Oxide material containing Mg, Cu and Mn and preparation method and application of oxide material

An oxide and chemical technology, applied in electrical components, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of toxicity and high compound cost, and achieve high efficiency, low manufacturing cost, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

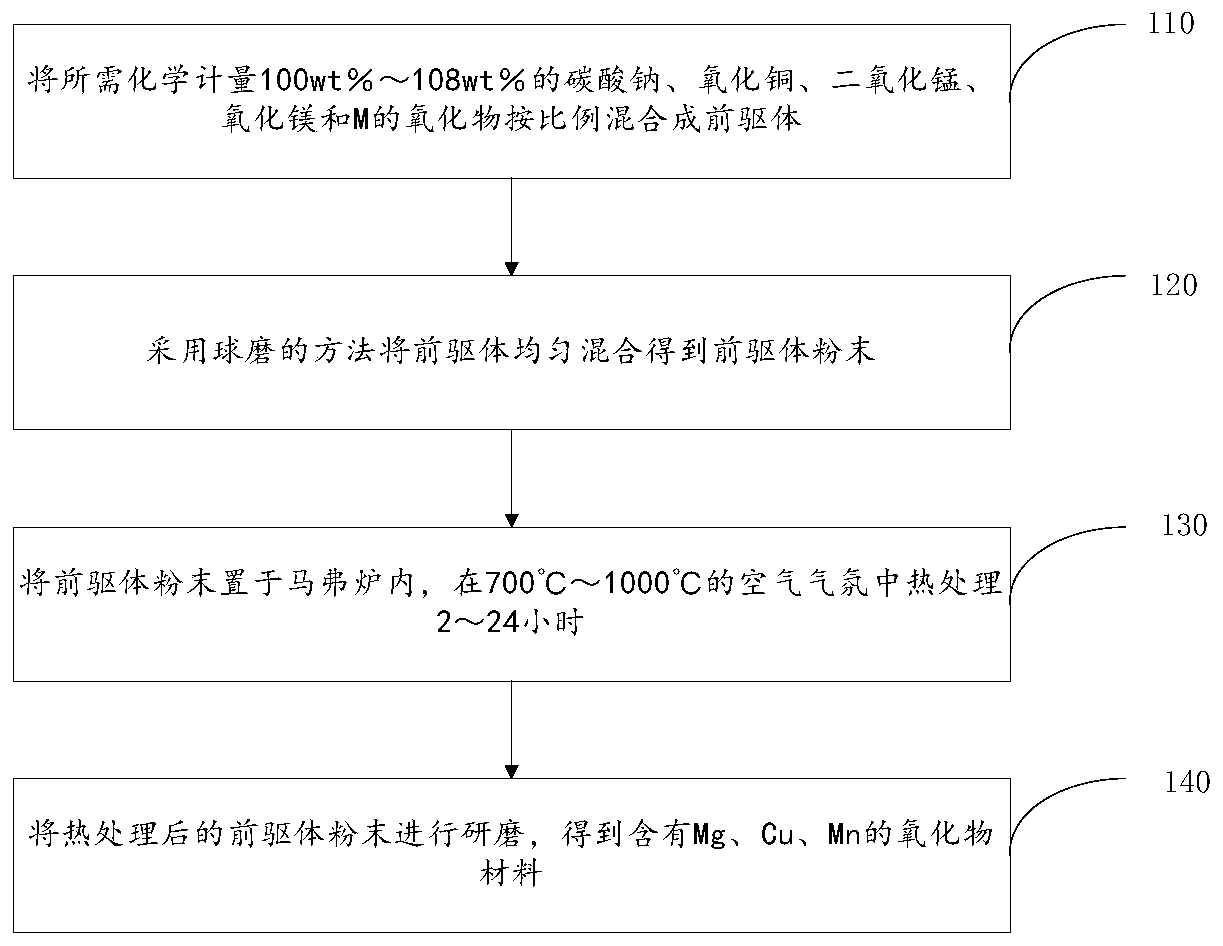

[0041] The embodiment of the present invention also provides a preparation method of the O3 phase layered oxide material containing Mg, Cu, and Mn at the same time, specifically a solid phase method. Its steps are as follows figure 2 shown, including:

[0042] Step 110, mixing the oxides of sodium carbonate, copper oxide, manganese dioxide, magnesium oxide and M with a required stoichiometric amount of 100wt% to 108wt% in proportion to form a precursor;

[0043] Among them, M is an element for doping and replacing the transition metal site, specifically including Fe 3+ , Zn 2+ , Ni 2+ , Li + , Al 3+ , B 3+ , Ti 4+ one or more of

[0044] Step 120, using a ball milling method to uniformly mix the precursor to obtain a precursor powder;

[0045] Step 130, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 700° C. to 1000° C. for 2 to 24 hours;

[0046] Step 140, grinding the heat-treated precursor powder to obtain an oxide m...

Embodiment 1

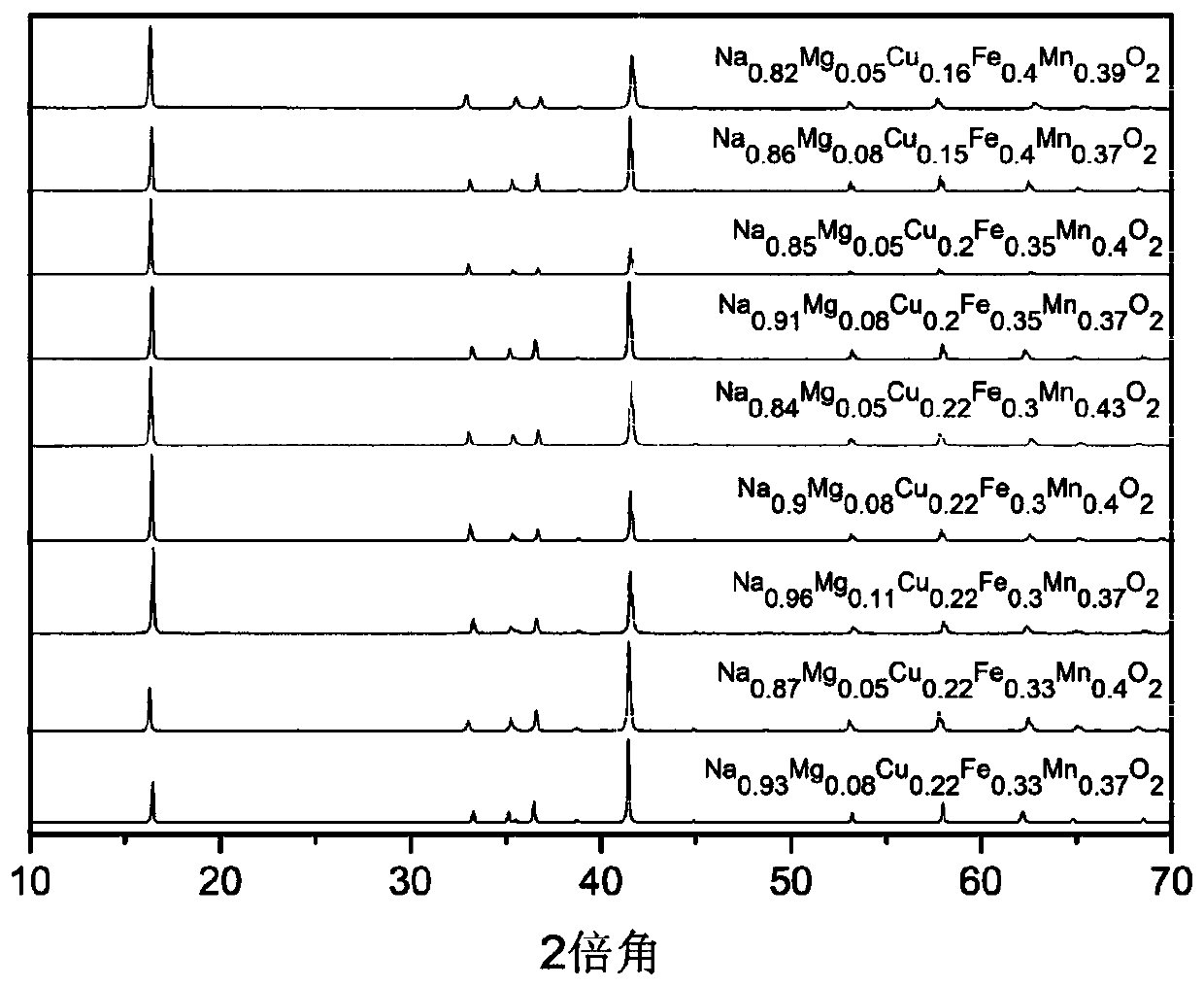

[0050] This embodiment provides a kind of oxide material Na containing Mg, Cu, Mn 0.9 Mg 0.08 Cu 0.22 Fe 0.3 mn 0.4 o 2 , and its preparation process is prepared by solid-phase method. Na 2 CO 3 , Fe 2 o 3 , CuO, MnO 2 , MgO were mixed according to the required stoichiometric ratio; ground for half an hour in an agate mortar to obtain a precursor; the precursor was pressed into tablets and transferred to Al 2 o 3 In the crucible, it was processed in a muffle furnace at 850° C. for 16 hours to obtain a black powder oxide material. Its XRD spectrum is as figure 1 shown.

[0051] The oxide material prepared above is used as the active material of the positive electrode material of the battery for the preparation of the sodium ion battery.

[0052] The prepared Na 0.9 Mg 0.08 Cu 0.22 Fe 0.3 mn 0.4 o 2 , the powder is mixed with acetylene black and the binder polyvinylidene fluoride (PVDF) according to the mass ratio of 80:10:10, adding an appropriate amount of ...

Embodiment 2

[0055] This embodiment provides a kind of oxide material Na containing Mg, Cu, Mn 0.84 Mg 0.05 Cu 0.22 Fe 0.3 mn 0.43 o 2 , the preparation process is the same as that of Example 1 above, but Na 2 CO 3 , Fe 2 o 3 , CuO, MnO 2 , MgO with different stoichiometric ratios, the black powder oxide material Na 0.84 Mg 0.05 Cu 0.22 Fe 0.3 mn 0.43 o 2 XRD spectrum such as figure 1 shown.

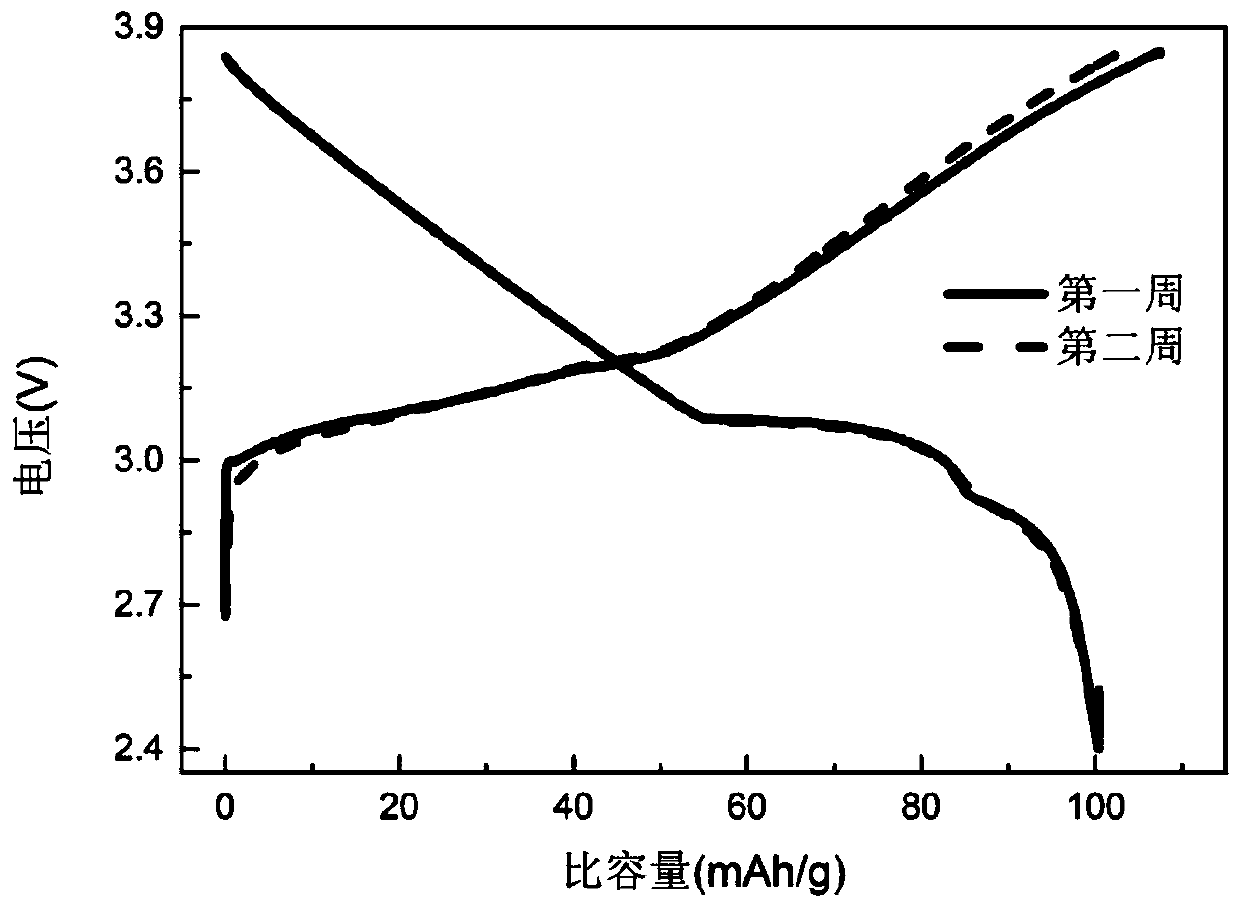

[0056] The oxide material prepared above was used as the active material of the positive electrode material of the battery for the preparation of the sodium ion battery, and electrochemical charge and discharge tests were carried out. Its preparation process and test method are the same as in Example 1. The test voltage ranges are 2.35V~3.95V, 2.4V~3.9V, 2.4V~4V, 2.4V~4.1V, 2.4V~4.2V, 2.4V~4.3V, 2.4V~4.4V, 2.4V~4.5V V. Figure 11 Shown in the test voltage range is 2.35V ~ 3.95V, the first cycle and the second cycle charge and discharge curves. It can be seen that when the test vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com