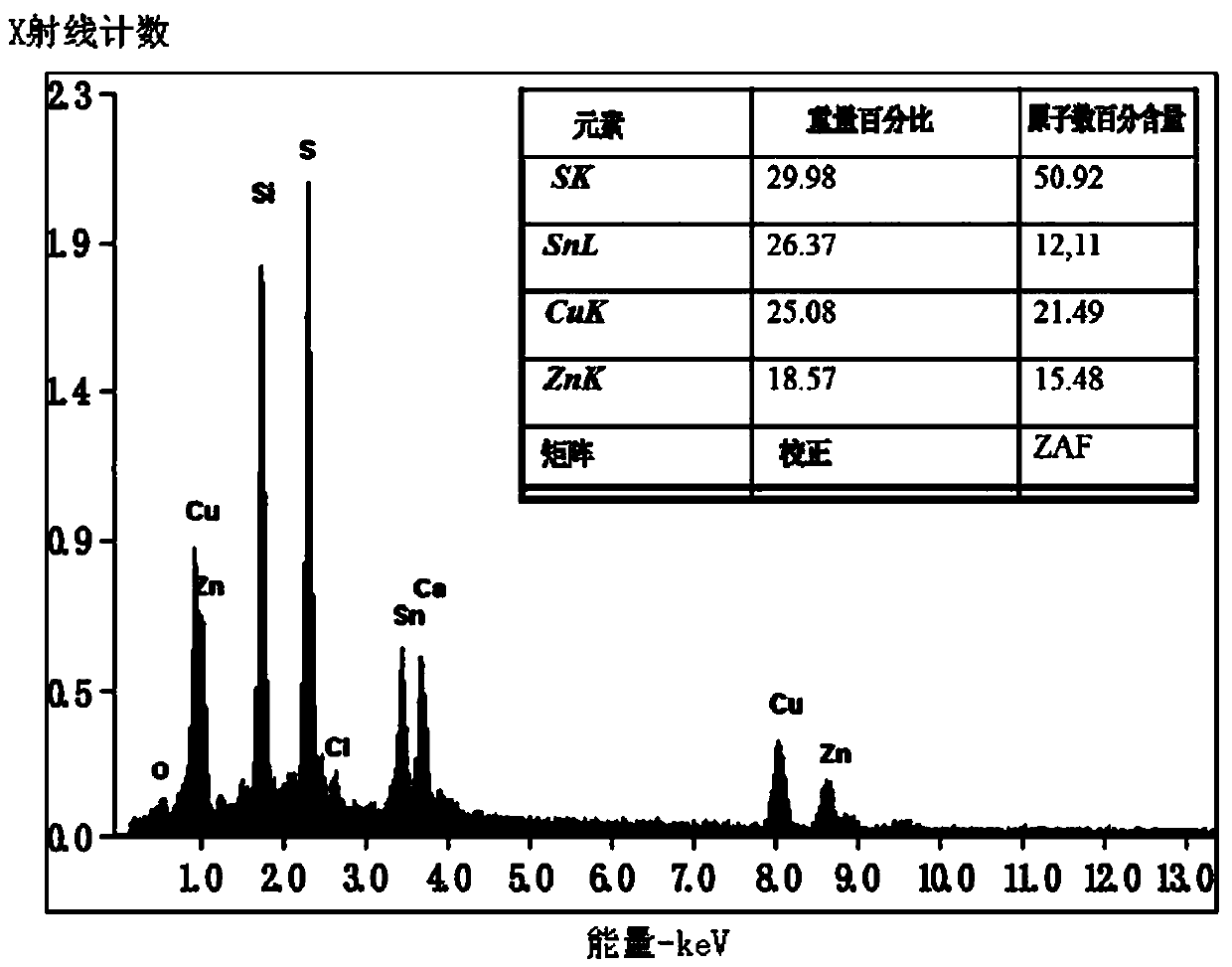

[0055] (3), prepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com