Ferromanganese cerium adsorbent for mercury removal and preparation method of ferromanganese cerium adsorbent

A ferromanganese and mercury removal technology, applied in the field of materials science, can solve the problems of high operating cost and poor mercury removal effect of mercury removal technology, and achieve the effect of good mercury removal performance, significant technological progress, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

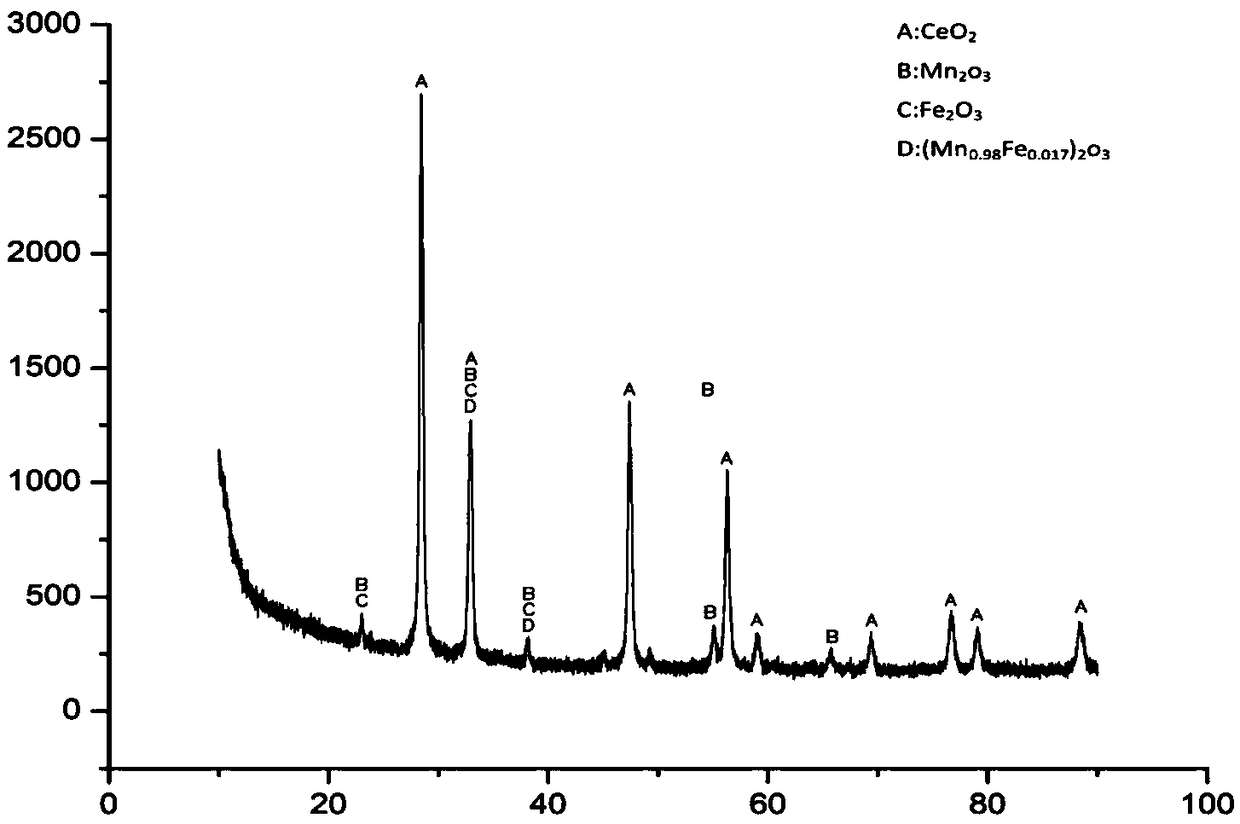

Embodiment 1

[0023] A kind of manganese-iron-cerium adsorption material for mercury removal is made of the following raw materials in parts by weight:

[0024]

[0025] Said a kind of manganese iron cerium adsorption material for mercury removal is prepared by the following specific steps:

[0026] (1) Mix manganese acetate, cerium nitrate, and ferric nitrate, add deionized water, place in the container, stir with a magnetic stirrer for 60 minutes to fully dissolve the solid;

[0027] (2) Put the container into a 120°C electric constant temperature blast drying oven to dry for 18 hours;

[0028] (3) The sample was roasted in a muffle furnace at 500° C. for 6 hours, and after being fully cooled, it was taken out and rolled, and the catalyst particles of 40-80 meshes were screened out to obtain the prepared sample.

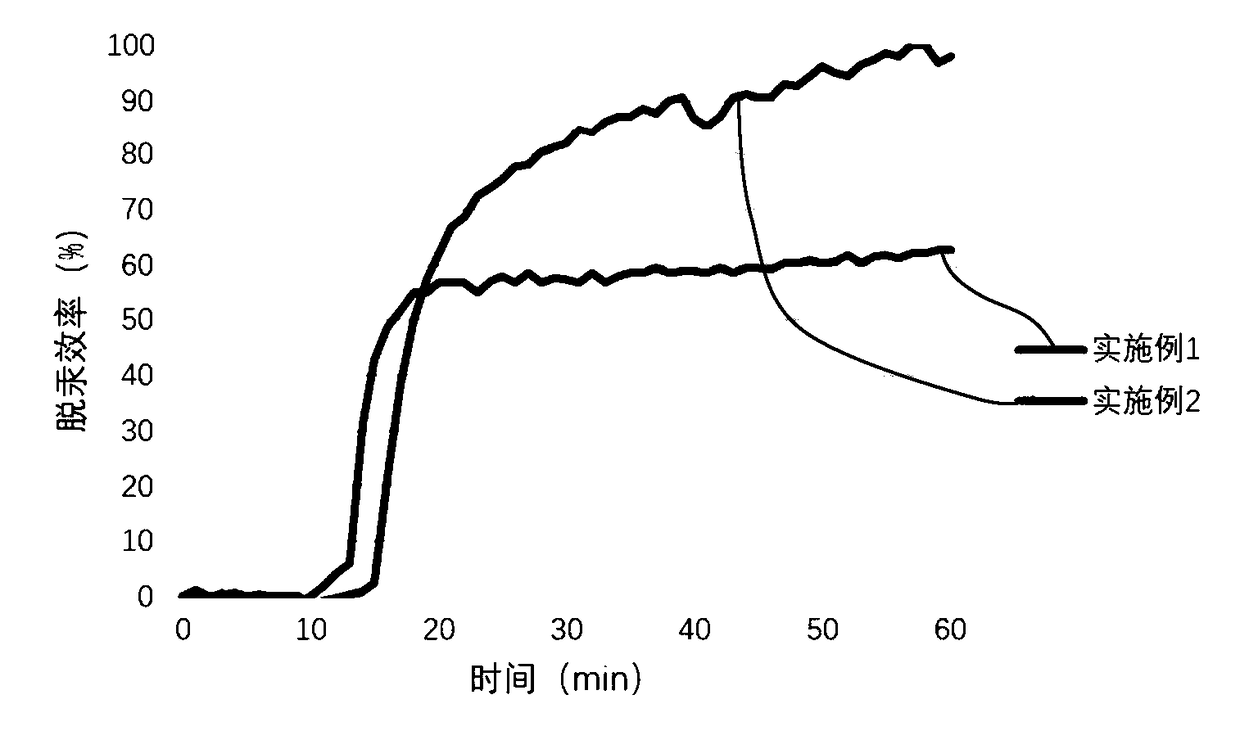

[0029] The prepared manganese-iron-cerium adsorbent is kept at a constant temperature of 120°C in a high-purity nitrogen atmosphere, the nitrogen flow rate is 1.3L / min, and ...

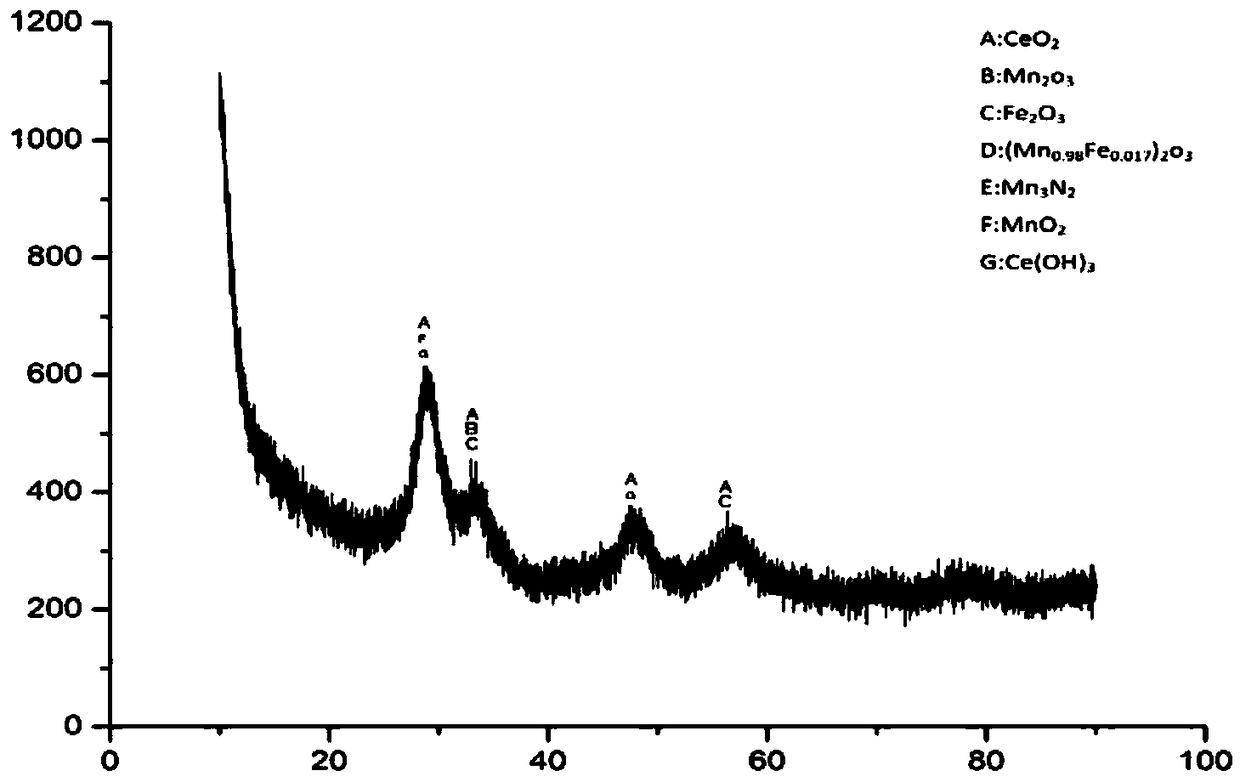

Embodiment 2

[0031] A kind of manganese-iron-cerium adsorption material for mercury removal is made of the following raw materials in parts by weight:

[0032]

[0033] Said a kind of manganese iron cerium adsorption material for mercury removal is prepared by the following specific steps:

[0034] (1) Mix manganese acetate, cerium nitrate, and ferric nitrate, add deionized water, place in the container, stir with a magnetic stirrer for 60 minutes to fully dissolve the solid;

[0035] (2) Put the container into a 120°C electric constant temperature blast drying oven to dry for 18 hours;

[0036] (3) The sample was roasted in a muffle furnace at 500° C. for 6 hours, and after being fully cooled, it was taken out and rolled, and the catalyst particles of 40-80 meshes were screened out to obtain the prepared sample.

[0037] The prepared manganese-iron-cerium adsorbent is kept at a constant temperature of 120°C in a high-purity nitrogen atmosphere, the nitrogen flow rate is 1.3L / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com