Lithium-containing metal oxide lithium electricity nanoelectrode materials and preparation method thereof

A lithium metal oxide and nano-electrode technology, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve problems such as nanostructure collapse, particle coarsening, and fusion between particles, so as to reduce energy consumption and production costs , the effect of improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

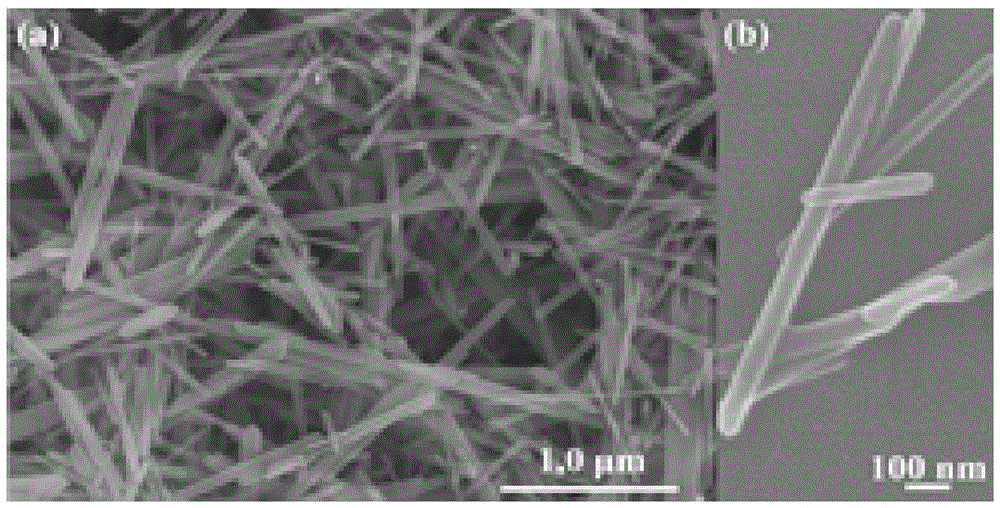

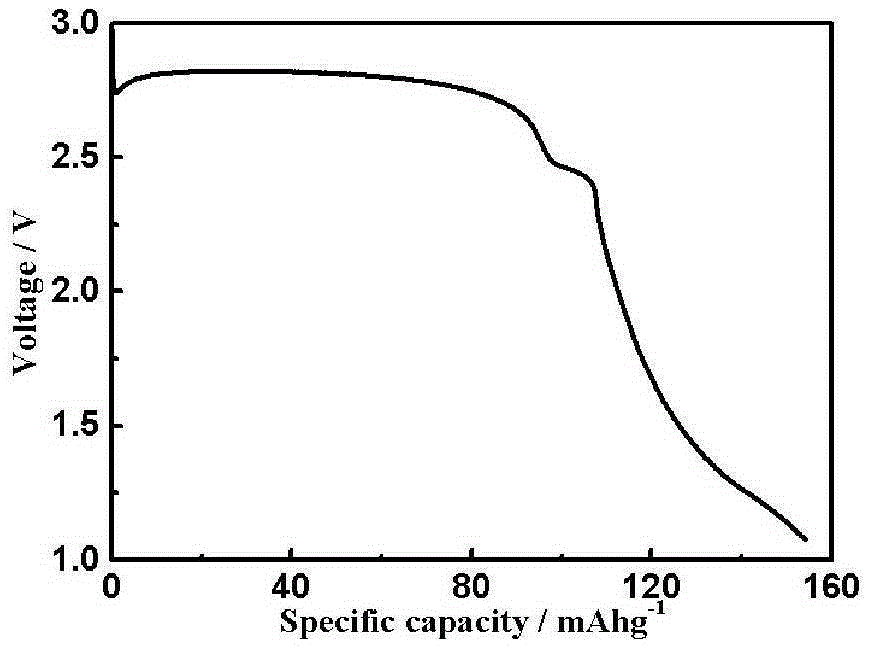

[0038] Example 1: Electrochemical lithiation-assisted preparation of lithium manganate nanorods

[0039] 1) Hydrothermal preparation of manganese dioxide nanorods:

[0040] Mn(C with a molar ratio of 1:1 2 h 3 o 2 ) 2 4H 2 O and Na 2 S 2 o 8 Dissolve in 80mL deionized water, stir at a constant speed for half an hour to prepare a 1mol / L aqueous solution, then transfer the obtained uniform solution to a 100ml polytetrafluoroethylene container sealed with a stainless steel container, and place it in a preheated Hydrothermal reaction at 130°C for 12 hours in a drying oven, cooled to room temperature with the furnace, centrifuged and washed three times with deionized water, washed once more with absolute ethanol, dried at 80°C for 10 hours, and finally obtained as attached figure 2 The shown diameter is about 20 ~ 100nm β-MnO 2 Nano stave.

[0041] 2) Manganese dioxide nanorod electrode preparation and battery assembly:

[0042] β-MnO 2 Nanorods (90%) were uniformly mi...

Embodiment 2

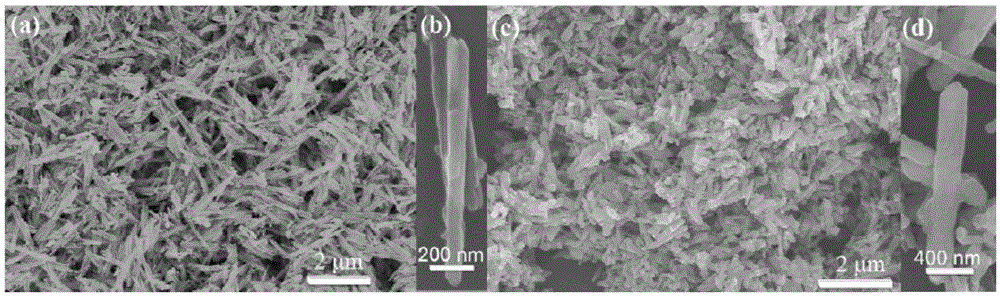

[0047] Example 2: Porous LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Electrochemical lithiation-assisted preparation of nanospheres

[0048] 1) (Ni 1 / 3 co 1 / 3 mn 1 / 3 )CO 3 Hydrothermal preparation of nanospheres:

[0049] Ni(C with a molar ratio of 1:1:1 2 h 3 o 2 ) 2 4H 2 O, Co (C 2 h 3 o 2 ) 2 4H 2 O and Mn(C 2 h 3 o 2 ) 2 4H 2 O was dissolved in 80mL of a mixed solution of deionized water and ethylene glycol (volume mixing ratio between 0.5 and 1.5), stirred at a constant speed for half an hour to obtain a mixed solution of 0.2 to 0.8 mol / L, and 0.016 to 0.064 After mol urea, transfer the obtained homogeneous solution into a 100ml polytetrafluoroethylene container sealed with a stainless steel container, place it in a preheated drying oven, and conduct a hydrothermal reaction at 130-200°C for 10-24 hours. After cooling to room temperature, it was centrifuged and washed three times with deionized water, washed once more with absolute ethanol, and dried at 80°C for 10 h...

Embodiment 3

[0058] Example 3: xLi 2 MnO 3 ·(1-x)LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Electrochemical Lithiation Assisted Preparation of (0

[0059] 1) (Ni (1-x) / 3 co (1-x) / 3 mn (1+2x) / 3 )CO 3 Hydrothermal preparation of nanospheres:

[0060] Ni(C 2 h 3 o 2 ) 2 4H 2 O, Co (C 2 h 3 o 2 )2 4H 2 O and Mn(C 2 h 3 o 2 ) 2 4H 2 O was dissolved in 80mL of a mixed solution of deionized water and ethylene glycol (volume mixing ratio between 0.5 and 1.5), stirred at a constant speed for half an hour to obtain a mixed solution of 0.2 to 0.8 mol / L, and 0.016 to 0.064 After mol urea, transfer the obtained homogeneous solution into a 100ml polytetrafluoroethylene container sealed with a stainless steel container, place it in a preheated drying oven, and conduct a hydrothermal reaction at 130-200°C for 10-24 hours. After cooling to room temperature, centrifuge and wash three times with deionized water, wash once more with absolute ethanol, and dry at 80°C for 10 hours to fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com