A kind of photocatalytic system and preparation method thereof

A catalytic system, photoelectric catalysis technology, applied in the field of photocatalysis, can solve the problems of strong reduction reaction competitiveness, low selectivity of multi-carbon products, etc., and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

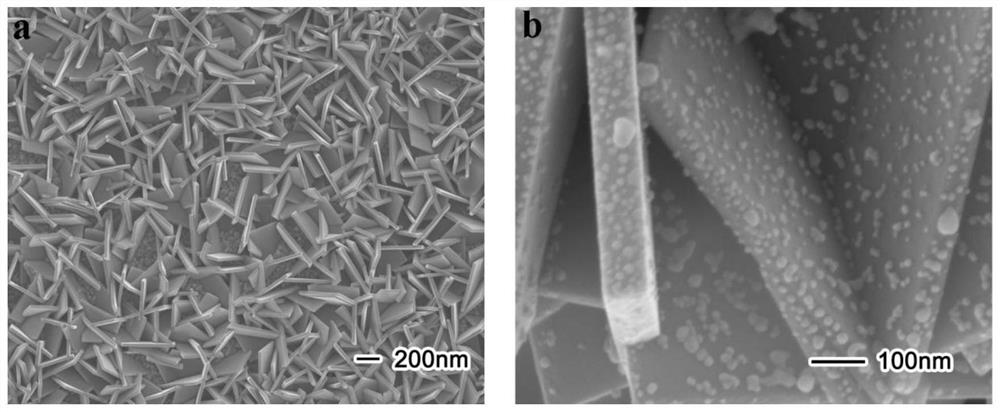

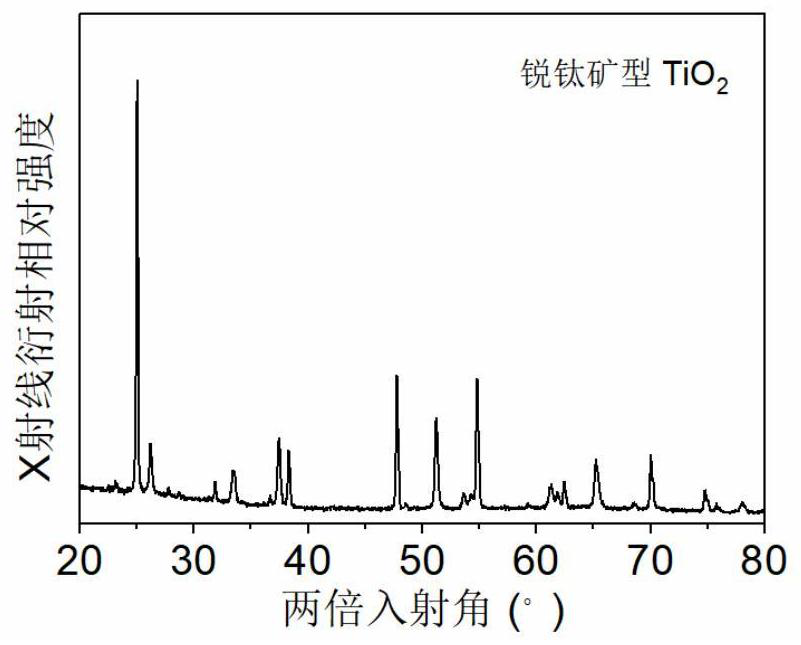

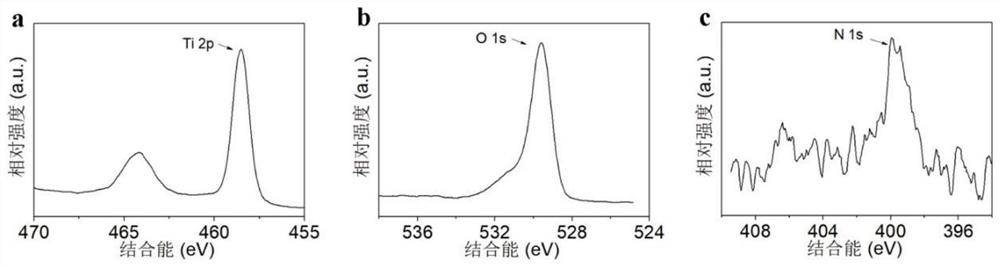

[0060] N-doped TiO modified by Au nanocrystals 2 The steps of the preparation method of the nanosheet array are as follows:

[0061] a) FTO glass surface removal treatment: Ultrasonic cleaning and drying of FTO glass in isopropanol, acetone, ethanol and deionized water respectively.

[0062] b) Preparation of TiO on the surface of FTO glass 2 Nanosheet array: adopt hydrothermal method, hydrothermal method is composed of solution and active components, wherein the components and ratio of solution are 50wt% hydrochloric acid, 50wt% water; active components and ratio are: n-butyl titanate , accounting for 1.67wt% of hydrochloric acid and water quality; ammonium fluorotitanate, accounting for 1.6wt% of hydrochloric acid and water quality. Stir the above solution in the polytetrafluoroethylene lining at room temperature for 20 minutes, and then put a piece of FTO conductive glass treated in step a) into the autoclave with the conductive side down, and keep it warm at 170°C for 12...

Embodiment 2

[0076] Copper foam as the base, Zn doped Cu 2 O film preparation method steps are as follows:

[0077]a) Impurity removal treatment on the surface of foamed copper: Soak the foamed copper in 30wt% NaOH solution to remove surface oily impurities, then ultrasonically clean it in deionized water, and dry it for use.

[0078] b) Electrodeposition of Zn-doped Cu on the surface of copper foam 2 O thin film: a three-electrode electrolysis system is adopted, a piece of copper foam treated in step a) is used as the working electrode, the Ag / AgCl electrode and the platinum sheet electrode are used as the reference electrode and the counter electrode respectively, and the electrolyte is composed of a solution and an active component. The components and proportioning of the solution are 70wt% of water, 30wt% of lactic acid, and the active components and proportioning are: copper sulfate (pentahydrate), accounting for 7.1wt% of lactic acid and water quality; zinc sulfate (heptahydrate), a...

Embodiment 3

[0088] Gas program temperature control desorption

[0089] Programmed temperature-controlled desorption can characterize the physical and chemical adsorption capacity of the sample for the target gas. In this example, the CO 2 , CO and CH 4 Three gases, with CO 2 Gas is taken as an example to illustrate the specific embodiment. Firstly, Example 2 and Comparative Example 2 were pretreated at 200°C under He for 1 h, and after cooling to room temperature, they were treated with CO 2 The catalyst was purged for 1 h to saturated adsorption, and the catalyst was purged with He for 30 min, and then the gas desorption experiment was started at a heating rate of 10 °C / min, and the desorbed CO was detected by a mass spectrometer. 2 .

[0090] Figure 10 For Example 2 and Comparative Example 2 For (a) CO 2 , (b) CH 4 And (c) Programmed temperature control of CO gas to remove the figure. As can be seen by comparison, Example 2 for CO 2 and CH 4 The desorption peak area of Zn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric charge | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com