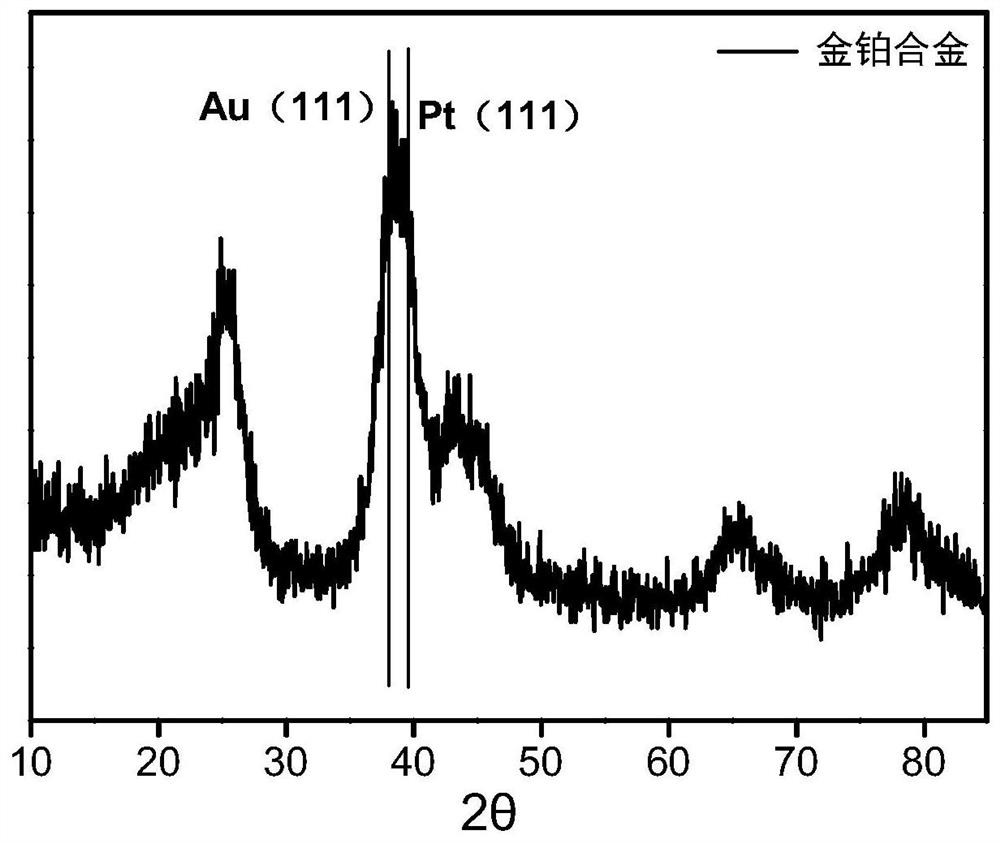

Supported gold-platinum alloy electrode for electrocatalytic reduction of CO2 and preparation method thereof

A gold-platinum alloy, supported technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low selection of catalytic products, low yield, poor catalyst stability, etc., to achieve improved binding energy, simple process, enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

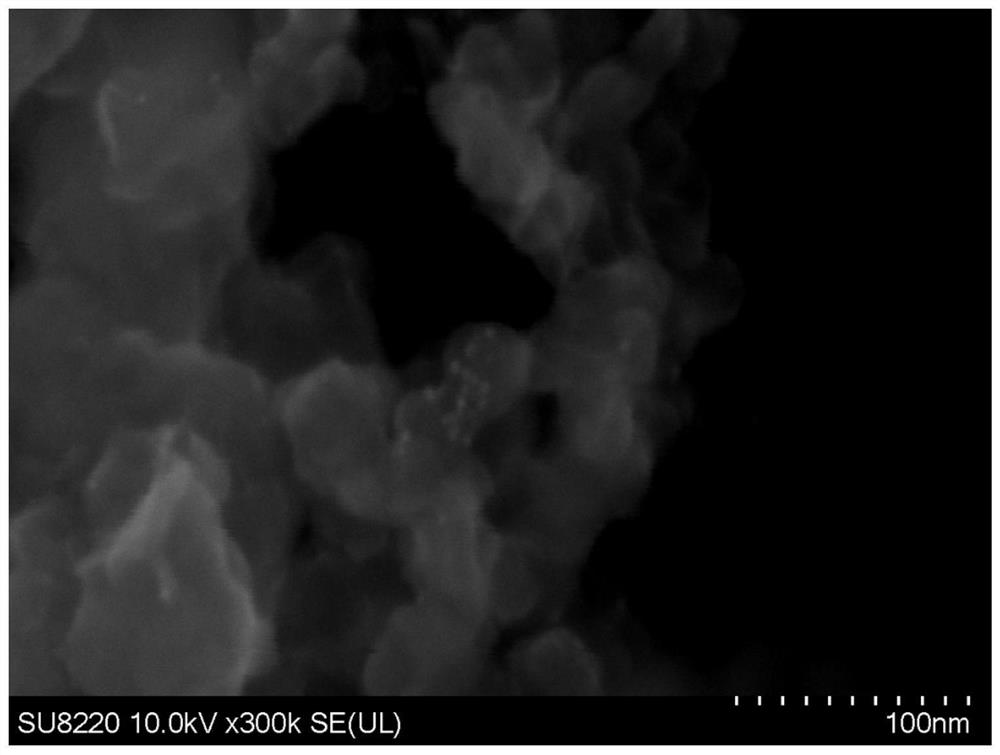

Embodiment 1

[0030] Electrocatalytic reduction of CO 2 The preparation method of the supported type gold-platinum alloy electrode comprises the following steps:

[0031] (1) Take 5g of Vulcan XC-72R carbon black, add it to 200mL of acetone solution, raise the temperature to 60°C, condense and reflux, keep the temperature for 4h, dry and wash, remove the acetone solution on the surface; add 200mL (1:5) of hydrochloric acid solution Heated to 120°C, condensed and refluxed, kept at a constant temperature for 10 hours, dried and washed to remove the surface hydrochloric acid solution; added to 200mL5mol / L nitric acid solution, heated to 120°C, condensed and refluxed at a constant temperature for 10 hours, dried and washed to remove the surface nitric acid solution . Dry for 10 hours to obtain a hydrophilic Vulcan XC-72R carbon black carrier.

[0032] (2) Take 30 mg of the carbon black carrier treated in step (1), add an appropriate amount of deionized water, and perform ultrasonic treatment ...

Embodiment 2

[0036] Electrocatalytic reduction of CO 2 The preparation method of the supported type gold-platinum alloy electrode comprises the following steps:

[0037] (1) Take 10g of Vulcan XC-72R carbon black, add it to 200mL of acetone solution, raise the temperature to 60°C, condense and reflux, keep the temperature for 4h, dry and wash, remove the acetone solution on the surface; add 200mL (1:5) of hydrochloric acid solution Heated to 120°C, condensed and refluxed, kept at a constant temperature for 10 hours, dried and washed to remove the surface hydrochloric acid solution; added to 200mL5mol / L nitric acid solution, heated to 120°C, condensed and refluxed at a constant temperature for 10 hours, dried and washed to remove the surface nitric acid solution . Dry for 10 hours to obtain a hydrophilic Vulcan XC-72R carbon black carrier.

[0038] (2) Take 30 mg of the Vulcan XC-72R carbon black carrier treated in step (1), add an appropriate amount of deionized water, and perform ultras...

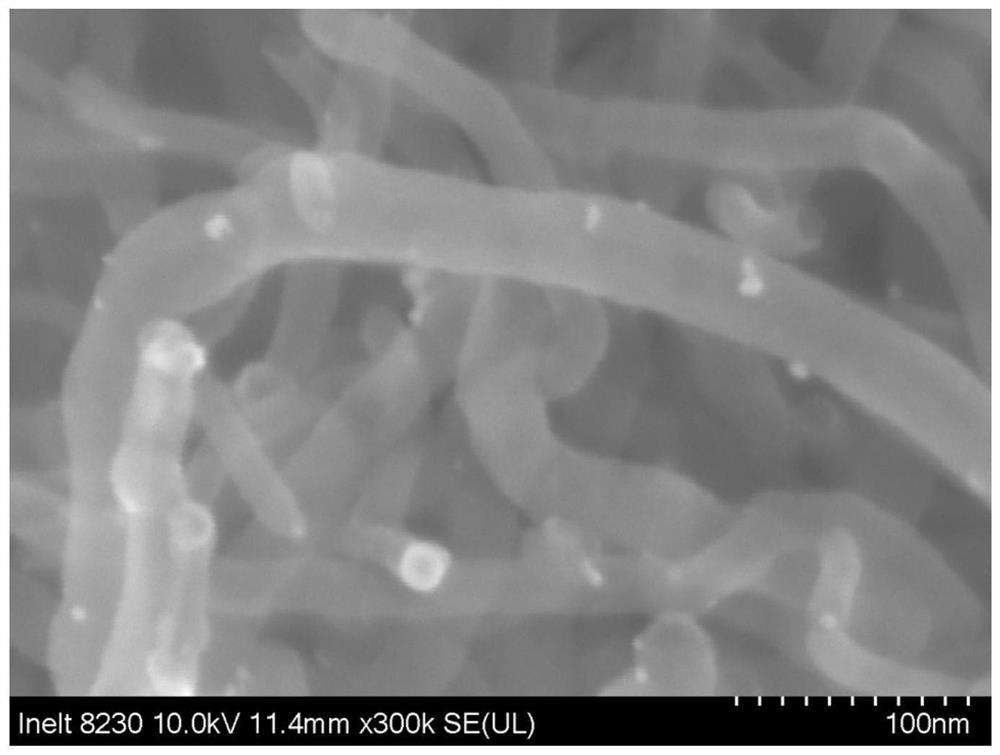

Embodiment 3

[0041] Electrocatalytic reduction of CO 2 The preparation method of the loaded type gold-platinum alloy electrode comprises the following steps:

[0042] (1) Take 10g of carbon nanotubes, add them to 200mL of acetone solution, raise the temperature to 60°C, condense and reflux, keep the temperature constant for 4h, dry and wash, remove the acetone solution on the surface; add it to 200mL (1:5) of hydrochloric acid solution, Heat to 120°C, condense and reflux, keep the temperature for 10 hours, dry and wash to remove the surface hydrochloric acid solution; add to 200mL5mol / L nitric acid solution, heat to 120°C, condense and reflux, keep the temperature for 10 hours, dry and wash to remove the surface nitric acid solution. Dry for 10 hours to obtain a hydrophilic carbon nanotube carrier.

[0043] (2) Take 30 mg of the carbon nanotube carrier treated in step (1), add an appropriate amount of deionized water, and perform ultrasonic treatment for 40 min for later use. 20mL oleyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com