Preparation method of oxide modified MCM-48 molecular sieve, and applications of oxide modified MCM-48 molecular sieve in denitration synergistic mercury removal

A MCM-48, molecular sieve technology, applied in the field of molecular sieve, can solve the problems of lack of system, in-depth understanding of reaction mechanism, difference in flue gas composition, poor poisoning performance, etc., and achieve good mercury removal performance, simple method and large pore size effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

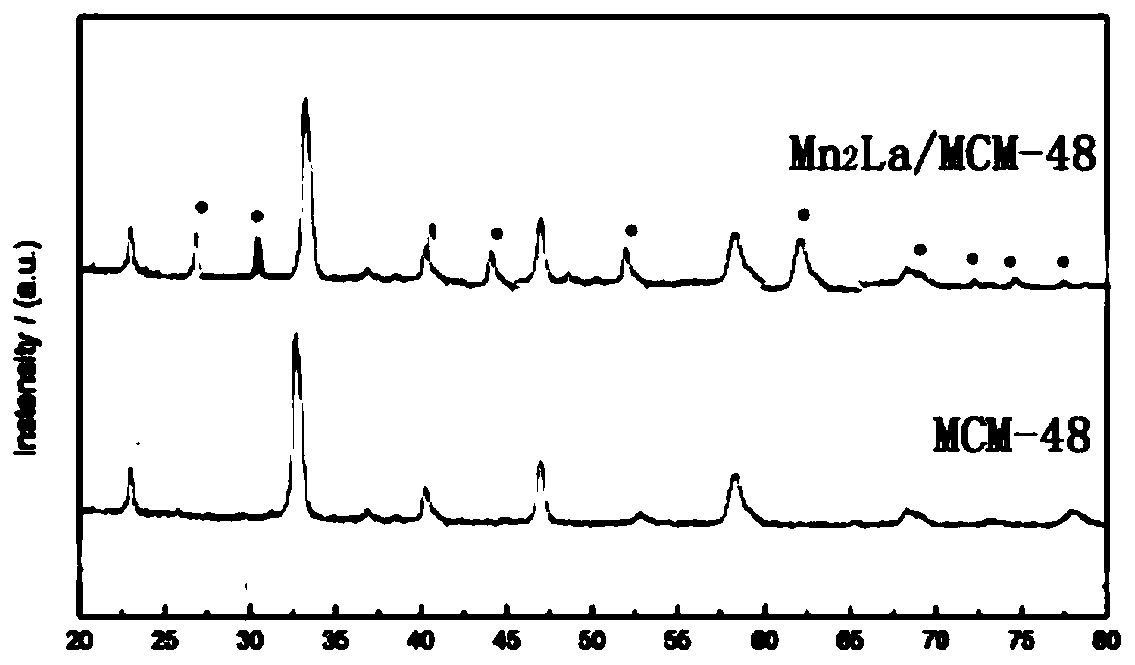

[0061] In the first step, first dissolve MCM-48 molecular sieve in ethanol and reflux, wash and dry and repeat twice, then dissolve it in n-hexane and ultrasonically disperse, and add 3-aminopropyltriethoxysilane (APTES) dropwise. ) Continue to sonicate for 30 minutes; finally, move the treated MCM-48 molecular sieve into a water bath to reflux for 12 hours, filter, wash and dry for subsequent experiments.

[0062] The second step, pretreatment of manganese-based and lanthanum-based materials: weigh 2.5g 50% Mn(NO 3 ) 2 Solution, configure 50mL solution in a beaker; weigh 1.02g La(NO 3 ) 2 ·6H 2 O, configure 50mL solution in a beaker; mix the two solutions and mix well, indicating MnLa 0.5 Solution

[0063] The third step, weigh 5g of the treated MCM-48 molecular sieve, add Mn 2 In the beaker of La solution, mix well;

[0064] The fourth step, put the mixed solution in a magnetic stirrer, stir at a uniform speed for 12 hours at room temperature, and then put the mixed solution in an ...

Embodiment 2

[0068] The difference from Example 1 is that

[0069] In the second step, the mixed solution is Mn 2 Co solution.

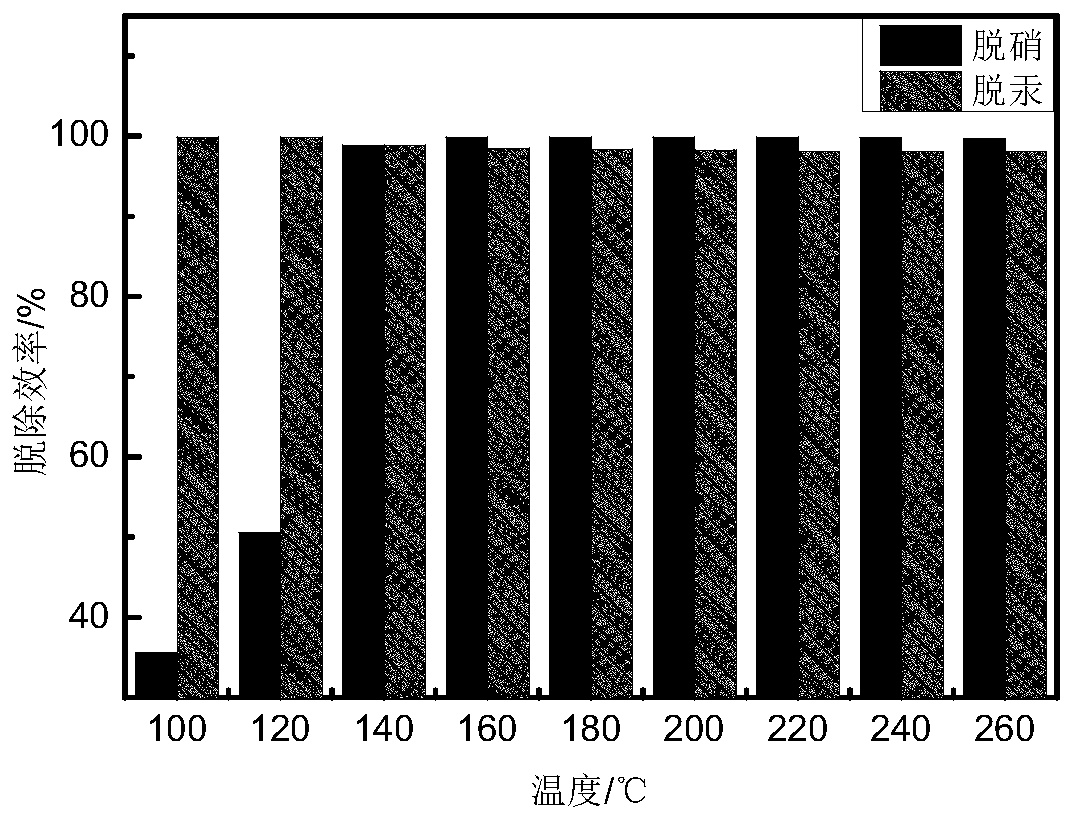

[0070] Select the simulated flue gas NO content of 0.1%, NH 3 Content 0.12%, O 2 The content is 5%, the rest is N 2 Perform balance gas, and at the same time, obtain a certain concentration of Hg in the mercury permeation tube by changing the temperature of the water bath 0 Steam, Hg 0 The flow rate of the carrier gas is 90mL / min, the total gas flow rate is 667mL / min, and the space velocity is 10000h -1 , Carry out denitration and mercury removal experiments in the temperature range of 100-260℃. The experimental results show that the denitration efficiency is about 95% at 160-240°C, and the mercury removal efficiency is about 94%.

Embodiment 3

[0072] The difference from Example 1 is that

[0073] In the second step, the mixed solution is Mn 2 Ce solution.

[0074] Select the simulated flue gas NO content of 0.1%, NH 3 Content 0.12%, O 2 The content is 5%, the rest is N 2 Perform balance gas, and at the same time, obtain a certain concentration of Hg in the mercury permeation tube by changing the temperature of the water bath 0 Steam, Hg 0 The flow rate of the carrier gas is 90mL / min, the total gas flow rate is 667mL / min, and the space velocity is 10000h -1 , Carry out denitration and mercury removal experiments in the temperature range of 100-260℃. The experimental results show that the denitration efficiency is about 95% at 160-240°C, and the mercury removal efficiency is about 92%.

[0075] From the foregoing Examples 1 to 3, it can be seen that the temperature range for denitration and mercury removal of the present invention should be controlled at 160-240°C, and the manganese lanthanum oxide modified MCM-48 catalyst h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com