Shock wave tunnel test device and test method

A test device and tunnel technology, applied in the field of shock tubes, can solve the problems of unsatisfactory and difficult to obtain high-pressure plane waves, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

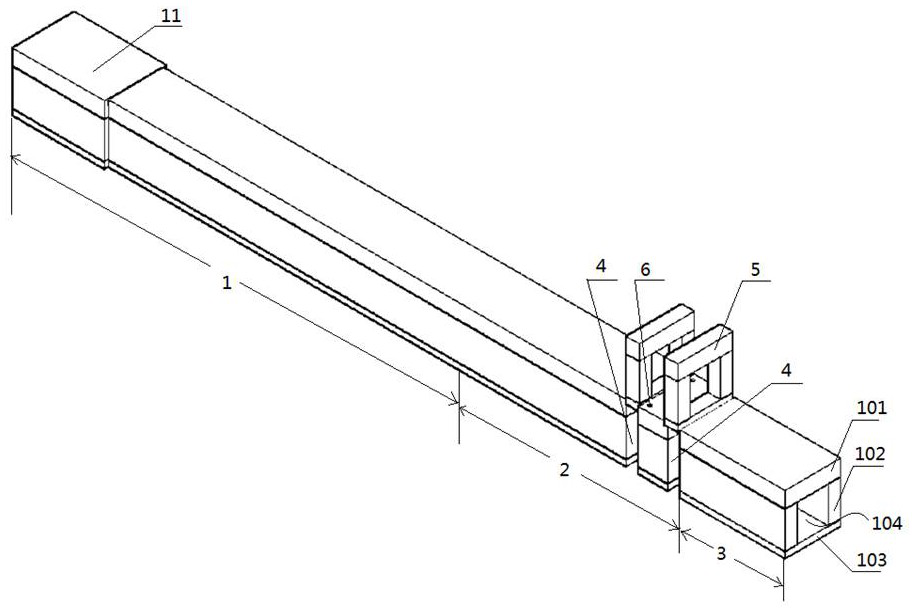

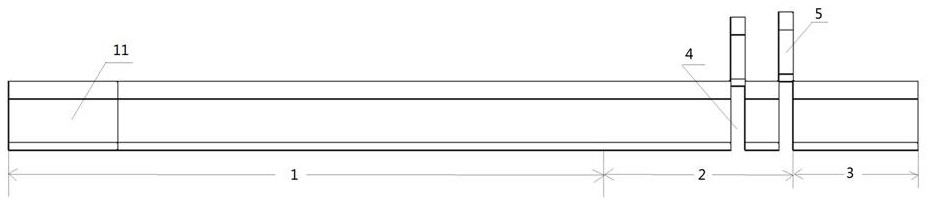

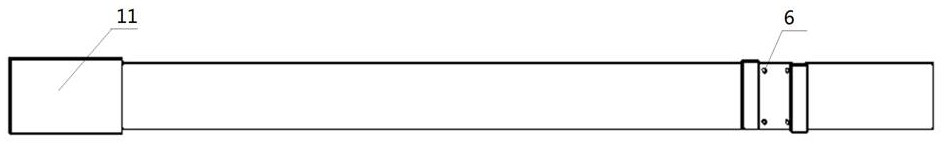

[0026] like figure 1As shown, the shock wave tunnel test device according to the preferred embodiment of the present invention adopts a reinforced concrete rectangular cylindrical structure, the two ends of the rectangular cylindrical structure are not closed, and the rectangular cylindrical structure is composed of a top plate 101, two side plates 102 and a bottom plate 103 , and form a tunnel 104 inside it, the shock tunnel test device includes: a planar shock wave forming section 1, which includes a head 11 arranged at one end of the shock wave tunnel test device, and the head 11 is used to receive the explosion shock wave generated by the explosive explosion. Wherein, the length of the planar shock wave forming section 1 is 30m, and the two side plates 102 of the head 11 of the planar shock wave forming section 1 are thickened to prevent the head from being damaged by the initial high pressure shock wave formed by the explosion. The thickness of the two side plates 102 of ...

Embodiment 2

[0030] In a preferred embodiment, the thickness of the movable concrete prefabricated frame 5 is slightly less than the width equal to the draw-in groove 4, the movable concrete prefabricated frame 5 is a hollow structure, and the outer frame cross-sectional size of the movable concrete prefabricated frame 5 is equal to that of the shock wave tunnel test device. Cross-sectional size, the cross-sectional size of the inner frame of the movable concrete prefabricated frame 5 is equal to the cross-sectional size of the tunnel 104 . When the concrete prefabricated test component or the movable concrete prefabricated frame 5 is vertically inserted into the slot 4, a gap of 2 cm is left between both sides of the slot 4 and the concrete prefabricated test component or the movable concrete prefabricated frame 5 to prevent hoisting difficulty. Wherein, when the movable concrete prefabricated frame 5 is hoisted in the two clamping slots 4, it is used for shock wave biological damage test...

Embodiment 3

[0041] The present invention also provides a shock tunnel test method comprising the following steps: placing the explosive at a certain distance from the outside of the head 11 of the plane shock wave forming section 1 of the above-mentioned shock tunnel test device; The concrete prefabricated test components or the movable concrete prefabricated frame 5 are hoisted directly in the two slots 4 at the end of the test section 2, and a plurality of pressure sensors are buried in the tunnel roof 101 and the two side plates 102; The generated high-pressure explosion shock wave enters the tunnel 104 from the head 11, and is reflected multiple times on the tunnel side wall of the remaining part of the plane shock wave forming section 1 and propagates forward; when the explosion shock wave moves to the tunnel 30m and forms a stable plane When the shock wave enters the test section; in the test section 2, the explosion shock wave develops into a plane shock wave that meets the test req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com