Rod-shaped cerium oxide-supported samarium-manganese composite oxide catalyst and preparation method thereof

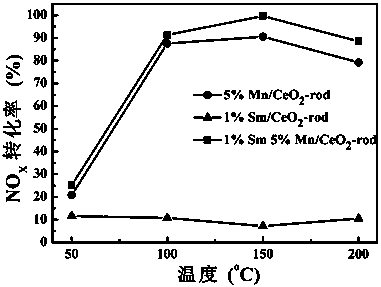

A composite oxide and cerium oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as wide temperature window denitrification performance, and achieve broadened The effect of active temperature window, increased content, increased specific surface area and surface oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Synthesis of rod-shaped cerium oxide support: prepare a cerium nitrate solution with a concentration of 0.0444 mol / L, which is designated as solution 1; prepare a sodium hydroxide solution with a concentration of 8 mol / L, and let it cool naturally to room temperature, which is designated as solution 2. Add 70 mL of solution 2 dropwise to solution 1 so that the molar ratio of the two is 1:180, stir vigorously for 1 h, transfer to a polytetrafluoroethylene reactor with a volume of 100 mL, and age at 110°C for 12 h . After taking out the hydrothermal kettle and waiting for cooling, the obtained rod-shaped cerium oxide precursor was placed in an oven and dried at 60°C for 12 hours, then placed in a muffle furnace for roasting, and the temperature was raised to 450°C at a heating rate of 3°C / min, and Calcined at this temperature for 4h to obtain a rod-shaped cerium oxide carrier. The obtained rod-shaped cerium oxide support is denoted as CeO 2 -rod.

[0031] (2) Prepa...

Embodiment 2

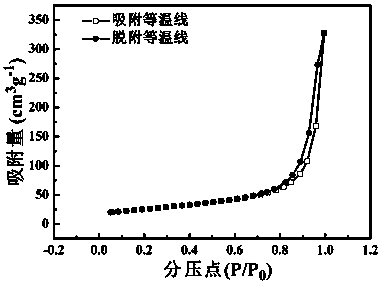

[0033] (1) Synthesis of rod-shaped cerium oxide support: Prepare a cerium nitrate solution with a concentration of 0.05 mol / L, which is designated as solution 1; prepare a sodium hydroxide solution with a concentration of 9 mol / L, and let it cool naturally to room temperature, which is designated as solution 2. 70 mL of solution 2 was added dropwise to solution 1 so that the molar ratio of the two was 1:180. After stirring vigorously for 1 h, it was transferred to a 100 mL polytetrafluoroethylene reactor and aged at 100 °C for 24 h. After taking out the hydrothermal kettle and waiting for cooling, the obtained rod-shaped cerium oxide precursor was placed in an oven and dried at 60°C for 12 hours, then placed in a muffle furnace for roasting, and the temperature was raised to 500°C at a heating rate of 1°C / min, and Calcined at this temperature for 3h to obtain a rod-shaped cerium oxide carrier. The specific surface area of the carrier is 90.13m 2 / g.

[0034] (2) Preparatio...

Embodiment 3

[0037] (1) Synthesis of rod-shaped cerium oxide support: Prepare a cerium nitrate solution with a concentration of 0.05 mol / L, which is designated as solution 1; prepare a sodium hydroxide solution with a concentration of 9 mol / L, and let it cool naturally to room temperature, which is designated as solution 2. 70 mL of solution 2 was added dropwise to solution 1 so that the molar ratio of the two was 1:180. After stirring vigorously for 1 h, it was transferred to a polytetrafluoroethylene reactor with a volume of 100 mL, and aged at 100 °C for 24 h. After taking out the hydrothermal kettle and waiting for cooling, the obtained rod-shaped cerium oxide precursor was placed in an oven and dried at 80°C for 24 hours, then placed in a muffle furnace for roasting, and the temperature was raised to 550°C at a heating rate of 1°C / min, and Calcined at this temperature for 2h to obtain a rod-shaped cerium oxide carrier.

[0038] (2) Preparation of catalyst: Weigh 0.1773g of samarium(II...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com