A kind of high sphericity nanostructure stainless steel powder and preparation method thereof

A nanostructure, high sphericity technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor coating performance, high porosity, and difficulty in nanostructured powders. The effect of good sphericity and fluidity, small particle size distribution and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

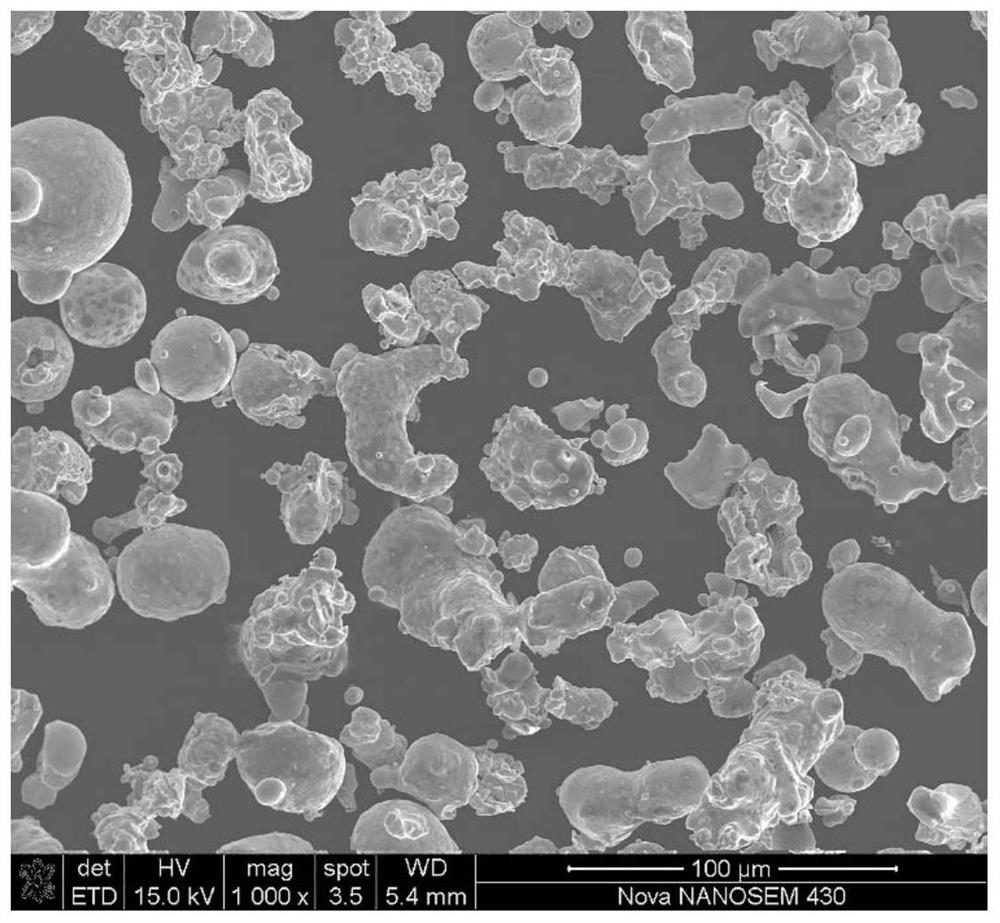

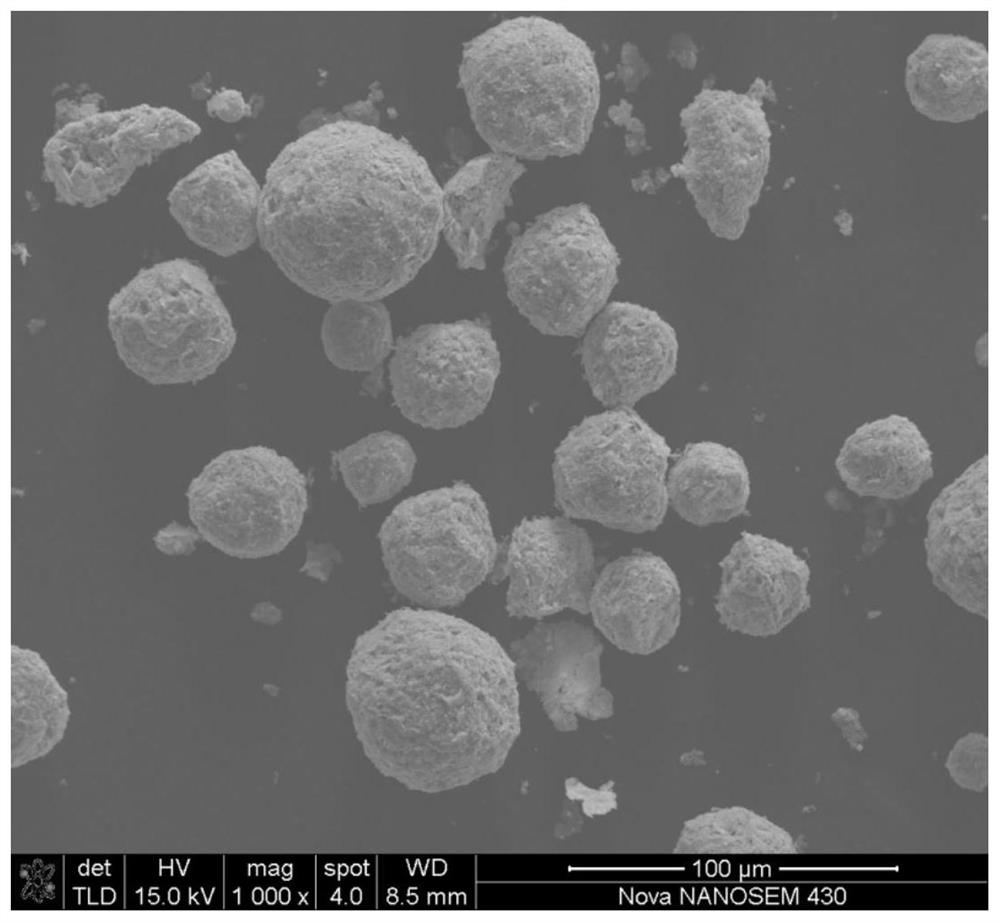

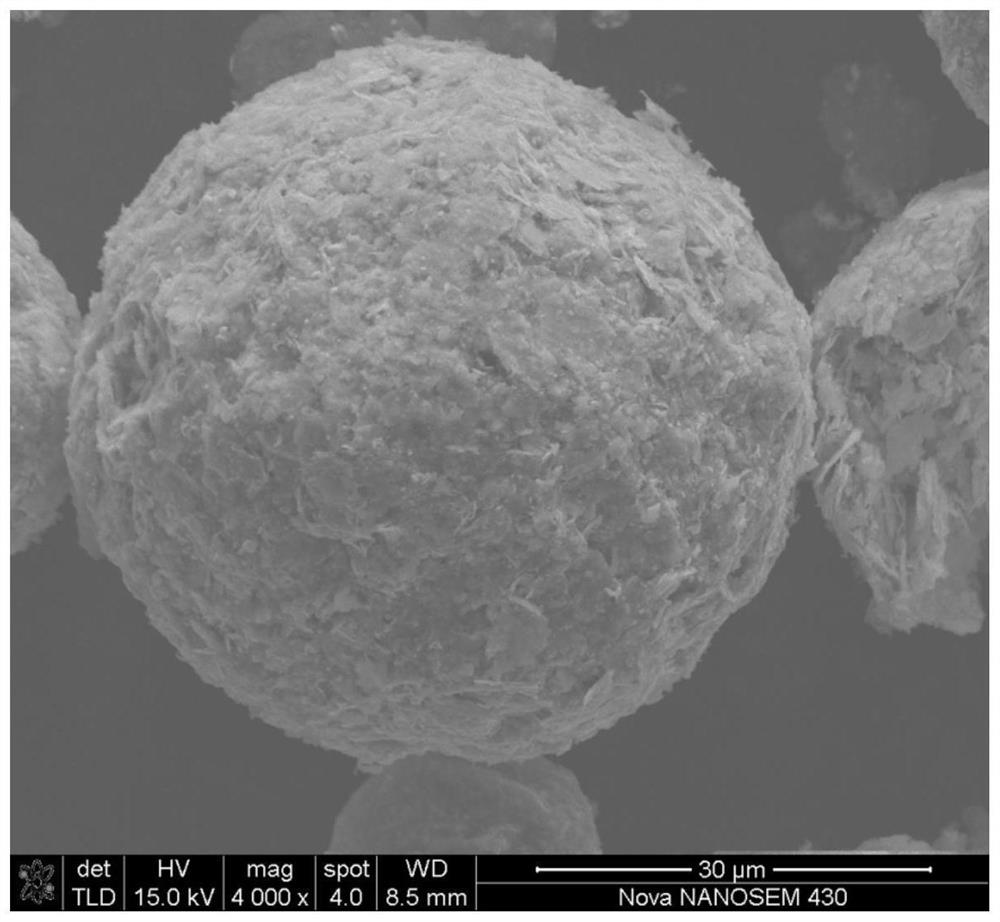

[0042] Preparation steps of high sphericity nanostructured stainless steel powder:

[0043] (1) The stainless steel powder and the process control agent (industrial alcohol) are added to the ball mill according to the content of industrial alcohol which is 1 / 2 of the volume of the ball mill, and the diameter is 3.0mm according to the ratio of ball to material ratio of 10:1. The zirconia grinding balls were ground in a protective argon atmosphere at a certain rotational speed of 1400 RPM for 1 h, and ground to nano-scale to obtain a slurry of powder A;

[0044] (2) the slurry of powder A is sprayed and granulated in the spray drying system, the spray drying system is a closed-loop high-speed centrifugal spray dryer, and the parameters of the spray drying system are: the inlet temperature is 150 ℃, and the outlet temperature is 60 ℃. ℃, the rotation speed of the atomizer is 12000RPM, and the nano-agglomeration powder with a certain sphericity is obtained, and the nano-agglomerat...

Embodiment 2

[0051] Preparation steps of high sphericity nanostructured stainless steel powder:

[0052] (1) The stainless steel powder and the process control agent (deionized water) are added to the ball mill according to the content of industrial alcohol which is 2 / 3 of the volume of the ball mill, and the diameter of the addition is 3.0 according to the ratio of the ball to material ratio of 10:1. The zirconia grinding balls of mm in size were ground in a protective argon atmosphere at a certain rotation speed of 1200 RPM for 3 hours, and ground to nano-scale to obtain a slurry of powder A;

[0053] (2) the slurry of powder A is carried out spray granulation in the spray drying system, the spray drying system is a closed-loop high-speed centrifugal spray dryer, and the parameters of the spray drying system are: the temperature of entering the tower is 200 ° C, and the temperature of leaving the tower is 90 °C. ℃, the rotation speed of the atomizer is 15000RPM, and the nano-agglomeratio...

Embodiment 3

[0058] Preparation steps of high sphericity nanostructured stainless steel powder:

[0059] (1) The stainless steel powder and the process control agent (industrial alcohol) are added to the ball mill according to the content of industrial alcohol which is 3 / 4 of the volume of the ball mill, and the diameter is 3.0mm according to the ratio of ball to material ratio of 10:1. The zirconia grinding balls were ground in a protective nitrogen atmosphere at a certain rotation speed of 1300RPM for 2 hours, and ground to sub-micron level to obtain a slurry of powder A;

[0060] (2) the slurry of powder A is carried out spray granulation in the spray drying system, the spray drying system is a closed-loop high-speed centrifugal spray dryer, and the parameters of the spray drying system are: 180 ℃ of inlet temperature, and 80 ℃ of outlet temperature ℃, the rotation speed of the atomizer is 14000RPM, the nano-agglomeration powder with a certain sphericity is obtained, and the nano-agglom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com