Nanoscale lithium vanadyl phosphate positive electrode material and preparation method thereof, lithium ion battery

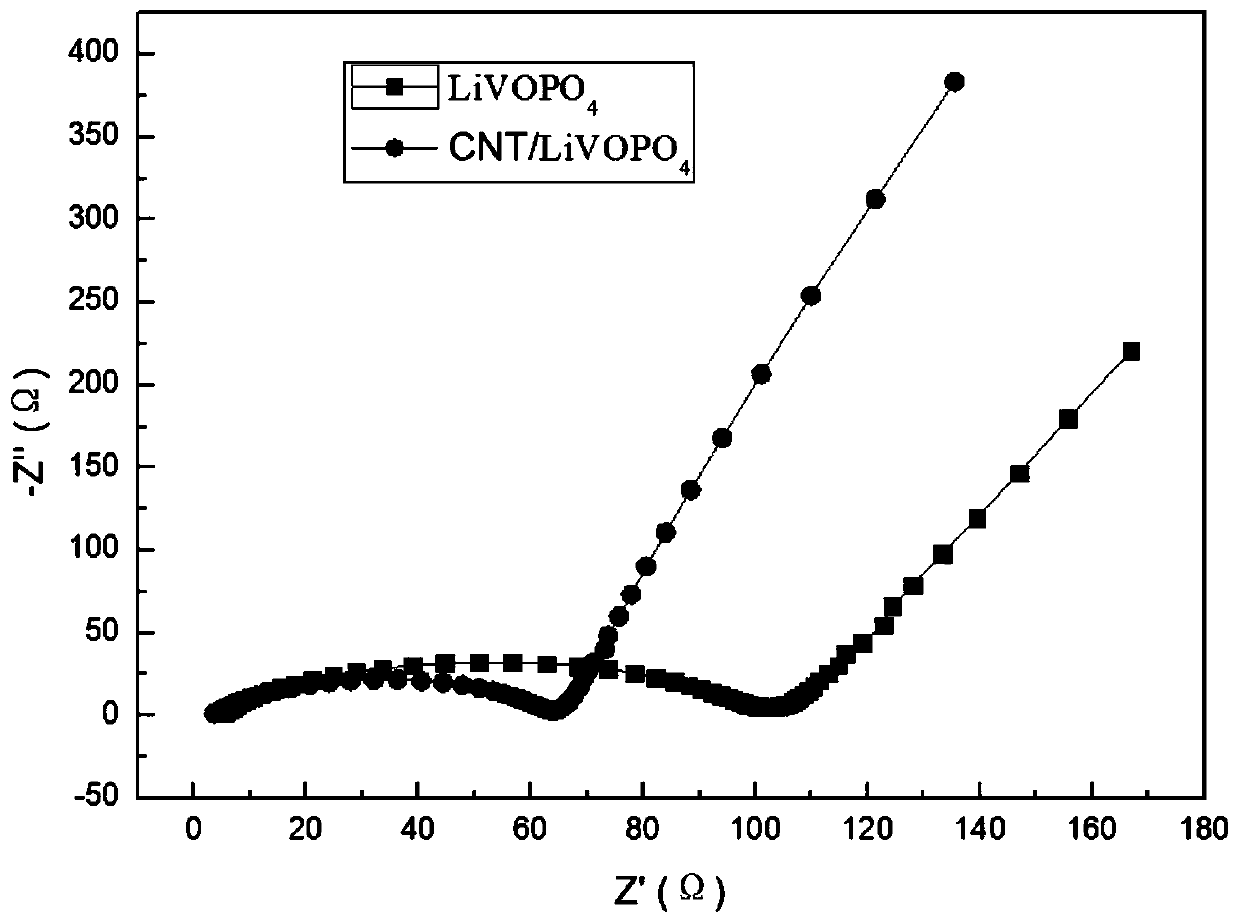

A technology of lithium vanadyl phosphate and cathode material, applied in nanotechnology, battery electrodes, nanotechnology and other directions, can solve the problems of poor electrical conductivity, large size of lithium vanadyl phosphate, poor electrochemical performance, etc., and achieve excellent electrical conductivity , The effect of inhibiting the growth of crystal nucleus and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention also provides a preparation method of nano-lithium vanadyl phosphate positive electrode material, comprising the following steps:

[0025] S01. Provide a lithium source, a vanadium source, a phosphorus source, and a polyacrylic acid complexing agent, mix them in a solvent, and adjust the pH to 3-6 to obtain a gel mixture;

[0026] S02. Drying the gel-like mixture and crushing it to obtain a lithium vanadyl phosphate precursor;

[0027] S03. Provide carbon nanotubes and dispersants, mix the lithium vanadyl phosphate precursor, carbon nanotubes, and dispersants, grind them, sinter in an inert atmosphere, crush and sieve to obtain nano-lithium vanadyl phosphate positive electrodes Material.

[0028] The preparation method of the nano-lithium vanadyl phosphate positive electrode material provided by the embodiment of the present invention has the following advantages:

[0029] First, under the action of a dispersant, through grindin...

Embodiment 1

[0048] A method for preparing a nanometer lithium vanadyl phosphate positive electrode material, comprising the following steps:

[0049] Weigh 0.8 mol of lithium carbonate, 1 mol of vanadium pentoxide, 0.9 mol of diammonium hydrogen phosphate, and 0.1 mol of hydrolyzed polymaleic anhydride, dissolve them in deionized water, and adjust the pH of the solution to 4 with oxalic acid;

[0050] Stir in a water bath at 70°C for 4h to form a gel-like mixture, then dry at 60°C in an air atmosphere for 12h, and then crush to form a powder to obtain a lithium vanadyl phosphate precursor;

[0051] Weigh 95% of the lithium vanadyl phosphate precursor, mix it with 1% carbon nanotubes, and 0.2% PVP, and stir it under the condition of 800r / min, then sand-mill to D50=1um; Dry at 100°C to obtain a composite material of CNT / lithium vanadyl phosphate;

[0052] The dried composite material was sintered at 800°C for 4 hours, then crushed and sieved to obtain the finished product.

Embodiment 2

[0054] A method for preparing a nanometer lithium vanadyl phosphate positive electrode material, comprising the following steps:

[0055] Weigh 0.9 mol of lithium nitrate, 1.2 mol of vanadium pentoxide, 1 mol of diammonium hydrogen phosphate, and 0.15 mol of polyacrylic acid, dissolve them in deionized water, adjust the pH of the solution to 5 with citric acid; stir in a water bath at 80°C for 6 hours until The sol was then dried at 60°C for 12 hours in an air atmosphere, and then crushed to form a powder to obtain a lithium vanadyl phosphate precursor;

[0056] Weigh 96.3% lithium vanadyl phosphate precursor, mix with 1.5% carbon nanotubes, 0.4% PVP, and stir under the condition of 1000r / min, then sand mill to D50=1um; put the grinding liquid under the protection environment of nitrogen Dry at 100°C to obtain a composite material of CNT / lithium vanadyl phosphate;

[0057] The dried composite material was sintered at 650°C for 6 hours, then crushed and sieved to obtain the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com