Patents

Literature

61results about How to "Good mercury removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for removing sulfur, nitre and mercury in smoke

InactiveCN103990362AEasy to transformReduce complexityDispersed particle separationAir quality improvementChlorine dioxideGas phase

The invention relates to a method and a device for removing sulfur, nitre and mercury in smoke. The method comprises the following steps: introducing dedusted smoke into a mixing device, injecting chlorine dioxide gas to carry out gas phase oxidation on the smoke, then introducing the smoke into a wet type sulfur removing device, removing high-valence nitric oxide, sulfur dioxide and HgC12 by taking a calcium-based sulfur removing size as an absorbent, and discharging the clean smoke into the atmosphere; or directly injecting the smoke into the chlorine dioxide gas to carry out gas phase oxidation, then introducing the smoke into a semidry type sulfur removing device, removing high-valence nitric oxide, sulfur dioxide and HgC12 by taking a calcium-based absorbent and humidified fly ash in the smoke as absorbing and removing agents, and discharging the clean smoke into the atmosphere. The method is based on an existing wet type sulfur removing device or semidry type sulfur removing device, thus facilitating the improvement. According to the method and device disclosed by the invention, dust and sulfur do not need to be removed in advance, so that used equipment are reduced, and the complexity of a system is reduced. In addition, an obvious mercury removal effect is also achieved, thereby really embodying the significance of combined removal.

Owner:SHANDONG UNIV

Preparation method of sulfurizing porous nanometer material for high-efficiency hydrargyrum removal

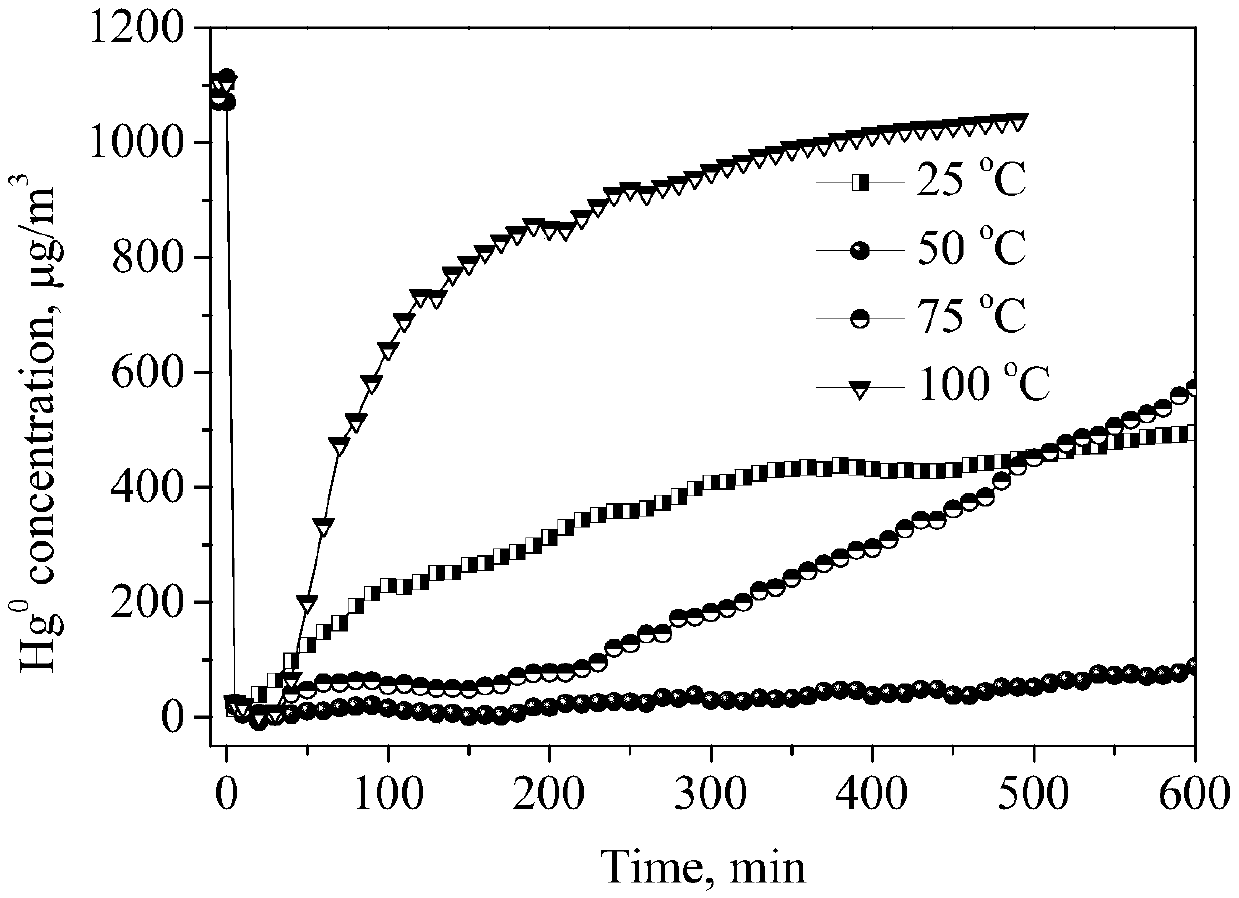

InactiveCN102247823AReduce viscosityReduce surface tensionOther chemical processesDispersed particle separationDry iceRoom temperature

The invention relates to high-efficiency sulfurizing hydrargyrum-removing porous nanometer carbon and a preparation method thereof, belonging to the field of chemistry. The preparation method comprises the following steps of: mixing porous nanometer carbon and sulfur, and then placing into a closed pressure vessel with dry ice or liquid carbon dioxide together; heating the closed pressure vessel to 31-200 DEG C to make the carbon dioxide reach a supercritical state, keeping for 1-48 hours, or heating the carbon dioxide to the supercritical state, then injecting into the closed pressure vesselcontaining a mixture of the porous nanometer carbon and the sulfur, and keeping for 1-48 hours; and then cooling to room temperature, and evacuating the carbon dioxide so as to prepare the sulfurizing porous nanometer carbon, wherein the mass percent of the sulfur contained in the sulfurizing porous nanometer carbon is 2-50 percent. According to the invention, high sulfurizing quantity and the quantity as well as the specific surface area of the sulfur available during hydrargyrum removal are furthest ensured by tactfully adopting the gas-liquid dual property of the supercritical carbon dioxide, and therefore an optimal hydrargyrum removing effect is achieved; in addition, the advantages of simple process, high efficiency, environment friendliness and low cost are achieved.

Owner:叶向荣 +1

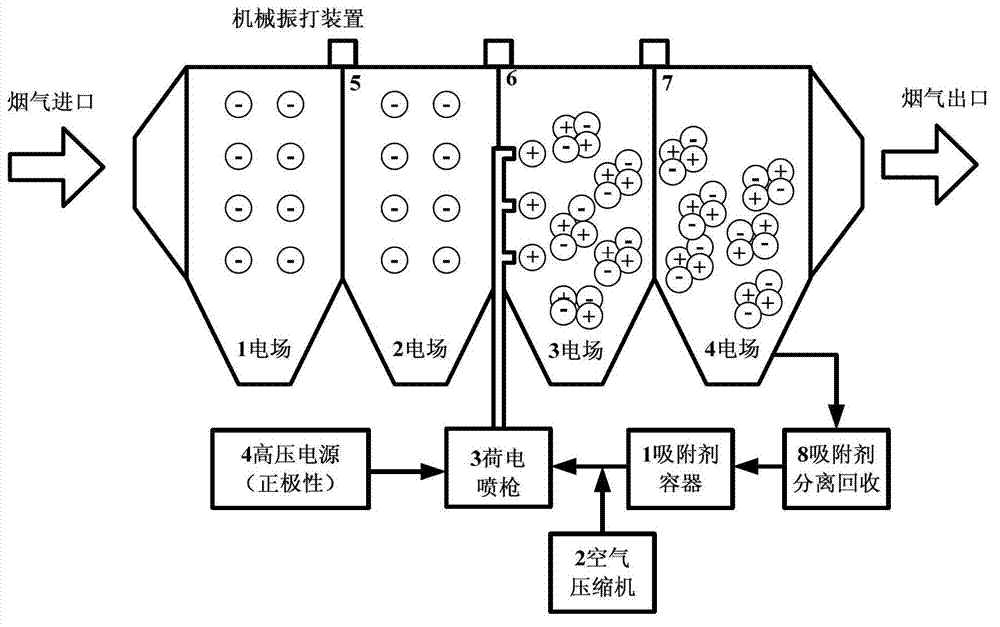

Method for removing fine particles and heavy metals in coal fume

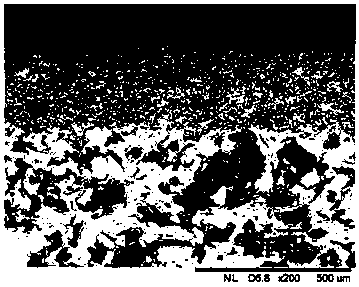

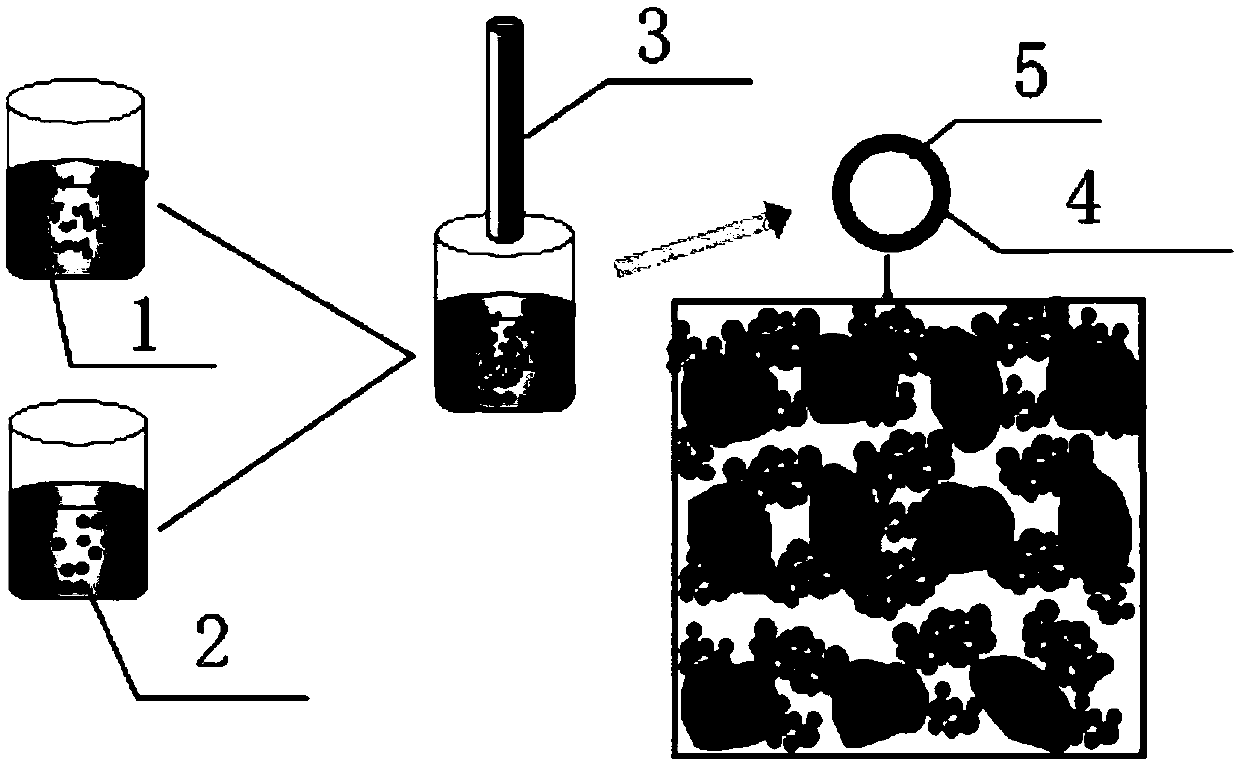

ActiveCN102773162ALarge structure sizeLess investmentElectrostatic separationVortex flow apparatusSorbentPre-charge

The invention relates to a method for removing fine particles and heavy metals in coal fume. The method is an electric precipitator coupling charging absorbing agglomeration technology. The method comprises the steps of: pre-charging (positive charge) on an adsorbent by a charging spray gun, and spraying the adsorbent to an area between two adjacent electric fields of the electric precipitator; by a Coulomb agglomeration action between a positively charged absorbent particle and a fine particle which is negatively charged by last electric field and is not captured, and an absorption action of the charged absorbent, capturing a plurality of pollutants including fine particles, heavy metals and condensable substances, onto the absorbent to form larger particles; and efficiently capturing the larger particles by the electric field at the back of the electric precipitator, so as to achieve the purpose of synergistically removing a plurality of pollutants in smoke. Compared with prior art, the method of removing fine particles and heavy metals in coal fume has the advantages of high efficiency and low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

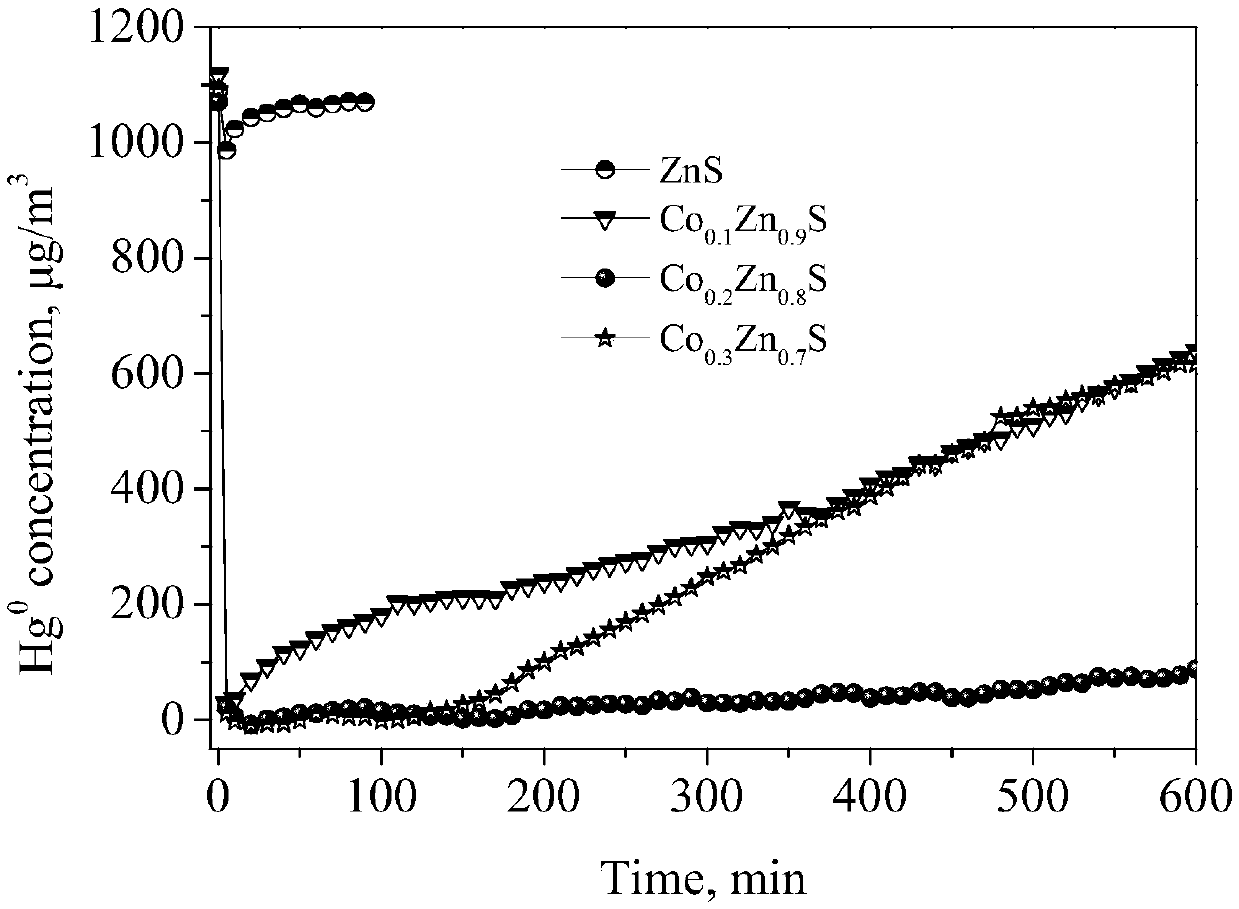

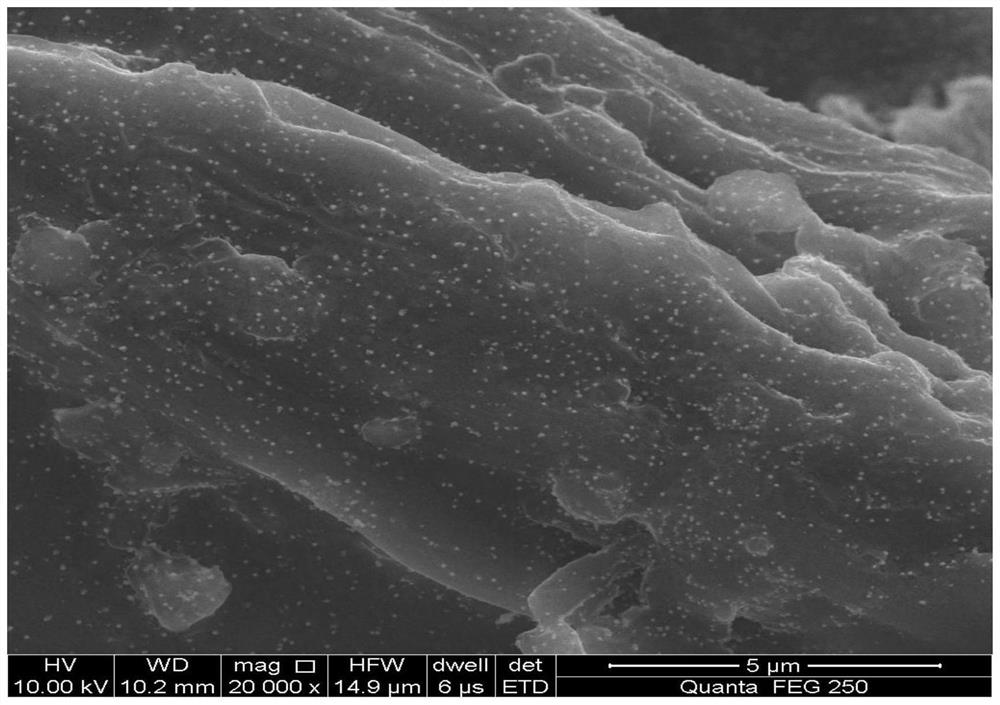

Zinc sulfide based mercury adsorbent for flue gas zero-valent mercury capturing and preparation method of zinc sulfide based mercury adsorbent

ActiveCN109092239ASimple processMild operating conditionsGas treatmentOther chemical processesSorbentFlue gas

The invention relates to a zinc sulfide base mercury adsorbent for flue gas zero-valent mercury capturing and a preparation method of the zinc sulfide based mercury adsorbent. The adsorbent is a cobalt-doped zinc sulfide mercury adsorption material CoxZn1-xS, in the formula, x represents the stoichiometric ratio of cobalt in a solution, and the stoichiometric ratio is 0.1-0.3. The preparation method comprises the following steps: (1) dissolving a cobalt salt and a zinc salt of a certain mole ratio into deionized water so as to obtain a mixed solution; (2) mixing and stirring the mixed solutionwith a precipitant; (3) putting a suspension liquid into a reactor, and carrying out heating treatment on the reactor in a baking oven; (4) repeatedly washing the obtained precipitate with deionizedwater, and drying, thereby obtaining the zinc sulfide based mercury adsorbent. Compared with the prior art, the preparation method is wide in raw material source, simple and controllable in preparation process and gentle in reaction condition, and the prepared adsorbent has a mercury adsorption capability which is improved by dozens of times when being compared with pure zinc sulfide, in additionhas a very good anti-SO2 influence property, is capable of maintaining certain high activity within a long time, and is particularly applicable to adsorption and removal of zero-valent mercury in a metallurgical flue gas.

Owner:SHANGHAI JIAO TONG UNIV

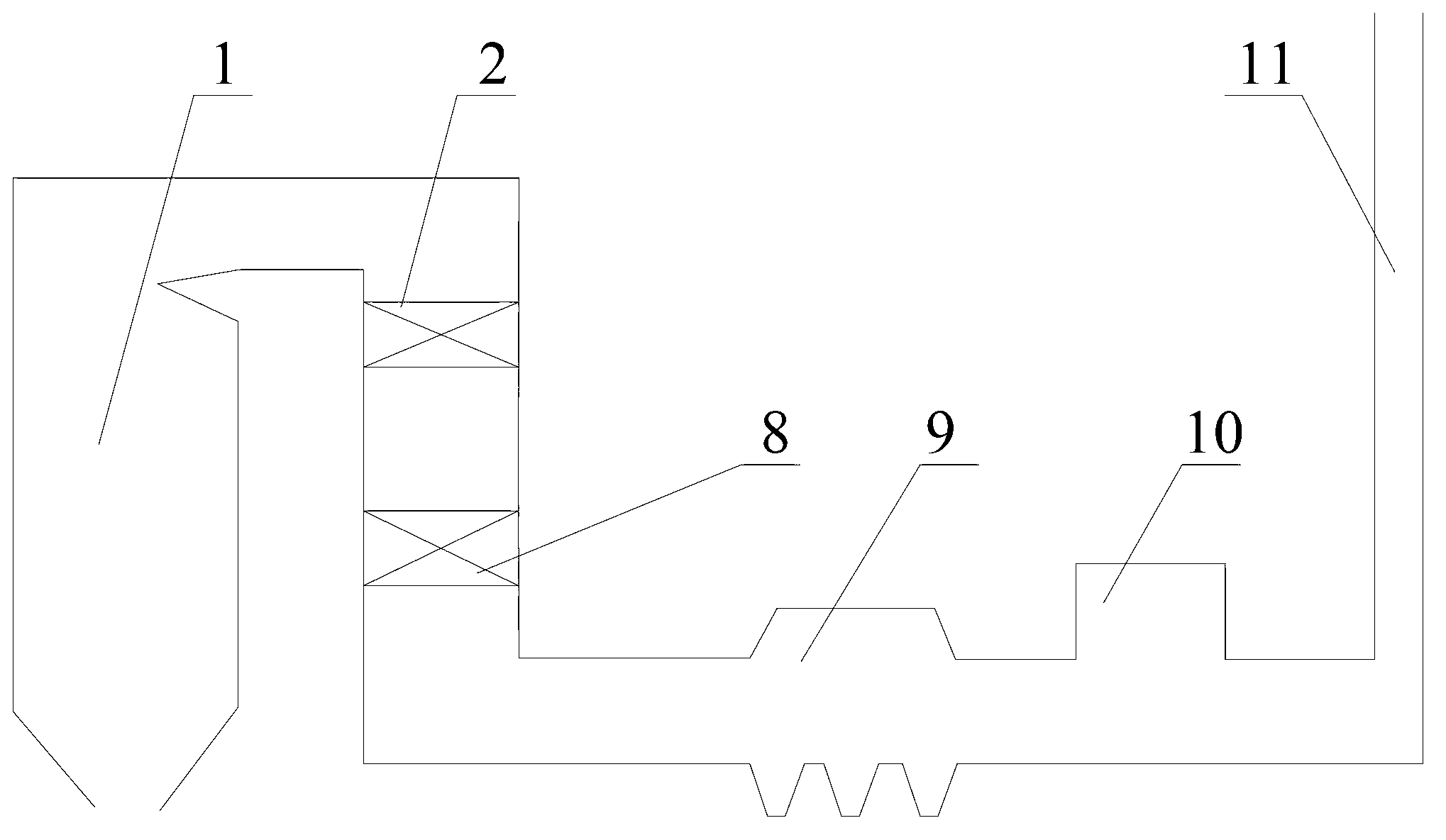

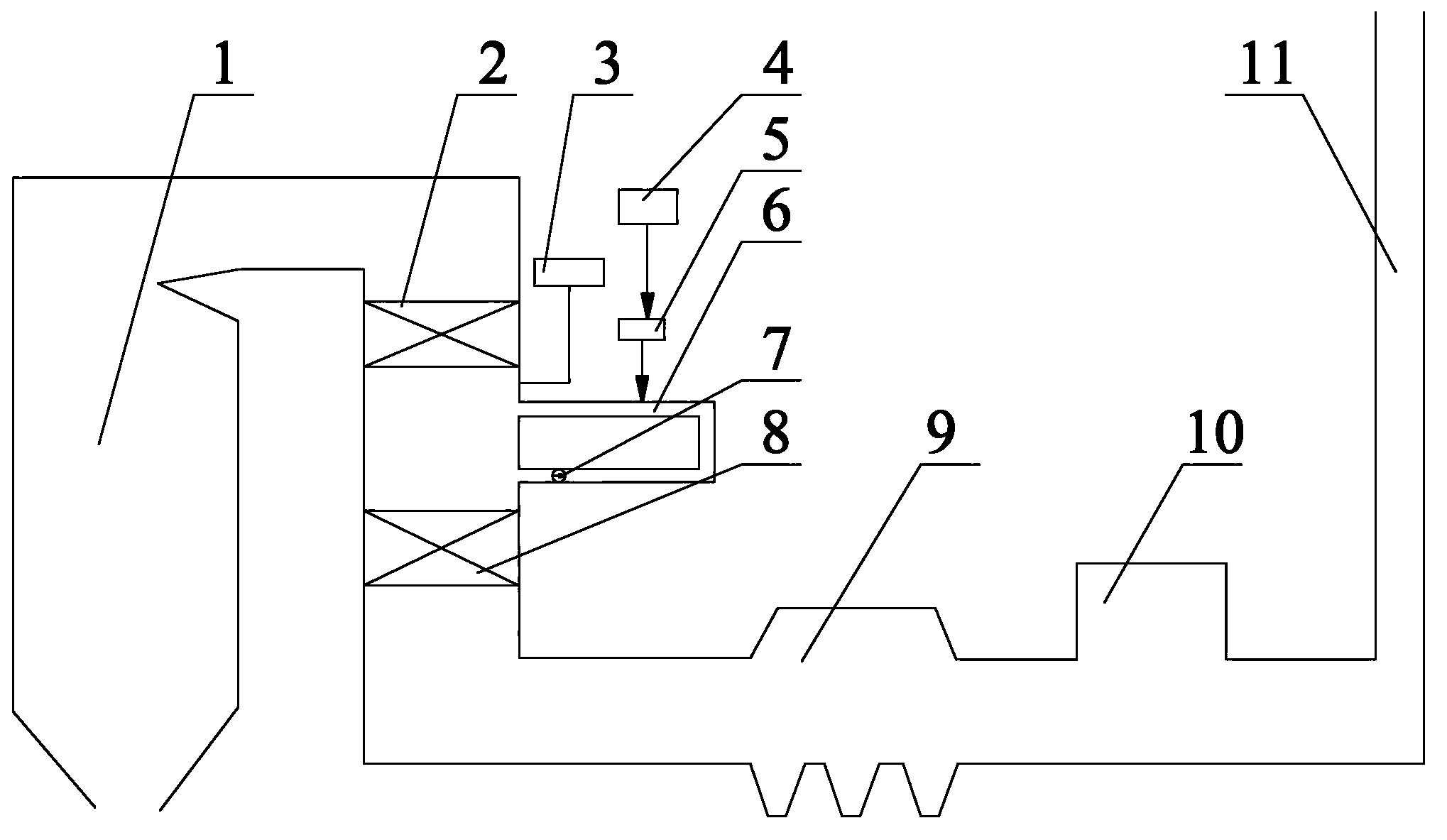

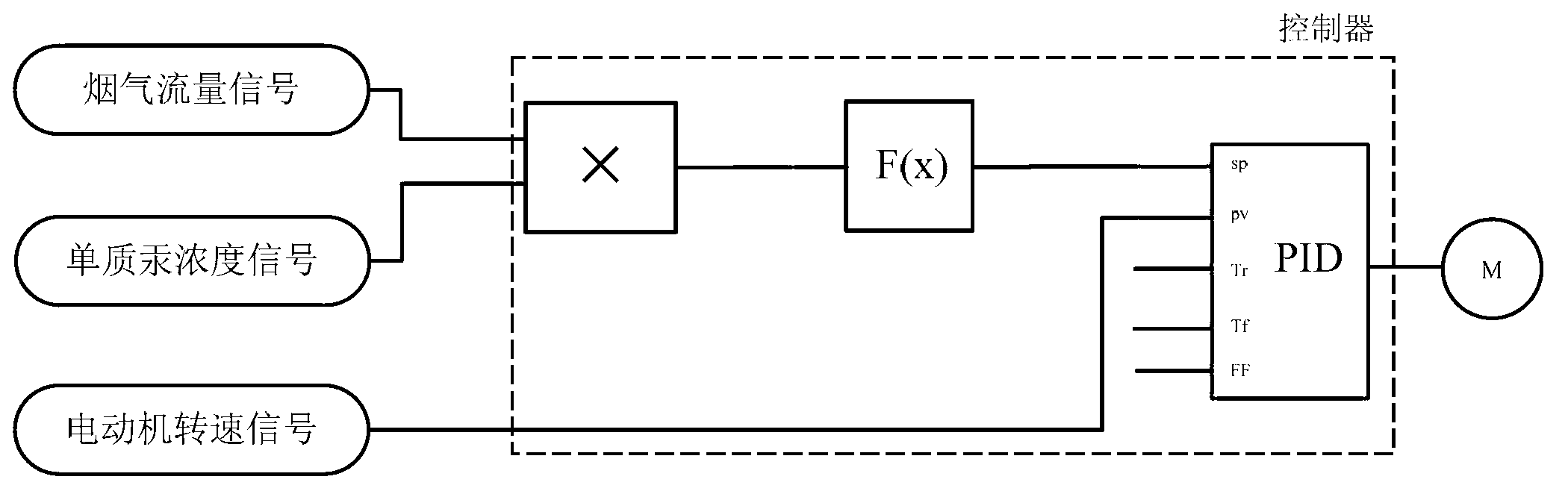

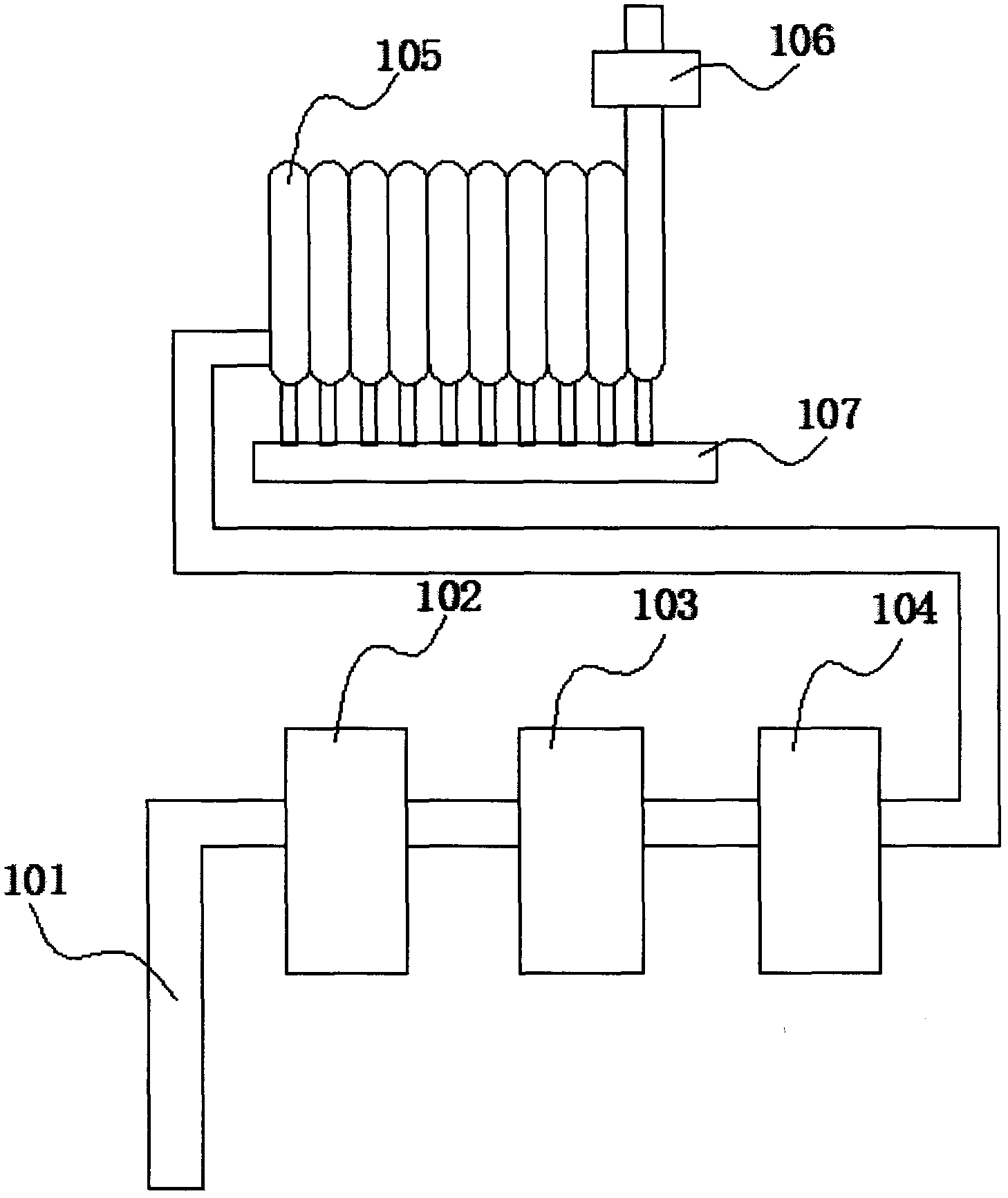

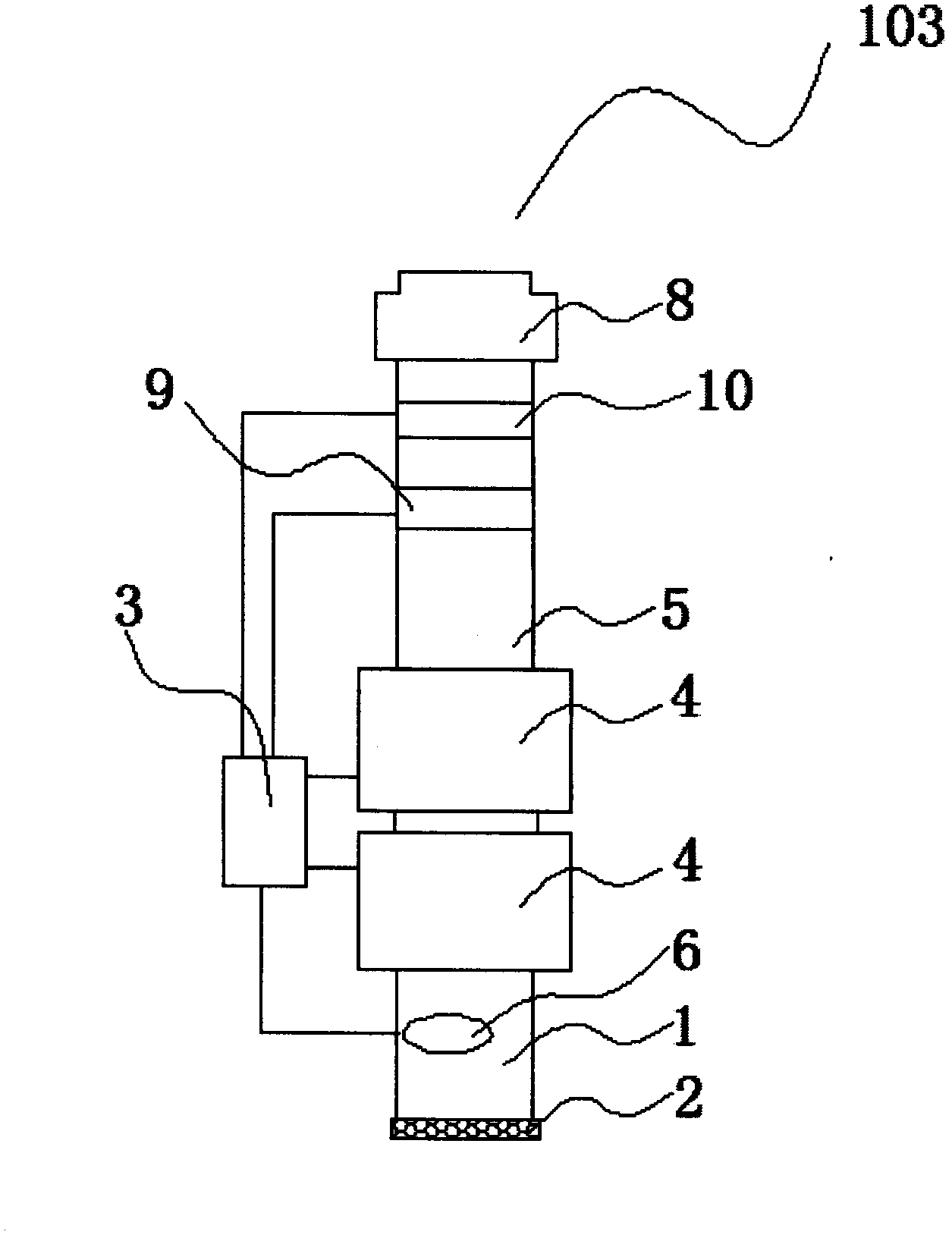

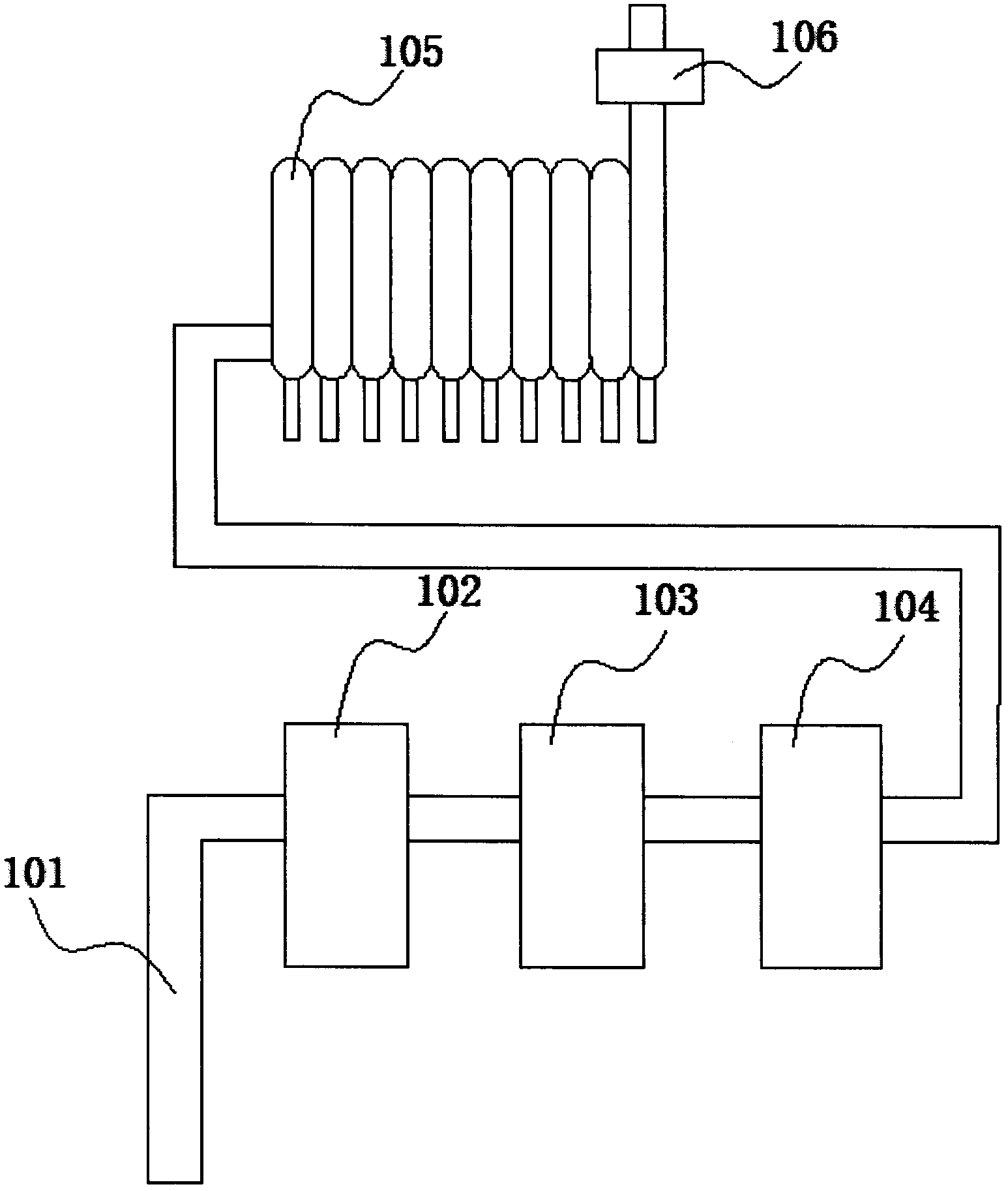

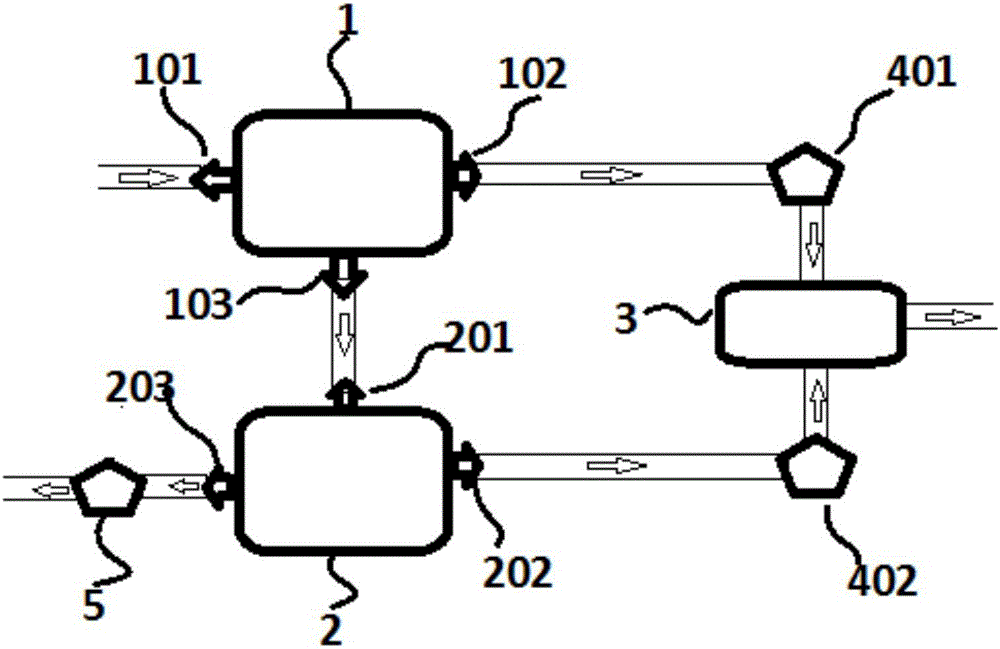

Intelligent demercuration addition agent adding system for coal-fired power plant

ActiveCN103170236AThe amount added is accurateImprove utilization efficiencyLighting and heating apparatusDispersed particle separationAir preheaterEngineering

The invention discloses an intelligent demercuration addition agent adding system for a coal-fired power plant. The intelligent demercuration addition agent adding system comprises a smoke mercury continuous on-line monitoring plant, a crushing device, a screw feeder, a circulating flue, a fan and an intelligent control device, wherein a smoke outlet of the circulating flue is formed in the outlet of an economizer in a tail flue, and a smoke inlet of the circulating flue is formed in the inlet of an air preheater in the tail flue; the fan is arranged in the circulating flue, a feeding port of the screw feeder is communicated with a discharge port of the crushing device, the discharge port of the screw feeder leads to the circulating flue, and a monitoring probe of the smoke mercury continuous on-line monitoring plant is arranged in the tail flue; and the smoke mercury continuous on-line monitoring device and the screw feeder are respectively and electrically connected with corresponding ports of the intelligent control device. The intelligent demercuration addition agent adding system provided by the invention has the characteristics that additive amount of a demercuration addition agent is exact, the utilization efficiency is high and a demercuration effect is good.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

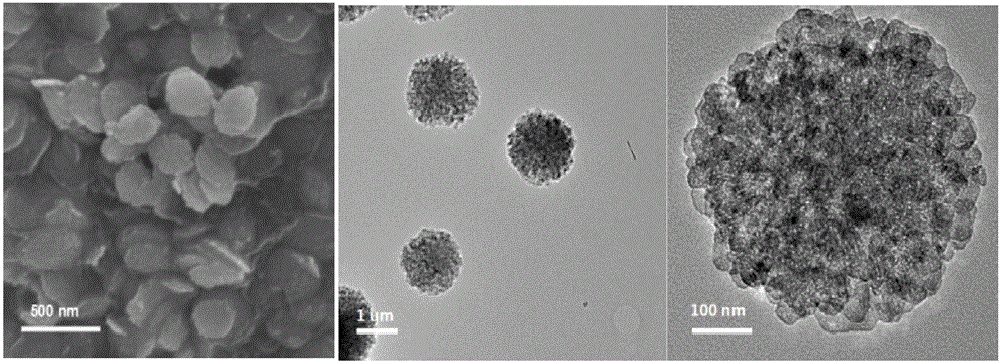

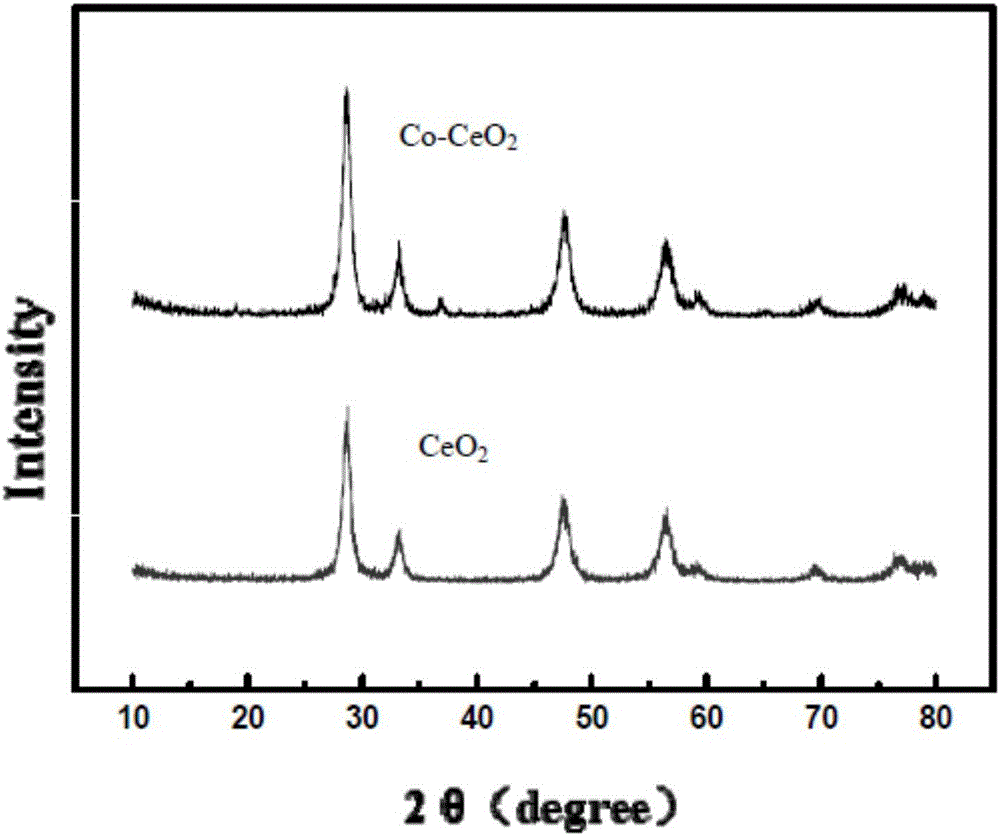

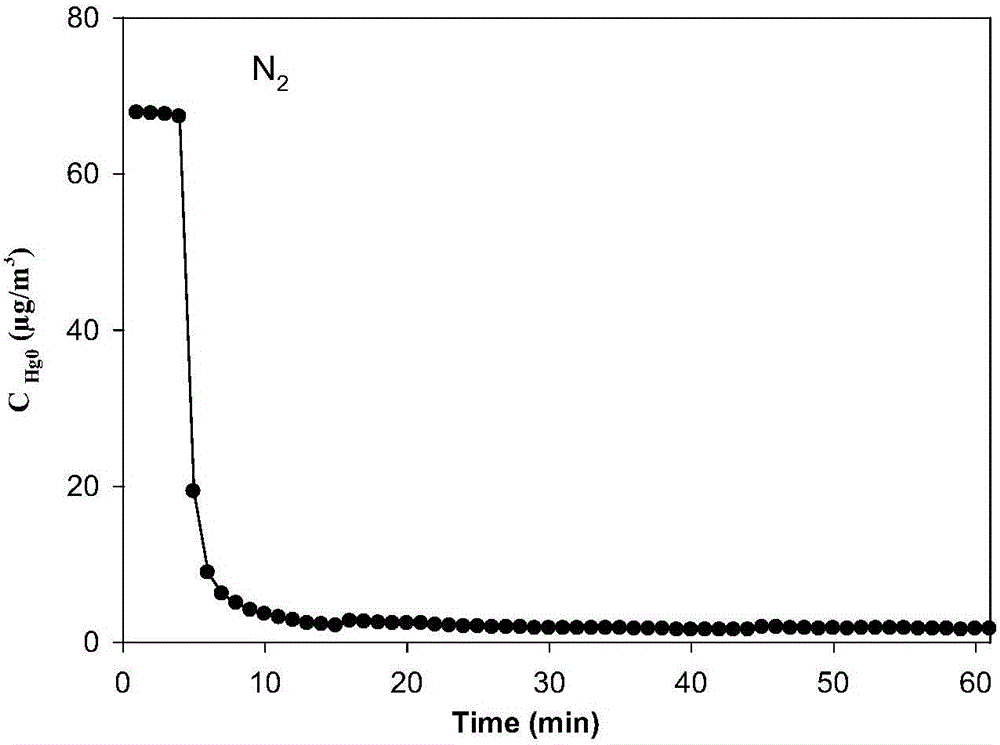

Cobalt-doped cerium oxide nanometer material with flaky structure and preparation and application thereof

ActiveCN106745170AThe preparation process is simple, clean and controllableRaw materials are easy to obtainDispersed particle separationNanotechnologyCerium nitrateOxygen

The invention discloses a cobalt-doped cerium oxide nanometer material with a flaky structure and preparation and application thereof in demercuration. A preparation method comprises the following steps of by using cerium nitrate and cobalt salt as raw materials according to a certain ratio, using urea as an alkaline source, and using polyvinylpyrrolidone as a surfactant, and mixing for hydrolysis reaction, so as to obtain a mixture; storing the mixture in a hydrothermal constant-temperature way, washing, drying, and calcining, so as to obtain the cobalt-doped cerium oxide nanometer material with regular shape, uniform size and the complete flaky structure. The prepared cobalt-doped cerium oxide nanometer material has the advantages that the structure is novel; the raw material is easy, and is easy to obtain; the procedure is simple, the reaction process is clean, and the secondary pollution is avoided; the cobalt-doped cerium oxide nanometer material is used for removing mercury in gas, the method is simple, the demercuration effect is good, and after Hg0 steam with concentration of 75mu g / m<3> is treated, under the condition of no oxygen or leading 4% of oxygen, the demercuration rate can reach 97% or above.

Owner:CENT SOUTH UNIV

Catalyst for removing harmful gas and preparation method and application thereof

ActiveCN107790152ALattice OxygenImprove adsorption capacityGas treatmentDispersed particle separationActivated carbonCopper oxide

The invention discloses a catalyst for removing harmful gas and a preparation method and application thereof. The catalyst uses activated carbon as a carrier and metal oxides are carried by the activated carbon. The metal oxides comprise copper oxide and manganese oxide according to a molar ratio of copper oxide to manganese oxide of 3: 1 to 1: 5. The catalyst has stable activity, does not easilycause catalyst poisoning, has good formaldehyde removal and mercury removal performances and can be industrially applied on a large scale. The catalyst is prepared from easily available raw materials.The preparation method is simple and a preparation cost of the catalyst is low.

Owner:HUNAN UNIV

Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic film and preparation method thereof

ActiveCN109603533AImprove purification effectIncrease contactPhysical/chemical process catalystsDispersed particle filtrationReactive siteAdhesive

The invention belongs to the field of air purification, in particular to an Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic filmand a preparation method thereof. The catalytic film is composed of a ceramic support and an active catalytic layer spread in a hole channel of the ceramic support, the active catalytic layer comprises a two-dimensional MXene nanosheet, AgNO3, active metal, a carrier, a dispersing agent and an adhesive; according to the invention, the two-dimensional layered MXene nanosheet is used as a structural guiding agent to prepare the Ag and two-dimensional MXene modified high-temperature flue gas dust removal, denitration and mercury removal catalytic film; the introduction of the two-dimensional MXene nano material enables the catalytic layer to have a two-dimensional and three-dimensional assembly structure, more active sites are provided, the contact between gas and the catalyst is increased,and the denitration and mercury removal efficiency is improved; meanwhile, by utilizing the separation performance of the film, the dust removal, denitration and mercury removal integrated treatment can be achieved at high temperature, and the flue gas purification process is simplified.

Owner:CHINASALT JINTAN

Flue gas dust-removal mercury-removal desulfurizing system

InactiveCN103657366AEasy loadingTo achieve the purpose of automatic controlCombination devicesGas phaseFiltration

The invention relates to a flue gas dust-removal mercury-removal desulfurizing system. The system comprises a flue gas temperature control pipe, a flue gas oxidizing tower, a flue gas dust-removal device and a mercury adsorption chamber, which are connected sequentially. The flue gas dust-removal mercury-removal desulfurizing system is to carry out physical filtration and electrostatic adsorption to effectively filter, settle and separate out coarse and fine particles and dust in the high-temperature flue gas for several times, and initially remove large-granular mercury from the flue gas to facilitate reducing the load of the follow-up flue gas mercury-removal device. When the mercury is removed, firstly the temperature of the flue gas in the temperature control pipe is controlled at 140 DEG C; the chlorine gas is jet to oxidize the flue gas to generate gas-phase mercury ions; then the gas-phase mercury ions are adsorbed by bromine-loaded activated carbon; the residual mercury and sulfide are completely adsorbed by an ammonia water spray manner; at last, ammonium sulfate and ammonium chloride generated through the ammonia water spray manner are prepared into a solid chemical fertilizer. The whole process is short and simple; the mercury removal effect is good.

Owner:JIANGSU XIONGYUE PETROLEUM MECHANICAL EQUIP MFG

Ferric-chlorine-modified active carbon adsorbent for removing mercury from smoke

ActiveCN103084145ASimple structureImprove pore structureOther chemical processesDispersed particle separationSorbentChloric acid

The invention discloses a ferric-chlorine-modified active carbon adsorbent for removing mercury from smoke. The modified active carbon adsorbent is obtained through the following steps of: preparing ferric nitrate-chloric acid mixed solution firstly, impregnating modified active carbon by using the mixed solution, then filtering out supernatant and drying to obtain the modified active carbon adsorbent. The invention aims at a jetting mercury removal technique of boiler smoke in a coal-fired power plant to provide a specialized efficient mercury removing adsorbent; the adsorbent is simple in preparation and low in cost; compared with an original active carbon, the adsorbent has the advantages of stronger mercury adsorption capability, larger adsorption amount and the like; and the adsorbent can effectively adsorb mercury from the smoke.

Owner:SOUTHEAST UNIV

Mercury removal agent for moisture mercury removal and preparation method of mercury removal agent

InactiveCN108456574AImprove mercury removal performanceGood mercury removal effectOther chemical processesGaseous fuelsActivated carbonVulcanization

The invention provides a mercury removal agent for moisture mercury removal. The mercury removal agent comprises an active substance, carrier particles and an auxiliary component, wherein the active substance is metal sulfide, wherein copper sulfide accounts for 80% or more by mass; the carrier particles include active aluminum oxide, coconut shell activated carbon and an adhesion promoter; the auxiliary component is silver sulfide; the active substance and the auxiliary component are loaded on the carrier particles. The invention also provides a preparation method of the mercury removal agent. The preparation method comprises the following steps: mixing the active aluminum oxide, the coconut shell activated carbon and the adhesion promoter, performing extrusion forming, and drying to obtain the carrier particles; impregnating the carrier particles in a solution containing Cu<2+> and Ag<+>; after complete impregnation, calcining at 500-800 DEG C to obtain a mercury removal agent precursor; impregnating the mercury removal agent precursor in a sulfide solution for 2-4h; after vulcanization, calcining at 500-800 DEG C to obtain the mercury removal agent, wherein the mercury removal agent has better mercury removal performance when the loading quantity of copper sulfide is the same.

Owner:SOUTHWEST PETROLEUM UNIV +1

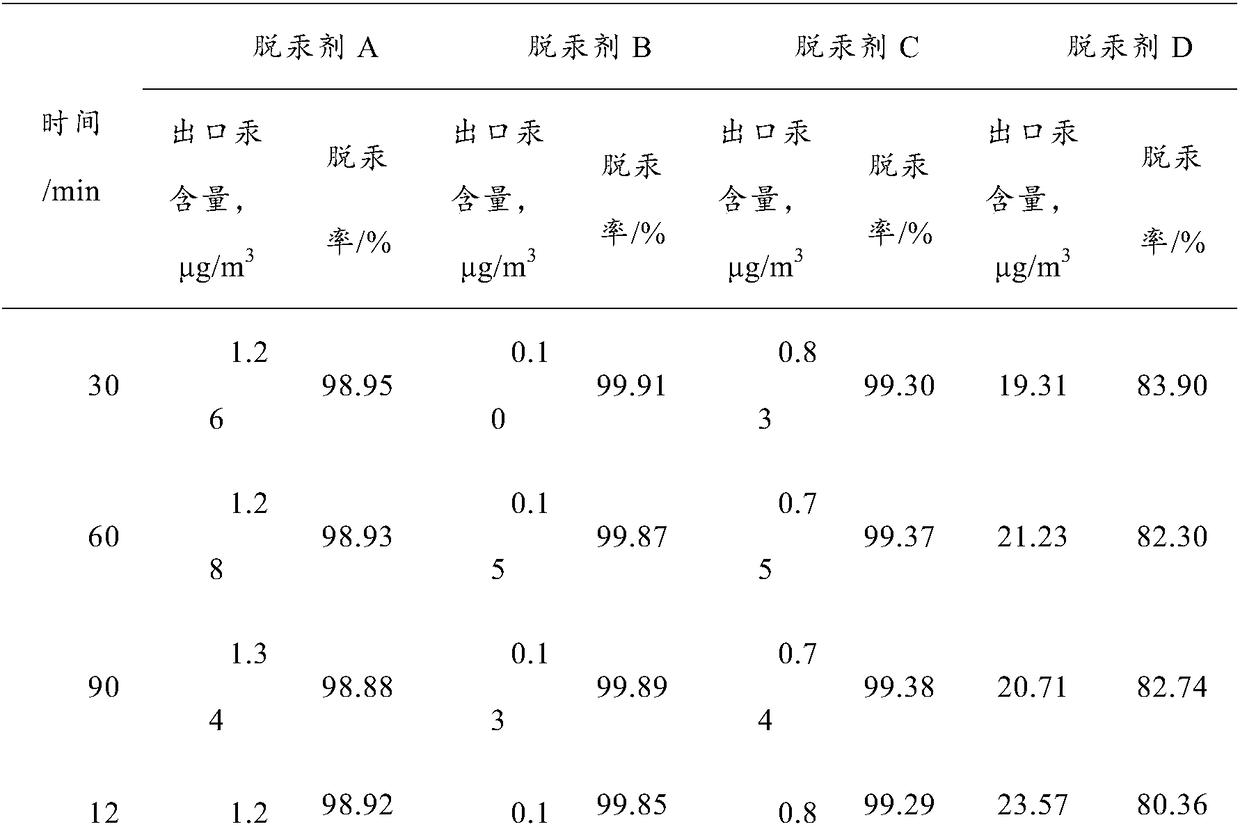

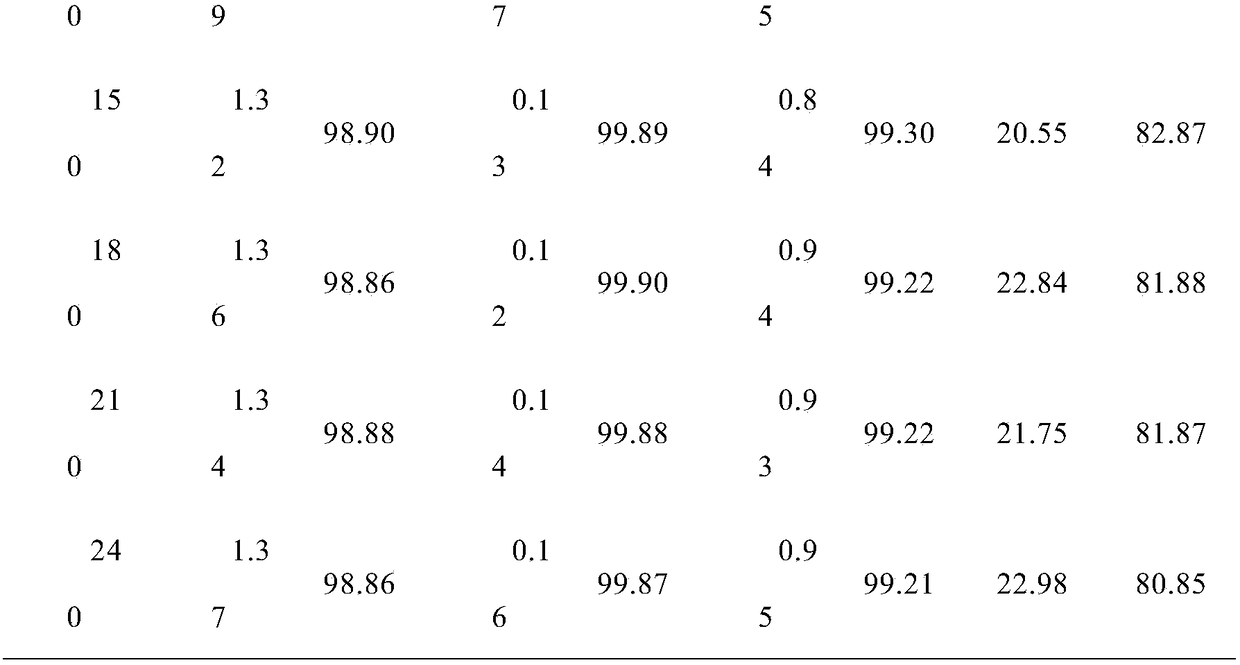

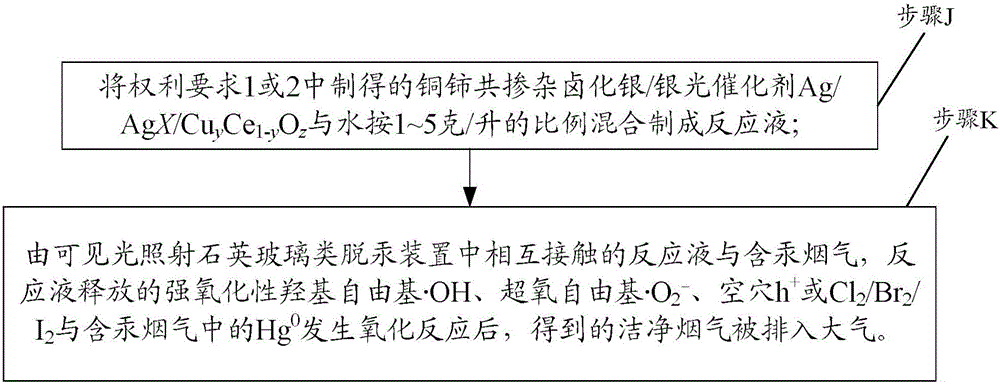

Preparation method of copper and cerium composite silver halide/silver photocatalyst and flue gas demercuration method adopting photocatalyst

ActiveCN105688951AImprove photocatalytic activityLow costPhysical/chemical process catalystsDispersed particle separationPotassiumCerium

The invention provides a preparation method of a copper and cerium composite silver halide / silver photocatalyst. The preparation method of the copper and cerium composite silver halide / silver photocatalyst comprises the following steps of mixing a ready Ce(NO3)3 solution with a Cu(NO3)2 solution, and then adding citric acid into an obtained first mixture, and heating insolating, grinding and sieving an obtained second mixture in sequence to obtain solid powder CuyCe1-yOz; adding the solid powder CuyCe1-yOz into an AgNO3 solution to obtain a solution A, and then adding a Na2CO3 solution into the solution A; afterwards, adding 0.1 mol of potassium chloride (KCl), potassium bromide (KBr) or potassium iodide (KI) into an obtained third mixture to obtain a solution B; culturing the solution B through a heating device, and then adding ethanediol into the cultured solution B to obtain a solution C; washing, drying, grinding and sieving the solution C to obtain the copper and cerium composite silver halide / silver photocatalyst. A flue gas demercuration method adopting the copper and cerium composite silver halide / silver photocatalyst comprises the following steps of making reaction liquid containing a copper and cerium codoped silver halide / silver photocatalyst; irradiating the reaction liquid and a mercury-containing flue gas by visible light to carry out demercuration. The preparation method of the copper and cerium composite silver halide / silver photocatalyst and the flue gas demercuration method adopting the copper and cerium composite silver halide / silver photocatalyst have the characteristics of good demercuration effect, low cost and the like, and can be widely applied to the field of atmospheric controlling.

Owner:HENAN POLYTECHNIC UNIV

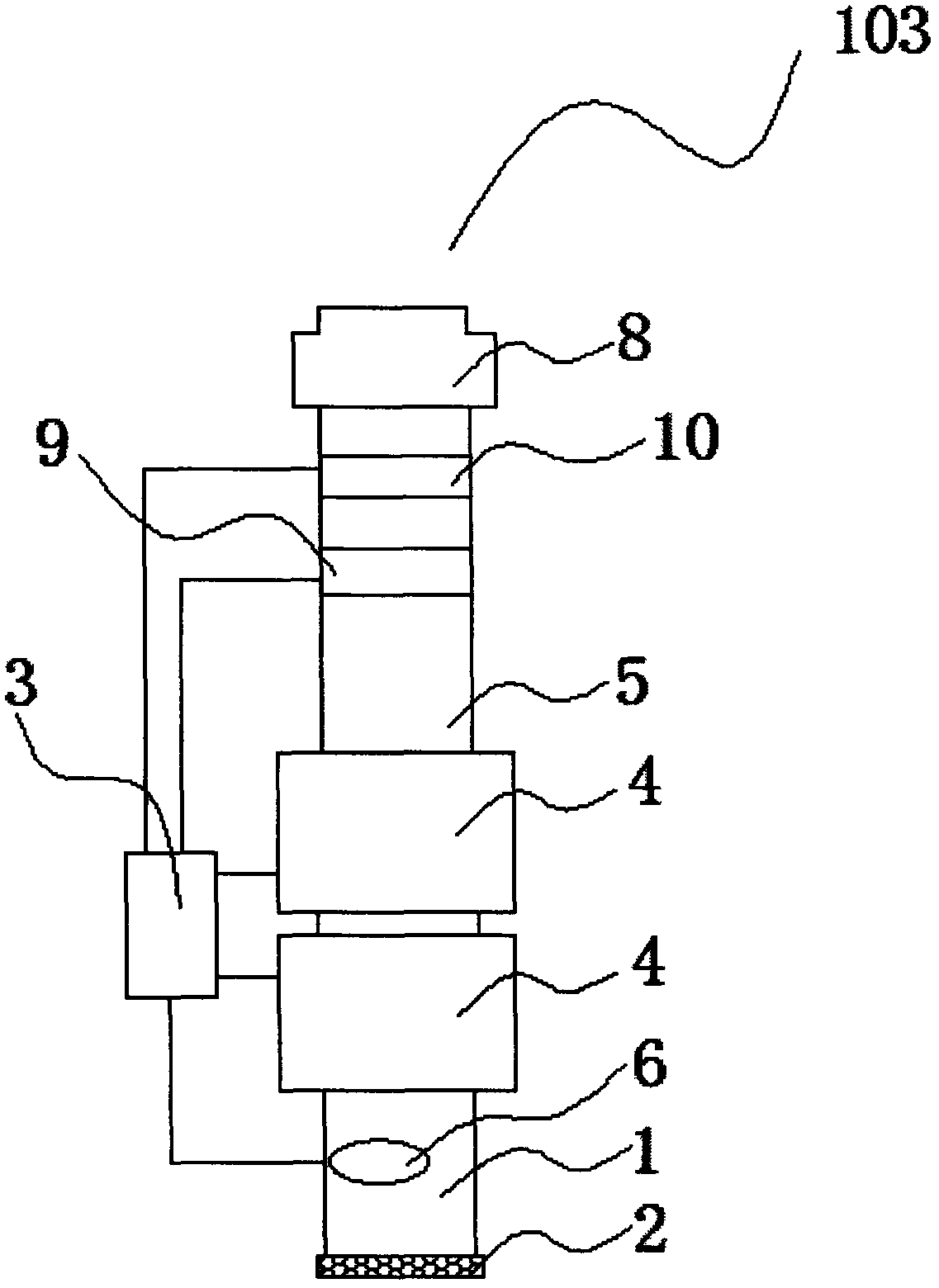

Flue gas dust-removing and mercury-removing system

InactiveCN103657372AEasy loadingTo achieve the purpose of automatic controlCombination devicesAutomatic controlGas phase

The invention relates to a flue gas dust-removing and mercury-removing system. The flue gas dust-removing and mercury-removing system mainly comprises a flue gas temperature control pipe, a flue gas oxidation tower, a flue gas dust-removing device and a mercury-adsorbing chamber which are connected with one another sequentially. According to the flue gas dust-removing and mercury-removing system provided by the invention, coarse-particle and fine-particle dust is separated from high-temperature flue gas by filtering for many times by physical filtration and static adsorption methods and by effectively settling, so that large-particle mercury is initially removed from the flue gas and the system is favorable for the load of the subsequent flue gas mercury-removing equipment; digital detection equipment is also provided, and digital detection signals can be output to a main control device, so that the automatic control purpose can be achieved. During mercury removal, the temperature of the flue gas is controlled to be about 140 DEG C through the temperature control pipe, the flue gas is oxidized by spraying chlorine to generate gas-phase mercury ions, the gas-phase mercury is adsorbed through bromine-carried active carbon, and finally the residual mercury and sulfide are adsorbed completely by spraying ammonia water. The whole flow is simple and short and the mercury-removing effect is good.

Owner:JIANGSU XIONGYUE PETROLEUM MECHANICAL EQUIP MFG

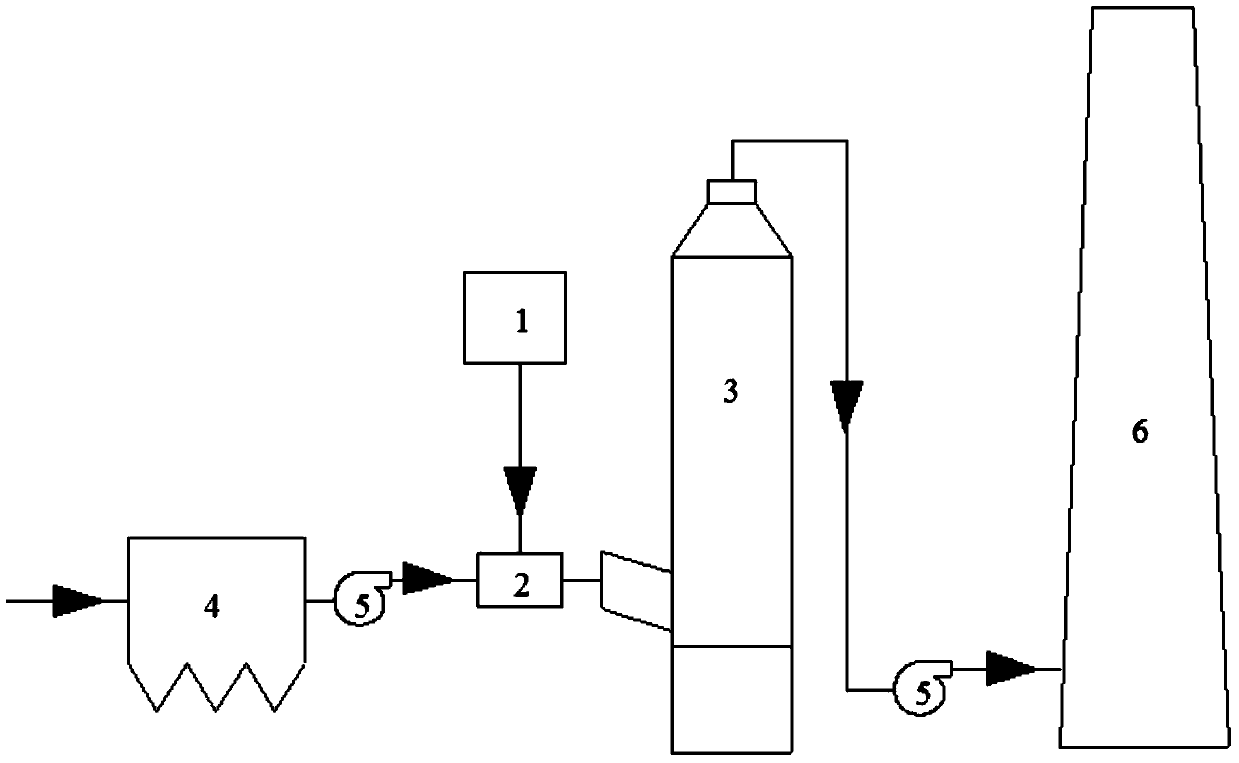

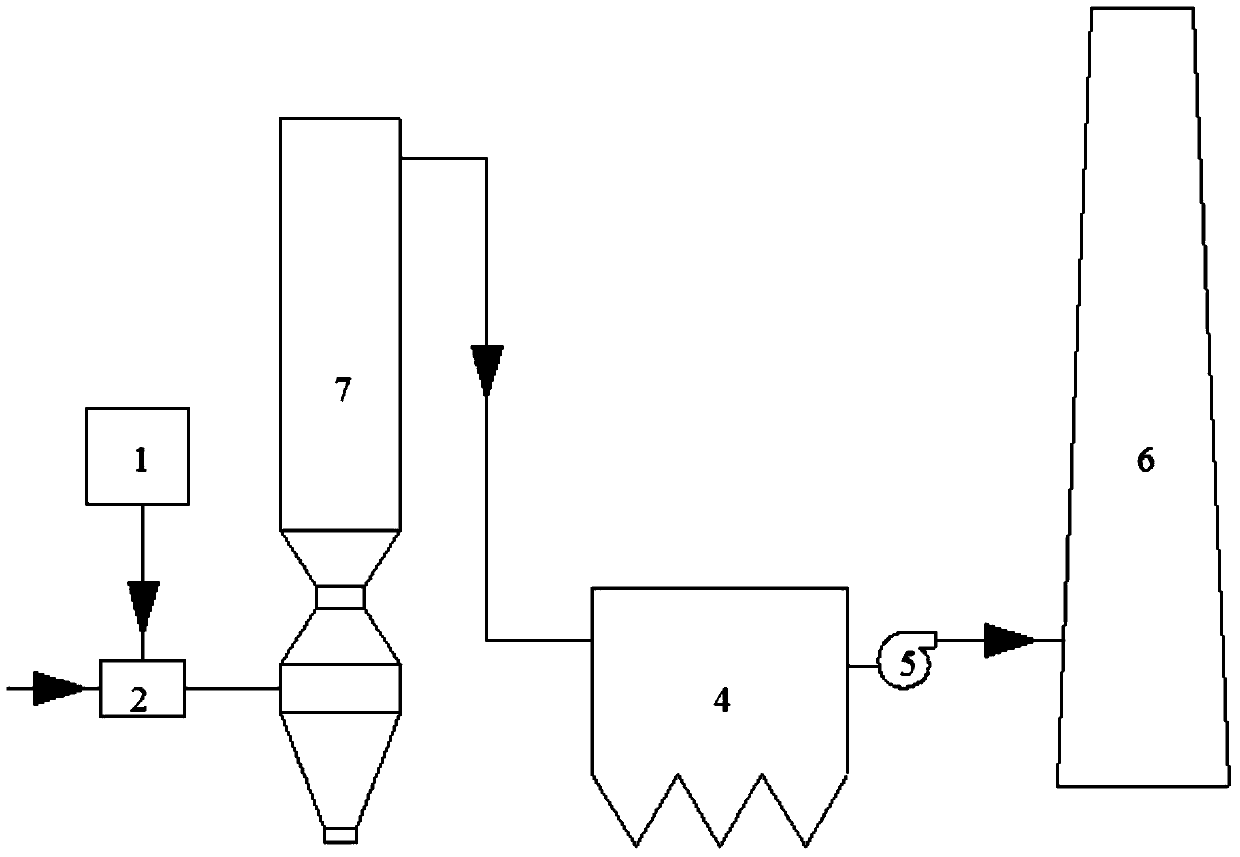

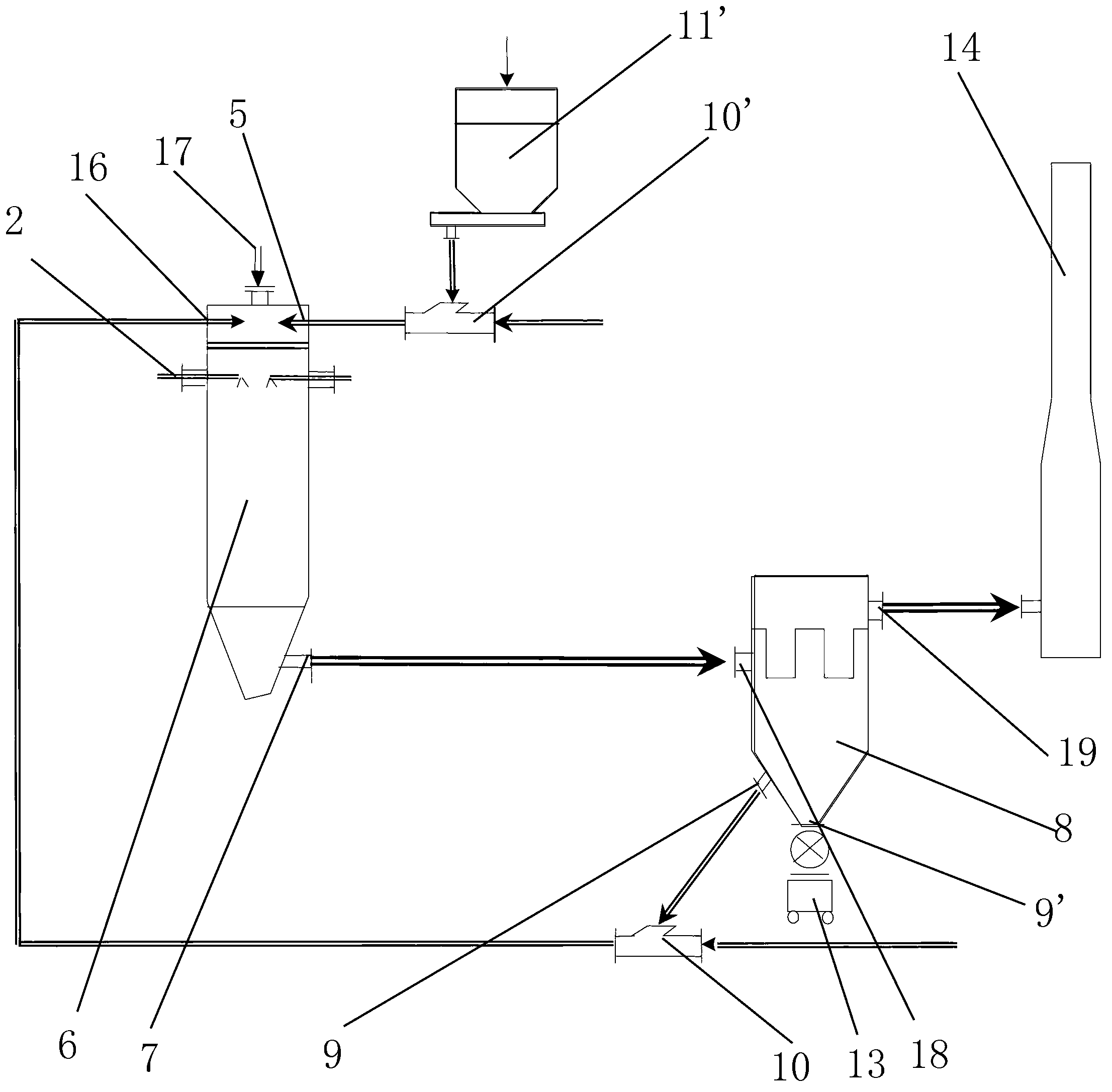

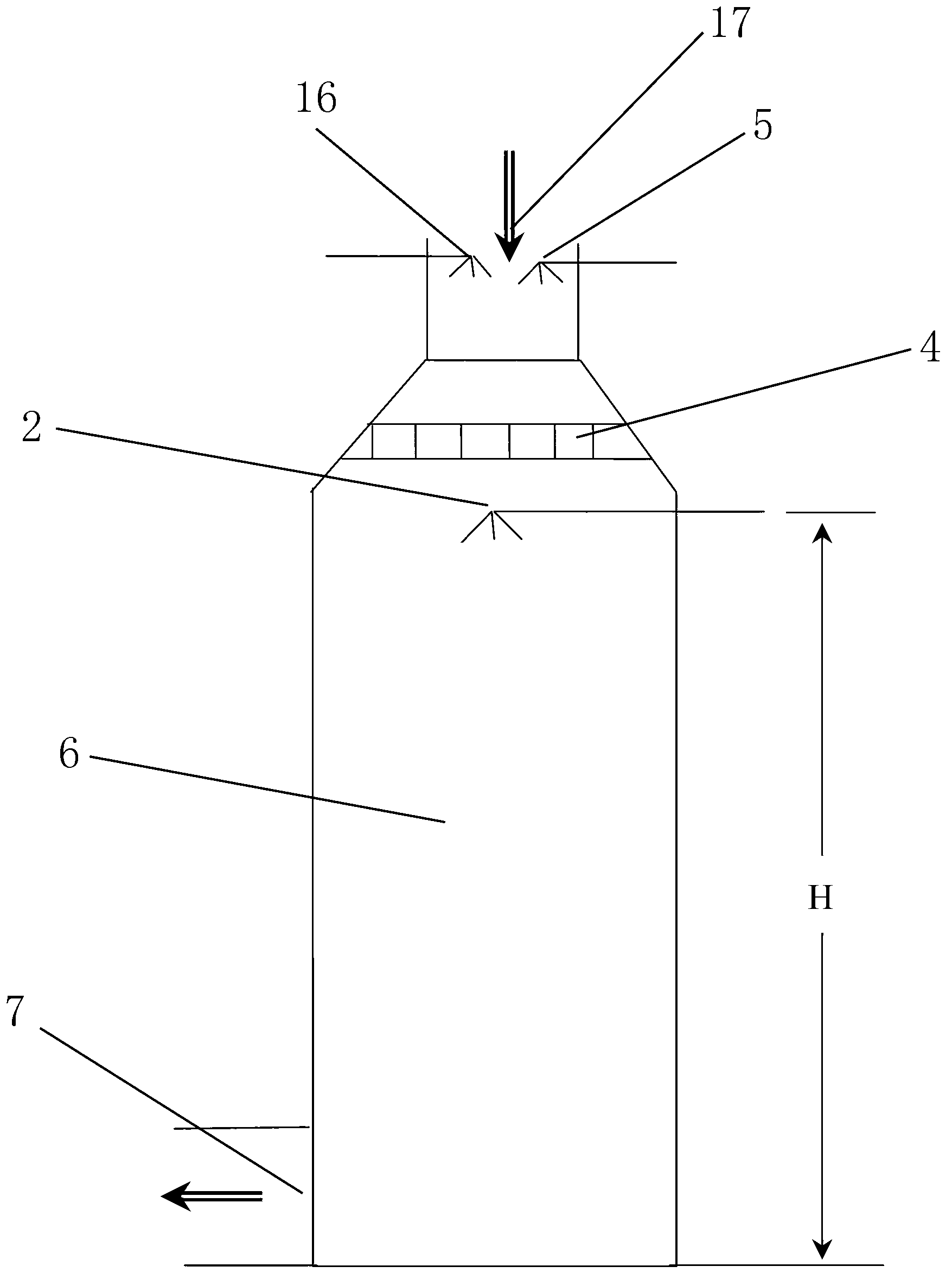

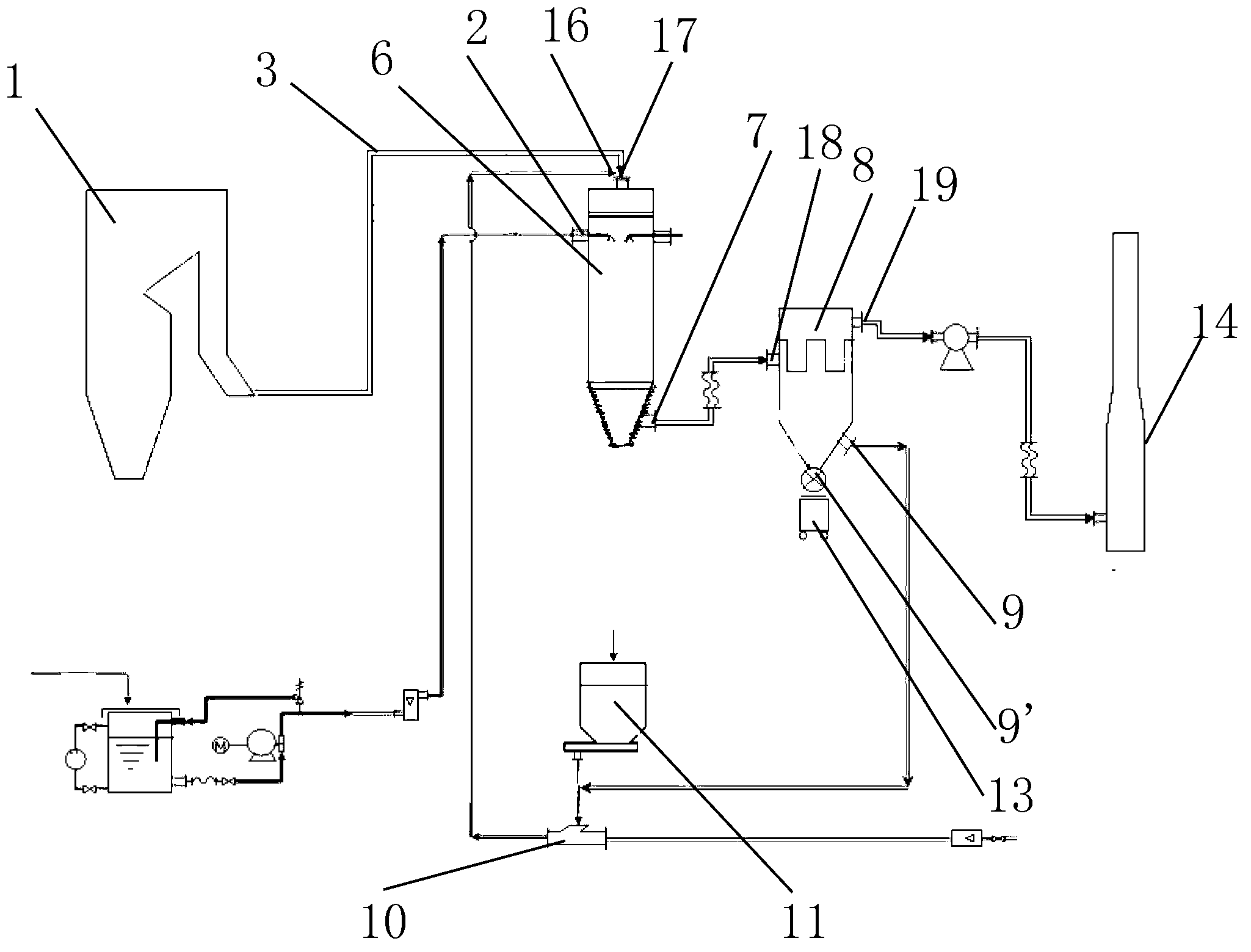

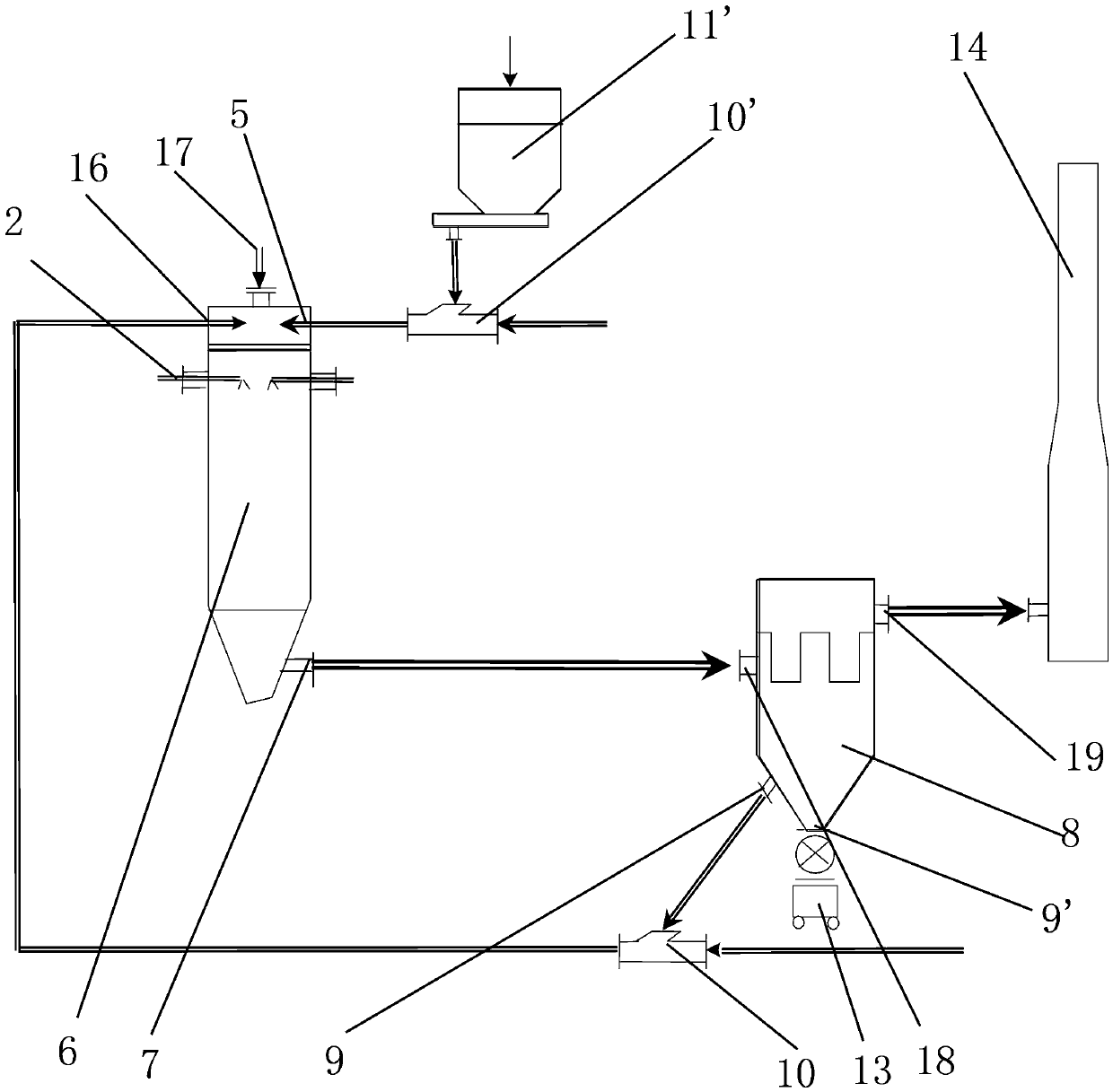

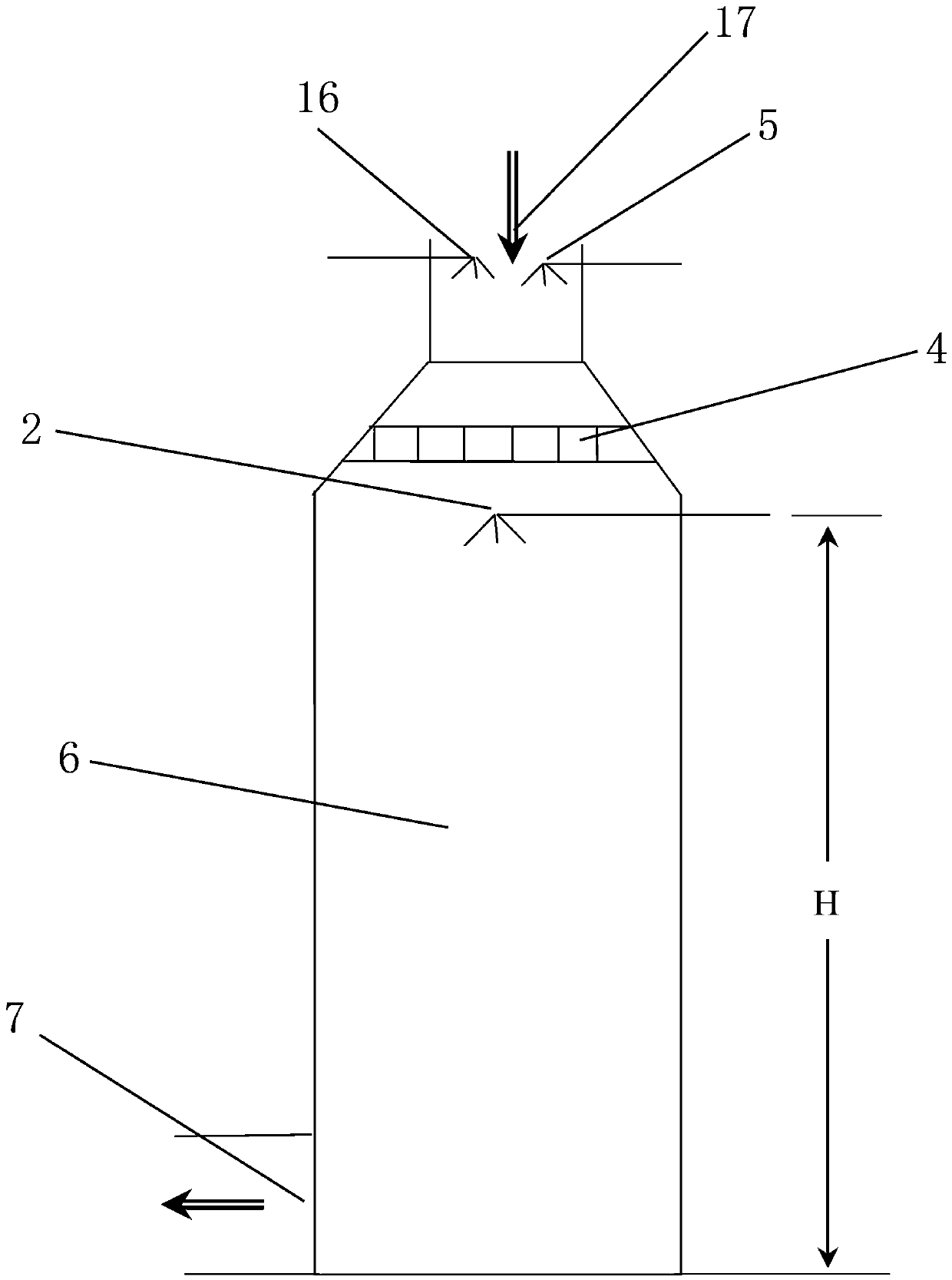

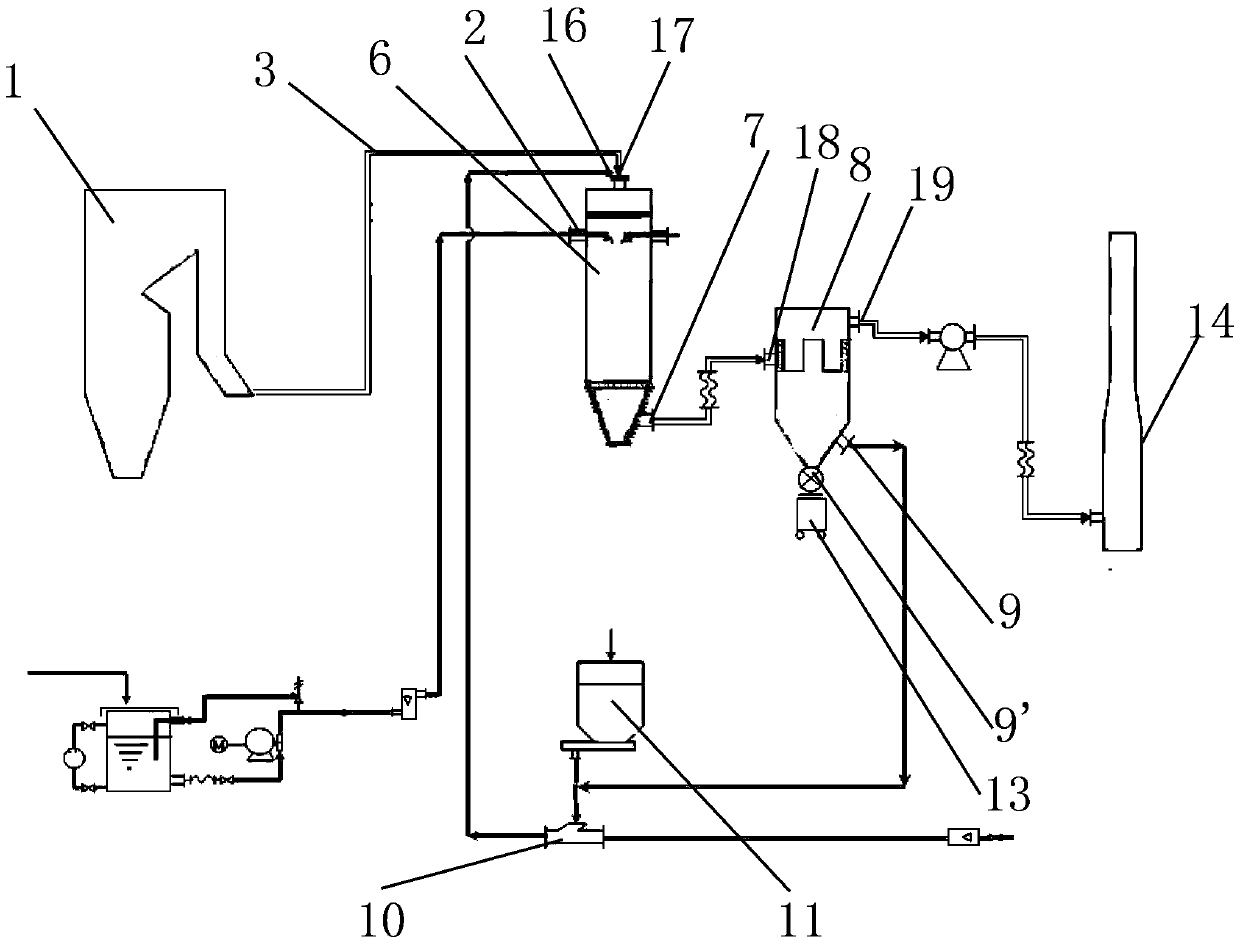

Efficient coal-fired flue gas sulfur removal and mercury removal method and device

InactiveCN103239985APromote absorptionPromote conversionGas treatmentEmission preventionWater vaporDistributor

The invention discloses an efficient coal-fired flue gas sulfur removal and mercury removal method and device, wherein lime and fly ash are activated by low-pressure water vapor in a boiler so as to enhance the sulfur removal and mercury removal effect. The method comprises the following steps of; firstly, activating lime or Ca(OH)2 used as a sulfur removal and mercury removal absorbent by using medium- and low-pressure water vapor, mixing with flue gas, and simultaneously, circularly conveying a part of fly ash to the top of a reaction tower to be mixed with the flue gas by using the medium- and low-pressure water vapor; spraying water mist into the reaction tower at the lower part of a flue gas distributor, wherein reduction of the flue gas temperature facilitates improvement of the reaction activity of SO2 and Ca(OH)2, and the flue gas humidity is beneficial for improving the utilization rate of the absorbent and improving the absorption performance of the sulfur removal and mercury removal agent to the mercury vapor; entering the flue gas to a bag type or electric bag compound dust remover after sulfur removal and mercury removal in the reaction tower, and conveying a part of collected fly ash to the reaction tower for cycle use so as to further improve the utilization rate of the absorbent; and conveying the purified glue gas to a chimney by a draught fan so as to be discharged. The device is lower in operating cost, and can reach higher sulfur removal and mercury removal effect in cooperation with the bag type dust remover or the electric bag compound dust remover.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

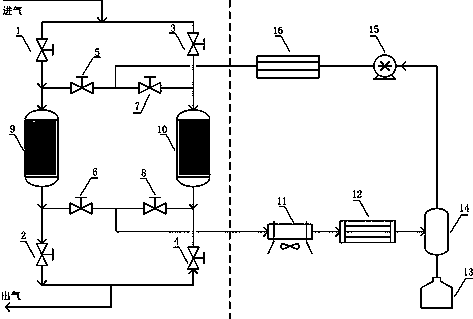

Novel mercury removal method for renewable natural gas

PendingCN110559793AAchieve recyclingGood mercury removal effectGas treatmentGaseous fuelsResource recoveryTower

The invention discloses a novel mercury removal method for renewable natural gas, belonging to the field of natural gas purification. According to the invention, a renewable mercury removal agent is adopted and loaded into a mercury removal tower, and then natural gas is introduced into the mercury removal tower so as to realize mercury removal of the natural gas; when the mercury content of the natural gas at the outlet of the mercury removal tower is close to a control standard, the mercury removal agent is heated and regenerated; mercury vapor generated during regeneration is cooled so as to realize the recovery of liquid mercury; and the regenerated mercury removal agent can be subjected to mercury removal treatment of natural gas again after cooling. The method not only can effectively reduce the mercury removal cost of the natural gas, but also can realize recovery and utilization of mercury resources.

Owner:河北石兴科技有限公司

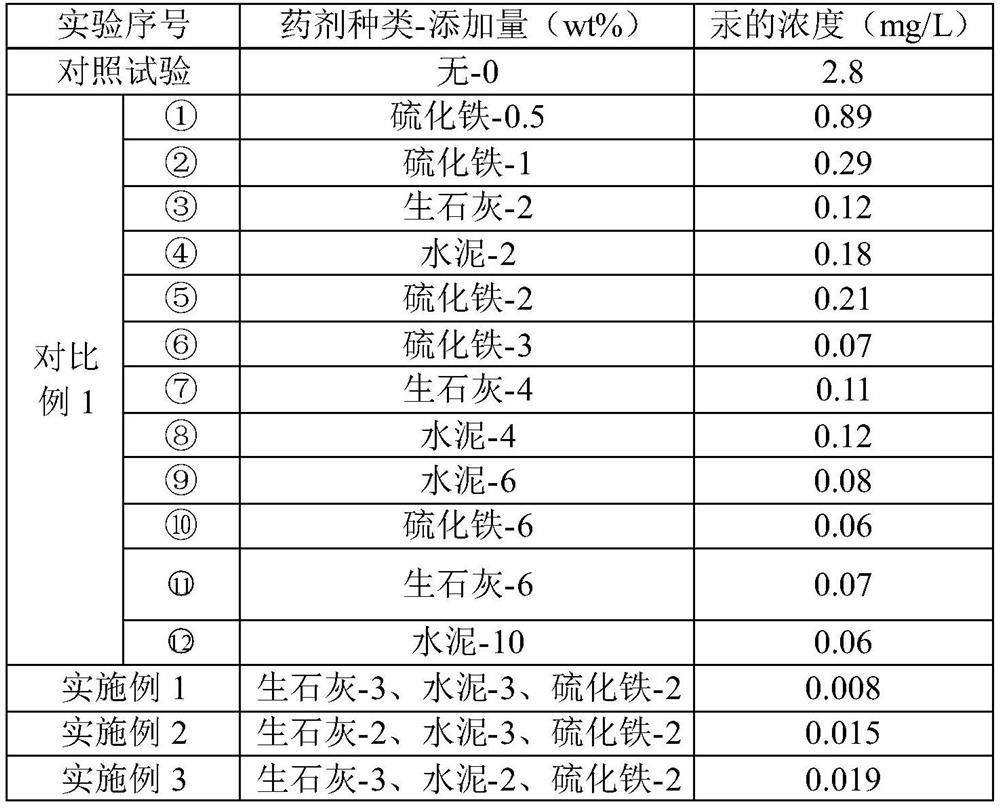

Remediation method for mercury-contaminated acid soil of mine

InactiveCN113000574AImprove the fixed effectImprove soil alkalinityContaminated soil reclamationContaminated soilsWater pollution

The invention relates to a restoration method for mercury-contaminated acid soil of a mine. The restoration method comprises the steps of pretreatment of a to-be-restored area of the contaminated soil, in-situ solidification / stabilization restoration, blocking and seepage prevention, building of a retaining wall, covering of foreign soil, building of a drainage ditch and restoration of vegetation. In allusion to mine acid mercury-contaminated soil, especially farmland remediation in a mine area, the compound mercury contamination treatment agent is adopted, a mixture of iron sulfide, cement and quick lime is added, the addition amounts of the quick lime and the cement are respectively 2-3% of the mass of the soil, and the addition amount of the iron sulfide is 2% of the mass of the soil. The mercury content in the contaminated soil containing water can be reduced to an extremely small amount, the fixing effect on mercury pollutants is enhanced, the mercury pollutants are prevented from being leached into surrounding water, the property of acid soil is improved, plant growth is facilitated, and the aim of ecological remediation is achieved. The method is low in cost, high in compressive strength and obvious in economic benefit.

Owner:江苏和而同环境建设有限公司

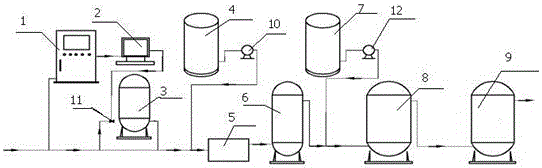

Device for treating industrial mercury-containing wastewater containing high-concentration chlorides and control method

ActiveCN105906094ARealize intelligenceImprove effluent qualityWater treatment parameter controlWater contaminantsHigh concentrationWater discharge

The invention discloses a device for treating industrial mercury-containing wastewater containing high-concentration chlorides and a control method. The device comprises a heavy metal online automatic analyzer, a PLC (Programmable Logic Controller) process intelligent feedback control system, a mercaptan composite inorganic ceramic filtering tower, a medicine storage pot, a buffer pool, a filter, a pH automatic modulation control system, an adsorption tower and an ion exchange tower; the heavy metal online automatic analyzer is arranged at an end opening of a water inlet pipe; one end of the heavy metal online automatic analyzer is connected with the mercaptan composite inorganic ceramic filtering tower through a pipeline; the mercaptan composite inorganic ceramic filtering tower is connected with the buffer pool through a pipeline; the medicine storage pot is arranged between the mercaptan composite inorganic ceramic filtering tower and the buffer pool; the buffer pool is connected with the filter through a pipeline; the filter is connected with the adsorption tower a the pipeline; the adsorption tower is connected with the ion exchange tower through a pipeline. According to the device and the control method disclosed by the invention, the intelligentization of the system is realized; meanwhile, the quality of water discharged from the system is improved, the treatment cost is reduced, a good mercury removing effect is realized, and no secondary pollution is caused.

Owner:芜湖市科邦新能源科技有限公司

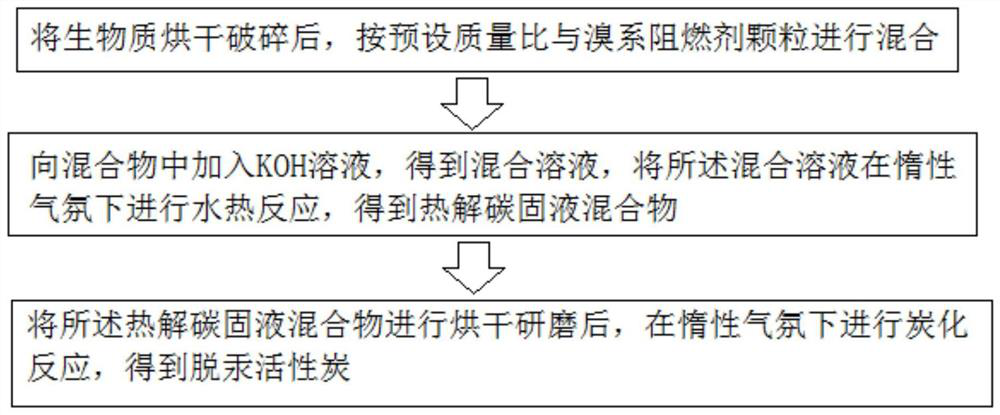

Method, product and application of brominated flame retardant and biomass to prepare mercury-removing activated carbon

ActiveCN110327880BWide variety of sourcesEnhanced chemical adsorption capacityGas treatmentOther chemical processesSorbentCarbonization

The invention belongs to the field of active carbon preparation, and discloses a method, a product and an application for preparing mercury removal active carbon by a bromine flame retardant and biomass. The method comprises the following steps: S1, drying and crushing the biomass, and mixing with bromine flame retardant particles according to a preset mass ratio; S2, adding a KOH solution into the mixture and carrying out hydrothermal reaction under an inert atmosphere to obtain a pyrolyzed carbon solid-liquid mixture; S3, drying and grinding the pyrolytic carbon solid-liquid mixture, and performing carbonization reaction under an inert atmosphere to obtain mercury removal activated carbon. The product is prepared by the method. According to the invention, brominated flame-retardant wasteplastics, biomass and KOH are pyrolyzed under the condition of full mixing, so that a a mercury removal adsorbent with higher mercury removal efficiency can be correspondingly obtained, the chemicaladsorption capability of the activated carbon on elemental mercury Hg0 is greatly improved, the mercury removal efficiency is improved, and therefore, the mercury removal active carbon is particularlysuitable for application occasions such as mercury removal of flue gas in power plants.

Owner:HUAZHONG UNIV OF SCI & TECH

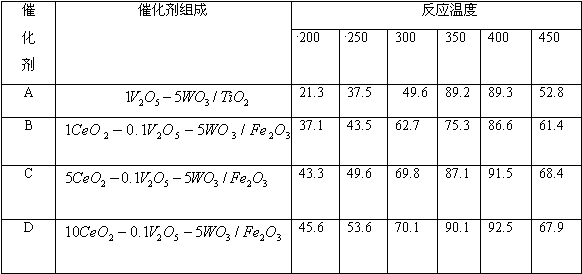

Ultra-low V mercury-removing catalyst containing Ce and preparation method thereof

ActiveCN103706371AEmission reductionHarm reductionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention provides an environment-friendly ultra-low V mercury-removing catalyst containing Ce and a preparation method thereof. According to the catalyst, Fe2O3 is taken as a carrier; an active substance is loaded on the carrier; WO3 is taken as a cocatalyst; the characteristic expression formula is CeO2-V2O5-WO3 / Fe2O3. The catalyst comprises the following components by percentage: 1-10% of CeO2, 0-0.1% of V2O5, 84-95% of Fe2O3 and 5% of WO3. The catalyst has an excellent oxidation effect of mercury, the discharge of Hg is obviously reduced, and the damage to the environment caused by the inactivated catalyst is reduced. The preparation method has the characteristics of simple technology, low cost and small damage to the environment, the requirements of flue gas denitration can be met, promotion of industrialization process of a denitration catalyst in China is facilitated, and the catalyst has a good application prospect.

Owner:CHONGQING UNIV +1

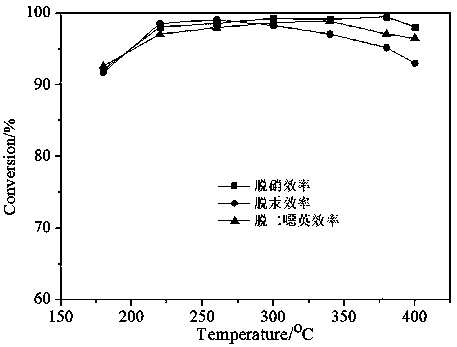

Denitration, demercuration and dioxin removal catalyst and preparation method thereof

ActiveCN111330636AWide active temperature windowGood hydrothermal stabilityMolecular sieve catalystsDispersed particle separationPtru catalystMeth-

The invention discloses a denitration, demercuration and dioxin removal catalyst and a preparation method thereof. According to the catalyst, a molecular sieve is adopted as a first carrier; titaniumdioxide is adopted as second carrier; cerium, tin and palladium are used as a first active component; vanadium, zirconium, neodymium and cobalt are used as second active components; two or more of molybdenum, yttrium, silver, lanthanum and nickel are used as cocatalysts; one or more of polyvinyl alcohol, carboxymethyl cellulose, liquid paraffin, ammonium polyacrylate, hydroxypropyl methyl cellulose or amino cellulose are used as forming auxiliaries; catalyst paste is prepared, and the flat plate type denitration catalyst is prepared through aging, coating, drying, shearing and calcining. The prepared catalyst has excellent denitration performance, mercury oxidation performance and dioxin removal performance at 180-400 DEG C, has good sulfur resistance and water resistance, and is suitablefor synergistic removal of coal-fired power plants, waste incineration power plants, steel sintering machines, glass kilns and the like.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

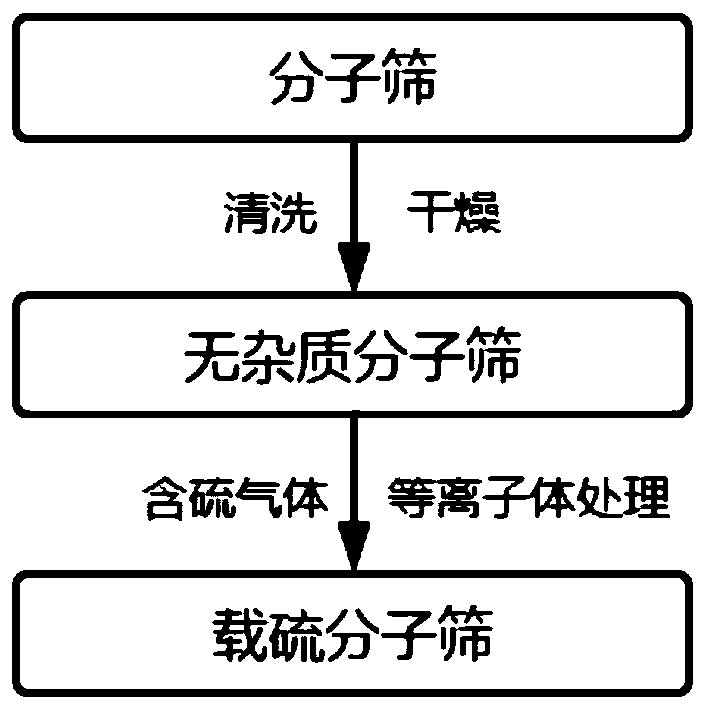

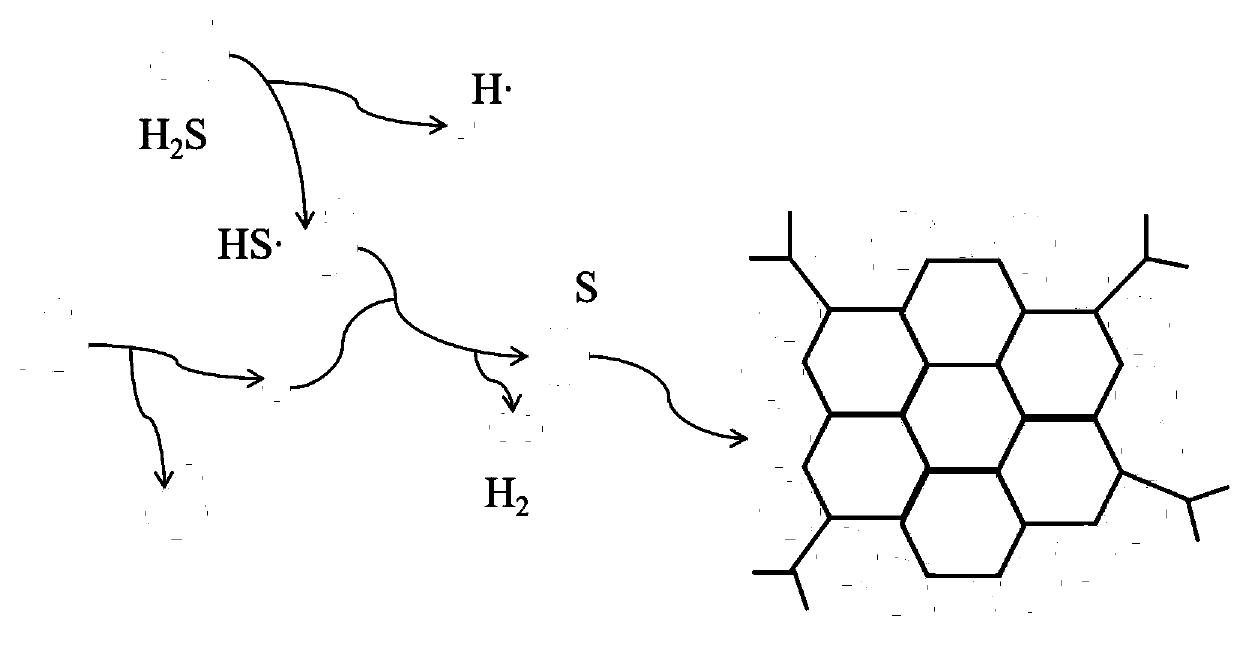

Sulfur-loaded molecular sieve for mercury removal and preparation method thereof

ActiveCN110292908AGood mercury removal effectSolve complex operationsGas treatmentOther chemical processesMolecular sieveFlue gas

The invention belongs to the field of mercury removal of coal-fired flue gas, and specifically discloses a sulfur-loaded molecular sieve for mercury removal and a preparation method thereof. Accordingto the preparation method, a molecular sieve placed in a sulfur-containing gas is subjected to plasma treatment, the sulfur-containing gas is converted into highly-active sulfur atoms or free radicals under the function of plasma and loaded on the molecular sieve to form sulfur active sites on the surface of the molecular sieve, and therefore the preparation of the sulfur-loaded molecular sieve is completed. Thus, the number of the sulfur active sites on the surface of the molecular sieve is increased, the mercury removal performance of the molecular sieve is improved, the preparation processis simple, the consumed time is short, the cost is low, the problem of complicated operation in the high-temperature activation and immersion modification methods is solved, products generated afterthe mercury removal of the sulfur-loaded molecular sieve are relatively stable, and the secondary release of mercury is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

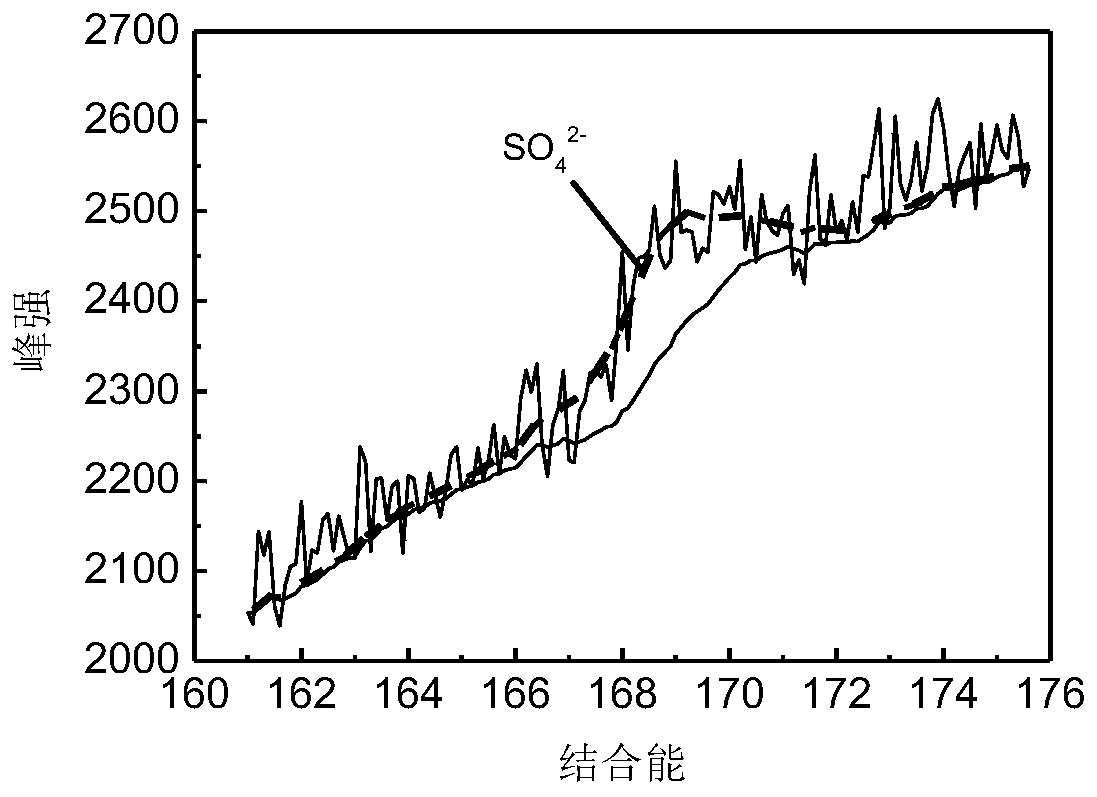

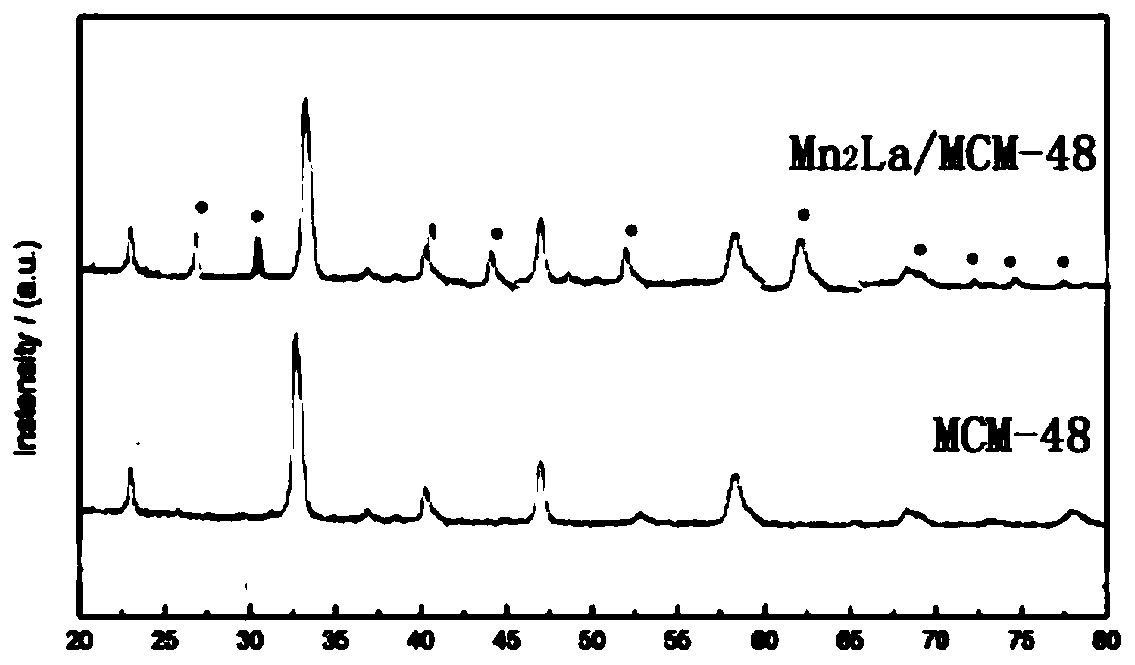

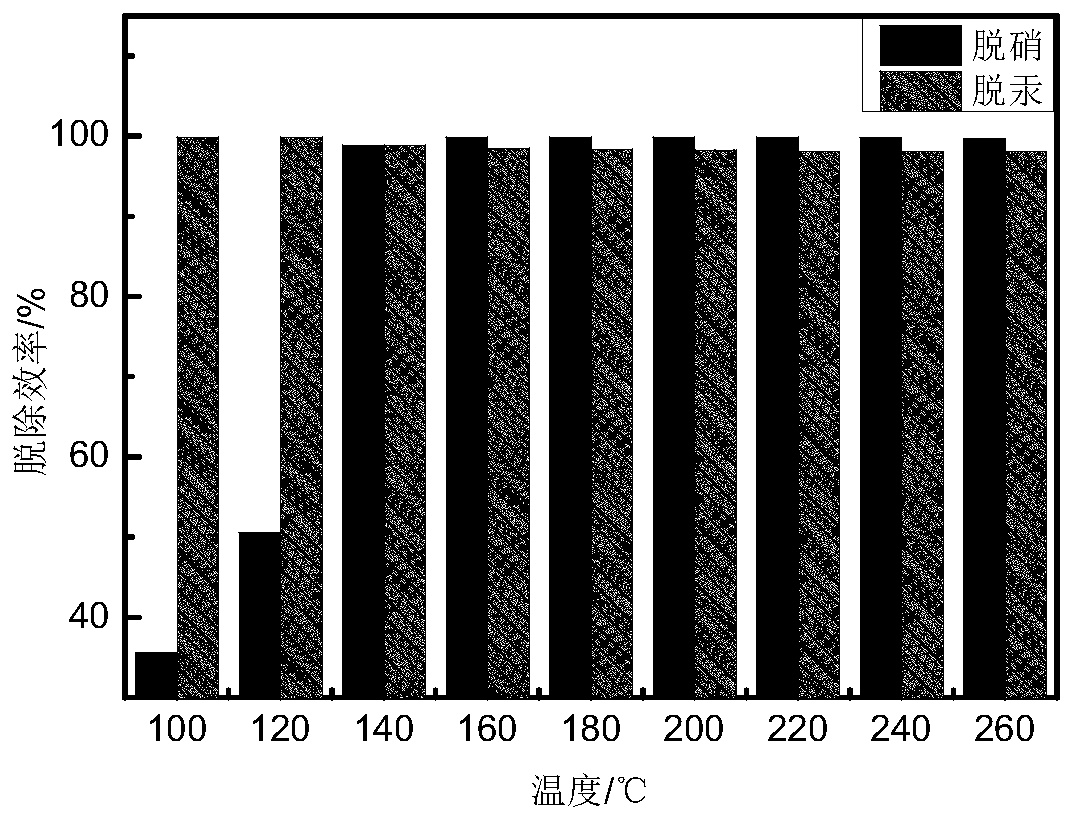

Preparation method of oxide modified MCM-48 molecular sieve, and applications of oxide modified MCM-48 molecular sieve in denitration synergistic mercury removal

ActiveCN110354892AUnique featuresGood mercury removal effectMolecular sieve catalystsDispersed particle separationMolecular sieveManganese

The invention discloses a preparation method of an oxide modified MCM-48 molecular sieve, and applications of the oxide modified MCM-48 molecular sieve in denitration synergistic mercury removal, andrelates to the technical field of molecular sieves. The method comprises: pre-treating a MCM-48 molecular sieve with no templating agent removal; synthesizing a MnN mixed solution by using a manganeseoxide as an active material and using a N oxide as an auxiliary agent; adding the MnN mixed solution to the molecular sieve, carrying out impregnation treatment, and drying; calcining the dried molecular sieve in air; and finally obtaining the oxide modified MCM-48 molecular sieve. According to the present invention, NOx and Hg0 removal experiments are performed on the prepared oxide modified MCM-48 molecular sieve, and denitration and mercury removal efficiency experiments are performed on the prepared oxide modified MCM-48 molecular sieve having different manganese-to-lanthanum molar ratiosby using different molar ratios, wherein the experiment results prove that the oxide modified MCM-48 molecular sieve has good mercury removal performance while can efficiently remove NOx at a low temperature.

Owner:SHANDONG UNIV OF SCI & TECH

Mesoporous carbon carrier and preparation method thereof

ActiveCN111135849AImprove surface reactivityLow surface reactivityCatalyst carriersCarbon compoundsSurface reactionPtru catalyst

The invention belongs to the technical field of petrochemical engineering, and particularly relates to a mesoporous carbon carrier and a preparation method thereof. The method comprises the followingsteps: adding a carbon source into a saturated solution of a nitrogen source, and uniformly mixing to obtain a first mixed solution; dipping a template into the first mixed solution to obtain a secondmixed solution; adding an activating agent into the second mixed solution for activation to obtain a first activated intermediate, and then dipping the first activated intermediate into the first mixed solution again for mixing to obtain a third mixed solution; and sequentially crystallizing, filtering, drying and thermally treating the third mixed solution to obtain the mesoporous carbon carrier. According to the method, the mesoporous carbon carrier with good chemical stability and low surface reaction activity can be prepared without adding strong oxidizing acid in the preparation process,the mesoporous carbon carrier has good acid and alkali resistance and high temperature resistance, and the mercury removal catalyst prepared from the mesoporous carbon carrier has a good mercury removal effect.

Owner:SHENYANG SANJUKAITE CATALYST

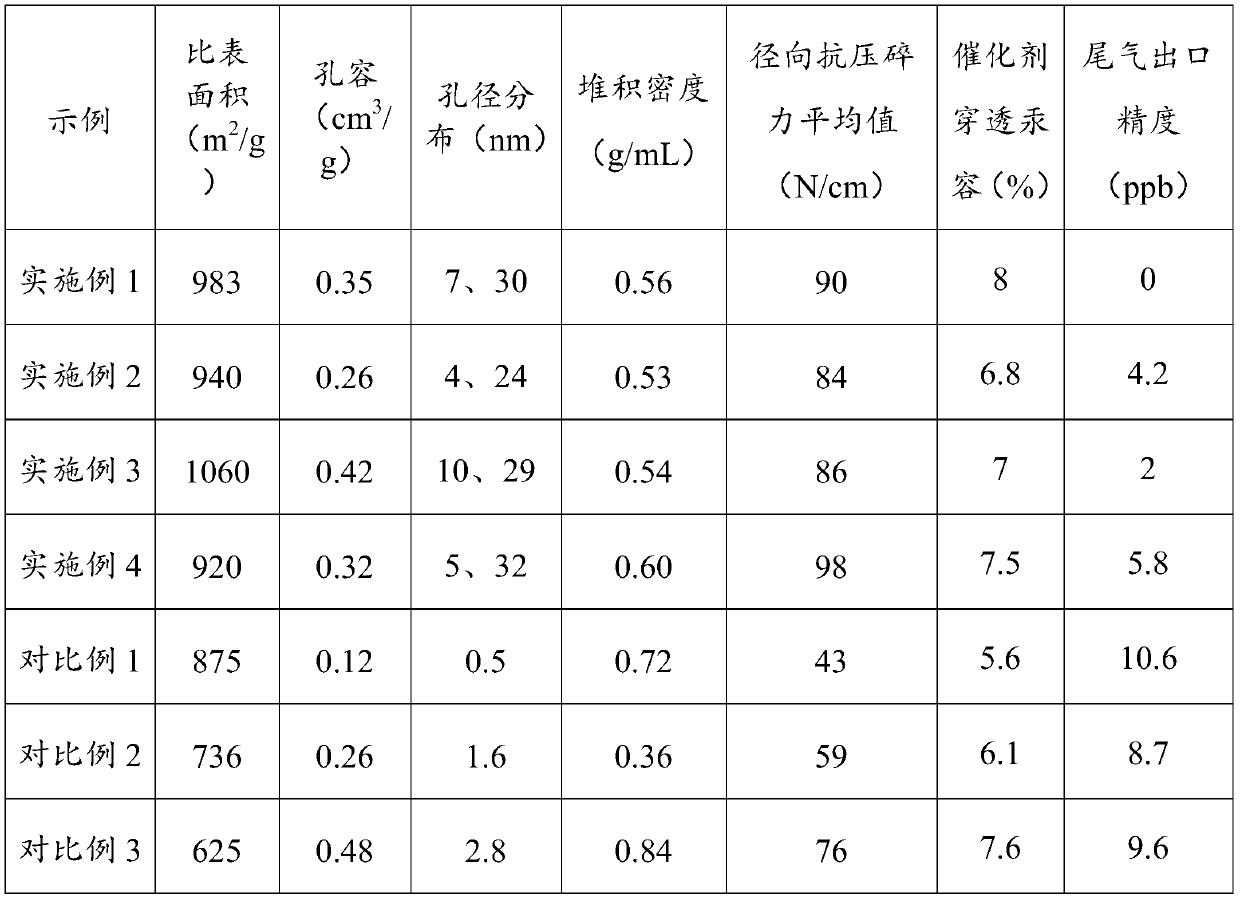

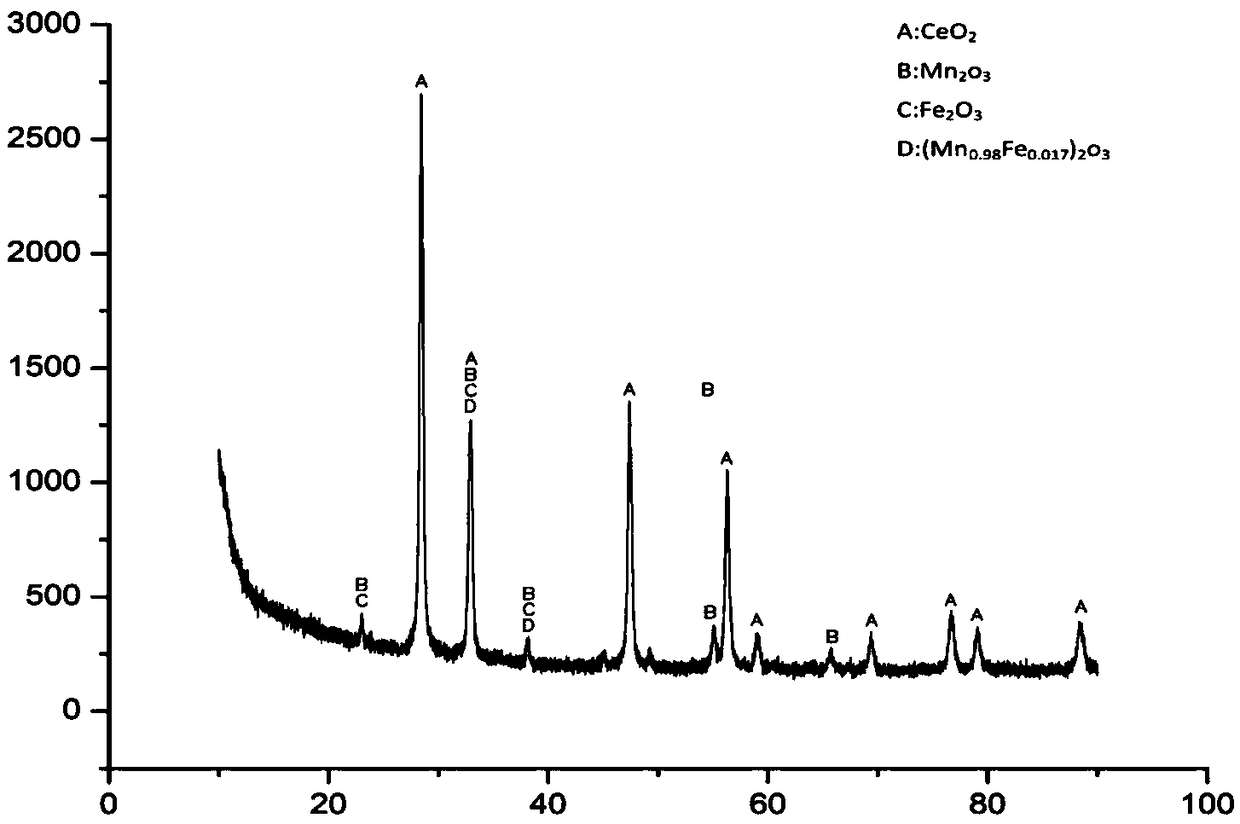

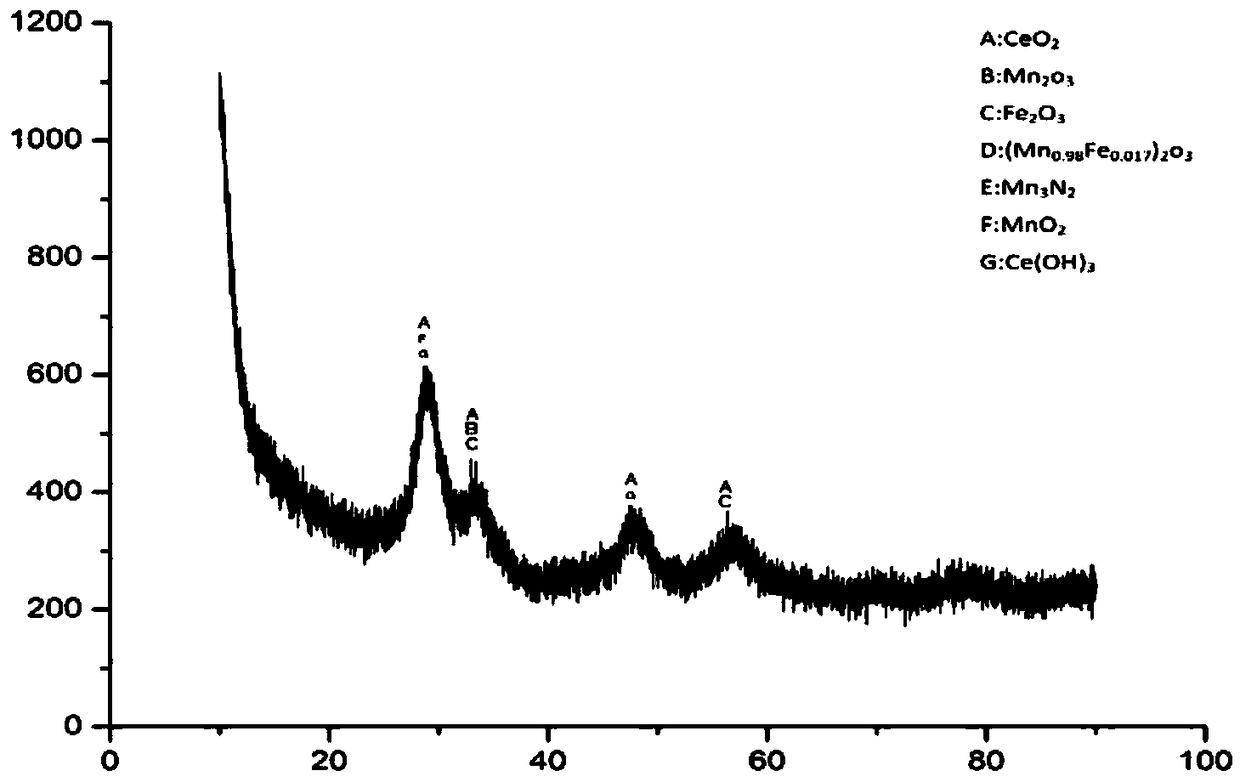

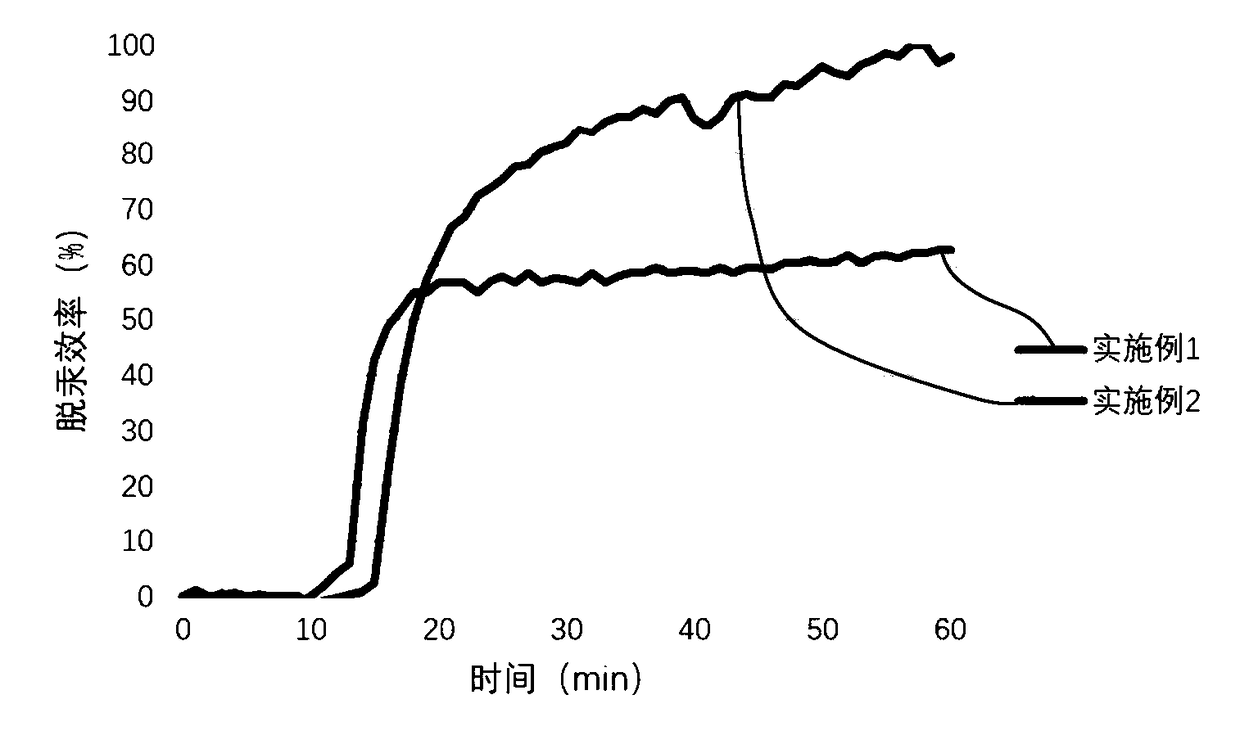

Ferromanganese cerium adsorbent for mercury removal and preparation method of ferromanganese cerium adsorbent

InactiveCN108993375ASignificant technological progressEfficient processOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsAcetic acidCerium nitrate

The invention provides a ferromanganese cerium adsorption material for mercury removal. The ferromanganese cerium adsorption material is prepared from the following raw materials in parts by weight: 1to 6 parts of manganese acetate, 2 to 12 parts of cerous nitrate, 1 to 6 parts of ferric nitrate and 50 to 70 parts of deionized water. The invention also provides a preparation method of the ferromanganese cerium adsorption material for the mercury removal. The preparation method comprises the following steps: fully stirring and dissolving manganese acetate, cerium nitrate, ferric nitrate and deionized water, carrying out drying treatment, calcining, cooling and then taking out for rolling and sifting out to form the ferromanganese cerium mercury-removal adsorption material. The preparationmethod disclosed by the invention has the advantages of wide source of raw materials, simple and controllable process and mild operation conditions; the obtained ferromanganese cerium mercury-removaladsorption material has the advantages that the mercury removal rate can reach 90 percent or above under certain atmospheric conditions; in addition, certain high activity in a relatively long periodof time can be maintained, so that the ferromanganese cerium adsorption material for the mercury removal has a broad application prospect in the field of mercury pollution control.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

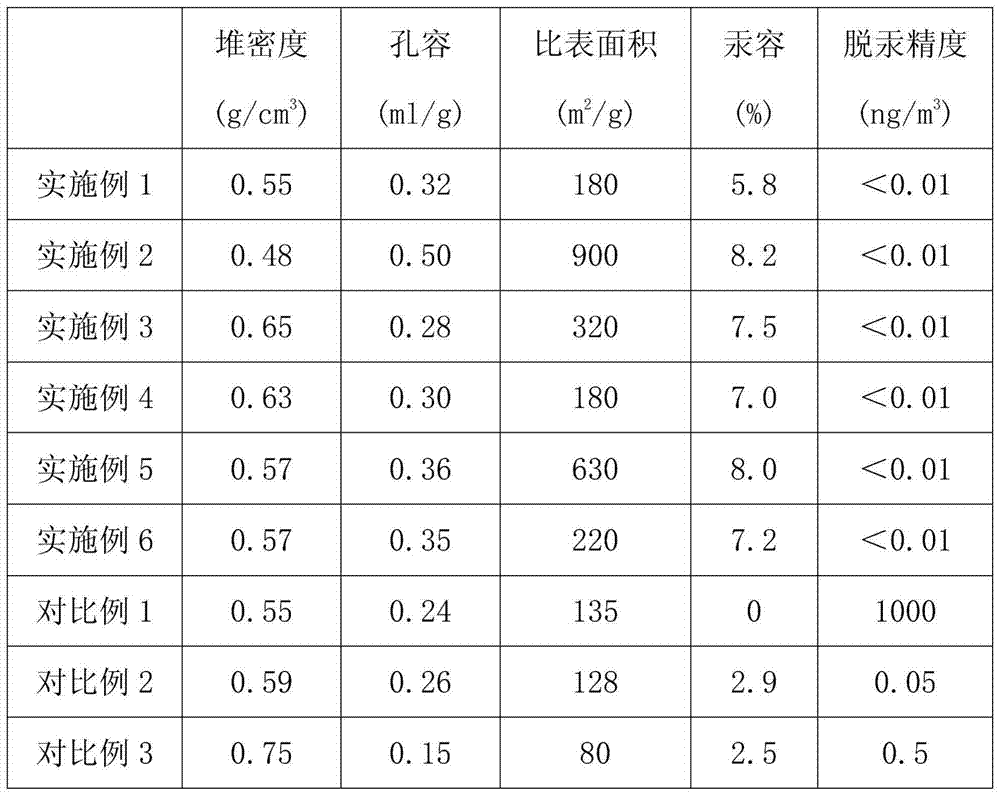

A kind of preparation method of copper sulfide mercury removal agent

ActiveCN105498469BReduce usageGood mercury removal effectGas treatmentDispersed particle separationActive componentGranularity

The invention provides a preparation method of a copper sulphide mercury removal agent. the preparation method comprises the following steps: mixing copper sulphide powder, a powdery carrier and an inorganic binder to form a mixture; spraying an organic binder aqueous solution into the mixture and rolling to form a ball; and drying the ball. By using copper sulphide with specific grain size and granularity as a raw material, on one hand, use of a vulcanizing agent is avoided so as to thoroughly solve problems of high toxicity, unbearable smell and residual vulcanizing agent existing in the preparation process of the copper sulphide mercury removal agent; and on the other hand, it is beneficial to increase active sites so as to make the mercury removal agent show excellent mercury removal activity. By the rolling mode, the active component is uniformly dispersed onto the surface of the carrier, and it is ensured that the mercury removal agent has a proper porous structure and as large specific surface area as possible. Thus, it helps raise mercury removal precision and mercury volume of the mercury removal agent and reduce bulk density of the mercury removal agent, and service life of the mercury removal agent is prolonged. Mercury removal cost is then reduced greatly.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of method that utilizes waste methanol catalyst to prepare mercury removing agent

ActiveCN104475009BGood three-dimensional structureHigh pore volumeGas treatmentOther chemical processesActive componentSulfur containing

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Mercury removal method and device for ammonia desulfurization slurry

ActiveCN106621778AThe method of mercury removal is simple and easyInhibition releaseGas treatmentDispersed particle separationSlurryNH3 compound

The present invention discloses a mercury removal method and a mercury removal device for ammonia desulfurization slurry. The method includes the following steps: (1) mixing the ammonia desulfurization slurry with a mercury removal agent, carrying out a reaction, and performing first solid-liquid separation to obtain a first supernatant and a solid precipitate; and (2) mixing the obtained first supernatant in the step (1) with ammonium sulfite, carrying out a reaction, and performing second solid-liquid separation to obtain a second supernatant and a precipitate. The invention provides a device which includes a mercury removal reaction tank, a mercury removal agent removal tank, a return pump, an ash removing device, a first discharge pump and a second discharge pump. The method provided by the invention achieves good mercury removal effects, and yields products with high quality. Equipment is simple, and the method is suitable for industrial promotion.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

High-efficiency coal-fired flue gas desulfurization and mercury removal method and device

InactiveCN103239985BPromote absorptionPromote conversionGas treatmentEmission preventionBaghouseDust control

A new method and device for flue gas desulfurization and mercury removal, in which lime and fly ash are activated by low-pressure steam in a boiler to enhance the effect of desulfurization and mercury removal. Firstly, the lime or Ca(OH)2 used as the desulfurization and mercury removal absorbent is activated and mixed with the flue gas by medium and low pressure water vapor, and at the same time, part of the fly ash is circulated to the top of the reaction tower to be mixed with the flue gas by medium and low pressure water vapor; Spray water mist into the reaction tower at the lower part of the flue gas distributor, the lower flue gas temperature is conducive to improving the reactivity of SO2 and Ca(OH)2, the humidity of the flue gas is conducive to improving the utilization rate of the absorbent, and improving the desulfurization and demercuration agent. Absorption properties of mercury vapor. The flue gas enters the bag type or electric bag composite dust collector after desulfurization and mercury removal in the reaction tower, and part of the collected fly ash is transported to the reaction tower for recycling to further improve the utilization rate of the absorbent; the purified flue gas is sent into the dust collector through the induced draft fan Chimney exhaust. The operating cost of the device is low, and it can achieve high desulfurization and mercury removal effects when used in conjunction with bag filter or electric bag composite dust removal equipment.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

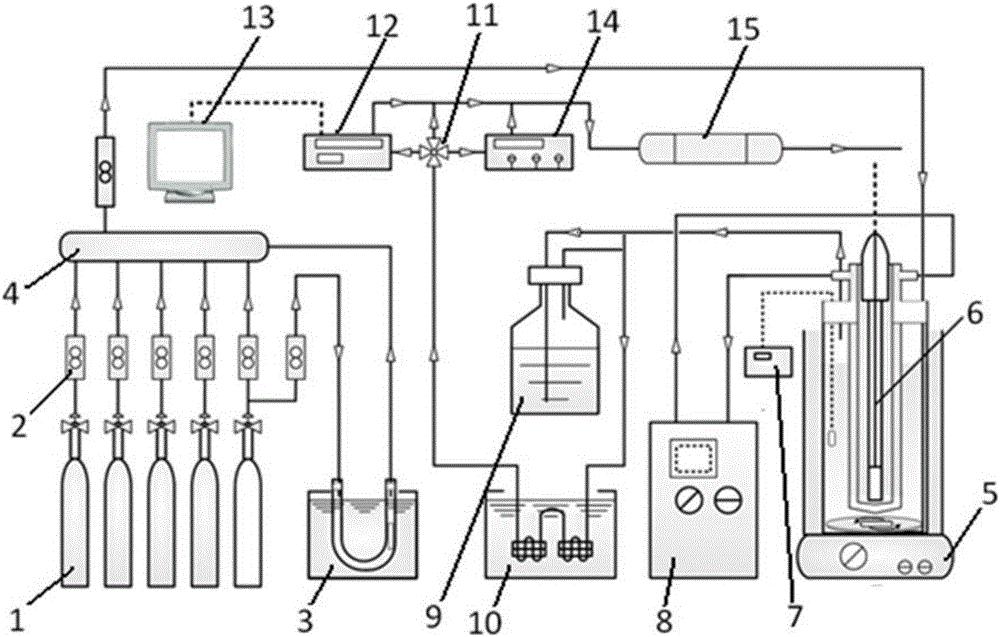

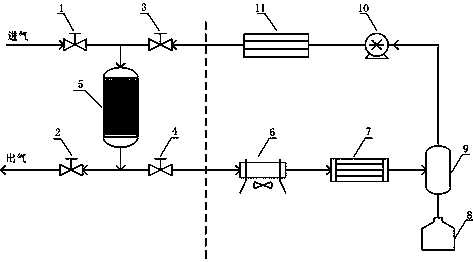

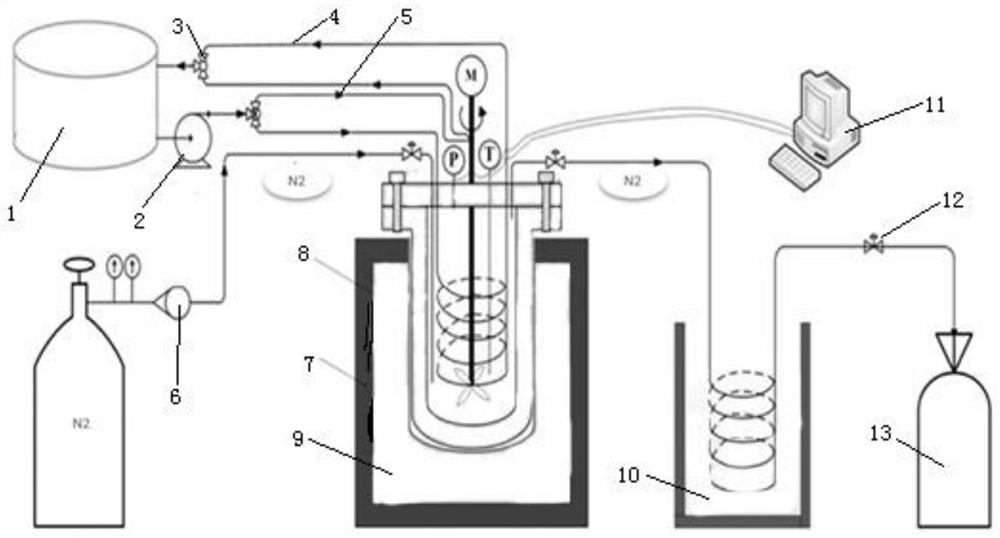

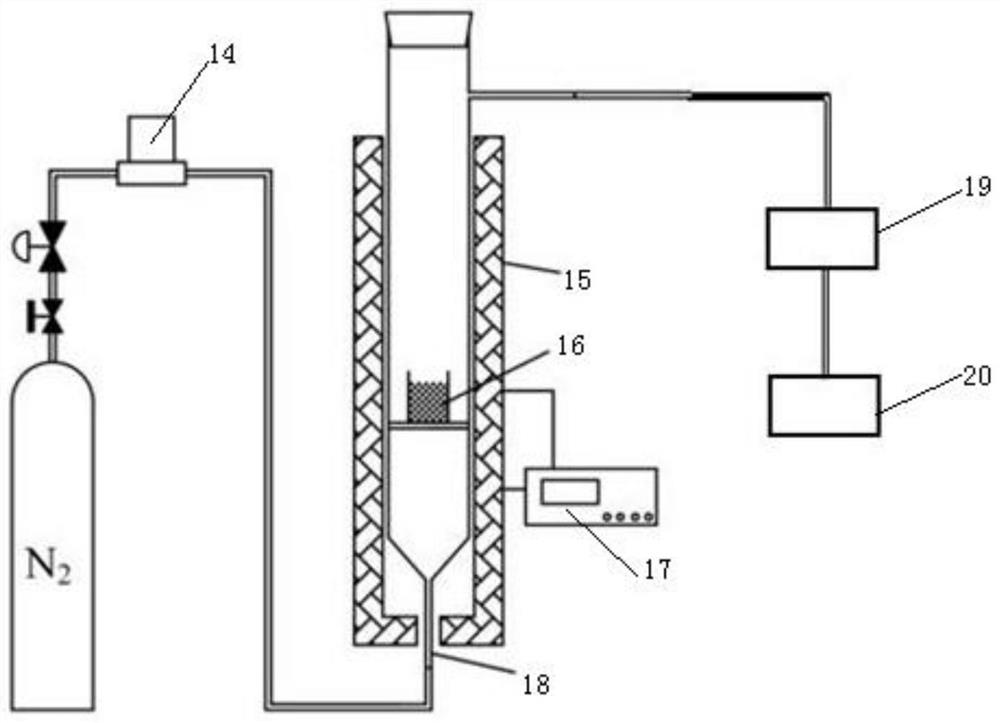

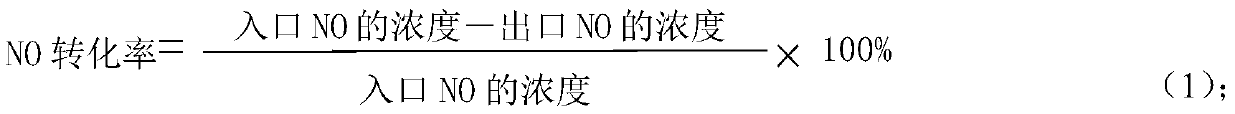

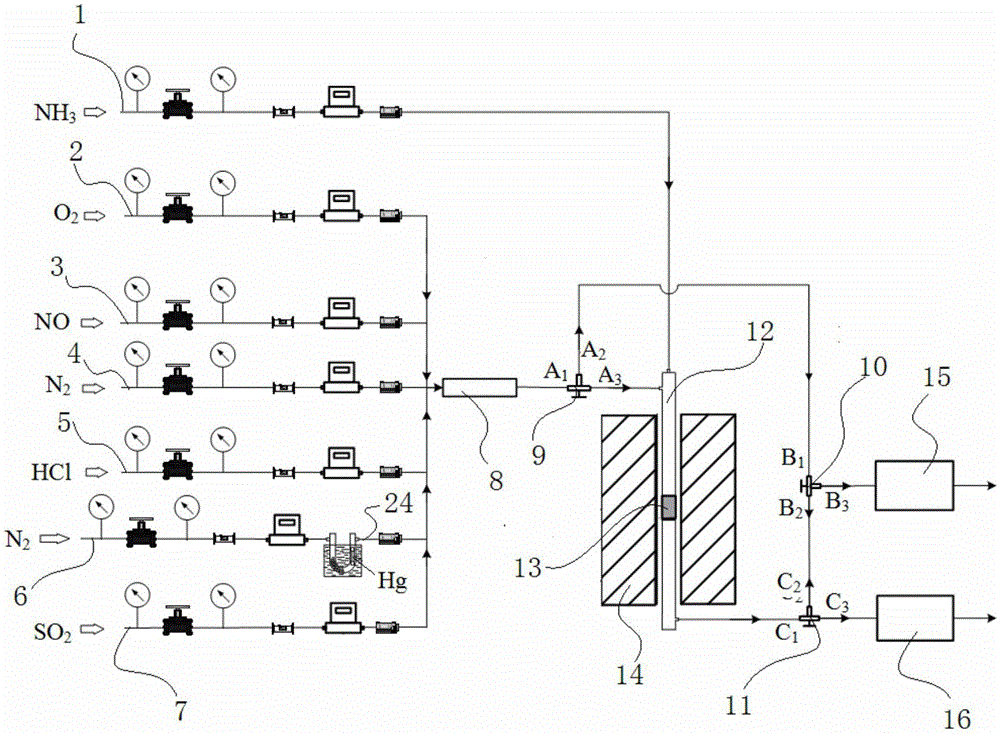

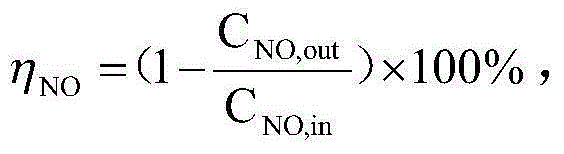

A device and method for jointly evaluating catalyst denitrification and mercury removal performance

InactiveCN103926370BPromote denitrificationGood mercury removal effectChemical analysis using catalysisJoint evaluationFlue gas

The aim of the invention is to provide a device and a method for joint evaluation of denitration and demercuration performances of a catalyst. The device comprises pipelines I, II, III, IV, V and VII, a pressure reducing valve, a filter, a mass flowmeter, a one-way valve, a preheating mixer, an electric heating furnace, three-way ball valves I, II and III, a flue gas analyzer, a mercury analyzer, and a catalytic reactor with two gas inlet and a gas outlet. Actual conditions of a factory are simulated by production of flue gases with different ratios. The catalyst with good effects both on denitration and demercuration specific to a specific flue gas can be selected by replacing of different types of catalysts.

Owner:CHONGQING UNIV

A kind of catalyst for removing harmful gas and its preparation method and application

ActiveCN107790152BImprove adsorption capacityImprove the effect of removing harmful gasesGas treatmentDispersed particle separationActivated carbonPtru catalyst

The invention discloses a catalyst for removing harmful gases and its preparation method and application. The catalyst uses activated carbon as a carrier, and metal oxides are loaded on the activated carbon. The metal oxides are copper oxide and manganese oxide; The molar ratio of copper oxide and manganese oxide is 3:1-1:5. The catalyst has stable activity and is not prone to catalyst poisoning. At the same time, it has good formaldehyde and mercury removal performance and can be used in large-scale industrial applications. Moreover, the raw materials of the catalyst are easy to obtain, the preparation method is simple, and the preparation cost of the catalyst is low.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com