Denitration catalyst employing shape effect for enhancing low temperature activity, preparation method and application thereof

A denitration catalyst and effect technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve low-temperature catalytic activity and selectivity is not high enough, active temperature window It is not wide enough, restricting the industrial application of catalysts, etc., to reduce and avoid catalyst poisoning, broad market application prospects, and low preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] CeO with different shapes 2 The preparation method of carrier, its characteristic steps are as follows:

[0027] (1) Cubic CeO 2 : Take a certain amount (9.6g) of solid sodium hydroxide and dissolve it in 30ml of deionized water, adjust the lye concentration to 6mol / L, then dissolve and cool to room temperature; take a certain amount of (2mmol, 0.87g) cerous nitrate Dissolve in 10ml of deionized water, stir to dissolve to room temperature, mix and stir the two for half an hour, then transfer the formed flocculent liquid to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 24 hours. The mixture was taken out, centrifuged, washed with distilled water until neutral, the mixture was put into an oven and dried at 110°C for 12 hours, and finally the dried product was taken out and roasted in a muffle furnace at 400°C for 3 hours to obtain cubic CeO 2 .

[0028] (2) Octahedral CeO 2: Take a certain amount (1mmol, 0.43g) of cerous nitrate and ...

Embodiment 1

[0037] Cubic Morphology CeO 2 The preparation method of carrier, its characteristic steps are as follows:

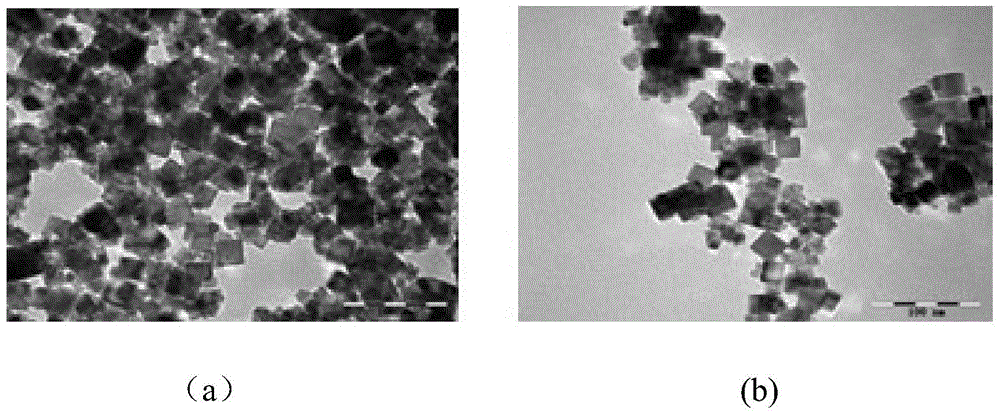

[0038] Weigh a certain amount (9.6g) of solid sodium hydroxide and dissolve it in 30ml of deionized water, adjust the concentration of lye to 6mol / L, then dissolve and cool to room temperature; weigh a certain amount (2mmol, 0.87g) of cerous nitrate solution In 10ml of deionized water, stir and dissolve to room temperature, mix and stir the two for half an hour, then transfer the formed flocculent liquid to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 24 hours. After the hydrothermal reaction is completed, the mixture Take it out, centrifuge it, wash it with distilled water until it is neutral, put the mixture in an oven and dry it at 110°C for 12 hours, and finally take out the dried product and bake it in a muffle furnace at 400°C for 3 hours to obtain cubic CeO 2 , which looks like figure 1 shown. From figure 1 -(a) It can be fo...

Embodiment 2

[0040] Octahedral CeO 2 The preparation method of carrier, its characteristic steps are as follows:

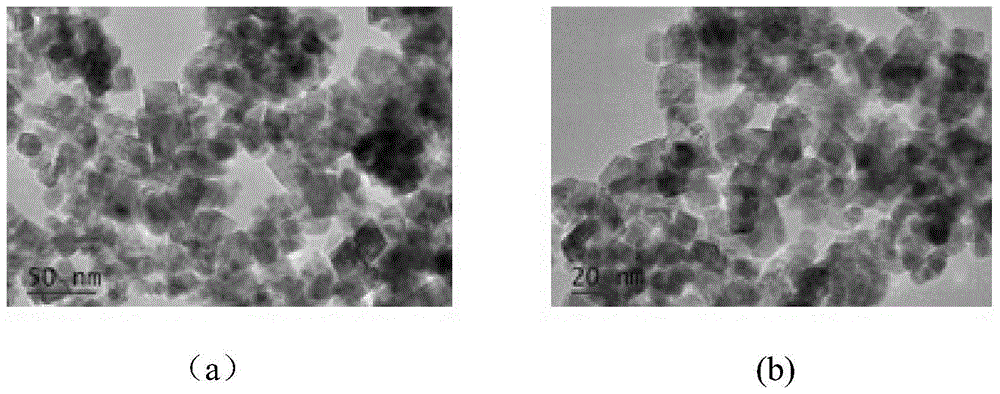

[0041] Take a certain amount (1mmol, 0.43g) of cerous nitrate and dissolve it in 25ml of deionized water, add 15ml of toluene, add 0.15ml of tert-butylamine after completely dissolving, and transfer the flocculent liquid to the hydrothermal reaction kettle after stirring for half an hour. 180°C hydrothermal reaction for 24h, the mixture was taken out after the hydrothermal reaction, centrifuged, washed with ethanol for 3 times, the resultant was put into an oven and dried at 110°C for 12h, after drying, it was roasted in a muffle furnace at 400°C for 3h , to obtain octahedral CeO 2 , which looks like figure 2 shown. From figure 2 -(a) it can be seen that the CeO prepared by this method 2 The carrier presents a typical octahedral morphology, while from figure 2 -(b) Octahedral CeO can be seen 2 The nanometer size of the carrier is relatively uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com