A method for preparing magnetic activated carbon from municipal sludge

A technology of magnetic activated carbon and municipal sludge, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of cumbersome preparation process of magnetic activated carbon, uneven distribution of activated carbon magnetic particles, high cost of activation reagents, etc., and achieve production Low cost, uniform distribution, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing magnetic activated carbon from municipal sludge, specifically comprising the following steps:

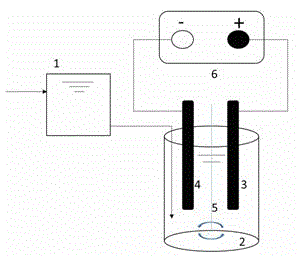

[0030] (1) Take 1L of municipal sludge from the secondary settling tank and place it in a 1.5L electrolytic cell with negative and positive poles, add 5g of sodium sulfate to the municipal sludge, and add sodium sulfate to the municipal sludge , and then carry out electrolytic treatment for 30 minutes;

[0031] Described electrolytic treatment is to use electric mixer to stir and control rotating speed to be 60rpm, electrolytic voltage is 20V, and electric current is electrolyzed under the condition of 1A;

[0032] In the electrolytic cell with two poles of cathode and anode, the distance between cathode and anode plates is 3 cm;

[0033] In the described electrolytic cell, the cathode plate is a titanium plate, and the anode plate is an iron plate;

[0034] The urban sludge moisture content is 99.1%;

[0035] (2) Centrifuge the municipal sludge afte...

Embodiment 2

[0042] A method for preparing magnetic activated carbon from municipal sludge, specifically comprising the following steps:

[0043] (1) Take 1L of urban sludge from the primary sedimentation tank and place it in a 1.5L electrolytic cell with negative and positive electrodes, add 5g of sodium sulfate to the sludge per liter of urban sludge, and add sodium sulfate to the sludge. Then carry out electrolytic treatment for 20min;

[0044] The electrolysis treatment is aeration and agitation, the electrolysis voltage is 25V, and the electrolysis is carried out under the condition of 1.3A current;

[0045] The aeration and agitation is performed by using an air pump for aeration and agitation, and the aeration flow rate is 1.2L / min;

[0046] In the electrolytic cell with two poles of cathode and anode, the distance between cathode and anode plates is 2cm;

[0047] In the described electrolytic cell, the cathode plate is a titanium plate, and the anode plate is an iron plate;

[0...

Embodiment 3

[0054] A method for preparing magnetic activated carbon from municipal sludge, specifically comprising the following steps:

[0055] (1) Take 1L of urban sludge from the secondary sedimentation tank and place it in a 1.5L electrolytic cell with negative and positive electrodes, add 5g of sodium sulfate to the sludge per liter of urban sludge, and add sodium sulfate to the sludge. Then use a stabilized power supply to carry out electrolytic treatment for 30 minutes;

[0056] Described electrolytic treatment is to use electric mixer to stir and control rotating speed to be 80rpm, electrolytic voltage is 30V, and electric current is electrolyzed under the condition of 1.8A;

[0057] In the electrolytic cell with two poles of cathode and anode, the distance between cathode and anode plates is 5 cm;

[0058] In the described electrolytic cell, the cathode plate is a titanium plate, and the anode plate is an iron plate;

[0059] The urban sludge moisture content is 99.0%;

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com