A low-pressure ammonia synthesis process

A technology of ammonia synthesis and ammonia synthesis tower, which is applied in the field of ammonia synthesis, can solve the problems of low net value of exported ammonia, low utilization rate of nitrogen and hydrogen, and achieve the effects of reducing energy consumption, improving utilization rate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

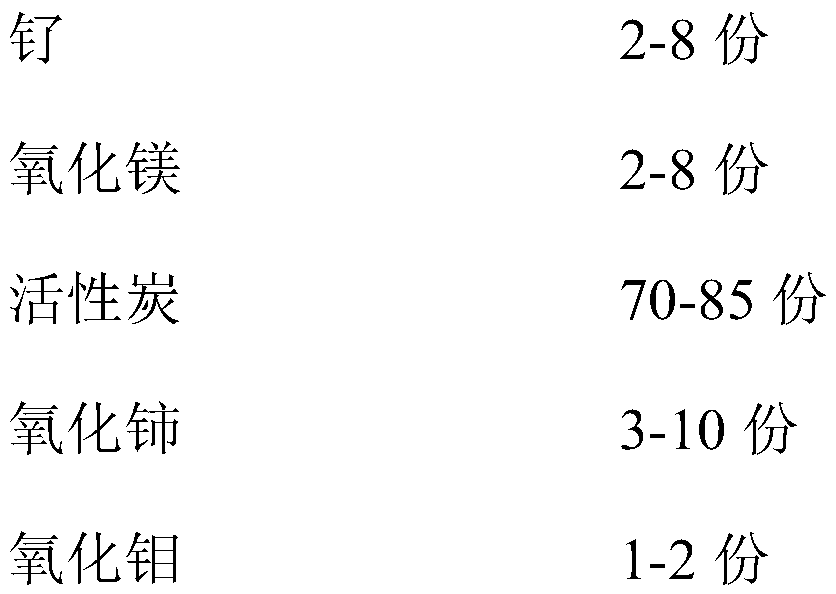

Method used

Image

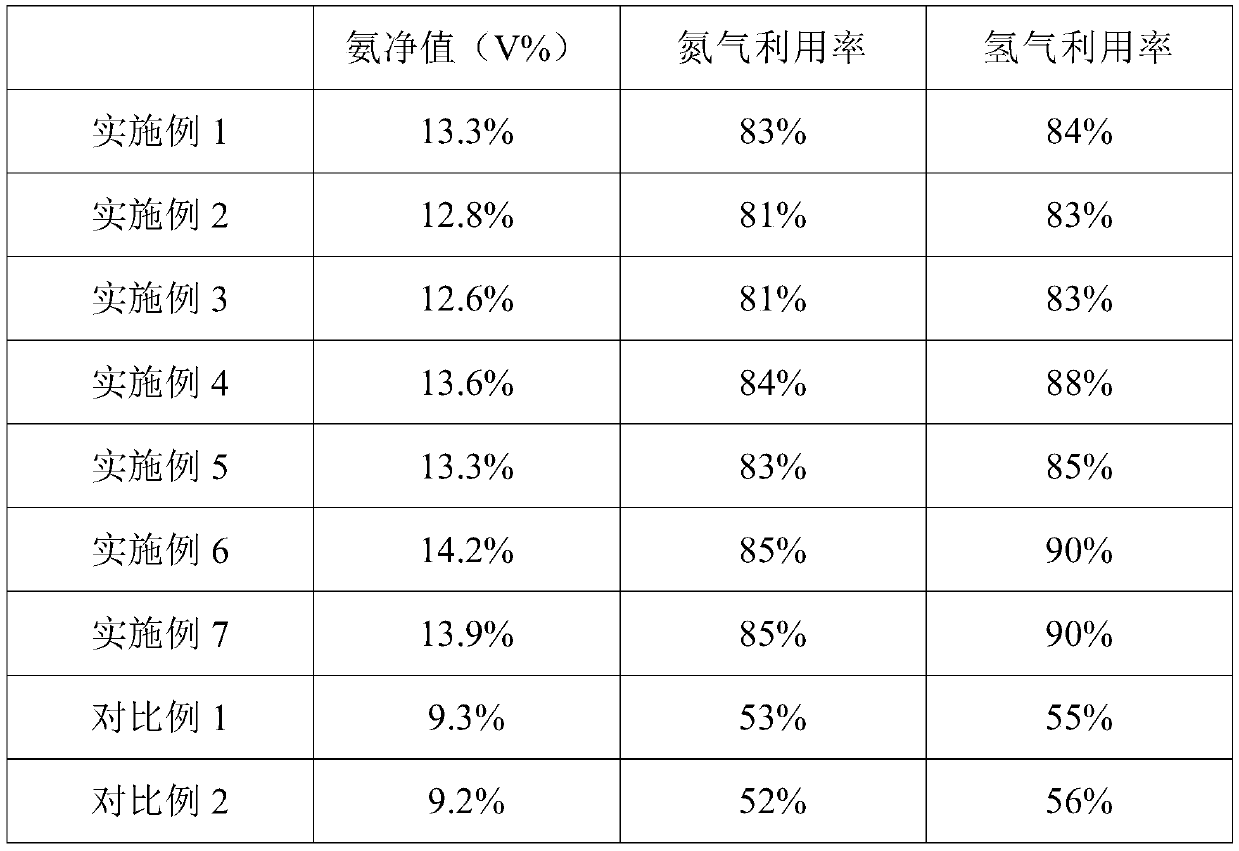

Examples

Embodiment 1

[0057] The present embodiment provides a kind of low-pressure ammonia synthesis process, comprising the following steps:

[0058] 1) Carry out cryogenic air separation to air, obtain nitrogen and oxygen, described oxygen and natural gas carry out pure oxygen autothermal conversion, obtain containing CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw material gas for the synthesis of ammonia; finally, the mixed gas is separated by electrolysis of water to obtain hydrogen; the hydrogen and nitrogen Mixed to form synthetic ammonia raw material gas, where S2 <10ppm, the molar ratio of hydrogen to nitrogen is 1.7:1;

[0059] 2) the above-mentioned synthetic ammonia raw material gas is 5000h with space velocity -1 The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synt...

Embodiment 2

[0069] The present embodiment provides a kind of low-pressure ammonia synthesis process, comprising the following steps:

[0070] 1) Carry out cryogenic air separation to air, obtain nitrogen and oxygen, described oxygen and natural gas carry out pure oxygen autothermal conversion, obtain containing CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw material gas for the synthesis of ammonia; finally, the mixed gas is separated by electrolysis of water to obtain hydrogen; the hydrogen and nitrogen Mixed to form synthetic ammonia raw material gas, where S2 <10ppm, the molar ratio of hydrogen to nitrogen is 1.5:1;

[0071] 2) The above-mentioned synthetic ammonia raw material gas is 6000h with space velocity -1 The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synt...

Embodiment 3

[0081] The present embodiment provides a kind of low-pressure ammonia synthesis process, comprising the following steps:

[0082] 1) Carry out cryogenic air separation to air, obtain nitrogen and oxygen, described oxygen and natural gas carry out pure oxygen autothermal conversion, obtain containing CO and H 2 The mixed gas; moreover, containing CO and H 2 The mixed gas is passed into the waste heat boiler to recover heat, and high-pressure steam is obtained, which is used to pressurize the raw material gas for the synthesis of ammonia; finally, the mixed gas is separated by electrolysis of water to obtain hydrogen; the hydrogen and nitrogen Mixed to form synthetic ammonia raw material gas, where S2 <10ppm, the molar ratio of hydrogen to nitrogen is 2.5:1;

[0083] 2) the above-mentioned synthetic ammonia raw material gas is 4000h with space velocity -1The primary ammonia synthesis is carried out in the first ammonia synthesis tower filled with iron-based catalyst, the synth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com