Preparation method for antibacterial material

A technology of antibacterial materials and materials, applied in the fields of botanical equipment and methods, biocides, plant growth regulators, etc., can solve the problems of unstable dispersion and uneven dispersion of nano-copper, and achieve improved dispersion stability and dispersion stability. The effect of improving performance and promoting nano-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

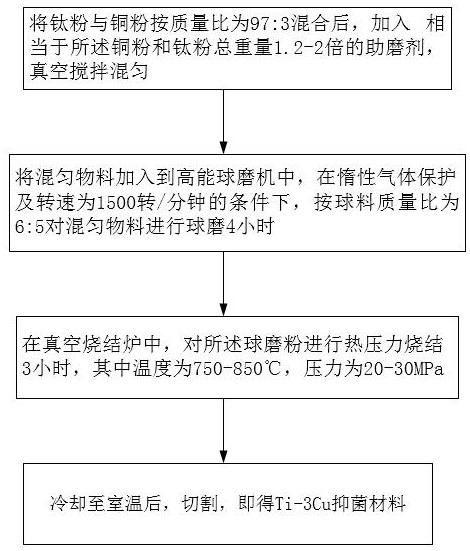

[0023] like figure 1 As shown, the present embodiment provides a preparation method of a bacteriostatic material, comprising the following steps:

[0024] Step 1: After mixing the titanium powder and the copper powder in a mass ratio of 97:3, add a grinding aid of 1.2-2 times the total weight of the copper powder and the titanium powder, and stir and mix under vacuum conditions. The grinding aid is prepared by mixing acetone, ethanol and ethylene glycol in a volume ratio of 7-8:3-5:1.

[0025] It should be noted that due to the extremely strong combining ability of titanium at high temperature, not only can it combine with oxygen, carbon, nitrogen and many other elements to form titanium compounds, but also the melting temperature of titanium compounds is inconsistent with the vacuum melting temperature. However, the titanium compound and the smelting mixture are smelted in the same state, and the vacuum smelting time is mainly based on the smelting setting of pure titanium a...

Embodiment 1

[0036] Present embodiment 1 provides a kind of preparation method of antibacterial material, comprises the following steps:

[0037] Step 1: After mixing titanium powder and copper powder in a mass ratio of 97:3, add a grinding aid that is 1.2 times the total weight of the copper powder and the titanium powder, and stir and mix evenly under vacuum conditions, wherein the The grinding aid is prepared by mixing acetone, ethanol and ethylene glycol in a volume ratio of 7:3:1. Among them, both the copper powder and the titanium powder are powders with a purity ≥99.99%.

[0038] Step 2: Add the mixed material of step 1 into the high-energy ball mill, under the condition of argon protection and the speed of the ball mill at 1500 rpm, according to the ball-to-material mass ratio of 6:5, the copper powder, copper powder and auxiliary The mixed material of the grinding agent was ball milled for 4 hours to obtain ball mill powder. Among them, the ball mill is composed of grinding ball...

Embodiment 2

[0042] Present embodiment 2 provides a kind of preparation method of antibacterial material, comprises the following steps:

[0043] Step 1: After mixing titanium powder and copper powder in a mass ratio of 97:3, add a grinding aid that is 1.5 times the total weight of the copper powder and the titanium powder, and stir and mix under vacuum conditions, wherein the The grinding aid is prepared by mixing acetone, ethanol and ethylene glycol in a volume ratio of 7:3:1. Among them, both the copper powder and the titanium powder are powders with a purity ≥99.99%.

[0044] Step 2: Add the mixed material of step 1 into the high-energy ball mill, under the condition of argon protection and the speed of the ball mill at 1500 rpm, according to the ball-to-material mass ratio of 6:5, the copper powder, copper powder and auxiliary The mixed material of the grinding agent was ball milled for 4 hours to obtain ball mill powder. Among them, the ball mill is composed of grinding balls with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com