Low-temperature SCR denitration catalyst based on kaoline and preparation method of catalyst

A denitration catalyst and kaolin technology, applied in the field of denitration catalysts, can solve the problems of high cost of titanium dioxide, cumbersome co-precipitation process, increase catalyst preparation cost, etc., and achieve the effects of good application prospect, strong denitration ability and wide active temperature window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

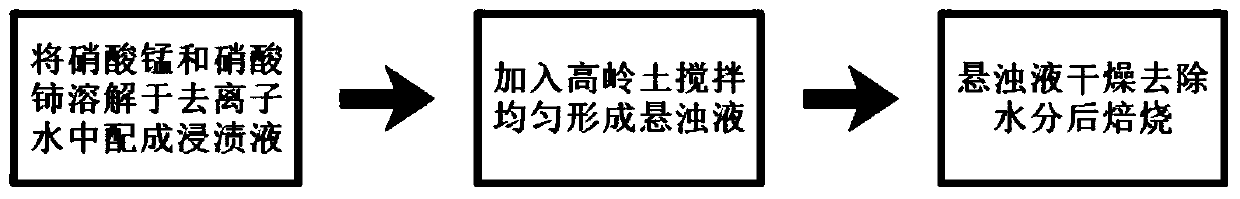

[0028] Such as figure 1 Shown, a kind of preparation method of above-mentioned low-temperature SCR denitration catalyst, this method comprises the following steps:

[0029] (a) select manganese nitrate and cerium nitrate as raw materials, mix the two and dissolve them in deionized water to obtain an impregnation solution;

[0030] (b) adding a certain quality of kaolin to the impregnation solution, stirring at room temperature to obtain a suspension;

[0031] (c) Magnetically stirring the suspension until it becomes viscous to obtain a mixture, which is dried and calcined to obtain the desired catalyst.

[0032] Preferably, in step (b), the stirring time at room temperature is 4h-6h, so that the active components can be better dispersed in the impregnation solution.

[0033] Preferably, in step (c), the temperature of the magnetic stirring is preferably 40°C to 80°C, and the stirring time is 3h to 6h, so that the active component is further dispersed in the impregnation solu...

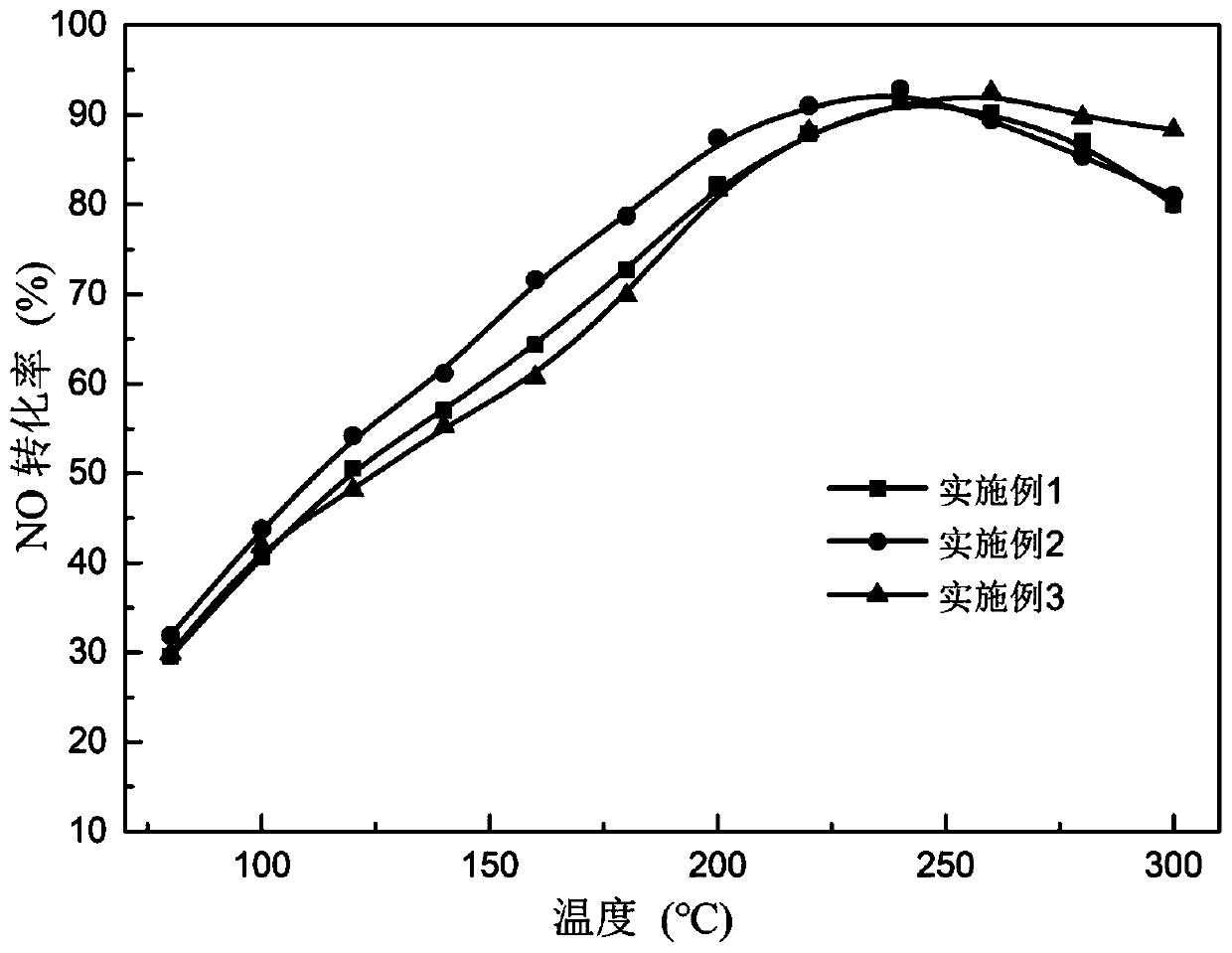

Embodiment 1

[0037] A. Accurately weigh 0.01mol Ce(NO 3 ) 3 ·6H 2 O and 0.05mol Mn(NO 3 ) 2 , dissolved in 80ml deionized water to form a solution, and magnetically stirred for 30min to mix well.

[0038] B. Accurately weigh 0.05 mol of kaolin and add it to the above-prepared solution. During this process, it is necessary to add kaolin slowly while vigorously stirring the solution magnetically, and magnetically stir for 6 hours at room temperature.

[0039] C. Continue to magnetically stir the white suspension obtained above at 80° C. for 3 h until the mixture becomes viscous.

[0040] D. Keep the above product at 80°C for 15h in a blast drying oven, take it out and bake it in a temperature-programmed muffle furnace at 500°C for 3h.

[0041] The catalyst activity test uses a micro-catalytic device to test the catalyst. The flue gas components used in the experiment are:

[0042] NOx concentration in flue gas is 800ppm, NOx / NH 3 = 1:1;

[0043] o 2 The concentration is 5%;

[0044...

Embodiment 2

[0048] A. Accurately weigh 0.01mol Ce(NO 3 ) 3 ·6H 2 O and 0.08mol Mn(NO 3 ) 2 , dissolved in 80ml deionized water to form a solution, and magnetically stirred for 30min to mix well.

[0049] B. Accurately weigh 0.08 mol of kaolin and add it to the above-prepared solution. During this process, it is necessary to add kaolin slowly while vigorously stirring the solution magnetically, and magnetically stir for 4 hours at room temperature.

[0050] C. Continue to magnetically stir the white suspension obtained above at 40° C. for 6 h until the mixture becomes viscous.

[0051] D. Keep the above product at 80°C for 15h in a blast drying oven, take it out and bake it in a temperature-programmed muffle furnace at 450°C for 4h.

[0052] The catalyst activity test uses a micro-catalytic device to test the catalyst. The flue gas components used in the experiment are:

[0053] NOx concentration in flue gas is 800ppm, NOx / NH 3 = 1:1;

[0054] o 2 The concentration is 5%;

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com