Denitration, demercuration and dioxin removal catalyst and preparation method thereof

A technology for removing dioxins and catalysts, applied in molecular sieve catalysts, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of complex composition of flue gas pollutants, increasing operating costs, and increasing the difficulty of treatment, etc. Achieve the effect of increasing surface chemical adsorption oxygen capacity, improving sulfur resistance, and good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

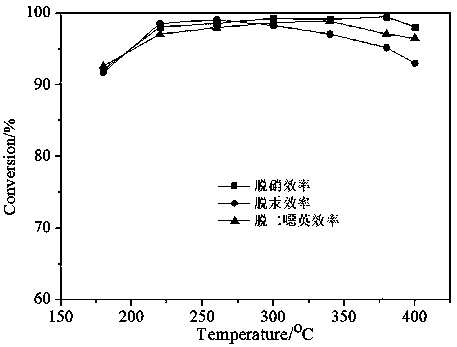

Image

Examples

Embodiment 1

[0042] Take a certain amount of tetrabutyl titanate and dissolve it in absolute ethanol to make solution a, respectively weigh a certain amount of cerium nitrate, tin tetrachloride, and palladium nitrate and dissolve it in deionized water to make solution b. Slowly drop b into solution a, stir evenly, add acetic acid dropwise to adjust the pH to 3, and obtain solution c. Place solution c in a water bath at 60°C, and ultrasonicate at a frequency of 80kHz, while quickly mixing SAPO-46 powder into solution c. After 60 minutes, the ultrasound was turned off, and the gel was prepared by standing at 70°C for 120 minutes. The solution was quickly frozen in liquid nitrogen, and then quickly transferred to a freeze dryer for drying at a drying temperature of -40°C and a pressure of 25pa. After drying, it was calcined at 550°C for 3 hours and ground to 120nm to obtain a preliminary catalyst.

[0043] Weigh a certain amount of ammonium metavanadate, zirconium oxychloride, and cobalt ni...

Embodiment 2

[0047] Take a certain amount of tetrabutyl titanate and dissolve it in absolute ethanol to make solution a, respectively weigh a certain amount of cerium nitrate, tin tetrachloride, and palladium nitrate and dissolve it in deionized water to make solution b. Slowly drop b into solution a, stir evenly, add citric acid dropwise to adjust the pH to 5, and obtain solution c. Put the solution c in a water bath at 90°C, and sonicate at a frequency of 80kHz, and at the same time quickly mix the SAPO-46 powder into the solution c. After 60 minutes, turn off the ultrasound, and stand at 95°C for 30 minutes to obtain a gel. The solution was quickly frozen in liquid nitrogen, and then quickly transferred to a freeze dryer for drying at a drying temperature of -60°C and a pressure of 13pa. After drying, it was calcined at 550°C for 5 hours and ground to 80nm to obtain a preliminary catalyst.

[0048] Take by weighing a certain amount of ammonium metavanadate, zirconium oxychloride, coba...

Embodiment 3

[0052] Take a certain amount of tetraisooctyl titanate and dissolve it in absolute ethanol to make solution a, respectively take a certain amount of cerium nitrate, tin tetrachloride, and palladium nitrate and dissolve it in deionized water to make solution b. Solution b was slowly dropped into solution a, stirred evenly, and citric acid was added dropwise to adjust the pH to 3 to prepare solution c. Place solution c in a water bath at 70°C, and ultrasonicate at a frequency of 120kHz, while quickly mixing SAPO-46 powder into solution c. After 40 minutes, turn off the ultrasound, and stand at 72°C for 45 minutes to obtain a gel. The solution was quickly frozen in liquid nitrogen, and then quickly transferred to a freeze dryer for drying at a drying temperature of -50°C and a pressure of 20pa. After drying, it was calcined at 500°C for 3 hours and ground to 90nm to obtain a preliminary catalyst.

[0053] Weigh a certain amount of ammonium metavanadate, zirconium oxychloride, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com