Preparation method and application of samarium cuprate nano-photocatalytic powder

A technology of catalytic powder and nano-powder, which is applied in the field of photocatalysis, can solve the problems of unsatisfactory preparation method, complicated and difficult preparation process, poor product performance, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

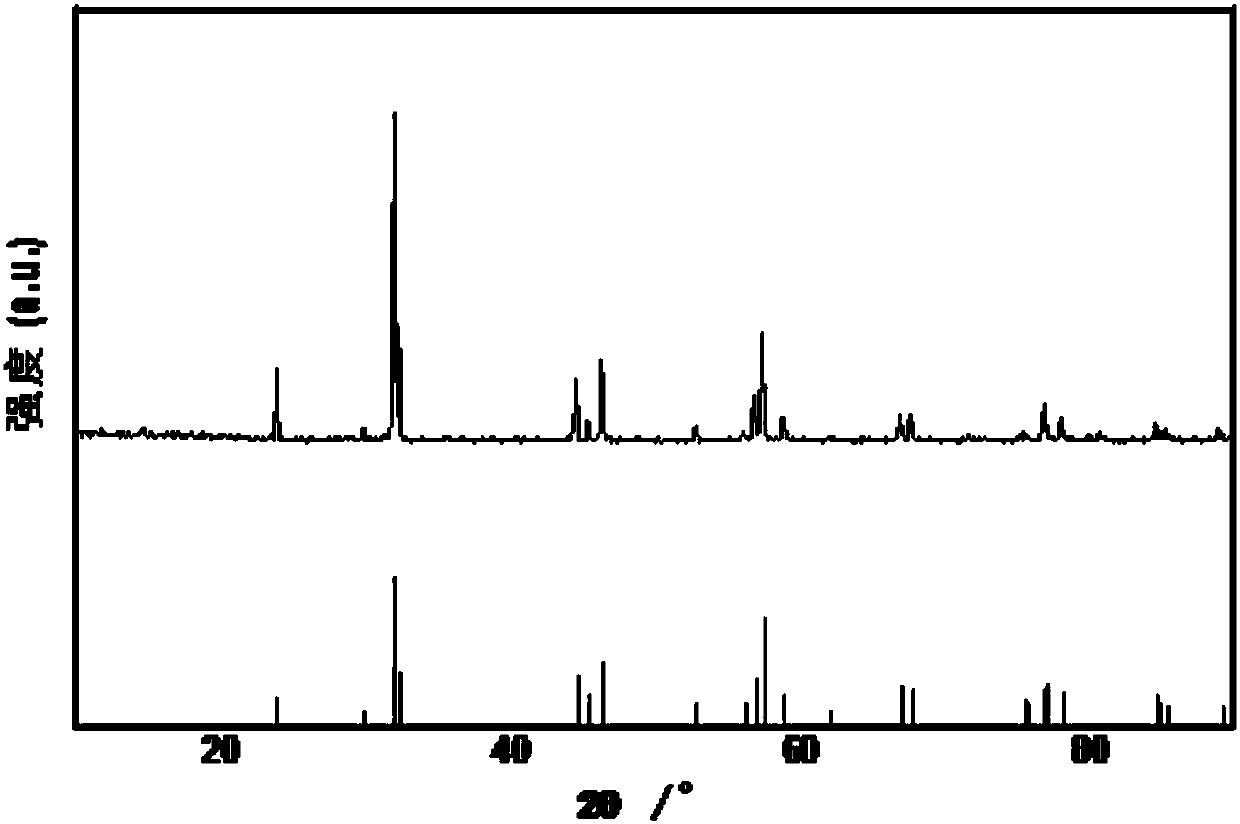

Embodiment 1

[0034] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the medium weighed 0.0067molCu(CH 3 COO) 2 ·H 2 O and 0.0134mol samarium acetate are dissolved in deionized water, and the volume consumption of deionized water is 4 times of the total molar mass of copper acetate and samarium acetate, mixed uniformly to obtain solution A;

[0035] (2) Add 3 g of phenolic resin to solution A, add 1 g of dimethylglyoxime, heat and stir at 60° C. for 2 hours, until the solution becomes viscous to obtain substance B;

[0036] (3) Electrospinning is used to prepare nano-scale photocatalytic composite oxides. During the preparation process, an AC variable electric field of ±10V is applied to the positive and negative electrodes of the original electrospinning equipment to control the direction of its current and form a rectangular tooth shape. Radio waves: Apply positive and negative DC electric fields, the voltage of the positive and negative DC electr...

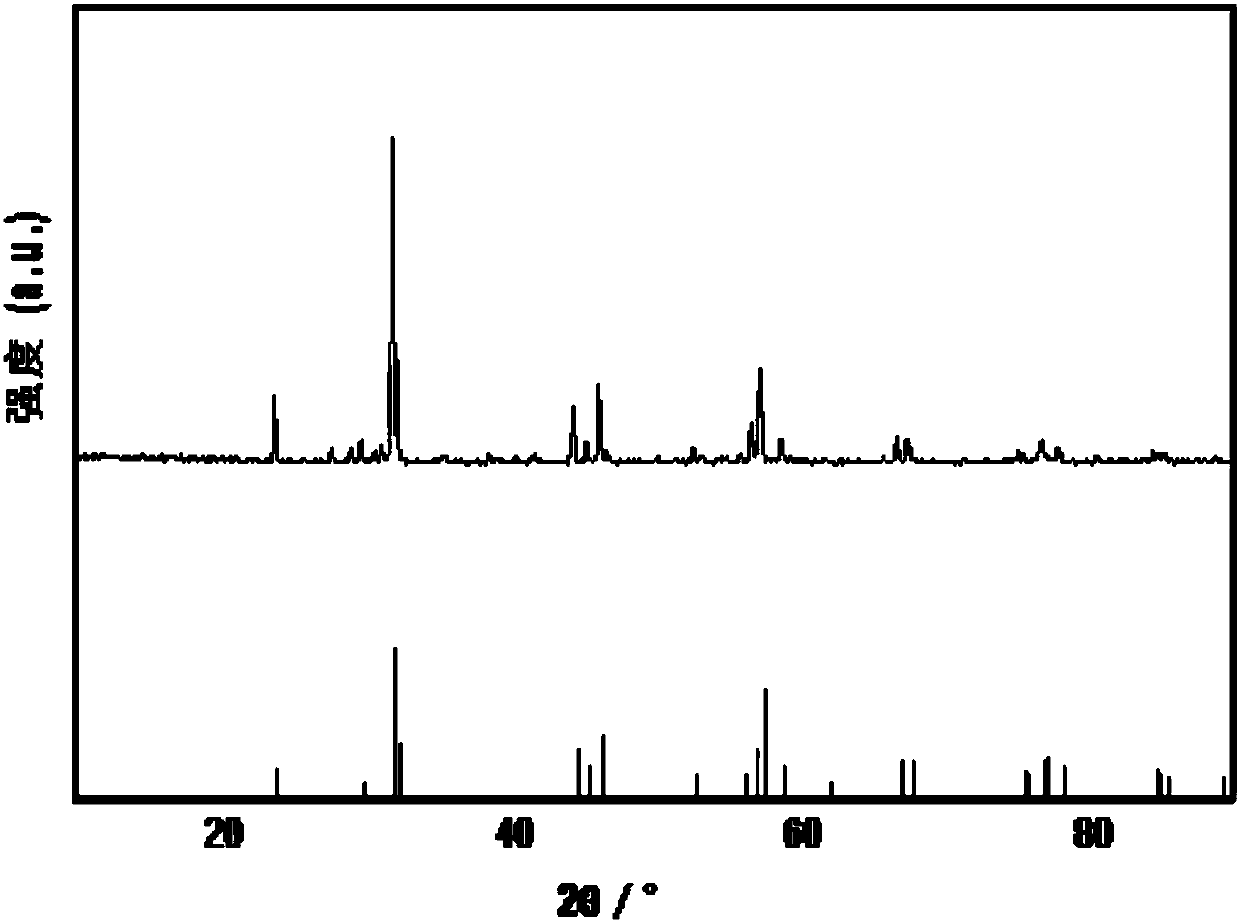

Embodiment 2

[0041] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the medium weighed 0.0067molCu(CH 3 COO) 2 ·H 2 O and 0.0134mol samarium carbonate are dissolved in deionized water, and the consumption of deionized water is 5 times of the total mass of copper acetate and samarium carbonate, mixed uniformly to obtain solution A;

[0042] (2) Add 3g of phenolic resin to solution A, add 1.5g of dimethylglyoxime, heat and stir at 80°C for 2h, until the solution becomes viscous to obtain substance B;

[0043](3) Electrospinning is used to prepare nano-scale photocatalytic composite oxides. During the preparation process, an AC variable electric field of ±5V is applied to the positive and negative electrodes of the original electrospinning equipment to control the direction of its current and form a rectangular tooth shape. Radio waves: Apply positive and negative DC electric fields, the voltage of the positive and negative DC electric fields is ±800V...

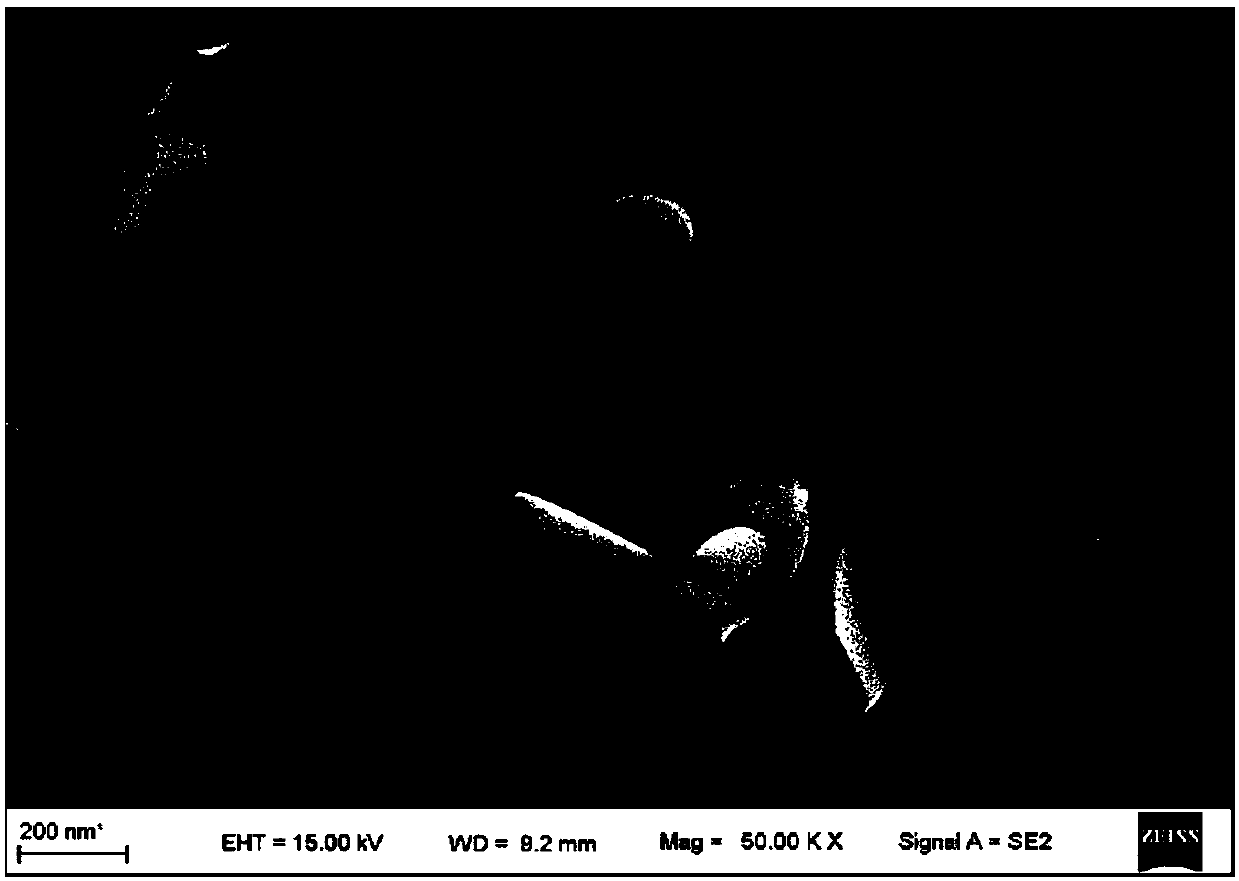

Embodiment 3

[0048] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the medium weighed 0.0067mol copper nitrate and 0.0134mol samarium nitrate, dissolved in deionized water, the amount of deionized water was 6 times the total mass of copper nitrate and samarium nitrate, mixed uniformly to obtain solution A;

[0049] (2) Add 4 g of phenolic resin to solution A, add 2 g of dimethylglyoxime, heat and stir at 80° C. for 1 h, until the solution becomes viscous to obtain substance B;

[0050] (3) Electrospinning is used to prepare nano-scale photocatalytic composite oxides. During the preparation process, an AC variable electric field of ±5V is applied to the positive and negative electrodes of the original electrospinning equipment to control the direction of its current and form a rectangular tooth shape. Radio waves: Apply positive and negative DC electric fields, the voltage of the positive and negative DC electric fields is ±1000V, and the reaction tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com