Composite powder formed by uniformly doping nano-La2O3 in nano-Mo and preparation method thereof

A composite powder and uniform doping technology, which is applied in the field of nano-La2O3 doping, can solve the problems of low efficiency, long cycle, complex process, etc., and achieve the effects of high efficiency, short reaction time and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

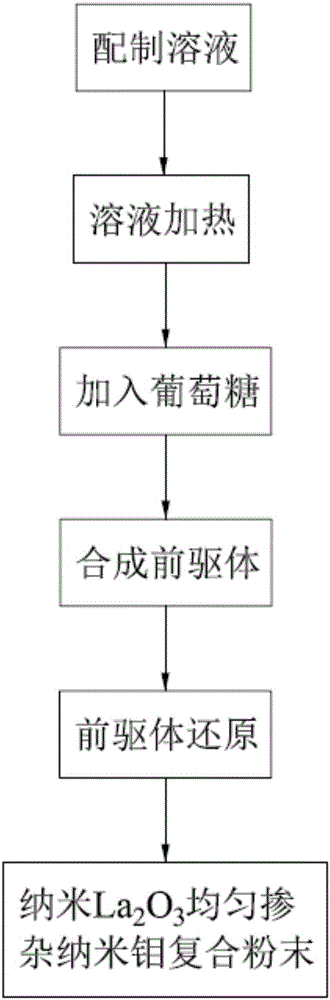

[0027] A nano La 2 o 3 The preparation process of uniformly doped nano-molybdenum composite powder is as follows: figure 1 shown.

[0028] (1) Put 12.4g of ammonium molybdate tetrahydrate, 16g of ammonium nitrate, 8g of glycine and 0.22g of lanthanum nitrate hexahydrate into a 1000ml beaker, add 100ml of deionized water, and stir until completely dissolved to form a mixed solution.

[0029] (2) Place the beaker containing the above mixed solution on a heating furnace and heat it at 200°C.

[0030] (3) After the solution boils for 3 to 5 minutes, add 4.5g of glucose and stir fully at the same time.

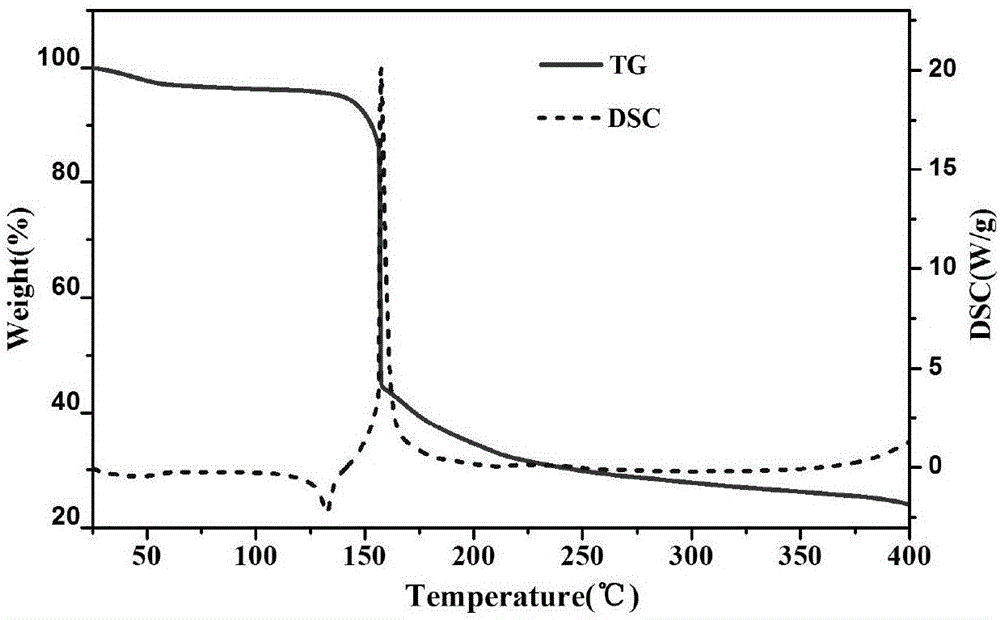

[0031] (4) Continue to heat the solution after adding glucose at 200°C. When the solution forms a light blue sol, lower the temperature to 160°C. The reaction begins and a fluffy foam-like substance is formed. After 3 to 5 minutes, the reaction end, get La 2 o 3 / MoO x Precursor powder. Its TG / DSC curve is as follows figure 2 shown.

[0032] (5) The above La 2 o 3 / MoO ...

Embodiment 2

[0036] (1) Put 12.4g of ammonium molybdate tetrahydrate, 20g of ammonium nitrate, 8g of glycine and 0.55g of lanthanum nitrate hexahydrate into a 1000ml beaker, add 100ml of deionized water, and stir until completely dissolved to form a mixed solution.

[0037] (2) Place the beaker containing the above mixed solution on a heating furnace and heat it at 200°C.

[0038] (3) After the solution boils for 3 to 5 minutes, add 6.8g of glucose and stir fully at the same time.

[0039] (4) Continue to heat the solution after adding glucose at 200°C. When the solution forms a light blue sol, lower the temperature to 160°C. The reaction begins and a fluffy foam-like substance is formed. After 3 to 5 minutes, the reaction end, get La 2 o 3 / MoO x Precursor powder.

[0040] (5) The above La 2 o 3 / MoO x The precursor powder was put into the atmosphere heating furnace, and reduced at 750°C for 3 hours under the flowing hydrogen of 900ml / min. After the reduction, it was cooled with th...

Embodiment 3

[0044] (1) Put 12.4g of ammonium molybdate tetrahydrate, 24g of ammonium nitrate, 8g of glycine and 0.94g of lanthanum nitrate hexahydrate into a 1000ml beaker, add 100ml of deionized water, and stir until completely dissolved to form a mixed solution.

[0045] (2) Place the beaker containing the above mixed solution on a heating furnace and heat it at 200°C.

[0046] (3) After the solution boils for 3-5 minutes, add 9g of glucose and stir fully at the same time.

[0047] (4) Continue to heat the solution after adding glucose at 200°C. When the solution forms a light blue sol, lower the temperature to 160°C. The reaction begins and a fluffy foam-like substance is formed. After 3 to 5 minutes, the reaction end, get La 2 o 3 / MoO x Precursor powder.

[0048] (5) The above La 2 o 3 / MoO x The precursor powder was put into the atmosphere heating furnace, under the flowing hydrogen of 1000ml / min, the reduction was carried out at 700°C for 4 hours, after the reduction was com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com