Method for preparing ultra-small oxide and carbon compounded lithium battery negative electrode material by microwave method

A negative electrode material and oxide technology, which is applied in the direction of battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of low comprehensive performance such as lithium-ion battery capacity and conductivity, complicated preparation process, and high cost, and achieve high capacity. and cycle stability, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

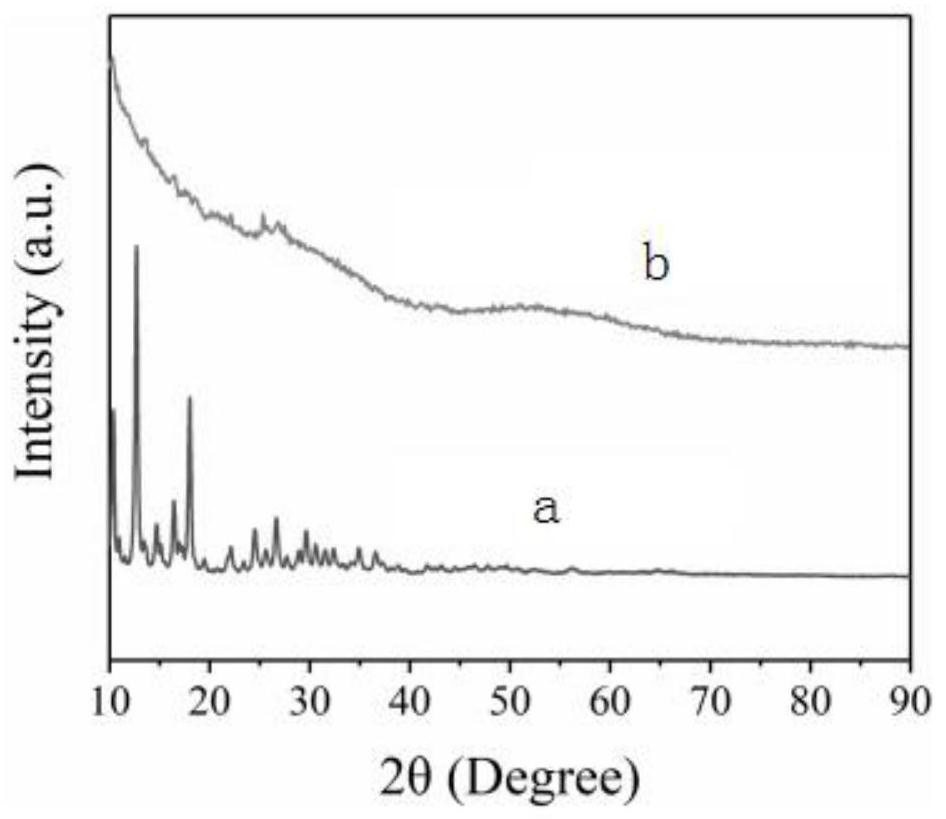

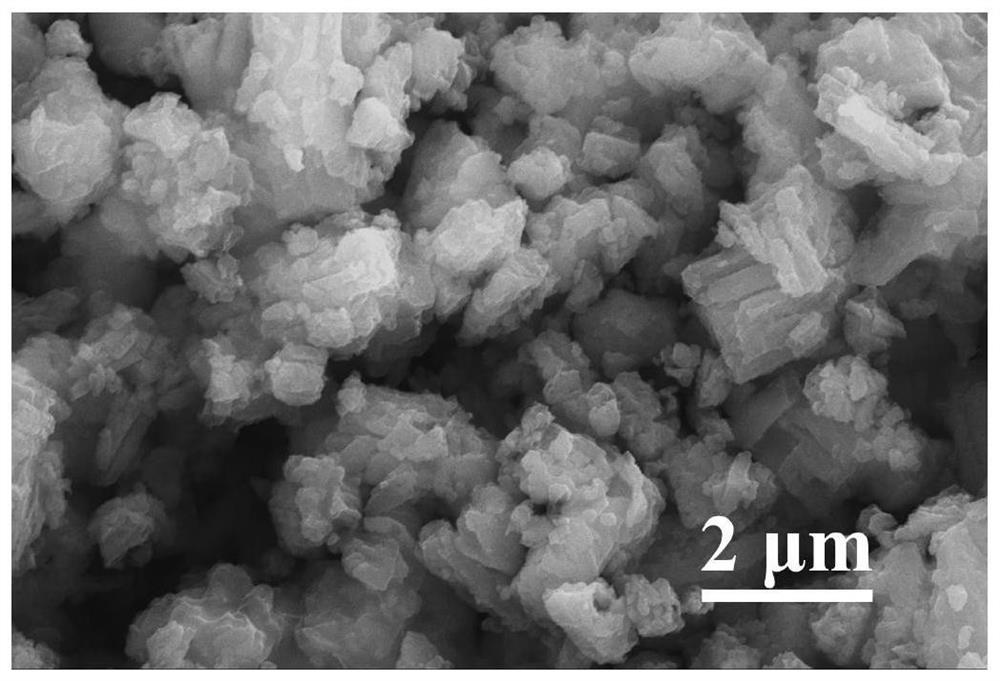

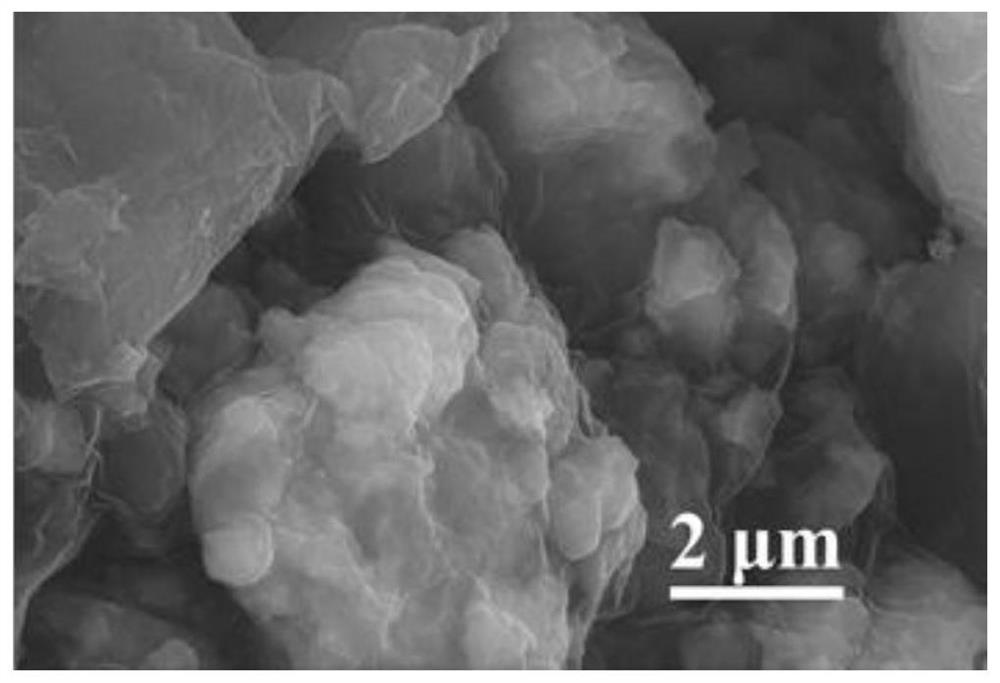

Image

Examples

specific Embodiment approach 1

[0046] DETAILED DESCRIPTION OF THE INVENTION First: A method of preparing an ultra-small oxide and a carbon composite of a microwave method according to a microwave method of the present embodiment performs according to the following procedure:

[0047] 1. Soak 200mg of ZIF-8 soak in a concentration of 0.22 mol / L at 600 rpm. Sncl 2 · 2h 2 In the N-methylpyrrolidanone solution, soaking 2 h, the mixture was stirred at 600 rpm to obtain a mixed solution, and the solid phase was dried at 60 ° C for 1 h, and the ZIF-8 powder of the pericine ion was obtained.

[0048] Second, 60 mg of the ZIF-8 powder of 60 mg of pericine ions is mixed with 15 mg of graphene powder and then ground for 20 min, then the abrasive product is heated under 750 W, and the mixed powder is obtained;

[0049]Third, the two step obtained mixed powder was placed in the nitric acid solution soaking 2h, complete cleaning, after suction filtration and dried at 60 deg.] C IH, to obtain ultra-small carbon composite ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com