Method for preparing micro-mesopore XAD-2 by low temperature plasma

A technology of XAD-2 and low-temperature plasma, which is applied in the field of plasma preparation of micro-mesoporous XAD-2, can solve the problems of matrix performance damage, damage to raw material body performance, etc., and achieve low cost, enhanced self-binding force, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

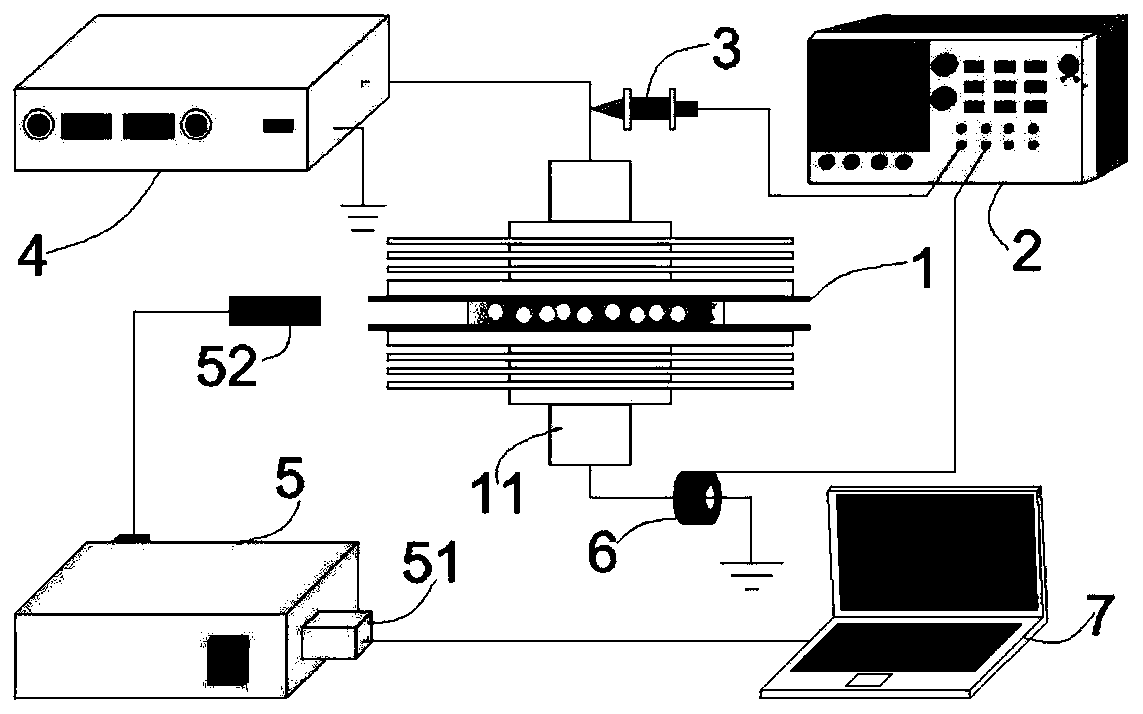

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing micro-mesoporous XAD-2 by low-temperature plasma, the raw material pretreatment is as follows: the raw material XAD-2 is placed in a bottle of absolute ethanol solution, and oscillated 3-5 times in an ultrasonic oscillator, each oscillation is 20 -30min to fully remove the impurities on the surface of XAD-2 and restore XAD-2 to a wet state, then wash it with deionized water several times until it becomes neutral, and finally place it in a vacuum drying oven at 80-120°C for 12 -24h, the pretreated XAD-2 was obtained.

[0032] In this embodiment, the selected parameters are as follows: the oscillation frequency of the ultrasonic oscillator is 40kHz, the oscillation time is 20min, the number of oscillations is 3 times, the number of times of washing with deionized water is 7 times, the temperature of the vacuum drying oven is 100°C, and the drying time For 16h, the pretreated XAD-2 sample was obtained. Set the voltage of the high-voltage nanosecond ...

Embodiment 2

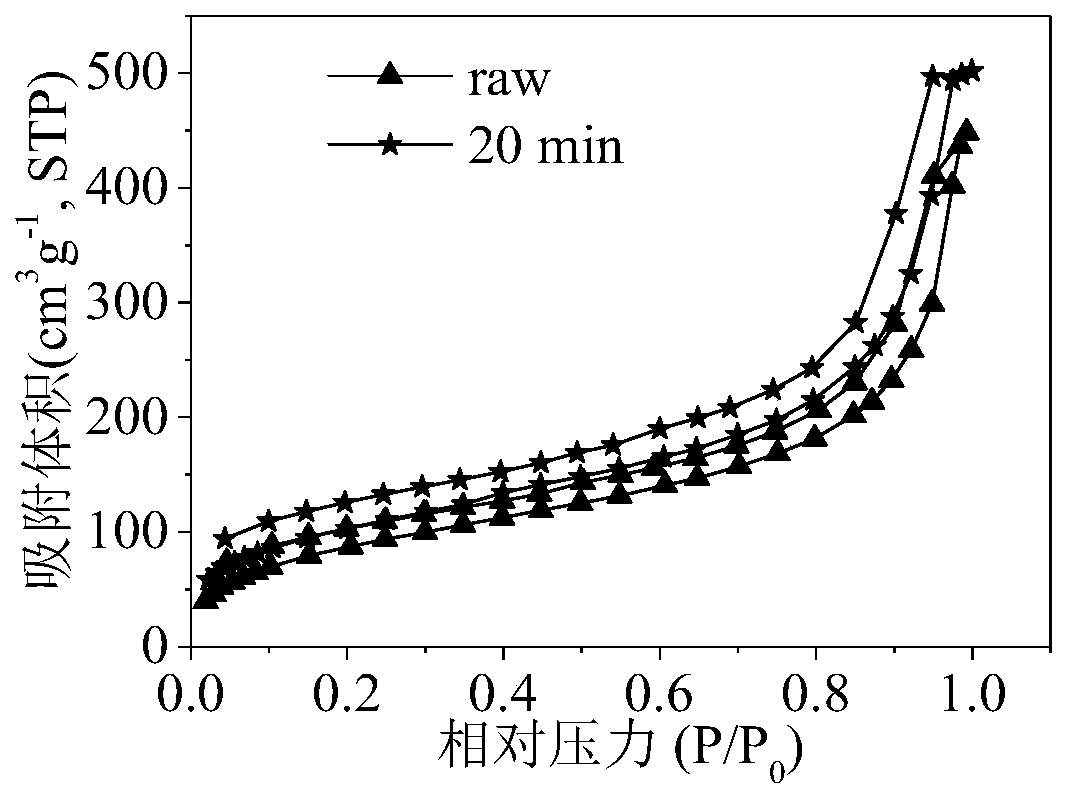

[0045] In this embodiment, the selected parameters are as follows: XAD-2 soaked in absolute ethanol is oscillated with an ultrasonic oscillator, the oscillation frequency is set to 20kHz, the oscillation time is 30min, and the number of oscillations is 5 times, and then washed with deionized water 10 times, the washed XAD-2 was dried in a vacuum drying oven, the temperature of the drying oven was set at 120°C, and the drying time was 12 hours to obtain a pretreated XAD-2 sample. Set the voltage of the high-voltage nanosecond bipolar narrow pulse plasma triggering power supply to 20kV, the frequency to 200Hz, the pulse width to 60ns, and the rising edge time to 10ns to discharge the pretreated XAD-2 for 10 minutes to obtain a new micro-mesoporous XAD- 2, such as Figure 7 As shown, and has a good adsorption effect on naphthalene, such as Figure 8 shown.

Embodiment 3

[0047] In this embodiment, the selected parameters are as follows: XAD-2 soaked in absolute ethanol is oscillated with an ultrasonic oscillator, the oscillation frequency is set to 25kHz, the oscillation time is 25min, the number of oscillations is 4 times, and then washed with deionized water 8 times, the washed XAD-2 was dried in a vacuum drying oven, the temperature of the drying oven was set at 80°C, and the drying time was 24 hours to obtain a pretreated XAD-2 sample. Set the voltage of the high-voltage nanosecond bipolar narrow pulse plasma trigger power supply to 25kV, the frequency to 180Hz, the pulse width to 75ns, and the rising edge time to 15ns to discharge the pretreated XAD-2 for 3min, 5min...25min to obtain a new Micro-mesoporous XAD-2, the prepared micro-mesoporous XAD-2 has a good adsorption effect on naphthalene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com