A solid organic material cracking system

A technology of organic materials and pyrolysis system, which is applied in the field of waste treatment and resource utilization, can solve the problems of pyrolysis products not meeting environmental protection requirements, low controllability of pyrolysis treatment process, and low pyrolysis efficiency, so as to improve energy utilization rate and reduce pyrolysis Time, the effect of improving the cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

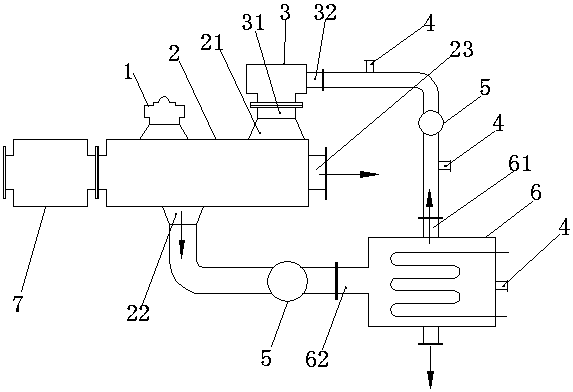

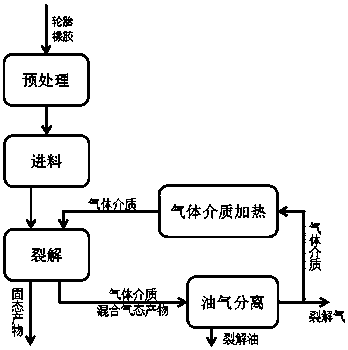

[0041] A solid organic material cracking system, comprising a microwave generator 1, a composite cracking chamber 2 connected to the microwave generator 1, and an oil-gas separation device 6, the composite cracking chamber 2 is provided with a composite cracking chamber inlet 21 and a composite cracking chamber Cavity gas outlet 22, the oil-gas separation device 6 is provided with an oil-gas separation device inlet 62 and an oil-gas separation device outlet 61, and also includes a gas heating device 3, and the gas heating device 3 is provided with a gas heating device inlet Port 32 and the gas heating device gas outlet 31, the gas heating device inlet 32 is communicated with the oil-gas separation device gas outlet 61, the gas heating device gas outlet 31 is communicated with the composite cracking chamber gas inlet 21, the oil-gas separation The air inlet 62 of the device communicates with the gas outlet 22 of the composite cracking chamber. The cracking system also includes...

Embodiment 2

[0043] A solid organic material cracking system, comprising a microwave generator 1, a composite cracking chamber 2 connected to the microwave generator 1, and an oil-gas separation device 6, the composite cracking chamber 2 is provided with a composite cracking chamber inlet 21 and a composite cracking chamber Cavity gas outlet 22, the oil-gas separation device 6 is provided with an oil-gas separation device inlet 62 and an oil-gas separation device gas outlet 61, the system also includes a gas heating device 3, and the gas heating device 3 is provided with a gas heating device Device air inlet 32 and gas heating device air outlet 31, described gas heating device air inlet 32 is communicated with oil-gas separation device air outlet 61, and described gas heating device air outlet 31 is communicated with composite cracking chamber air inlet 21, so The air inlet 62 of the oil-gas separation device communicates with the gas outlet 22 of the composite cracking chamber, and the...

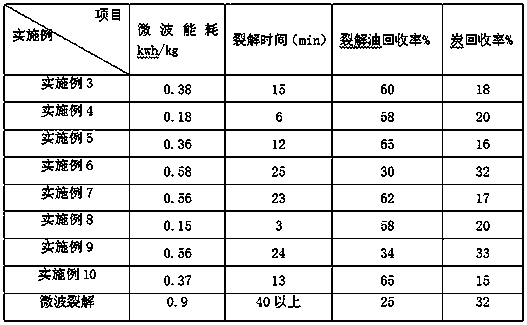

Embodiment 3

[0048] A solid organic material cracking system, comprising a microwave generator 1, a composite cracking chamber 2 connected to the microwave generator 1, and an oil-gas separation device 6, the composite cracking chamber 2 is provided with a composite cracking chamber inlet 21 and a composite cracking chamber Cavity gas outlet 22, the oil-gas separation device 6 is provided with an oil-gas separation device inlet 62 and an oil-gas separation device gas outlet 61, which is characterized in that it also includes a gas heating device 3, and the gas heating device 3 is provided with a gas The heating device air inlet 32 and the gas heating device gas outlet 31, the gas heating device air inlet 32 is communicated with the oil-gas separation device gas outlet 61, and the gas heating device gas outlet 31 is communicated with the composite cracking chamber air inlet 21, The air inlet 62 of the oil-gas separation device communicates with the gas outlet 22 of the composite cracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com