Method for removing fine particles and heavy metals in coal fume

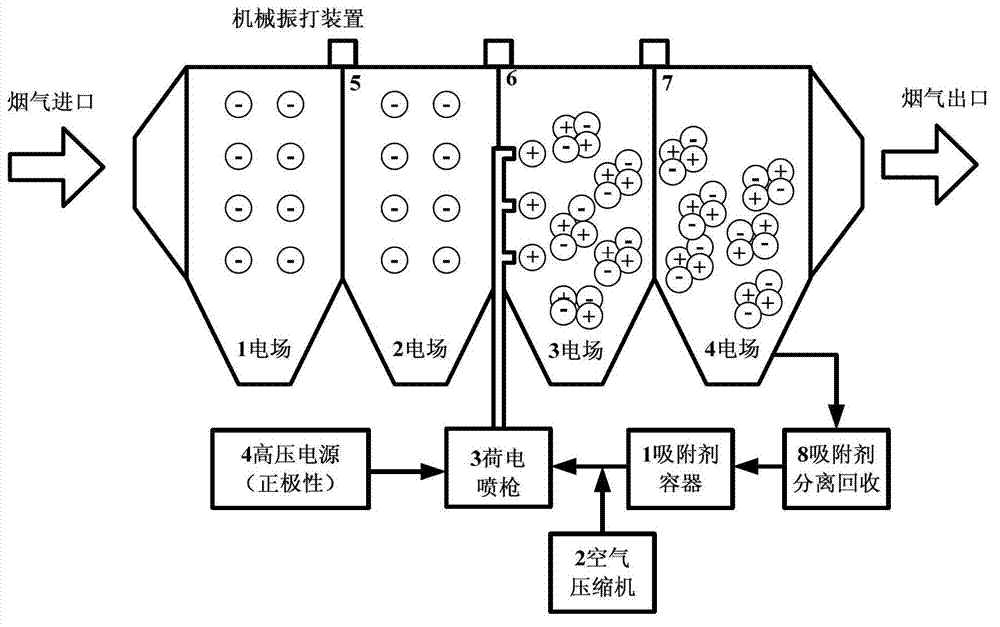

A coal-fired flue gas, fine particle technology, applied in chemical instruments and methods, solid separation, cyclone devices, etc., can solve the problems of inability to achieve Coulomb condensation effect, negligible electric charge, and insignificant effect, and achieve good mercury removal. effect, increase the degree of mixing, and increase the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention utilizes the experimental four electric field electrostatic precipitator of laboratory to carry out experiment. The length and width of the four dust collection plates in the electric area of the electrostatic precipitator are both 0.3m, and the total area of the dust collection plates is 0.72m 2 , The distance between dust collectors is 0.2m. The effective space of the bonding area between the electric fields is about 0.012m 3 . The discharge electrode structure of the spray gun is single-needle, the power supply voltage is 0-80kV, the charging current is 0-80 microampere, and the adsorbent injection rate is 0-1kg / h (continuously adjustable). The adsorbent is charged and sprayed into the area between two adjacent electric fields by using a spray gun.

[0035] The dust concentration in the simulated coal-fired flue gas is 2000mg / m 3 , the total mercury content is about 20μg / m 3 , SO 3 Concentration is 20ppm, flue gas flow rate is 200m 3 ...

Embodiment 2

[0038] The device and method are the same as in Example 1, except that magnesium oxide powder with a particle size of 40-60 μm is added in a proportion of 30 wt % while spraying on the iron-titanium adsorbent. The results show that after the adsorbent is mixed with magnesium oxide, the concentration of soot in the outlet flue gas can be reduced to 30mg / m 3 around, the removal rate of mercury remains basically the same, but the SO 3 The removal efficiency can be increased to about 70%. It can be seen that the mixed use of adsorbent and magnesium oxide can significantly improve the removal efficiency of various pollutants.

Embodiment 3

[0040] The device and method are the same as examples 1 and 2, and the experiment is carried out mainly on the recovery and separation of the adsorbent. A standard cyclone separator with a diameter of 250mm is used to process the mixture of adsorbent and fine particles collected by the electrostatic precipitator. According to the analysis of the results, after the adsorbent is separated by two high-speed cyclones, the fine particles attached to the surface can basically be stripped off and collected separately from the adsorbent through inertial separation, and the adsorbent can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com