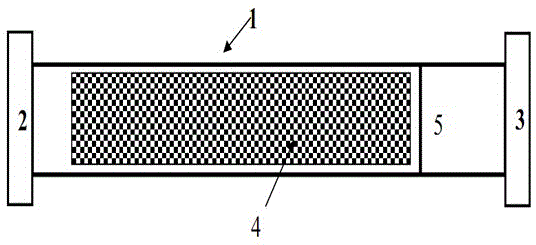

An adsorption column that simultaneously adsorbs heavy metal ions and volatile organic compounds in waste gas

A technology for volatile organic compounds and heavy metal ions, which is applied in the field of adsorption columns, can solve the problems that affect the cost and effect of waste gas treatment, and the lack of adsorbents, etc., and achieve the effects of high toxicity, short adsorption time and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Composite Adsorbent Material

[0027] 1) Pretreatment of carbon nanotubes: Put carbon nanotubes into a mixed solution of concentrated nitric acid and hydrofluoric acid, soak them under high pressure in an argon environment, maintain them at 120°C for 10 hours, cool them to room temperature, and then take out the carbon nanotubes. The nanotubes are washed and filtered with deionized water, and set aside;

[0028] 2) Preparation of calcium chloride: hydrochloric acid enters the reaction tank, and limestone is lifted into the reaction tank through a bucket elevator. After the reaction, the gas is washed with water in the tail gas scrubber and alkali washed in the tail gas scrubber, and the gas reaches the standard and is discharged by the induced draft fan. After the pH value of the liquid reaches 5, it enters the neutralization tank directly through the bypass pipe, and after adding lime milk to react, it is poured into the clarification tank through the ne...

Embodiment 2

[0038] 1) Pretreatment of carbon nanotubes: Put carbon nanotubes into a mixed solution of concentrated nitric acid and hydrofluoric acid, soak them under high pressure in an argon environment, maintain at 150°C for 15 hours, cool to room temperature, and then take out the carbon nanotubes. The nanotubes are washed and filtered with deionized water, and set aside;

[0039] 2) Preparation of calcium chloride: hydrochloric acid enters the reaction tank, and limestone is lifted into the reaction tank through a bucket elevator. After the reaction, the gas is washed by water in the tail gas scrubber and alkali washed by the tail gas scrubber. After the pH value of the liquid reaches 7, it enters the neutralization tank directly through the bypass pipe, and after adding lime milk to react, it is poured into the clarification tank through the neutralization pump, and the clarified liquid overflows into the clarification liquid tank, and the calcium chloride clear liquid is filtered En...

Embodiment 3

[0049] 1) Pretreatment of carbon nanotubes: Put carbon nanotubes into a mixed solution of concentrated nitric acid and hydrofluoric acid, soak them under high pressure in an argon environment, maintain them at 130°C for 18 hours, cool them to room temperature, and then take out the carbon nanotubes. The nanotubes are washed and filtered with deionized water, and set aside;

[0050] 2) Preparation of calcium chloride: hydrochloric acid enters the reaction tank, and limestone is lifted into the reaction tank through a bucket elevator. After the reaction, the gas is washed with water in the tail gas scrubber and alkali washed in the tail gas scrubber, and the gas reaches the standard and is discharged by the induced draft fan. After the pH value of the liquid reaches 6, it enters the neutralization tank directly through the bypass pipe, and after adding lime milk to react, it is poured into the clarification tank through the neutralization pump, and the clarified liquid overflows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com