Preparation method of molecular sieve-based low-temperature environment-friendly SCR denitration catalyst

The technology of denitration catalyst and molecular sieve is applied in the field of preparation of molecular sieve-based low-temperature environment-friendly SCR denitration catalyst, which can solve the problems of narrow active temperature window, catalyst soot poisoning and deactivation, loss of secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

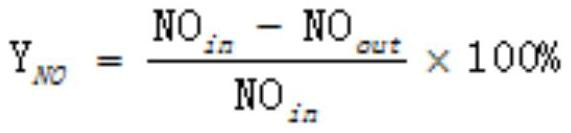

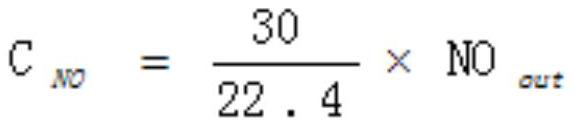

Embodiment 1

[0042] Take 5% Fe 2 o 3 / ZSM-5 molecular sieve 50g was added to 142.3g of water, so that the molecular sieve content was 26wt%. Add 85wt% formic acid solution under stirring condition to adjust pH=2.85. The cordierite powder was sieved through a 60-mesh sieve, and 9 g was added to 25.6 g of water, so that the mass fraction of cordierite was 26 wt%. Add 85wt% formic acid solution under stirring condition to adjust pH=2.85, and the mass ratio of cordierite to molecular sieve is 18%. Add 20g of pseudo-boehmite to 230g of water, the mass content of pseudo-boehmite in the slurry is 8wt%, add 85wt% formic acid solution under stirring conditions, adjust pH=3.65, the mass ratio of pseudo-boehmite to molecular sieve is 40%. The above-mentioned various slurries were stirred for 5 hours for later use. Use an 80-mesh sieve to sieve the scallop powder, take 3g and add it to water to disperse evenly. Under the condition of stirring, mix the above slurry into the pseudo-boehmite slurry...

Embodiment 2

[0045] Take 9% Fe 2 o 3 / ZSM-5 molecular sieve 50g was added to 142.3g of water, so that the molecular sieve content was 26wt%. Add 75wt% acetic acid solution under stirring condition to adjust pH=3.0. The mullite powder was sieved through a 60-mesh sieve, and 9 g was added to 25.6 g of water, so that the mass fraction of mullite was 26 wt%. Add 75wt% acetic acid solution under stirring condition to adjust pH=3.0, and the mass ratio of cordierite to molecular sieve is 18%. Add 20g of pseudo-boehmite to 230g of water, the mass content of pseudo-boehmite in the slurry is 8wt%, add 75wt% acetic acid solution under stirring conditions, adjust pH=3.7, the mass ratio of pseudo-boehmite to molecular sieve is 40%. The above-mentioned various slurries were stirred for 5 hours for later use. Sieve the starch through a 80-mesh sieve, take 3g and add it into water to disperse evenly. Under the condition of stirring, mix the above slurry into the pseudo-boehmite slurry, stir for 1.5 ho...

Embodiment 3

[0048] Take 5% Fe 2 o 3 / ZSM-5 molecular sieve 50g was added to 142.3g of water, so that the molecular sieve content was 26wt%. Concentrated nitric acid was added under stirring condition to adjust pH=2.9. The cordierite powder was sieved through a 60-mesh sieve, and 9 g was added to 25.6 g of water, so that the mass fraction of mullite was 26 wt%. Concentrated nitric acid was added under agitation to adjust the pH to 2.9, and the mass ratio of cordierite to molecular sieve was 18%. Add 20g of pseudo-boehmite to 230g of water, the mass content of pseudo-boehmite in the slurry is 8wt%, add concentrated nitric acid under stirring conditions, adjust pH=3.7, and the mass ratio of pseudo-boehmite to molecular sieve is 40% . The above-mentioned various slurries were stirred for 5 hours for later use. Use an 80-mesh sieve to sieve the scallop powder, take 1g and add it to water to disperse evenly. Under the condition of stirring, mix the above slurry into the pseudo-boehmite sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com