A device and method for jointly evaluating catalyst denitrification and mercury removal performance

A mercury removal performance and catalyst technology, applied in the direction of chemical analysis using catalysis, can solve problems such as complex flue gas composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

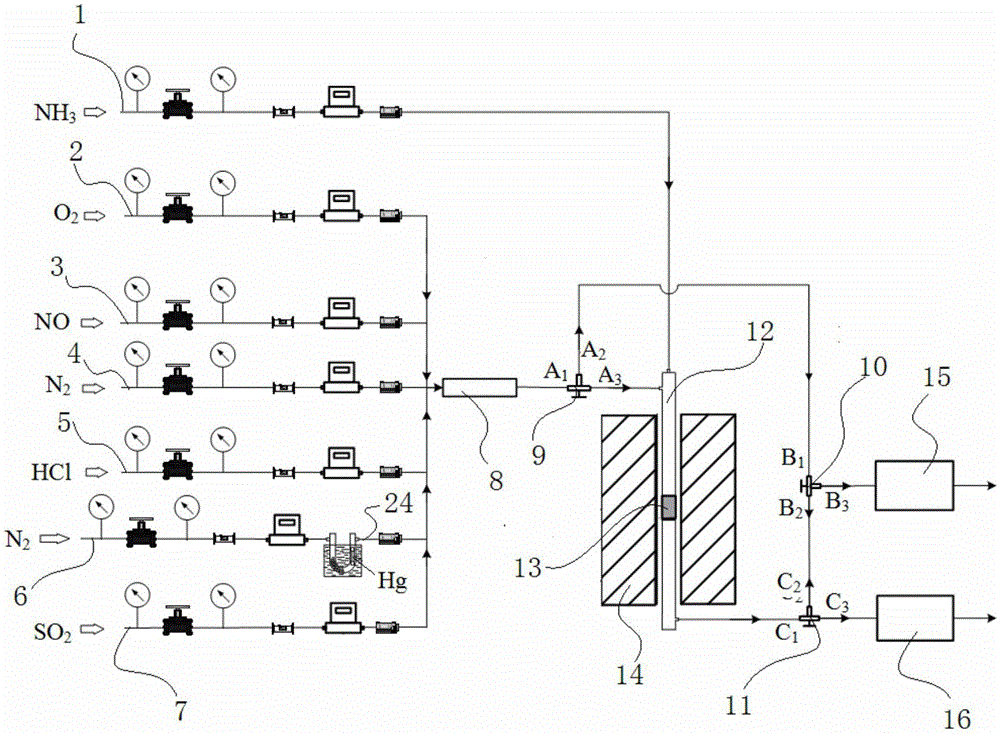

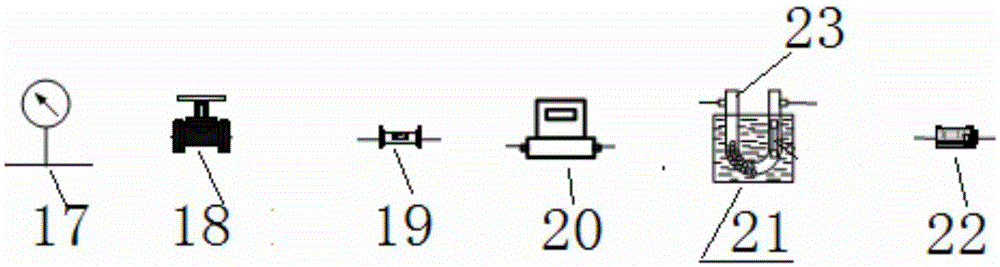

[0026] A device for jointly evaluating catalyst denitrification and mercury removal performance, including pipelines I to VII, preheating mixer 8, three-way ball valves I to III, flue gas analyzer 15 and mercury analyzer 16, and has two air inlets And a catalytic reactor 12 with a gas outlet. The catalytic reactor 12 is a vessel containing a catalyst therein. The gas entering from any inlet of the catalytic reactor 12 flows through the catalyst (usually fixed on the carrier), and then is discharged from the gas outlet.

[0027] The inlet of the pipeline I1 is connected to NH 3 The gas source and outlet are connected to the first air inlet of the catalytic reactor 12 .

[0028] The inlet connection of the pipeline II2 is O 2 The gas source and the outlet are connected to the air inlet of the preheating mixer 8 . The inlet of the pipeline III3 is connected to the NO gas source, and the outlet is connected to the air inlet of the preheating mixer 8 . The inlet connection N o...

Embodiment 2

[0034] In this example, the device described in Example 1 is used to jointly evaluate the method of catalyst denitrification and mercury removal performance, including the following steps:

[0035] 1) Adjust the three-way ball valve I9 so that A 1 Mouth and A 2 Port connection, A 3 The port is closed, adjust the three-way ball valve Ⅱ10, so that B 1 Mouth, B 2 Mouth and B 3 The ports are connected to each other, adjust the three-way ball valve Ⅲ11 so that C 2 Mouth and C 3 port connection, C 1 The mouth is closed. That is, the mixed gas coming out of the preheating mixer 8 directly enters the flue gas analyzer 15 and the mercury analyzer 16 without passing through the catalyst 13 .

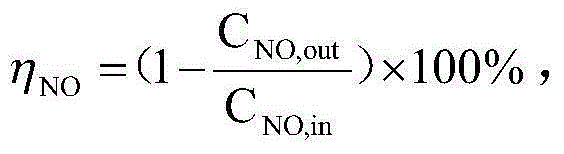

[0036] 2) Feed O into the preheating mixer 8 through pipelines Ⅱ~Ⅷ 2 , NO, N 2 , mercury vapor, HCl and SO 2 gas. At this moment, the one-way valve 22 on the pipeline I is closed. The flue gas analyzer 15 detects the initial concentration C of NO NO,in , the mercury analyzer 16 det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com