Preparation method and application of Ce-containing visible light catalytic nanomaterial

A nanomaterial and visible light technology, applied in the field of nanomaterials and photocatalytic materials, can solve the problem that the application prospect is not mentioned, and achieve the effects of small powder, energy saving and controllable specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

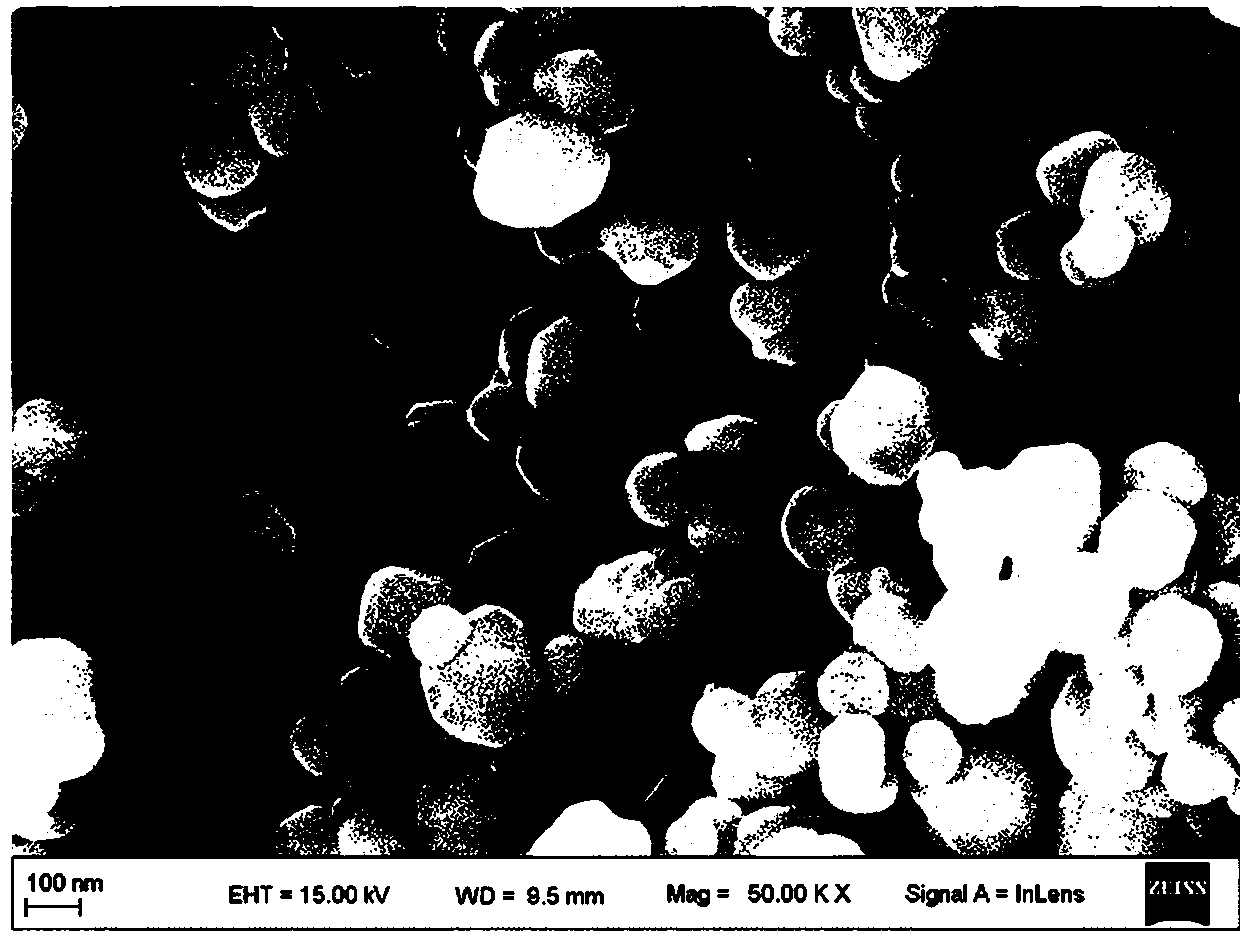

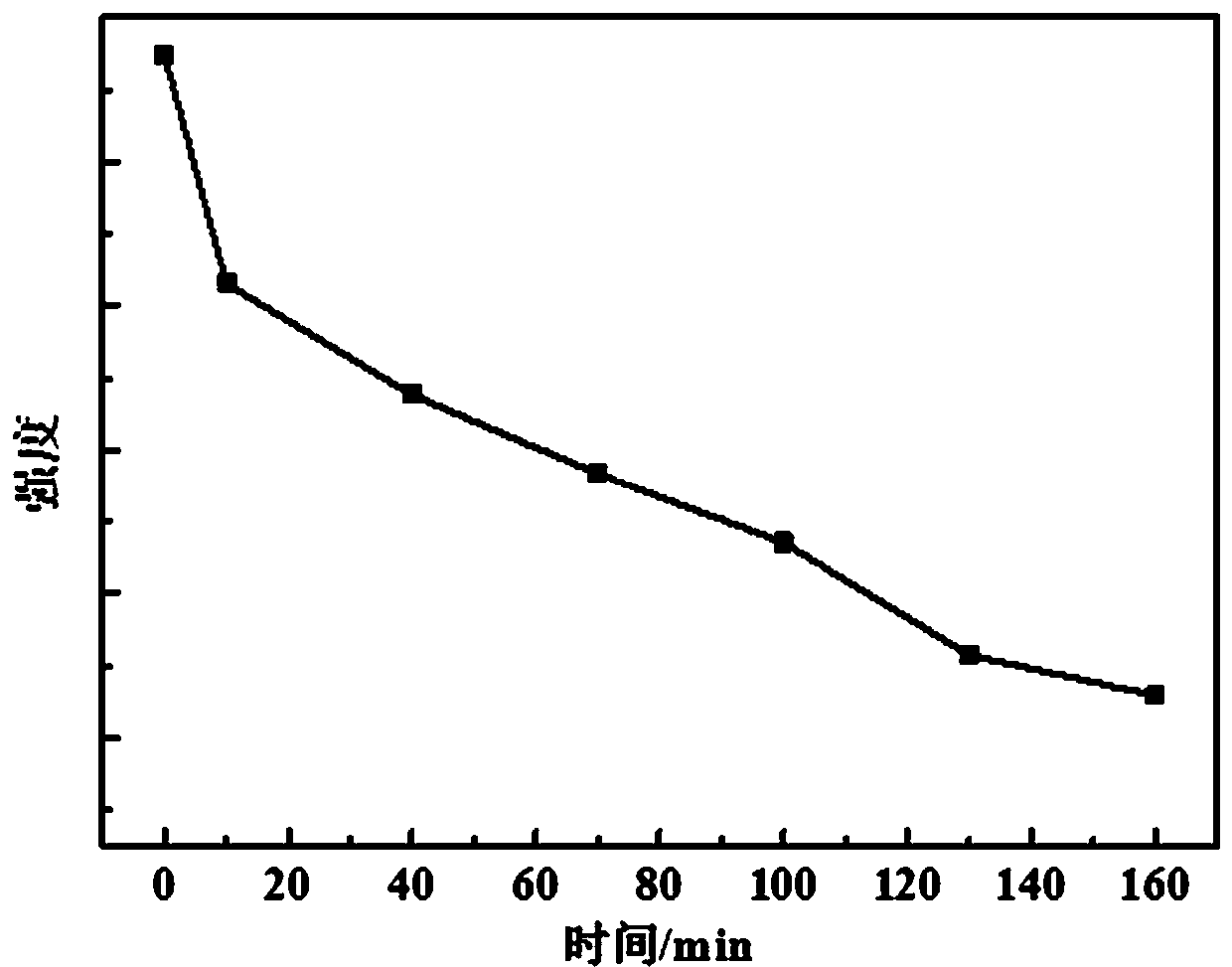

Embodiment 1

[0030] A method for preparing Ce-containing visible light catalytic nanomaterials, including the following steps: weigh 5 mmol copper acetate and 5 mmol cerium acetate, and dissolve them in deionized water. The volume of deionized water is 4 times the total molar mass of copper acetate and cerium acetate , Mechanically stir to completely dissolve to obtain solution A; weigh 30mmol of ammonia and 20mmol of diacetyl oxime dissolved in a mixed solution of 200ml of ethanol and 200ml of water, mechanically stir until completely dissolved, control the pH of the solution to 10, to obtain solution B ; Pour solution B slowly into solution A, add 2mmol polyethylene glycol 1000, magnetically stir for 1h (rotor speed is 800r / min) to obtain solution C; adopt improved electrospinning to prepare nanometer diameter composites, the preparation process In, on the basis of the existing electrospinning equipment power supply is ±1000V DC electric field, two metal plates are added at the bottom of t...

Embodiment 2

[0033] A method for preparing Ce-containing visible light catalytic nanomaterials, including the following steps: weigh 5 mmol copper nitrate and 5 mmol cerium nitrate, and dissolve them in deionized water. The volume of deionized water is 5 times the total molar mass of copper nitrate and cerium nitrate , Mechanically stir until completely dissolved to obtain solution A; weigh 30mmol ammonia and 20mmol diacetyl oxime dissolved in a mixed solution of 200ml ethanol and 200ml water, mechanically stir until completely dissolved to obtain solution B; slowly pour solution B into the solution In A, add 2mmol polyethylene glycol 2000, magnetically stir for 1h (rotor speed is 800r / min), control the pH of the solution to 10.5, and obtain solution C; adopt improved electrospinning to prepare nanometer diameter composite filaments During the preparation process, on the basis of the ±500V DC electric field of the existing electrospinning equipment, two metal plates are added to the bottom o...

Embodiment 3

[0037] A method for preparing Ce-containing visible light catalytic nanomaterials. Weigh 5mmol copper nitrate and 5mmol cerium nitrate, and dissolve them in deionized water. The volume of deionized water is 6 times the total molar mass of copper nitrate and cerium nitrate. Dissolve completely to obtain solution A; weigh 30mmol of triethylamine and 30mmol of sodium citrate (not a dispersant as defined in the present invention) and dissolve in a mixed solution of 300ml of ethanol and 300ml of water, and mechanically stir until completely dissolved to obtain solution B; B slowly pour into solution A, add 2.3mmol polyethylene glycol 2000, magnetically stir for 1h (rotor speed is 800r / min), control the pH of the solution to 11 to obtain solution C; adopt improved electrospinning to prepare nanometer diameter During the preparation process, on the basis of the ±2000V DC electric field of the existing electrospinning equipment, two metal plates are added to the bottom of the synthesis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com