SCR catalyst for ship diesel engine post-treatment, and preparation method thereof

A technology for SCR catalysts and marine diesel engines, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as unsatisfactory temperature window, hydrothermal stability, poor sulfur resistance performance, etc., and achieve broadened activity Temperature window, excellent hydrothermal aging resistance, and high denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

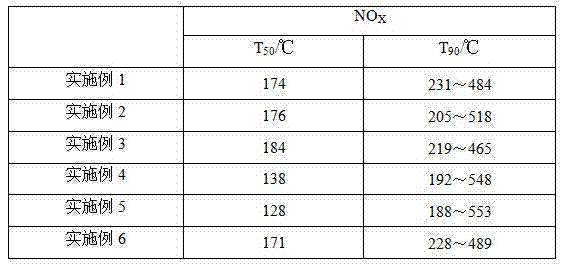

Embodiment 1

[0028] Embodiment 1: preparation V-ZSM-5 molecular sieve catalyst:

[0029] (1) High specific surface area ZSM-5 molecular sieve pretreatment: accurately weigh ZSM-5 molecular sieve powder (SiO 2 / Al 2 o 3 =50) 20g, put it in an oven, and dry it at 120°C for 3 hours to remove excess moisture in the molecular sieve;

[0030] (2) Preparation of active component solution: Weigh 2.078g of ammonium metavanadate in proportion, put it into a beaker, and inject 17.726g of water into the beaker (required water volume = ZSM-5 molecular sieve mass × ZSM-5 molecular sieve specific pore volume), stir well to make it evenly mixed;

[0031] (3) Catalyst preparation: place the pretreated ZSM-5 molecular sieve powder in a crucible, add the prepared active component solution drop by drop into the ZSM-5 molecular sieve powder with a rubber dropper, and keep stirring, Until the ZSM-5 molecular sieve powder becomes viscous, stop adding the active component solution dropwise. The prepared V-ZS...

Embodiment 2

[0032] Embodiment 2: preparation V-W-ZSM-5 molecular sieve catalyst:

[0033] (1) High specific surface area ZSM-5 molecular sieve pretreatment: accurately weigh ZSM-5 molecular sieve powder (SiO 2 / Al 2 o 3 =80) 20g, put it in an oven, and dry it at 120°C for 3 hours to remove excess moisture in the molecular sieve;

[0034](2) Preparation of active component solution: Weigh 2.078g of ammonium metavanadate and 2.352g of ammonium tungstate in proportion, put them into a beaker, and pour 20.060g of water into the beaker (required water volume = ZSM-5 molecular sieve mass × specific pore volume of ZSM-5 molecular sieve), stir well to make it evenly mixed;

[0035] (3) Catalyst preparation: place the pretreated ZSM-5 molecular sieve powder in a crucible, add the prepared active component solution drop by drop into the ZSM-5 molecular sieve powder with a rubber dropper, and keep stirring, Until the ZSM-5 molecular sieve powder becomes viscous, stop adding the active component ...

Embodiment 3

[0036] Embodiment 3: preparation V-Cu-ZSM-5 molecular sieve catalyst:

[0037] (1) High specific surface area ZSM-5 molecular sieve pretreatment: accurately weigh ZSM-5 molecular sieve powder (SiO 2 / Al 2 o 3 =80) 20g, put it in an oven, and dry it at 120°C for 3 hours to remove excess moisture in the molecular sieve;

[0038] (2) Preparation of active component solution: Weigh 1.768g of ammonium metavanadate and 1.826g of copper nitrate in proportion, put them into a beaker in turn, and pour 20.060g of water into the beaker (required water volume = ZSM-5 molecular sieve mass × specific pore volume of ZSM-5 molecular sieve), stir well to make it evenly mixed;

[0039] (3) Catalyst preparation: place the pretreated ZSM-5 molecular sieve powder in a crucible, add the prepared active component solution drop by drop into the ZSM-5 molecular sieve powder with a rubber dropper, and keep stirring, Until the ZSM-5 molecular sieve powder becomes viscous, stop adding the active comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com