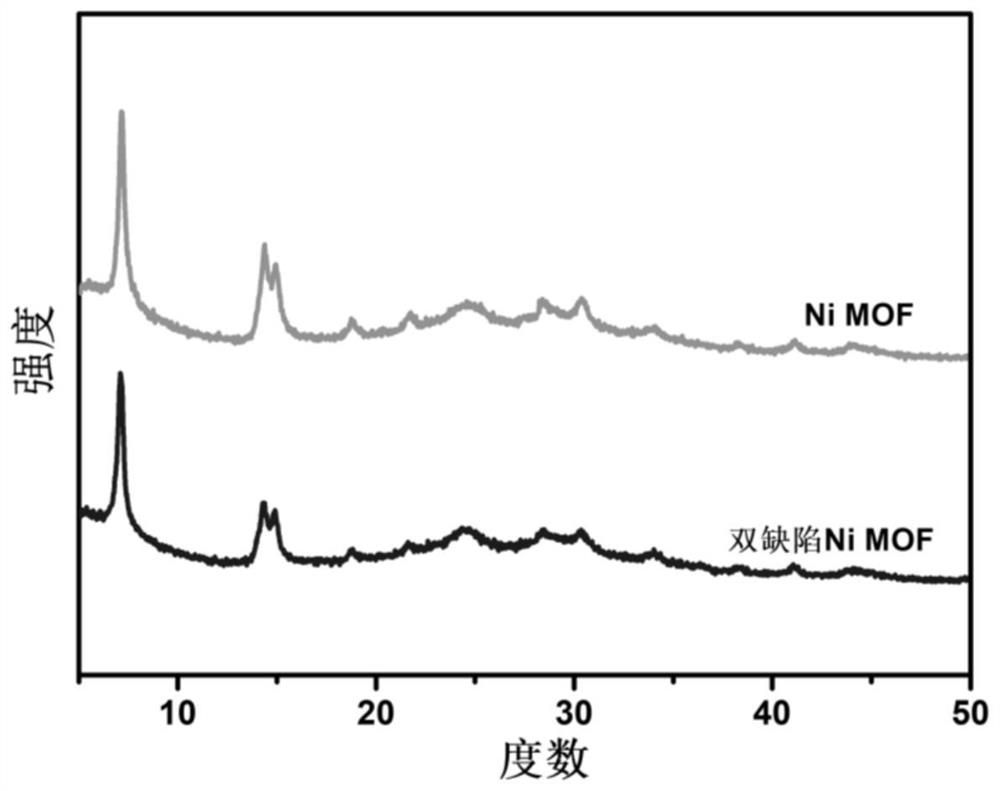

A double-defect ultrathin metal-organic framework nanosheet catalyst and its preparation method and application

An ultra-thin metal, organic framework technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of poor electrocatalytic performance and insufficient stability, and achieve rapid electrocatalytic decomposition of water and oxygen evolution reaction, good catalysis The effect of stability and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

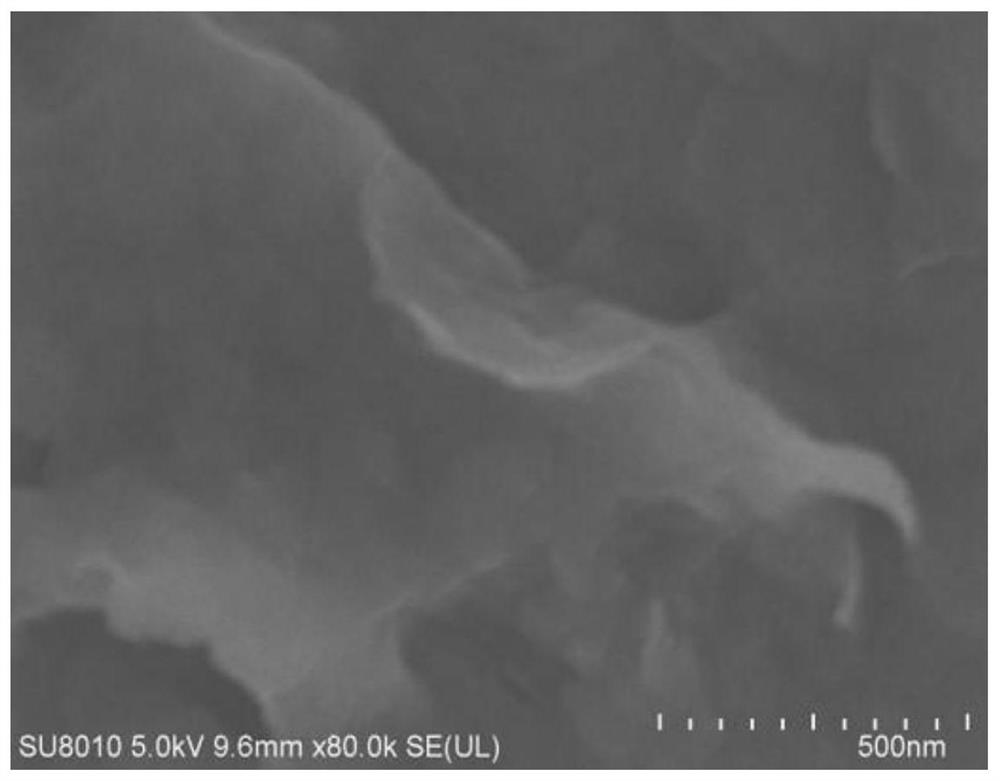

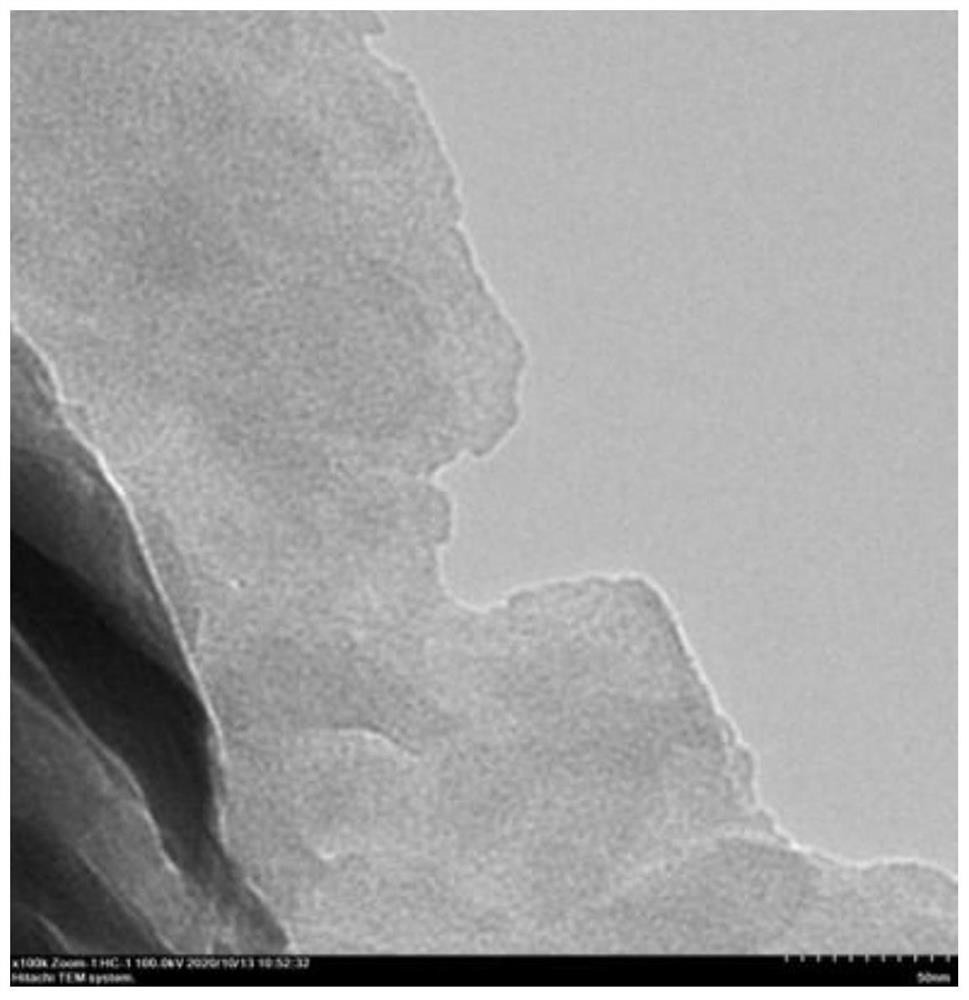

Embodiment 1

[0043] 129.7mg of 2,6-naphthalene dicarboxylic acid and 34.4mg of naphthoic acid were added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32mL:2mL:2mL), and then added to the above solution 190.2 mg of nickel chloride hexahydrate was added to the solution, and 1.5 mL of triethylamine was added rapidly at the same time, and magnetically stirred for 10 min. Then the above mixed solution was transferred to a cell disruptor, and ultrasonically peeled at 700W for 600 min. Then the mixed solution was irradiated for 3 h under simulated sunlight AM 1.5G with a light intensity of 80 mW cm -2 After the light is finished, it is washed several times with absolute ethanol, and the solid sample is separated by a 10000r / s high-speed centrifuge. Finally, the samples were vacuum-dried at room temperature for 12 h.

Embodiment 2

[0045] 151.3mg of 2,6-naphthalene dicarboxylic acid and 17.2mg of naphthoic acid were added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32mL:2mL:2mL), and then added to the above solution 190.2 mg of nickel chloride hexahydrate was added to the solution, and 1.5 mL of triethylamine was added rapidly at the same time, and magnetically stirred for 10 min. Then the above mixed solution was transferred to a cell disruptor, and ultrasonically peeled at 700W for 600 min. Then the mixed solution was irradiated for 3 h under simulated sunlight AM 1.5G with a light intensity of 80 mW cm -2 After the light is finished, it is washed several times with absolute ethanol, and the solid sample is separated by a 10000r / s high-speed centrifuge. Finally, the samples were vacuum-dried at room temperature for 12 h.

Embodiment 3

[0047] 108.1 mg of 2,6-naphthalene dicarboxylic acid and 51.6 mg of naphthoic acid were added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32mL:2mL:2mL), and then added to the above solution 190.2 mg of nickel chloride hexahydrate was added to the solution, and 1.5 mL of triethylamine was added rapidly at the same time, and magnetically stirred for 10 min. Then the above mixed solution was transferred to a cell disruptor, and ultrasonically peeled at 700W for 600 min. Then the mixed solution was irradiated for 3 h under simulated sunlight AM 1.5G with a light intensity of 80 mW cm -2 After the light is finished, it is washed several times with absolute ethanol, and the solid sample is separated by a 10000r / s high-speed centrifuge. Finally, the samples were vacuum-dried at room temperature for 12 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com