Close-packed hexagonal nickel and polycrystalline phase nickel heterojunction electrocatalyst as well as preparation method and application thereof

An electrocatalyst, hexagonal close-packed technology, applied in circuits, structural parts, electrical components, etc., can solve the hexagonal close-packed phase alkaline hydrogen oxidation reaction test, face-centered cubic phase and hexagonal close-packed phase that cannot be successfully prepared. The phase ratio cannot be controlled, and the control of the relative catalyst activity of the face-centered cubic phase and the hexagonal close-packed phase cannot be studied, so as to achieve the effects of high durability, optimized adsorption energy, and reduced generation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The invention provides a method for preparing a polycrystalline nickel heterojunction electrocatalyst, comprising the following steps:

[0072] S1, using the colloid method to prepare close-packed hexagonal nickel nanoparticles;

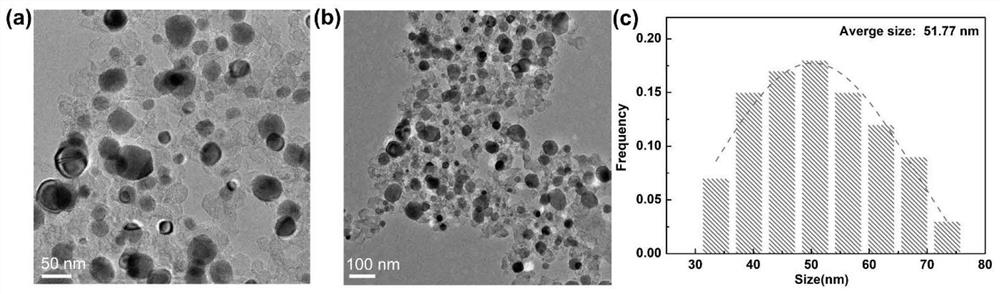

[0073] S2, dispersing the close-packed hexagonal nickel nanoparticles and carbon carrier prepared in step S1 in an organic solvent, ultrasonically treating them for 1 to 4 hours, and then collecting them by centrifugation and vacuum drying to obtain a mixture; then placing the mixture under reduction In a neutral atmosphere, calcining treatment at a calcination temperature higher than 250°C and lower than 600°C for 0.5-2h to obtain a close-packed hexagonal / face-centered cubic nickel heterojunction, which is a polycrystalline nickel heterojunction electrocatalyst.

[0074] Preferably, in step S1, the specific preparation method of the close-packed hexagonal nickel nanoparticles is:

[0075] Mix nickel acetylacetonate, glucose and oleylamine ac...

Embodiment 1

[0082] Embodiment 1 provides a kind of preparation method of close-packed hexagonal nickel electrocatalyst, comprising the following steps:

[0083] S1. Synthesis of close-packed hexagonal nickel:

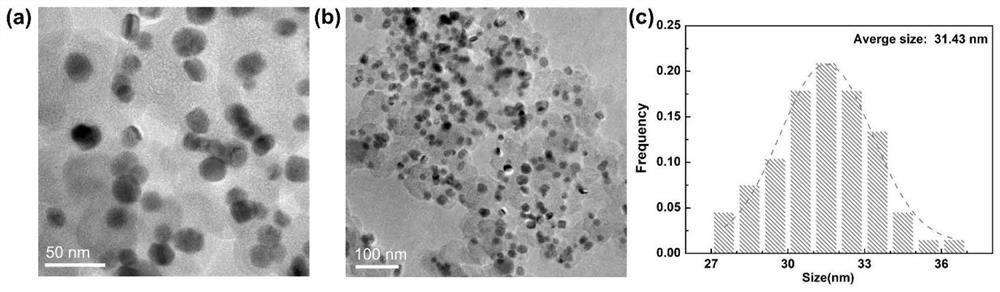

[0084] Usually, put 135mg of nickel acetylacetonate, 600mg of glucose and 10mL of oleylamine into a two-necked flask and stir, heat the mixture to 60°C to form a homogeneous solution and then blow it with nitrogen, keep the reaction temperature for 1 hour, at 10°C / min The speed is gradually heated to 190 ° C and maintained for 2 hours. The cooled product is washed with n-hexane and ethanol to remove impurities at least 3 times, and is collected by centrifugation at 9800rpm to prepare close-packed hexagonal nickel nanoparticles, such as figure 1 shown.

Embodiment 2

[0086] Embodiment 2 provides a kind of preparation method of polycrystalline nickel heterojunction electrocatalyst, comprises the following steps:

[0087] S1. Synthesis of close-packed hexagonal nickel:

[0088] Usually, put 135mg of nickel acetylacetonate, 600mg of glucose and 10mL of oleylamine into a two-necked flask and stir, heat the mixture to 60°C to form a homogeneous solution and then blow it with nitrogen, keep the reaction temperature for 1 hour, at 10°C / min The speed is gradually heated to 190 ° C and maintained for 2 hours. The cooled product is washed with n-hexane and ethanol to remove impurities at least 3 times, and is collected by centrifugation at 9800rpm to prepare close-packed hexagonal nickel nanoparticles, such as figure 1 shown.

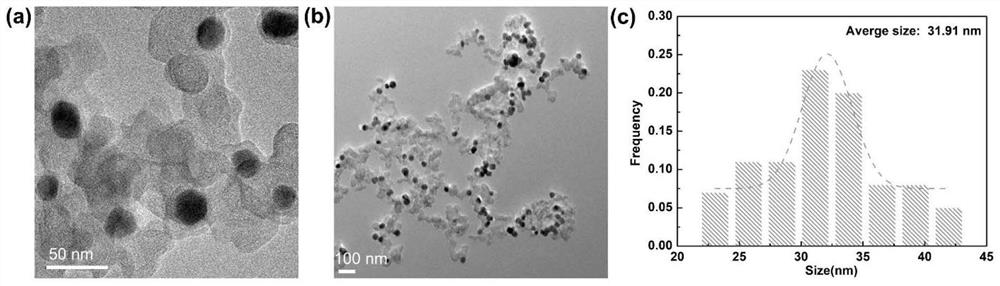

[0089] S2. Synthesis of close-packed hexagonal / face-centered cubic nickel heterojunction:

[0090] Disperse the hexagonal close-packed nickel nanoparticles and XC-72R carbon black prepared in step S1 in an ethanol solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com