Cracking technology and system of solid organic material

A technology of organic material and cracking system, which is applied in the field of waste treatment and resource utilization, can solve the problems of low controllability, low cracking efficiency, and high energy consumption in the cracking process, so as to improve microwave utilization efficiency, cracking efficiency, and temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

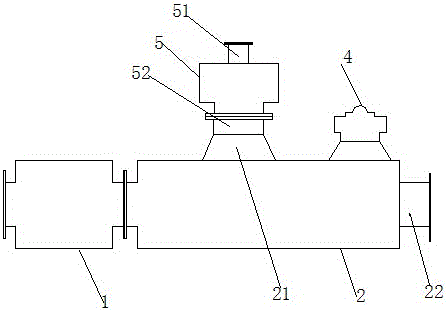

Image

Examples

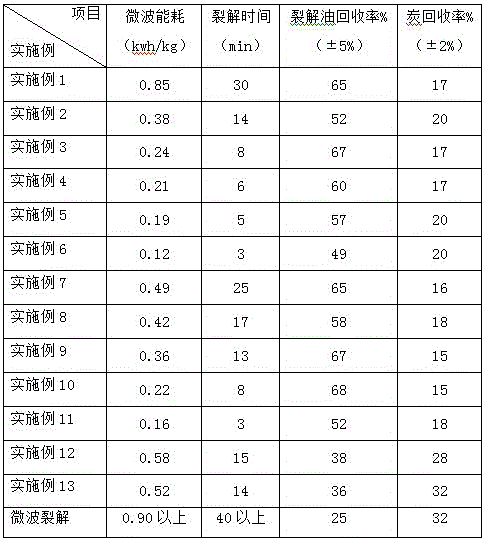

Embodiment 1

[0025] A solid organic material cracking process, the process is to first heat a gas medium to 200 DEG C, and then continuously pass the heated gas medium into a cracking device and microwaves simultaneously act on the solid organic material for cracking, and the gas medium is: nitrogen, and the solid organic material is biomass.

Embodiment 2

[0027] A solid organic material cracking process, the process is to first heat the gas to 800 ° C, and then continuously pass the heated gas medium into the cracking device and the microwave simultaneously act on the solid organic material for cracking, as described in this embodiment. The gas medium is water vapor. The solid organic material is biomass. This example heated the solid organic material to 30°C prior to cracking.

Embodiment 3

[0029] A solid organic material cracking process, the process is to first heat a gas medium to 450 ° C, and then continuously pass the heated gas medium into a cracking device and microwaves simultaneously act on the solid organic material for cracking. In this embodiment, The gaseous medium is carbon dioxide, and the solid organic material is plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com