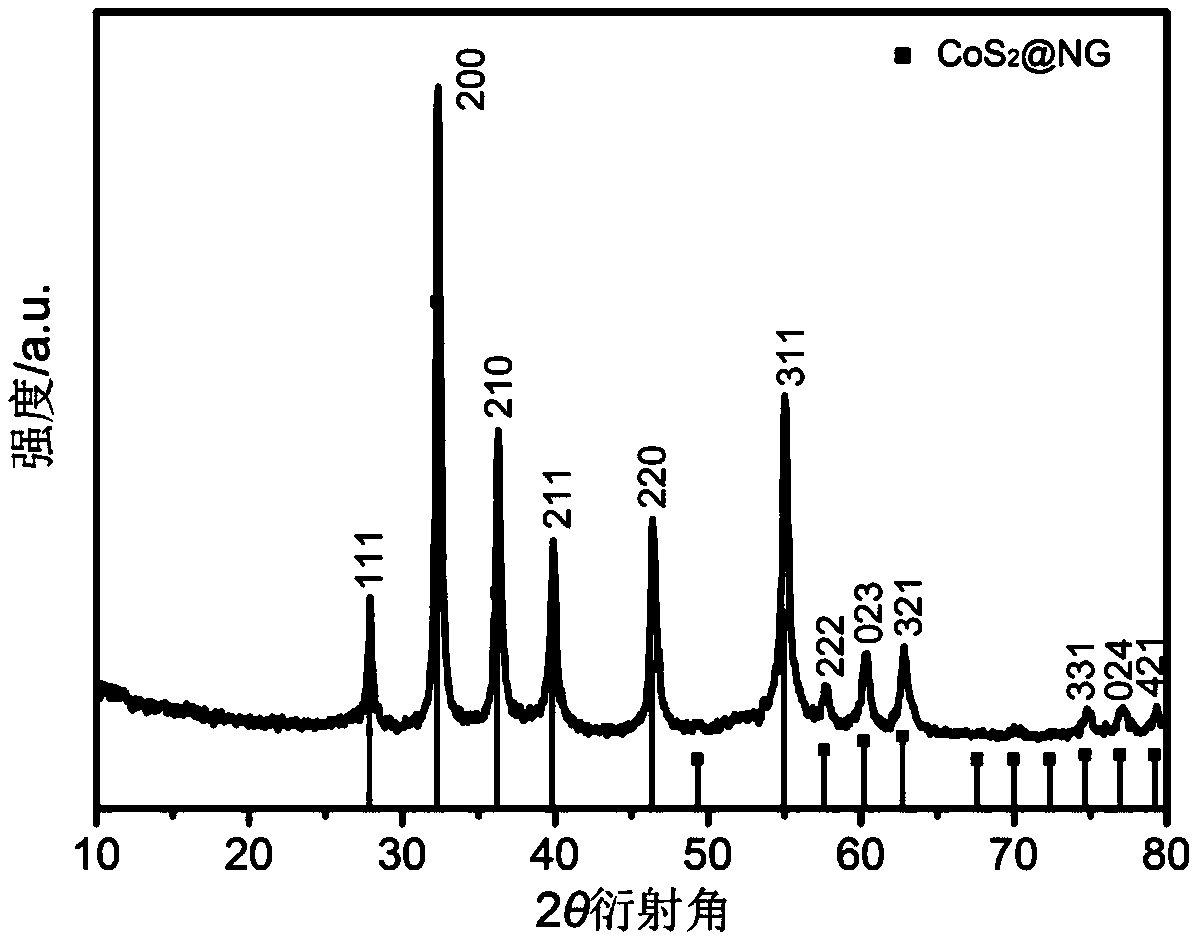

A core-shell cos2@ng nanocomposite material and its preparation and application

A nanocomposite material and nanoparticle technology, applied in the field of core-shell CoS2@NG nanocomposite materials and their preparation, can solve the problems of inability to large-scale application, scarcity of precious metals, etc., and achieve good hydrogen evolution electrocatalytic performance, low cost, and improved Effect of hydrogen evolution catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

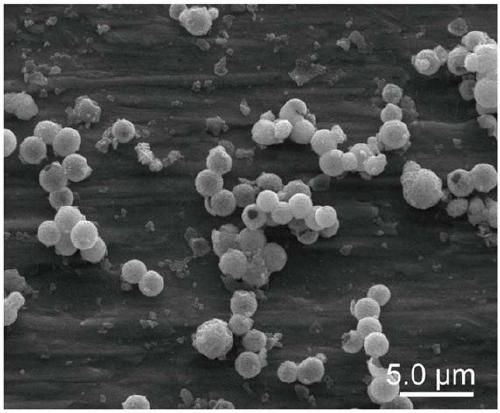

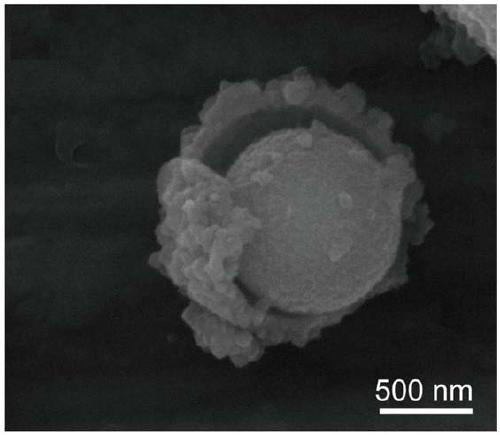

Image

Examples

Embodiment 1

[0044] This embodiment includes the following steps:

[0045] (1) Graphene oxide was prepared by the modified Hummers method.

[0046] (2) 294.413mg CoCl 2 ·6H 2 O and 310.238 mg Na 2 S 2 o 3 ·5H 2 O was dissolved in a solution of 10 mL deionized water and 30 mL ethanol, and stirred for 3 h to obtain a well-mixed blue solution.

[0047] (3) Add the solution obtained in step 2 into the reaction kettle, and then seal it. A stainless steel autoclave was placed in an electric furnace and heated at 160 °C for 24 h, and then allowed to cool naturally to room temperature. Finally, the black precipitate was collected by centrifugation, washed thoroughly with deionized water and ethanol six times, and dried in a vacuum oven at 60 °C for 12 h.

[0048] (4) CoS obtained in step 3 2 The particles (0.5 g) were dispersed in 30 mL of toluene solution by sonication. After 1h, 0.5mL APS was added to the above solution and stirred for 24h to obtain APS-modified CoS 2 particles. Then...

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] (1) Graphene oxide was prepared by the modified Hummers method.

[0054] (2) 280mg CoCl 2 ·6H 2 O and 290 mg Na 2 S 2 o 3 ·5H 2 O was dissolved in a solution of 20mL deionized water and 40mL ethanol, and stirred for 3h to obtain a uniformly mixed blue solution.

[0055] (3) Add the solution obtained in step 2 into the reaction kettle, and then seal it. A stainless steel autoclave was placed in an electric furnace and heated at 140° C. for 26 h, and then allowed to cool naturally to room temperature. Finally, the black precipitate was collected by centrifugation, washed thoroughly with deionized water and ethanol six times, and dried in a vacuum oven at 60 °C for 12 h.

[0056] (4) CoS obtained in step 3 2 The particles (0.6 g) were dispersed in 50 mL of toluene solution by sonication. After 1h, 0.6mL APS was added to the above solution and stirred for 24h to obtain APS-modified CoS 2 particles. Then, GO ...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] (1) Graphene oxide was prepared by the modified Hummers method.

[0061] (2) 310mg CoCl 2 ·6H 2 O and 320mg Na 2 S 2 o 3 ·5H 2 O was dissolved in a solution of 30mL deionized water and 50mL ethanol, and stirred for 3h to obtain a uniformly mixed blue solution.

[0062] (3) Add the solution obtained in step 2 into the reaction kettle, and then seal it. A stainless steel autoclave was placed in an electric furnace and heated at 180° C. for 18 h, and then allowed to cool naturally to room temperature. Finally, the black precipitate was collected by centrifugation, washed thoroughly with deionized water and ethanol six times, and dried in a vacuum oven at 60 °C for 12 h.

[0063] (4) CoS obtained in step 3 2 The particles (0.2 g) were dispersed in 40 mL of toluene solution by sonication. After 1h, 0.2mL APS was added to the above solution and stirred for 24h to obtain APS-modified CoS 2 particles. Then, GO (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com