Patents

Literature

163results about How to "Large structure size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

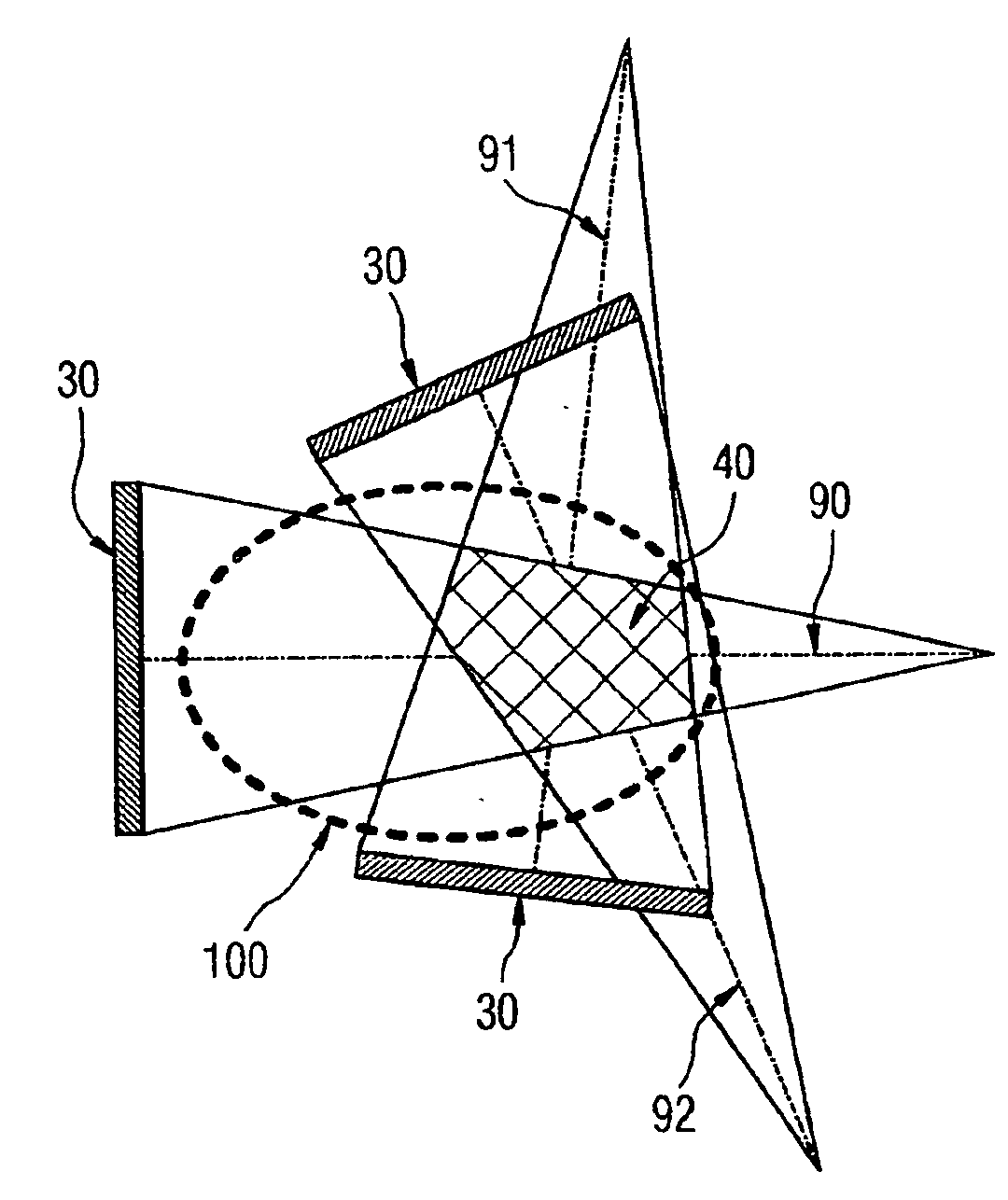

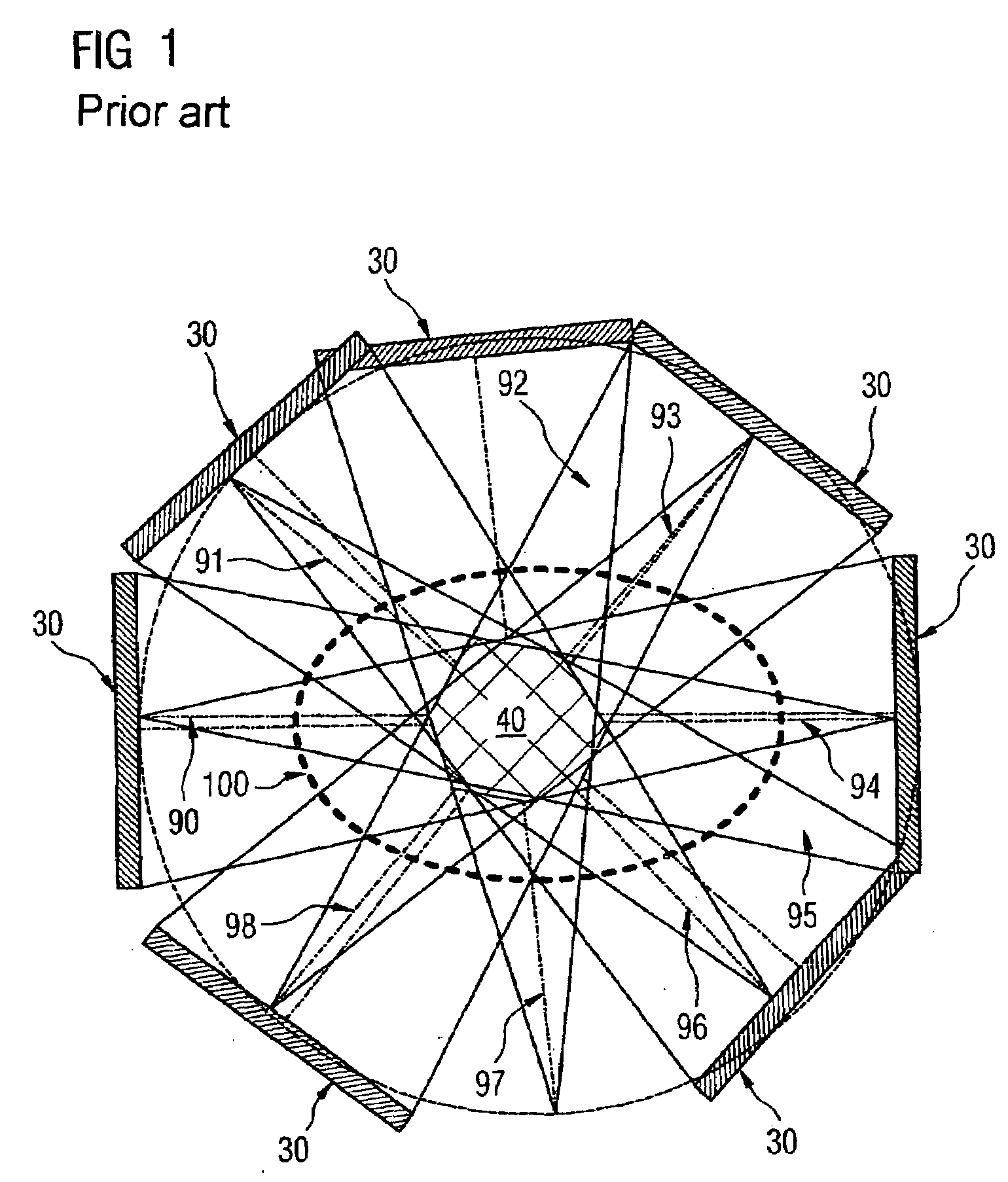

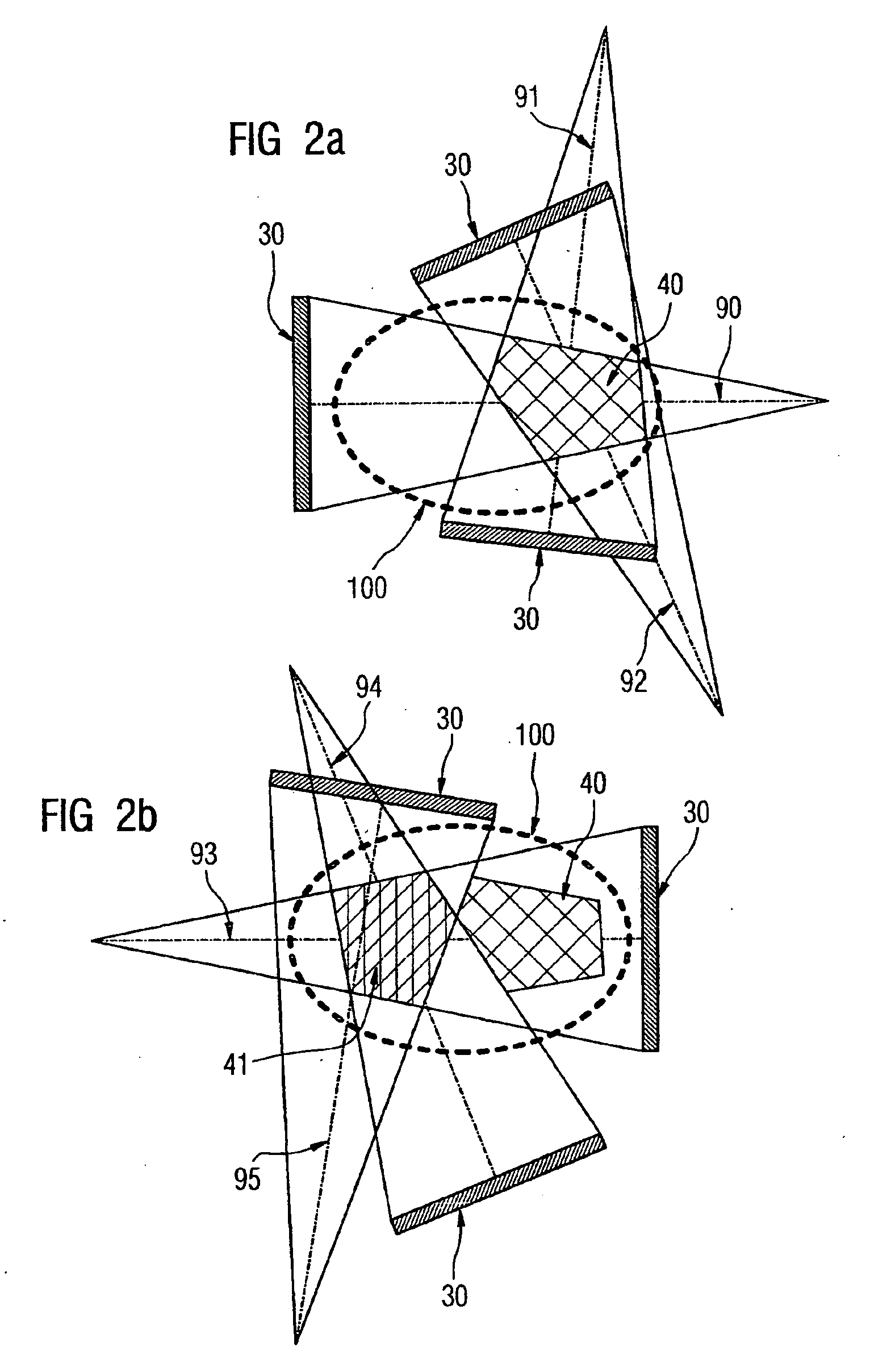

Method for generating a medical image and a medical imaging system

InactiveUS20080009717A1Free positioningLarge structure sizeReconstruction from projectionDiagnostic recording/measuringObject structureMedical imaging

The invention relates to a method for generating a medical image with at least one emission source and at least one detector of a medical imaging system, with the radiation from the emission source penetrating the object and attenuated by the object being detected by the detector to generate the medical image as a mapping of the object structure. The invention also relates to a medical imaging system for the generation of image data as a basis for the generation of a medical image. By the provision of a freely positionable emission source and a detector, the possibility of expanding the overlap area of the radiation thus detected up to the structural limits of the medical imaging system is provided. A volume image data record, e.g. a computer tomography (CT), thus forms the complete investigation object located between the emission source and the detector.

Owner:SIEMENS HEATHCARE GMBH

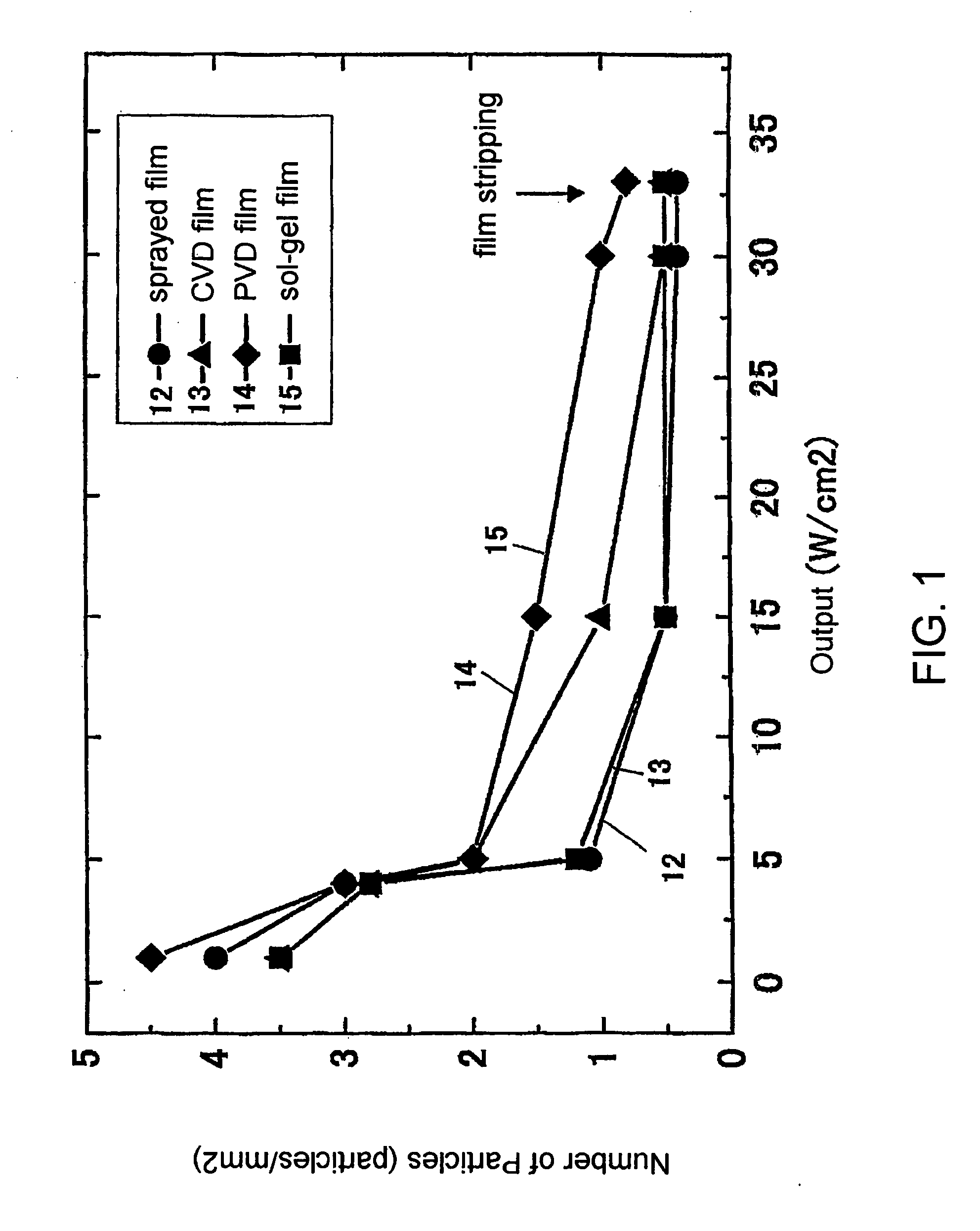

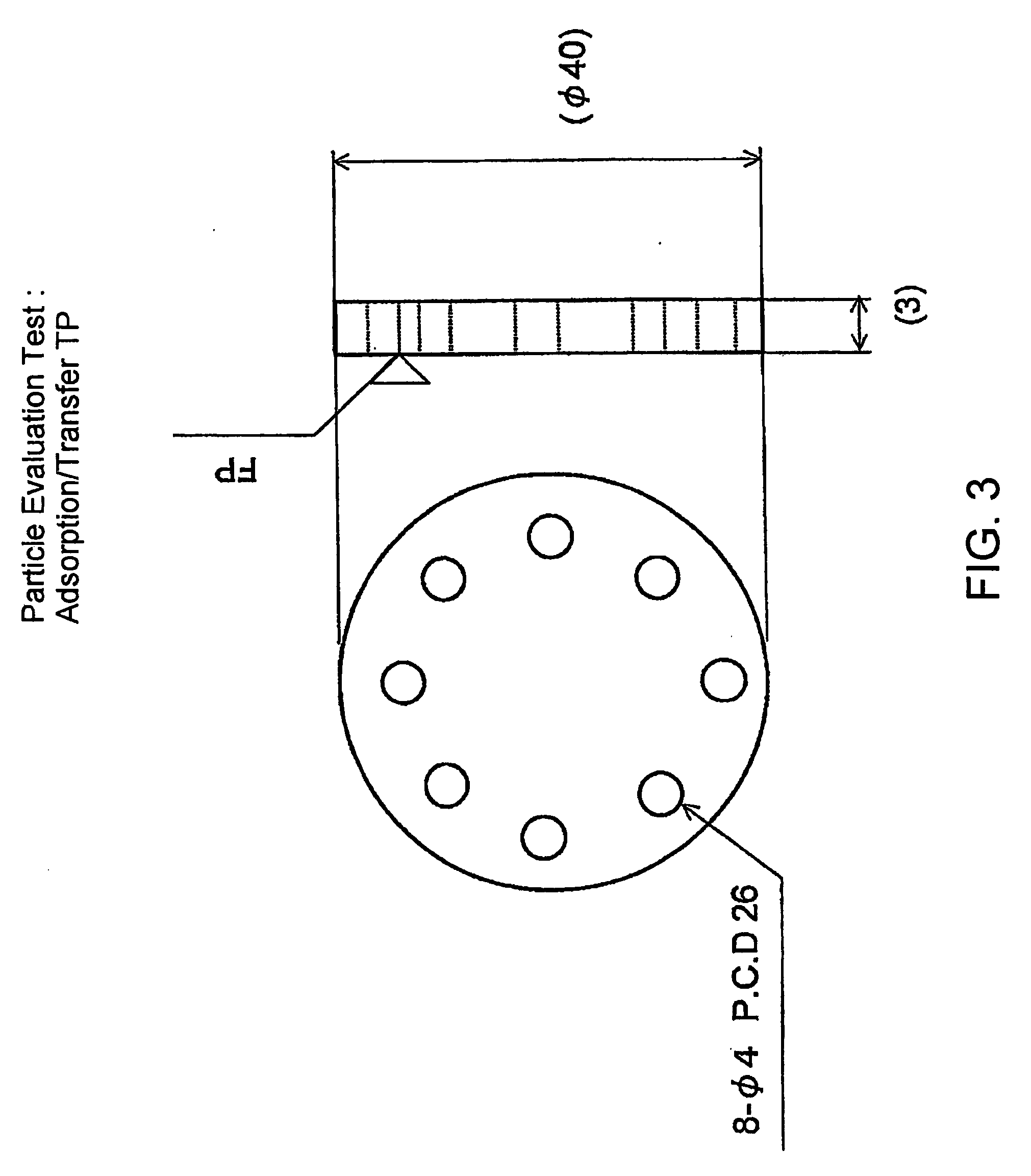

Multilayer structural body and method for cleaning the same

InactiveUS20090133713A1Quickly and economically copeLarge structure sizeMolten spray coatingElectrostatic cleaningMetallurgyCleaning methods

It has been difficult to provide a large-sized ceramic member quickly and economically. A multilayer structure is produced by forming a ceramic film on a base which is made of a material that can be shaped comparatively easily. The ceramic film is formed by a plasma spraying method, CVD method, PVD method, sol-gel method or the like. Alternatively, the ceramic film may be formed by a method combined with a spray deposit film.

Owner:TOHOKU UNIV +1

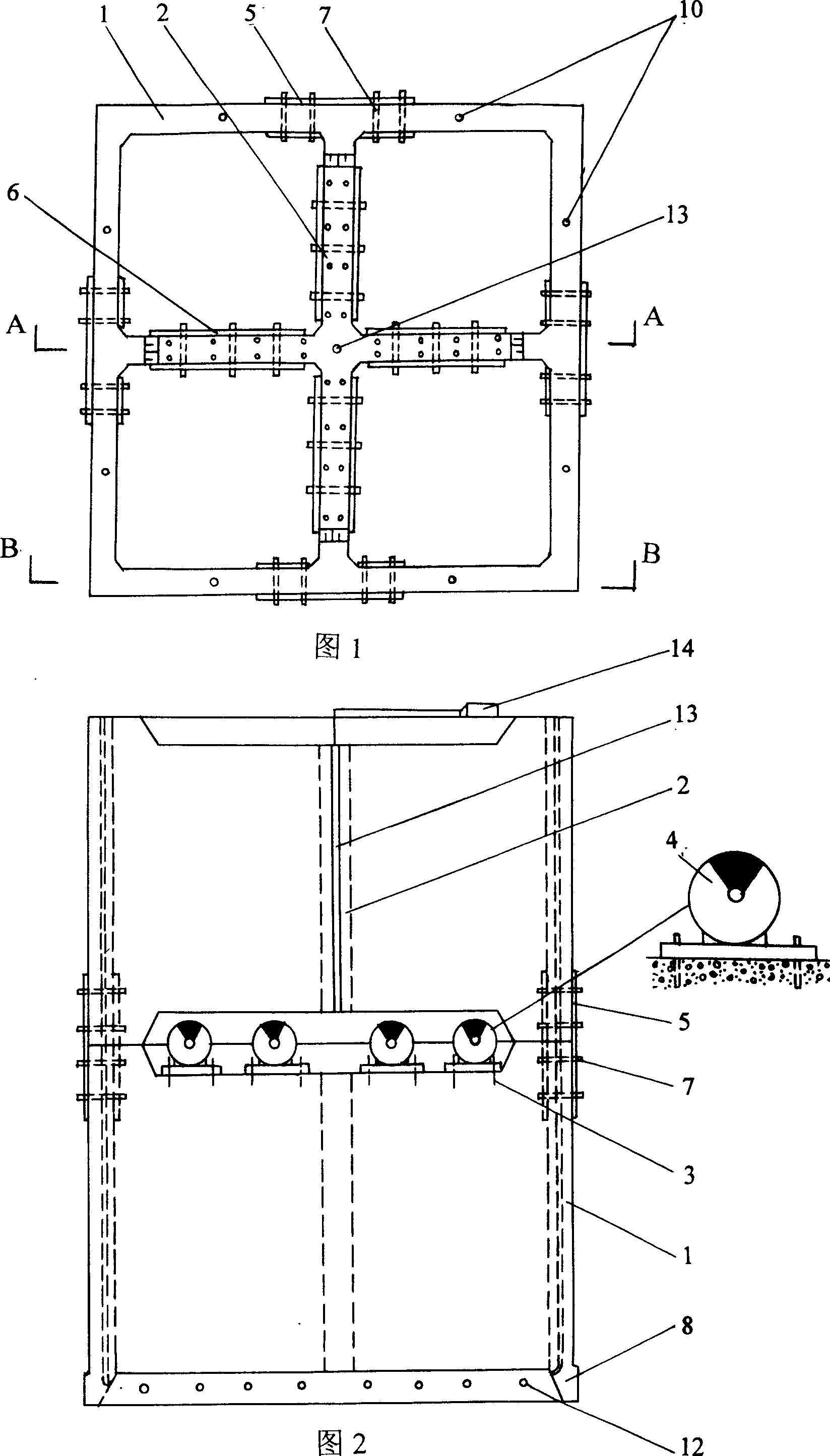

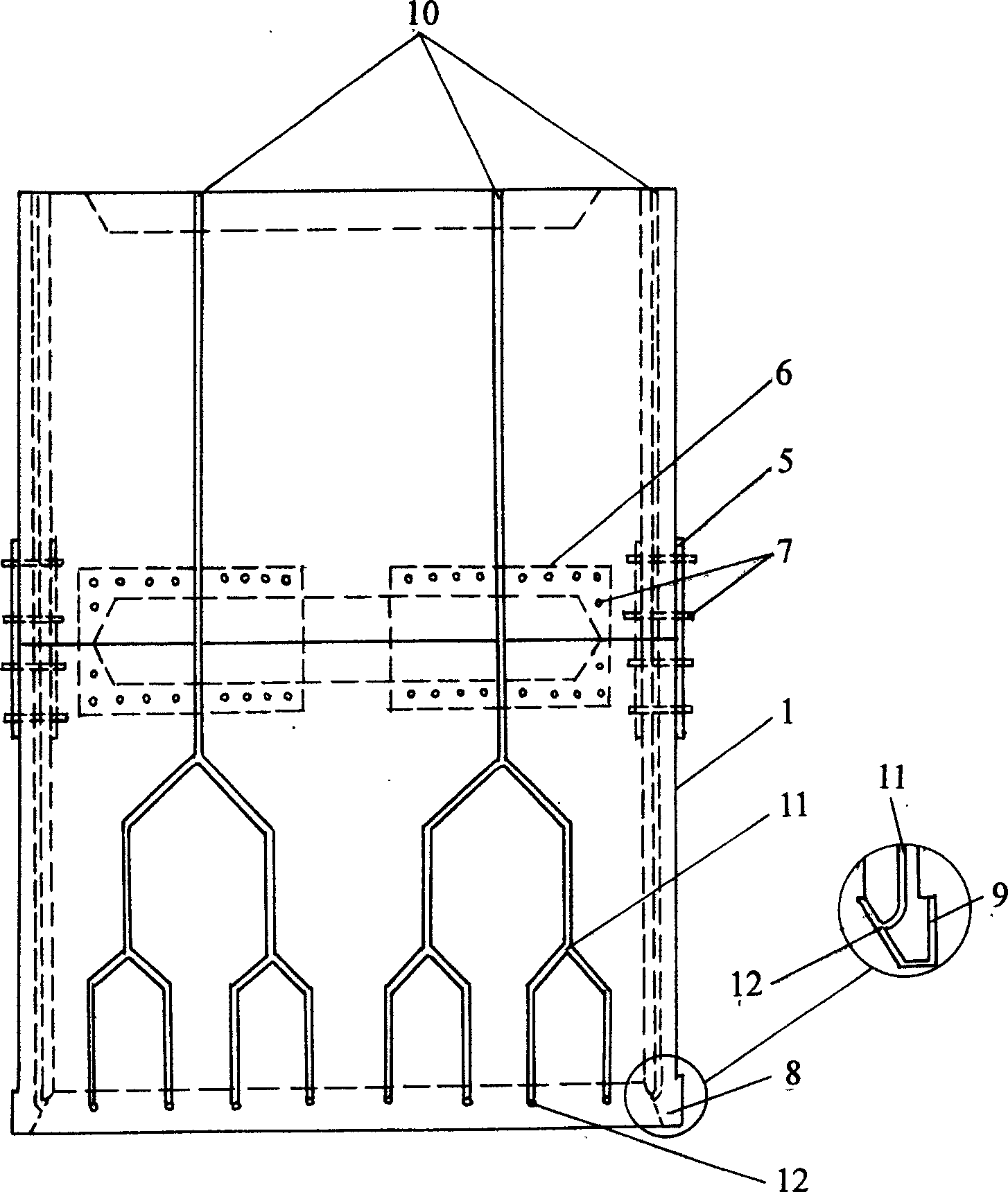

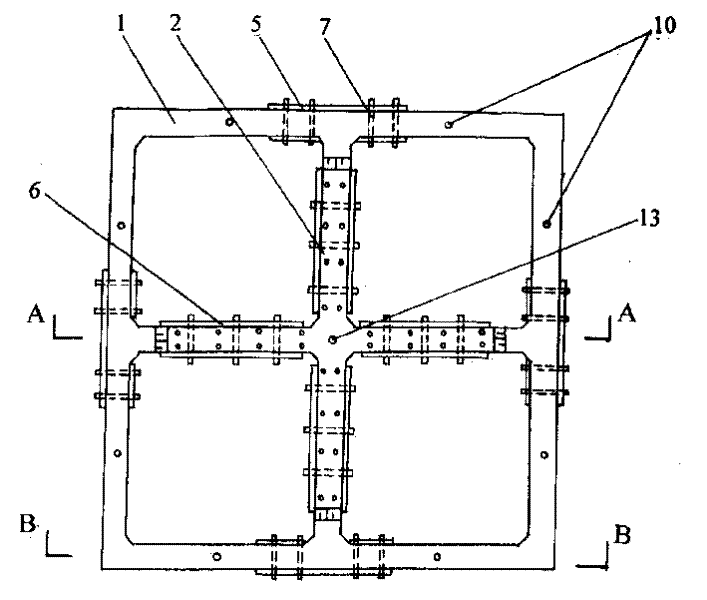

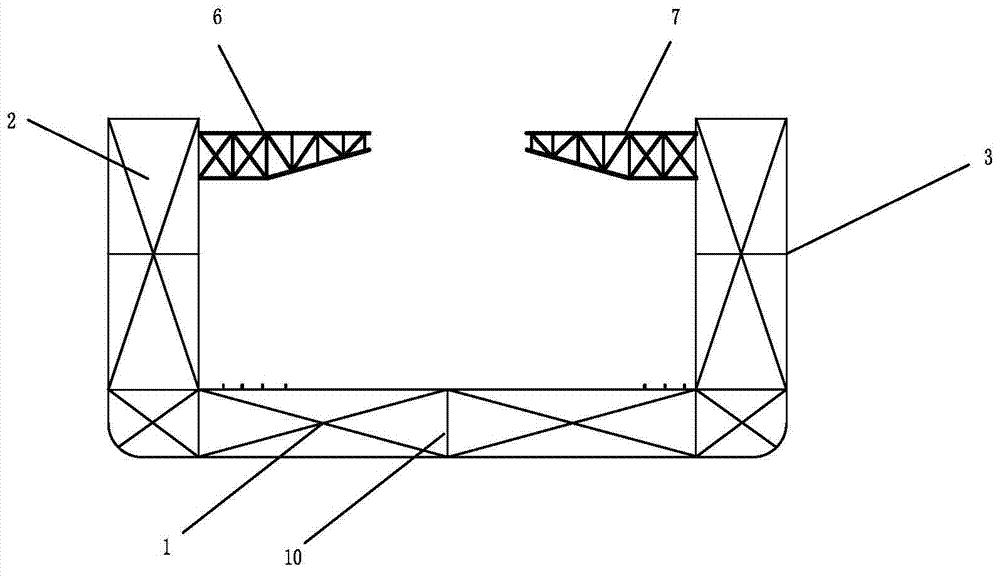

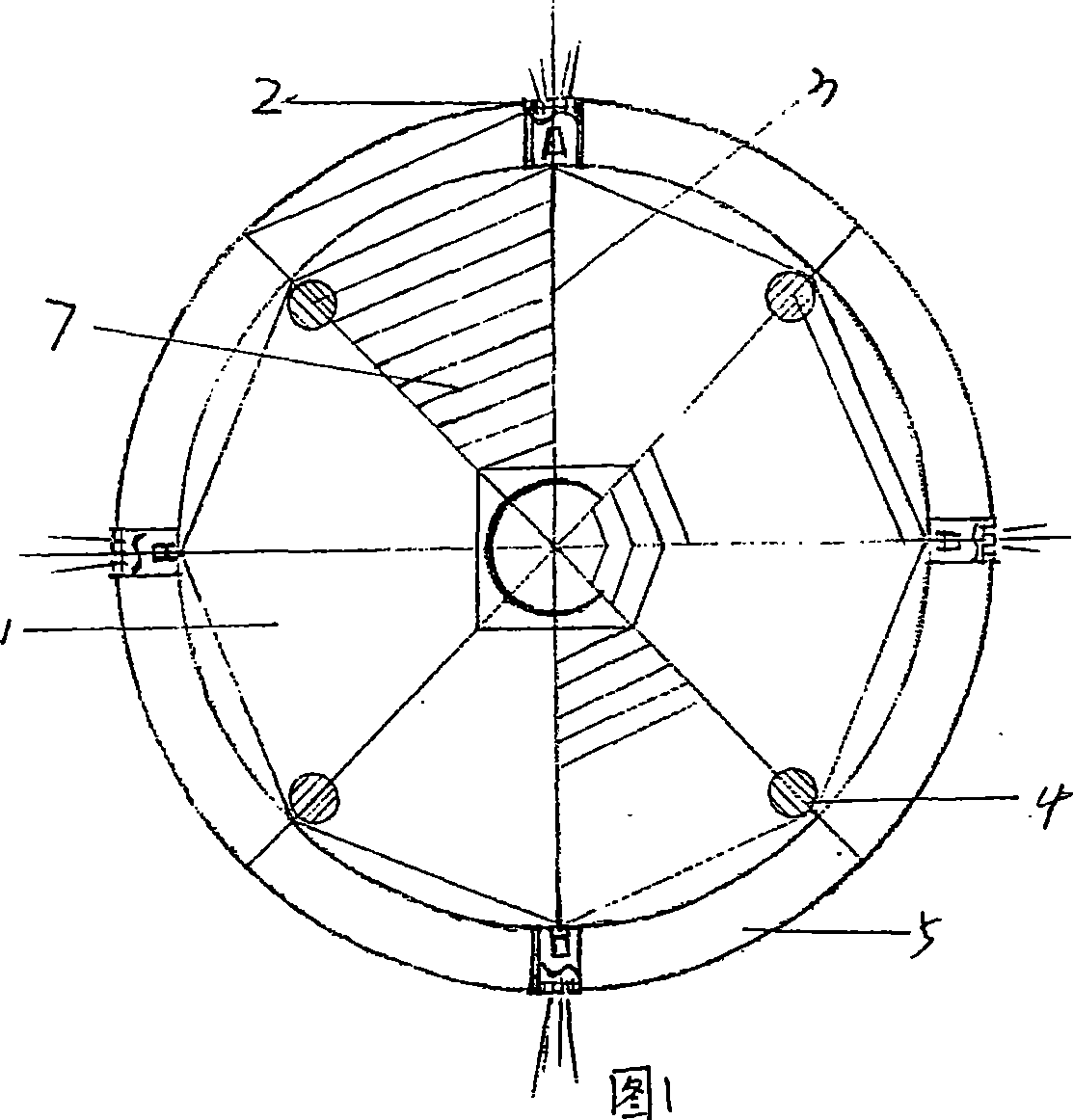

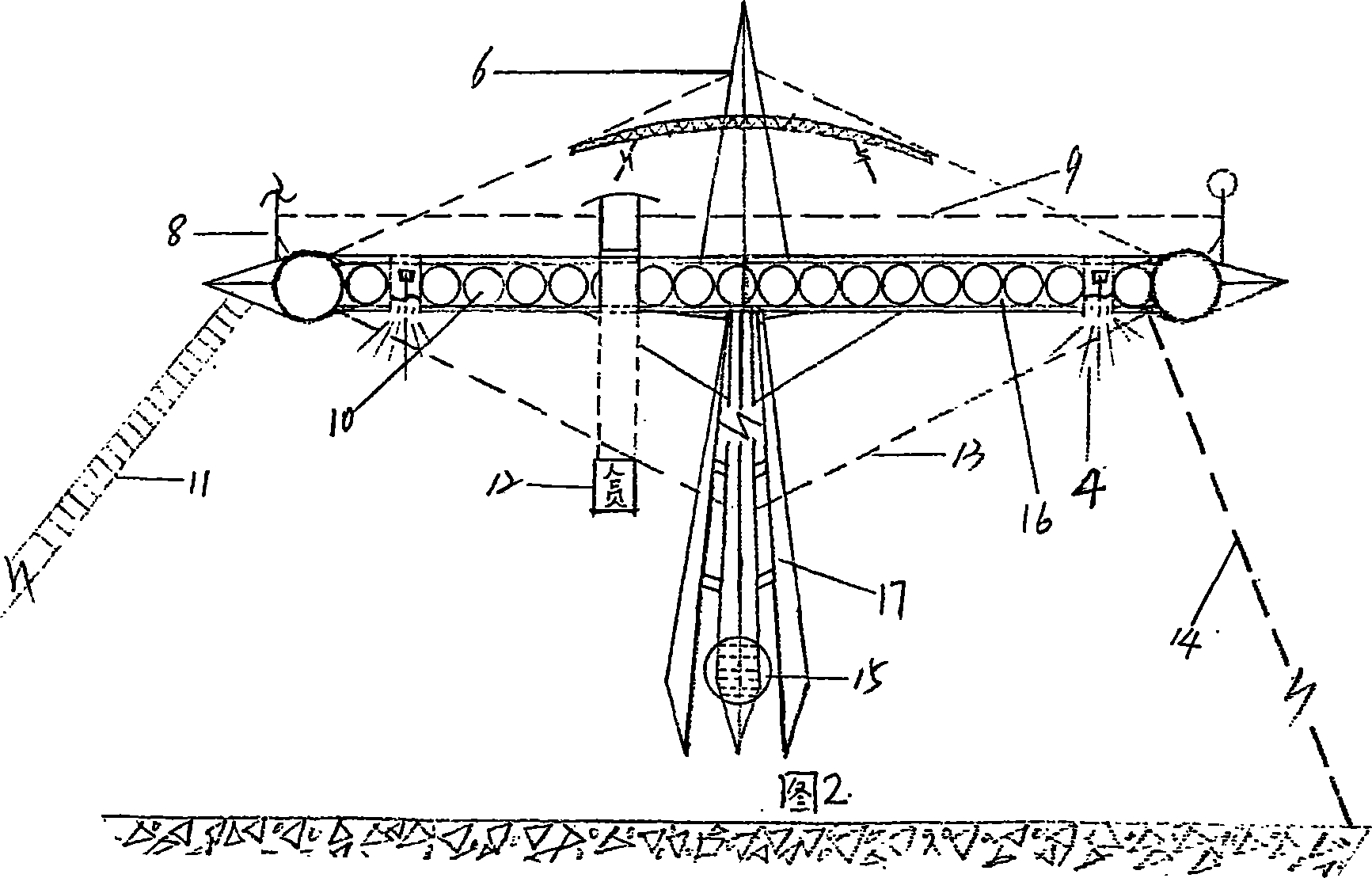

Caisson structure and fast construction method of opencaisson

The caisson structure contains caisson walls to constitute the caisson enclosure separated into several sections, and partition walls and crossbeams inside the caisson enclosure. There are edged feet in the lowest caisson section, steps on the containing partition walls between each two sections, vibrators inside the steps, built-in high pressure water pipe inside the caisson walls, branch pipes, built-in cable tubes communicated with the vibration controller, and clamping steel plates around the upper and the lower caisson enclosures and on two sides of the partitions to integrate the caisson structure. The fast construction method of open caisson includes sectional prefabrication, sectional installation and sectional stamping until reaching the designed height, and has fast construction speed and low cost.

Owner:王民寿

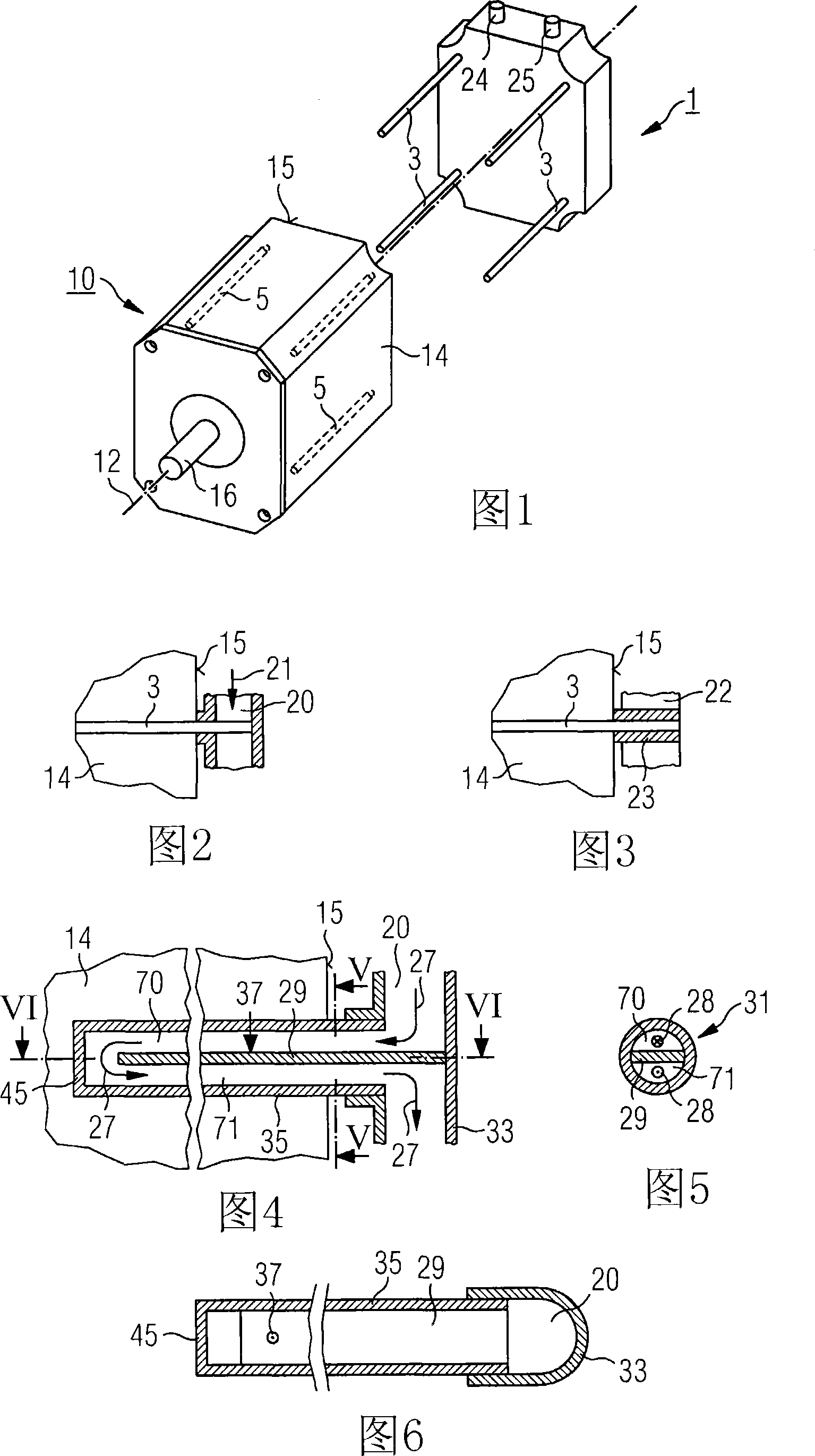

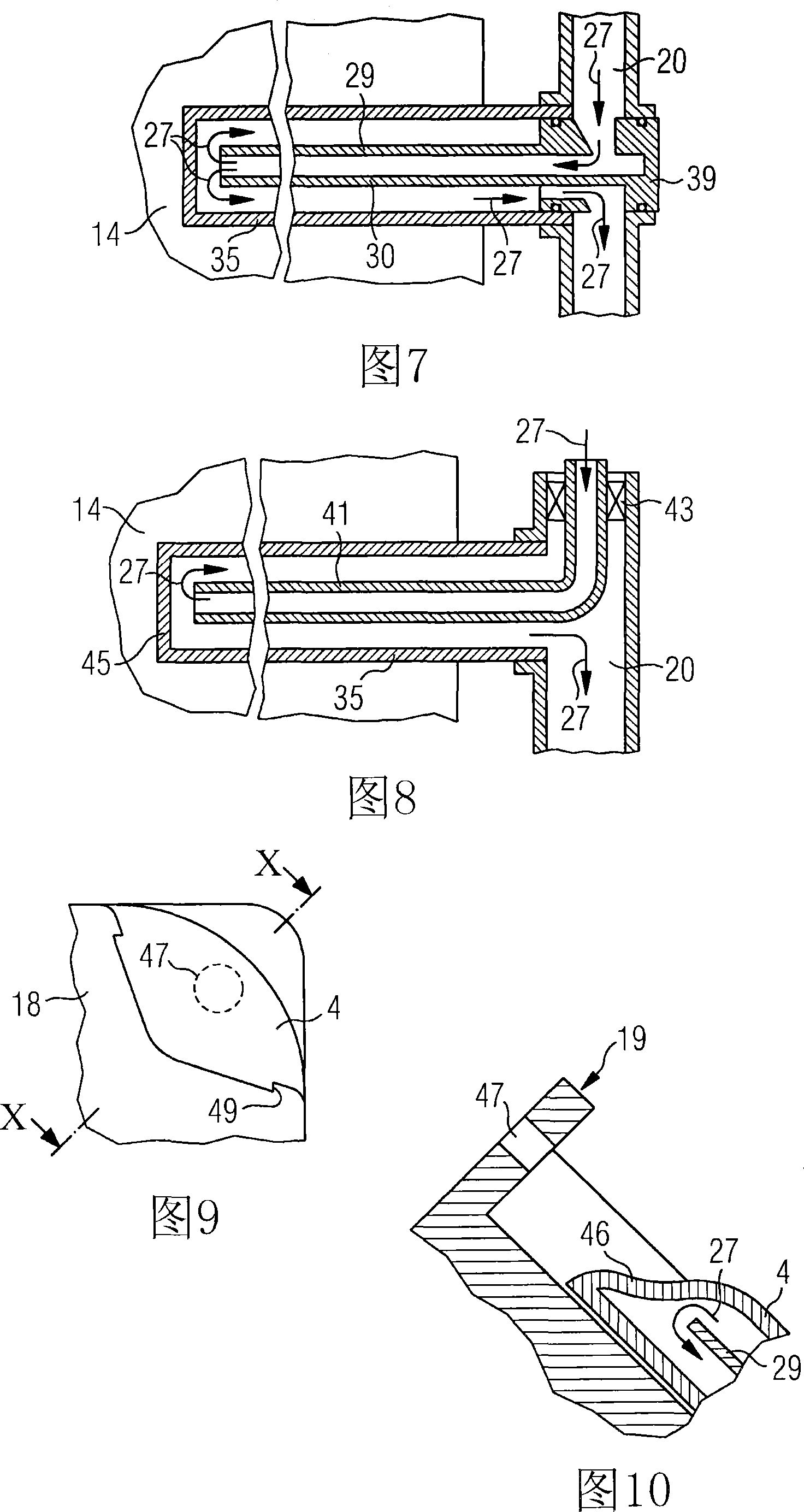

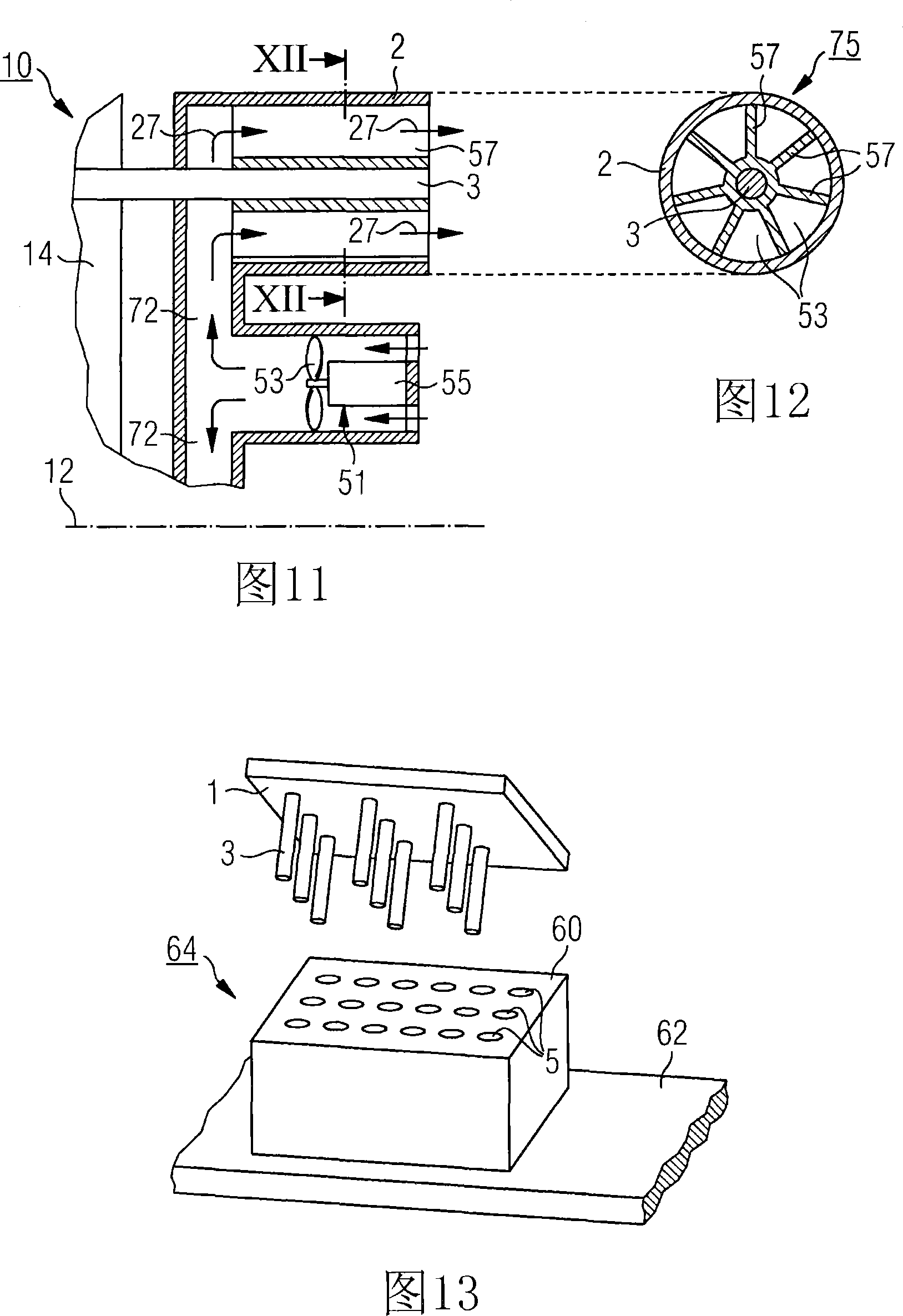

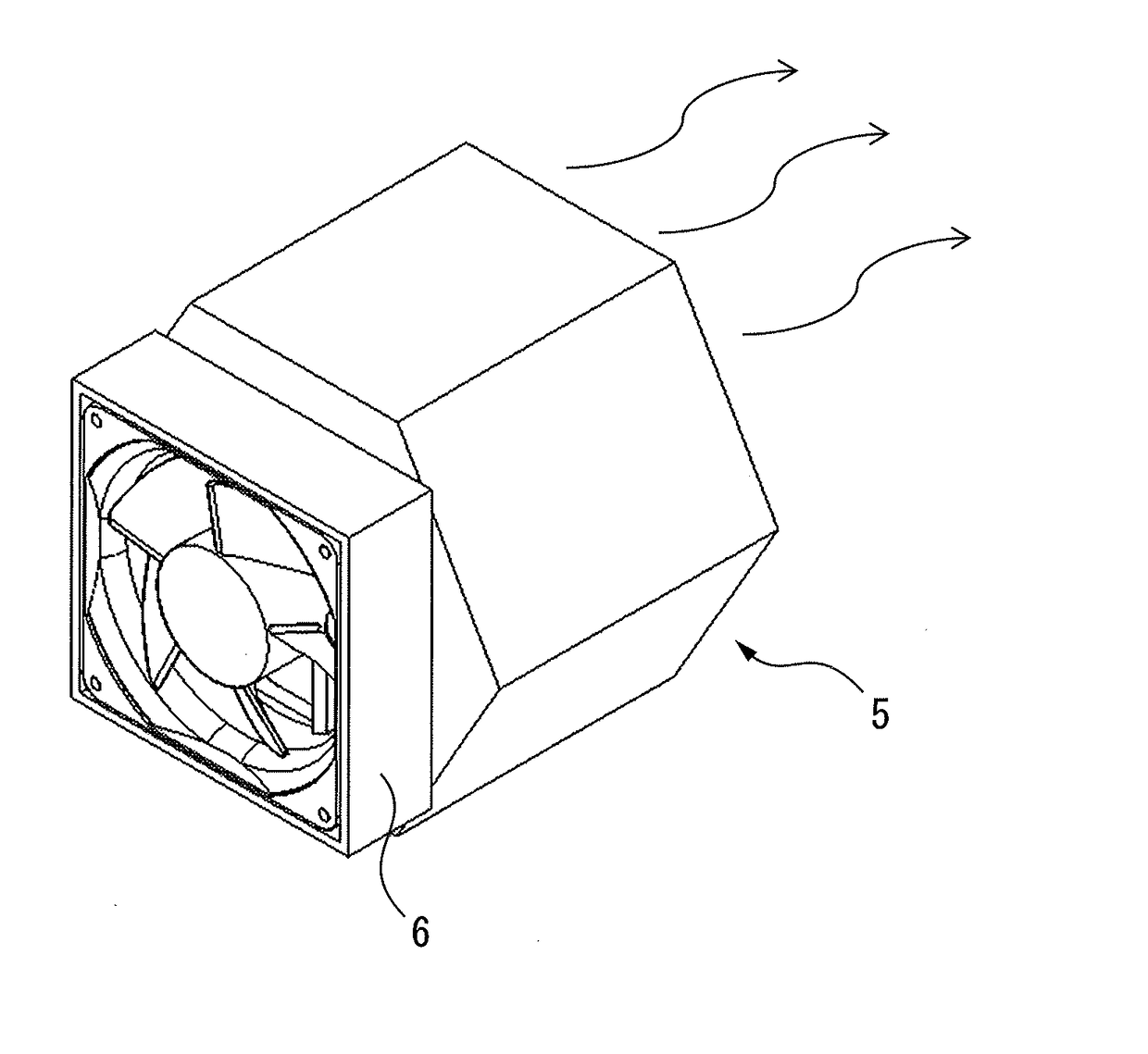

Cooling device pertaining to an electrical machine

InactiveCN101023572AIncrease cooling surfaceLarge structure sizeCooling/ventillation arrangementPropulsion systemsElectric machineHeat conducting

The invention relates to a cooling device (1,2) pertaining to an electrical machine (10), said cooling device (1,2) comprising at least one rod-shaped heat-conducting means (3,4) for heat-conductive connection to the electrical machine (10). The invention also relates to an electrical machine (10) comprising a housing (18) and / or a stator (14), said housing (18) and / or stator (14) being applied to a cooling device (1,2) comprising a rod-shaped heat-conducting means (3,4) extending axially in relation to the electrical machine. Said heat-conducting means (3,4) is to be received by the stator (14) and / or the housing (18) or arranged on the stator (14) and / or the housing (18).

Owner:SIEMENS AG

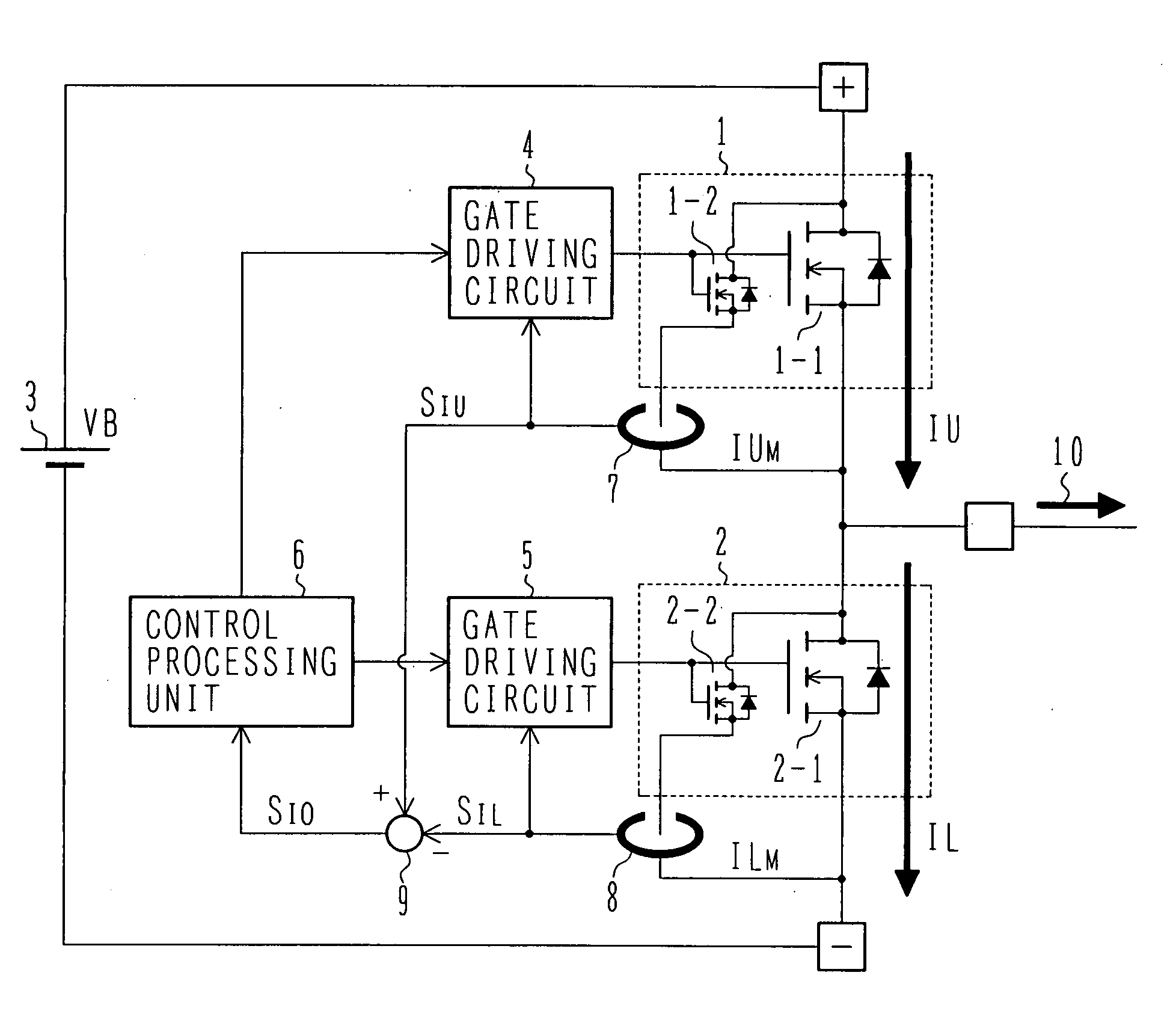

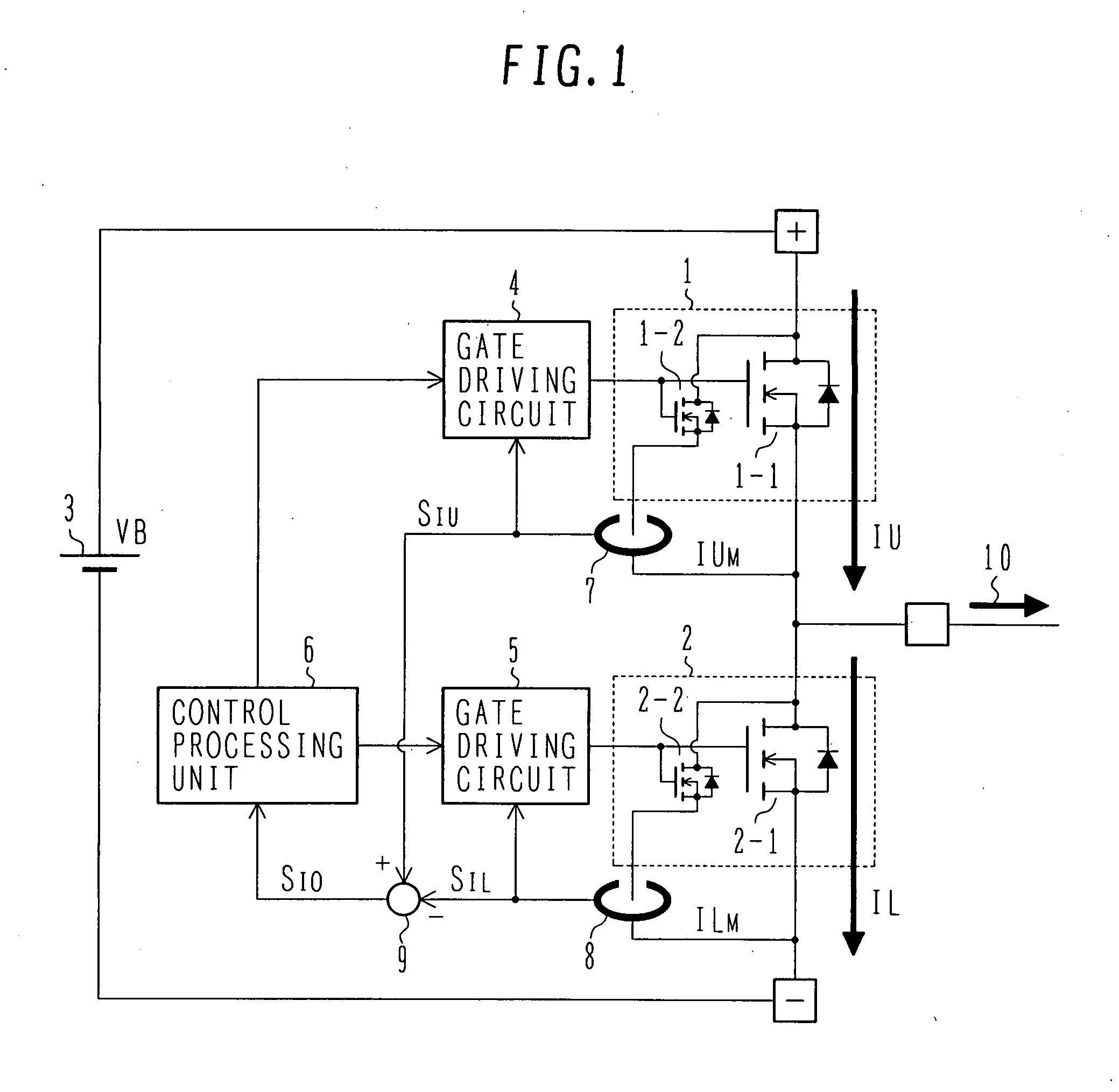

Power converter

InactiveUS20070229050A1Improve accuracySmall sizeTransistorElectronic switchingPositive powerDirect current

A power converter having a high side switching device and a low side switching device that are connected in series between a positive power supply terminal and a negative side power supply terminal for direct current, the connection point between the high side switching device and the low side switching device being set as an output terminal, and each of the high side switching device and the low side switching device being constructed by a switching device to which a current mirror device is appended, further including a high side current detecting unit for detecting current flowing in the current mirror device of the high side switching device, and a low side current detecting unit for detecting current flowing in the current mirror device of the low side switching device. A signal detected by the high side current detecting unit and a signal detected by the low side current detecting unit are differentiated from each other and set as a current value of the output terminal.

Owner:HITACHI LTD

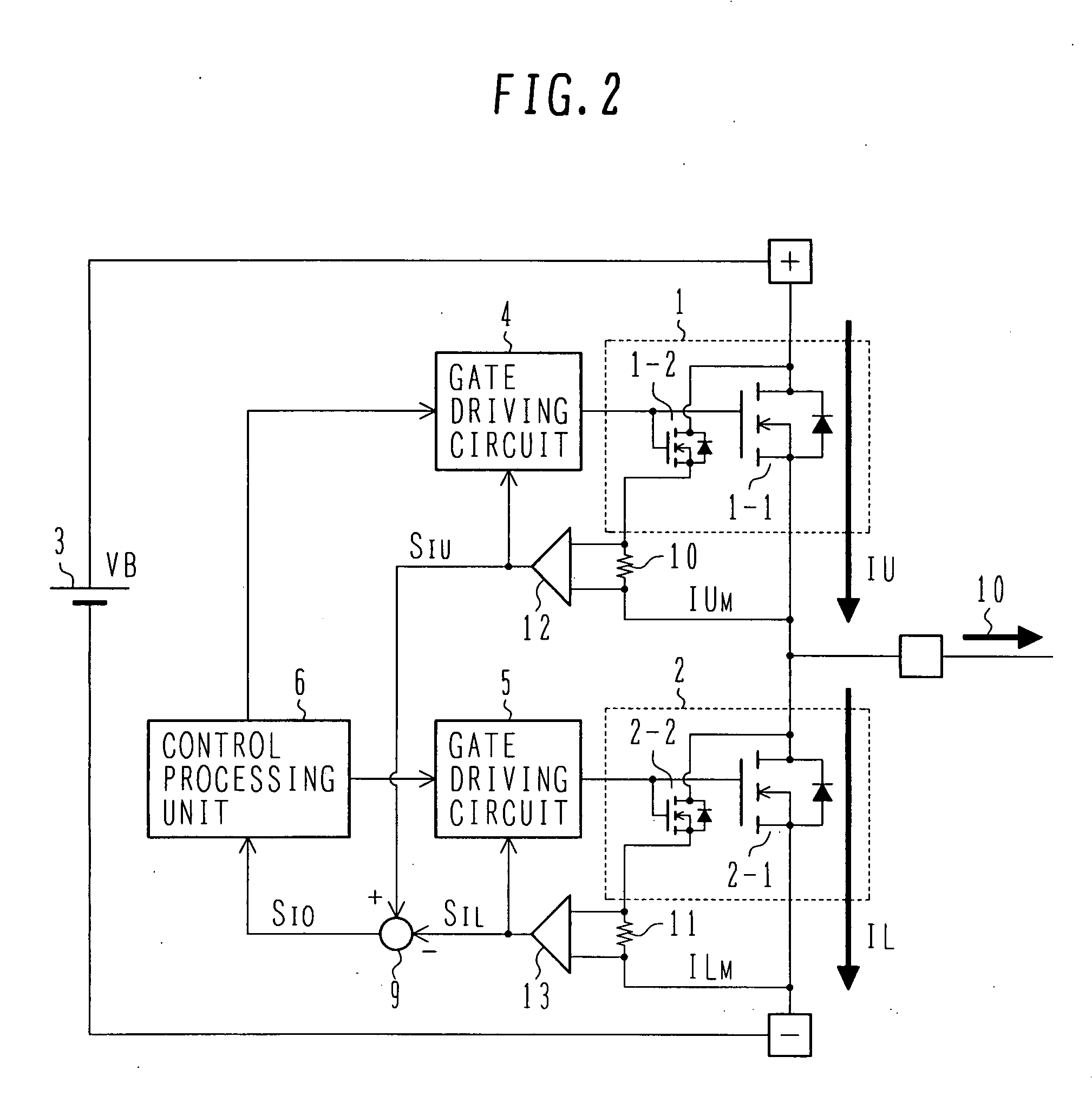

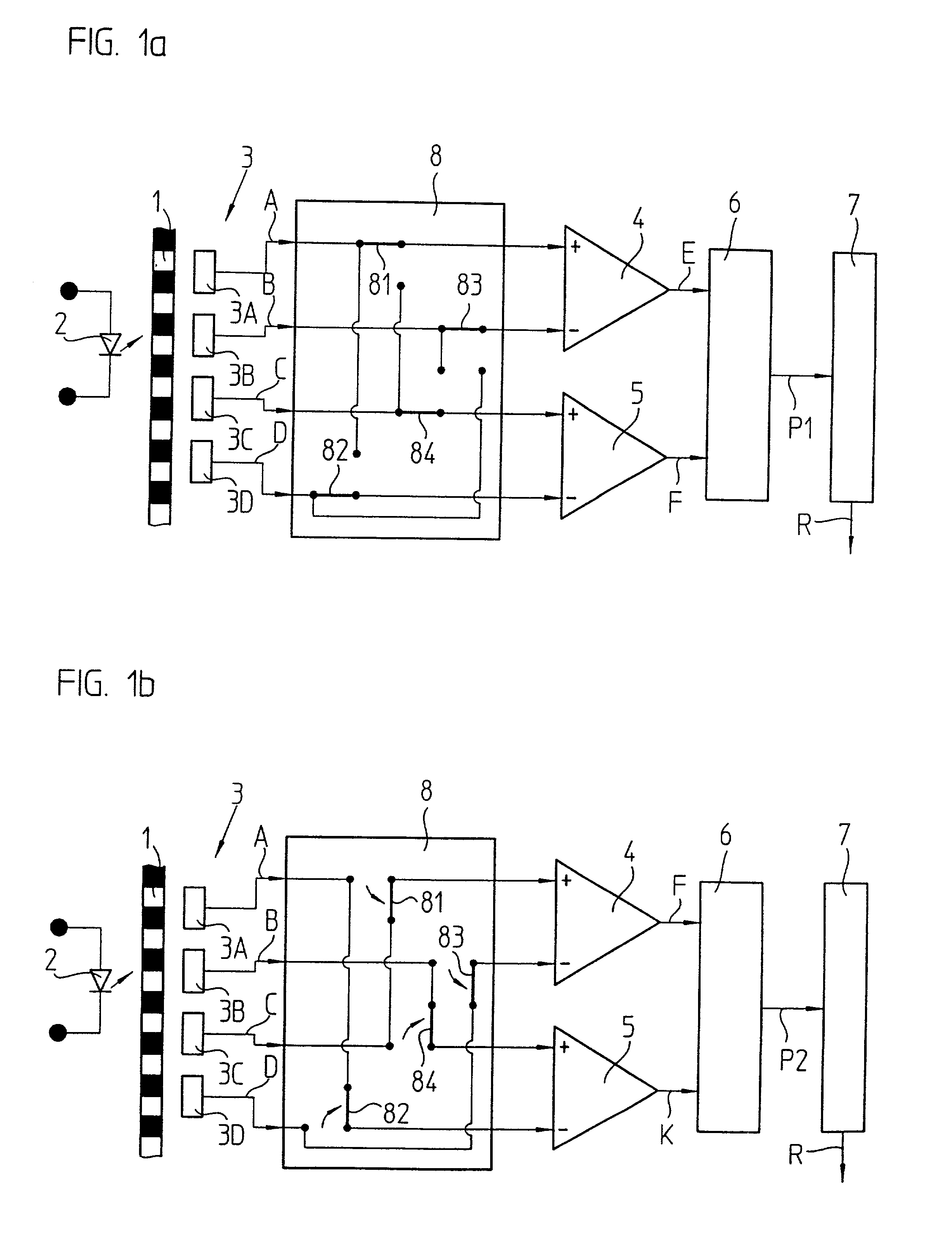

Position measuring system

InactiveUS7031031B1Large structure sizeSimply performedDigitally marking record carriersDigital computer detailsEngineeringError signal

A method for the functional control of a position measuring system that includes placing a scanning unit at a position with respect to a graduation, generating a first scanning signal and a second scanning signal during the displacing, forming a first measured position value, P1, in accordance with a first linkage rule that involves the first scanning signal and the second scanning signal and forming a second measured position value, P2, in accordance with a second linkage rule that involves the first scanning signal and the second scanning signal, wherein the first linkage rule differs from the second linkage rule. Comparing the first measured position value, P1, with the second measured position value, P2, and generating an error signal as a result of the comparing.

Owner:DR JOHANNES HEIDENHAIN GMBH

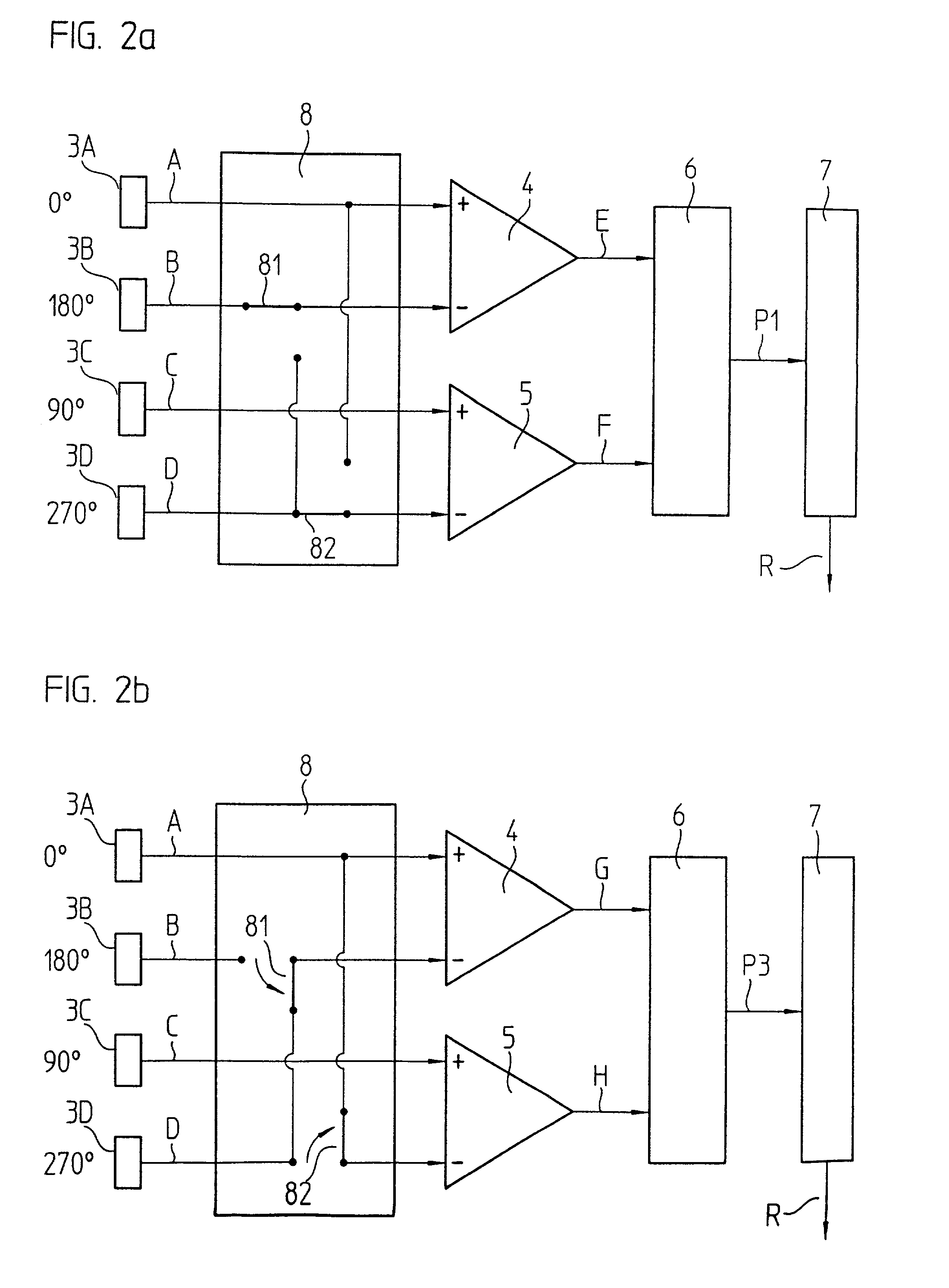

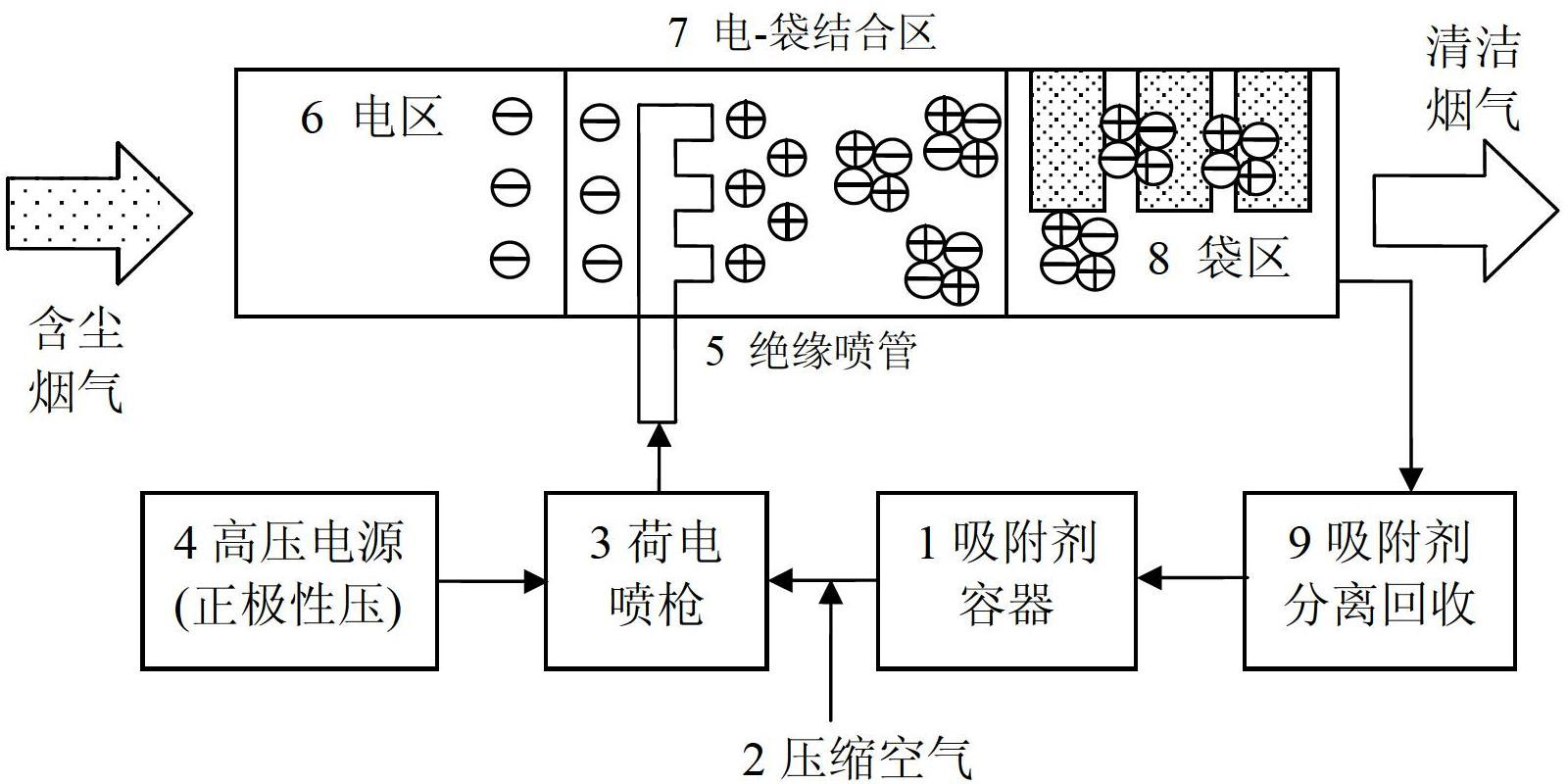

Method for removing fine particles and heavy metals in coal fume

ActiveCN102773162ALarge structure sizeLess investmentElectrostatic separationVortex flow apparatusSorbentPre-charge

The invention relates to a method for removing fine particles and heavy metals in coal fume. The method is an electric precipitator coupling charging absorbing agglomeration technology. The method comprises the steps of: pre-charging (positive charge) on an adsorbent by a charging spray gun, and spraying the adsorbent to an area between two adjacent electric fields of the electric precipitator; by a Coulomb agglomeration action between a positively charged absorbent particle and a fine particle which is negatively charged by last electric field and is not captured, and an absorption action of the charged absorbent, capturing a plurality of pollutants including fine particles, heavy metals and condensable substances, onto the absorbent to form larger particles; and efficiently capturing the larger particles by the electric field at the back of the electric precipitator, so as to achieve the purpose of synergistically removing a plurality of pollutants in smoke. Compared with prior art, the method of removing fine particles and heavy metals in coal fume has the advantages of high efficiency and low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

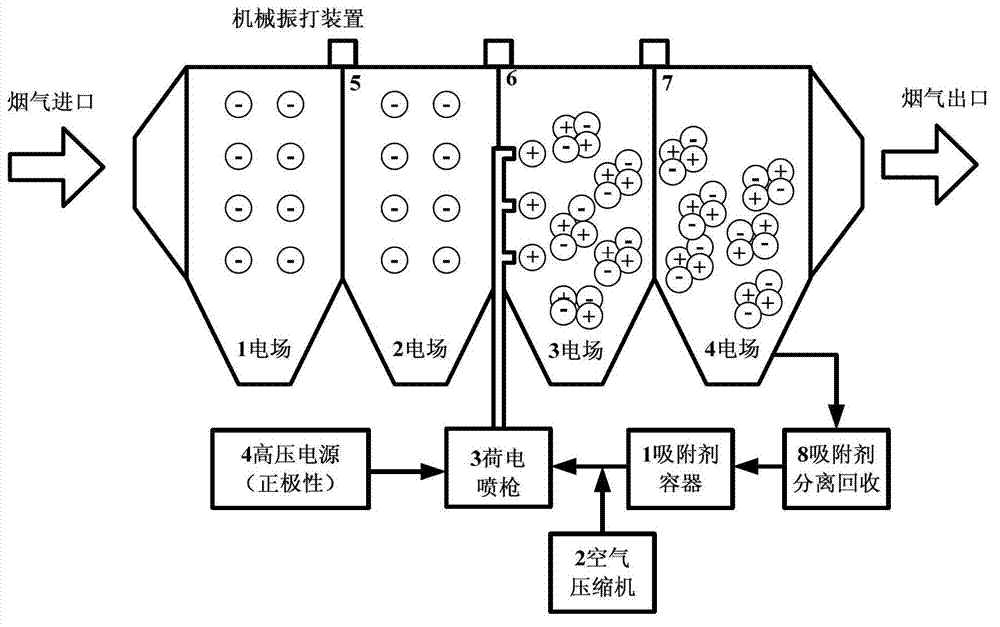

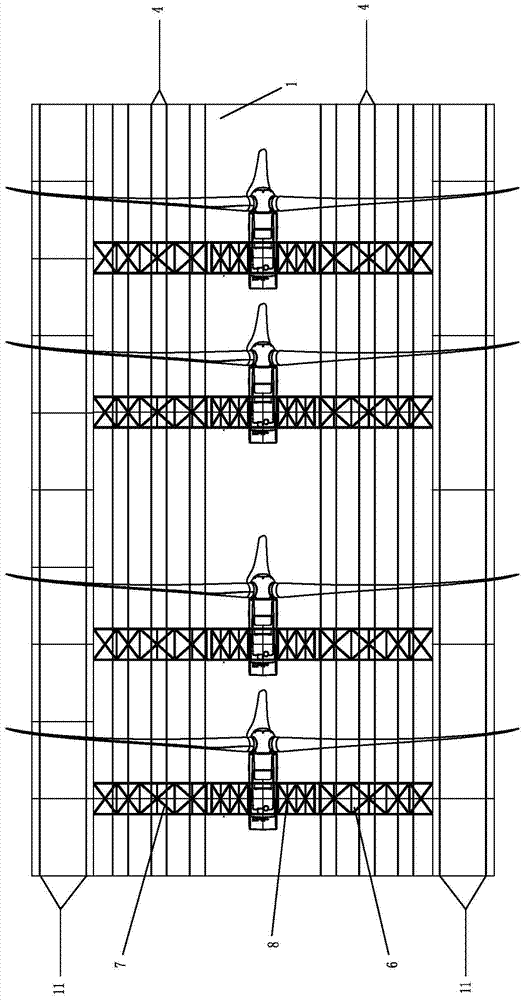

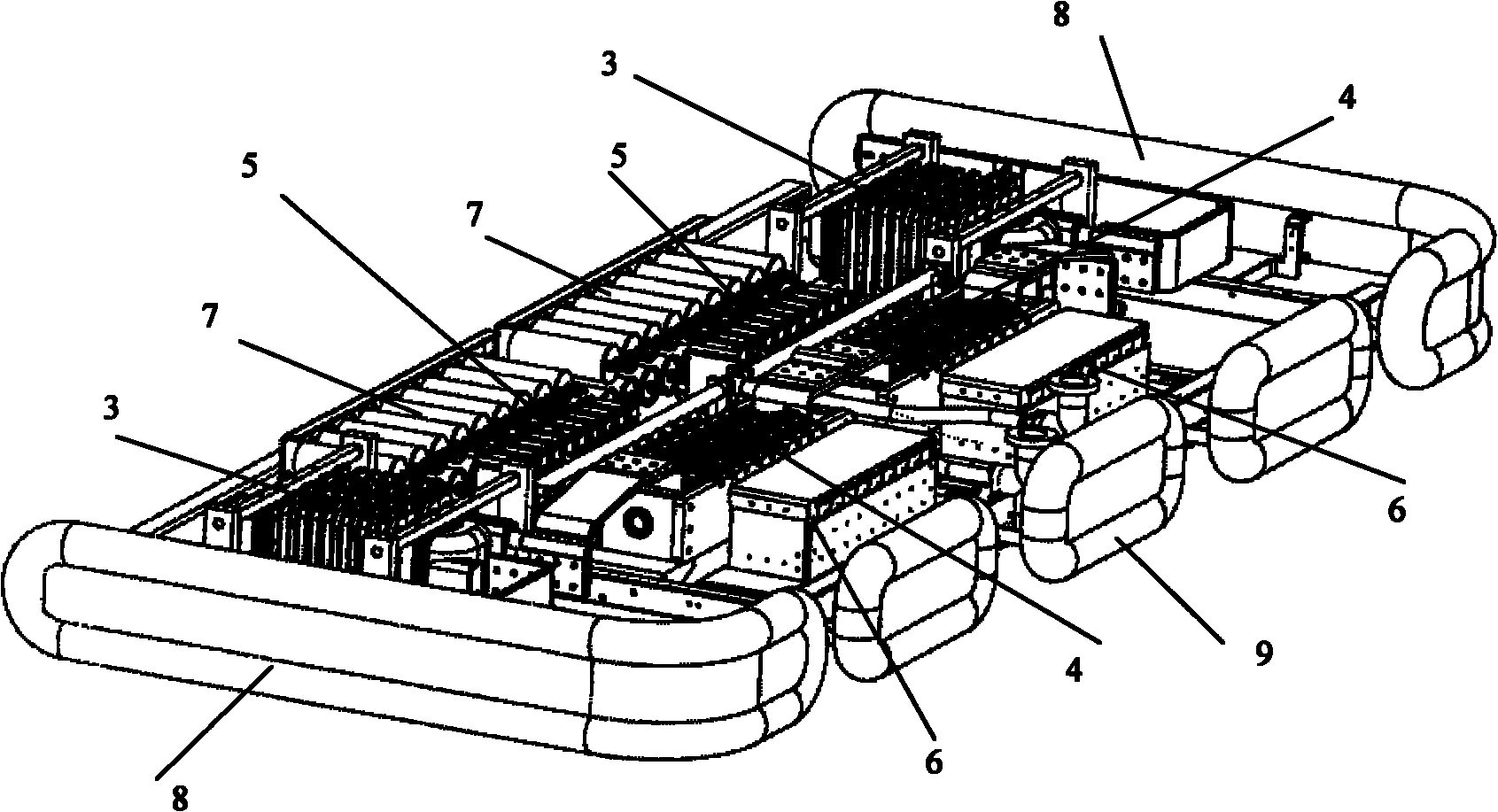

Floating type offshore wind power assembly platform and method using floating type offshore wind power assembly platform for assembly offshore wind turbine

InactiveCN103693170ALarge structure sizeImprove stabilityWind energy generationFloating buildingsElectricityMarine engineering

The invention discloses a floating type offshore wind power assembly platform, which comprises a platform, wherein a left ballast tank, which is higher than the platform, is arranged on a left board of the platform, a right ballast tank, which is higher than the platform, is arranged on a right board of the platform, the platform is provided with a bottom ballast tank, a transportation guide rail is arranged on the platform, a fixed jacklift used for fixing a fan tower drum is arranged between the left ballast tank and the right ballast tank on the platform, a left board side fixing support is arranged on the inner side of the upper part of the left ballast tank, a right board side fixing support is arranged on the inner side of the upper part of the right ballast tank, a fixed lifting bracket used for fixing the fan tower drum is arranged between the left board side fixing support and the right board side fixing support, and cranes are both arranged on the left bulkhead and the right bulkhead of the platform. The floating type offshore wind power assembly platform has the advantages of large structure size and good stability, and can normally work under a certain storm condition; furthermore, the offshore construction difficulty is reduced, the construction period is shortened, the flexibility of construction is improved, and different schemes can be adopted for installation according to different wind field conditions.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

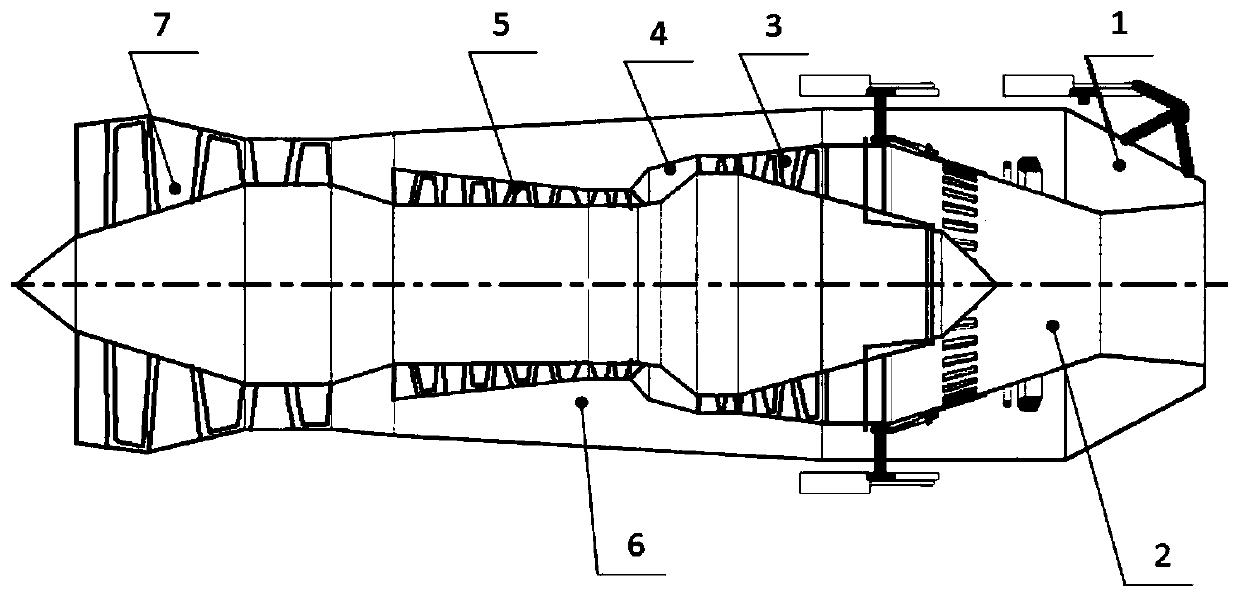

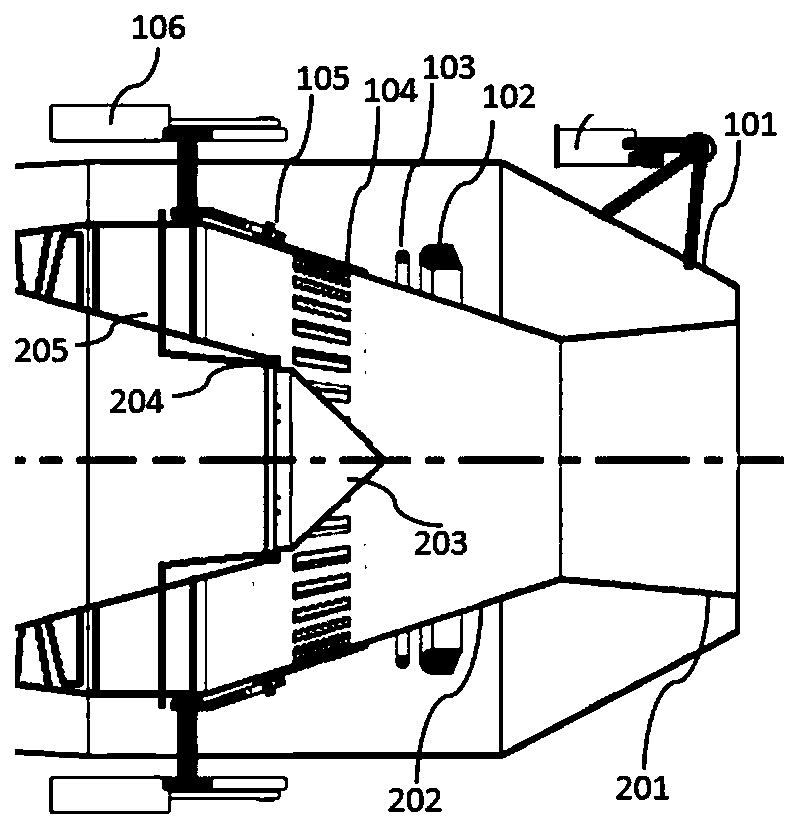

Turbofan engine

ActiveCN109854379AShorten the lengthRealize control areaGas turbine plantsJet propulsion plantsAviationCombustion chamber

The invention discloses a turbofan engine and belongs to the technical field of design of an aero turbofan engine. The engine comprises a second afterburner (2) and a first afterburner (1), wherein the second afterburner (2) comprises an afterburner inner spraying pipe and a main force exerting cavity; the afterburner inner spraying pipe is fixedly connected with the back end of an inner cylinder;the main force exerting cavity is positioned in the afterburner inner spraying pipe; a through hole is formed in the afterburner inner spraying pipe; the first afterburner (1) comprises an afterburner outer spraying pipe and an auxiliary force exerting cavity; the afterburner outer spraying pipe is fixedly connected with the back end of an outer cylinder; the auxiliary force exerting cavity is positioned between the afterburner outer spraying pipe and the afterburner inner spraying pipe; the first afterburner (1) also comprises a baffle; the baffle is controlled by an adjusting mechanism to close or open the through hole in the afterburner inner spraying pipe; and the opening section of the tail end of the afterburner outer spraying pipe is adjustable. The length and the weight of the afterburner are reduced by adjusting the afterburning condition of the main force exerting cavity and the auxiliary force exerting cavity.

Owner:AECC SHENYANG ENGINE RES INST

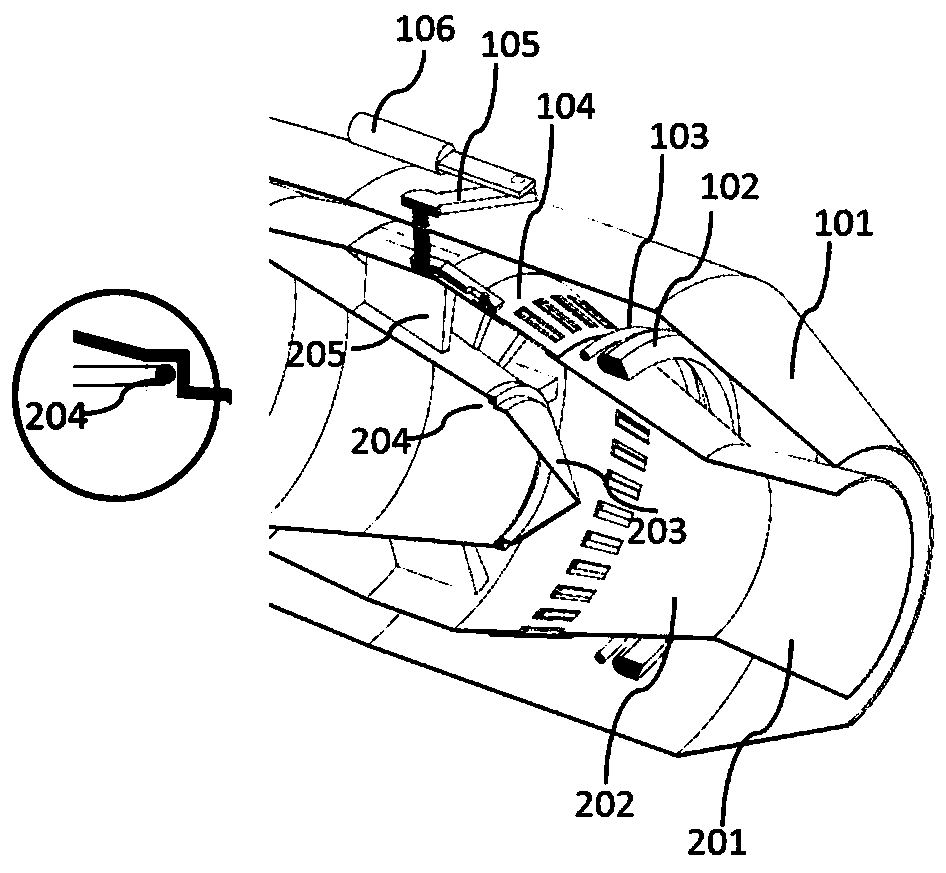

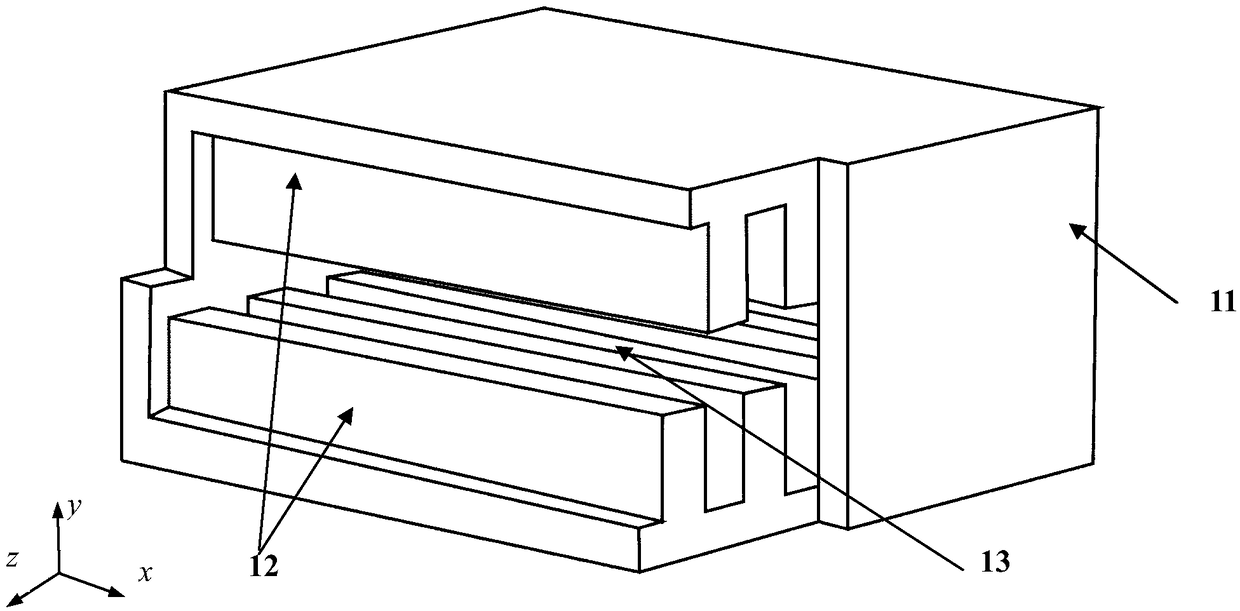

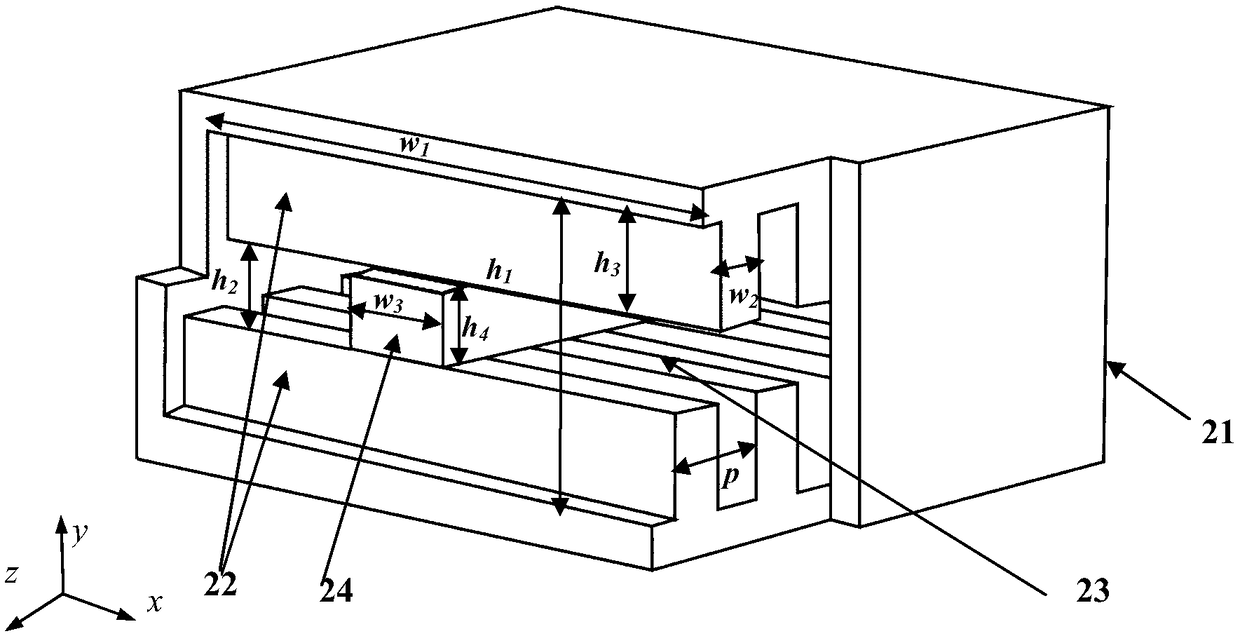

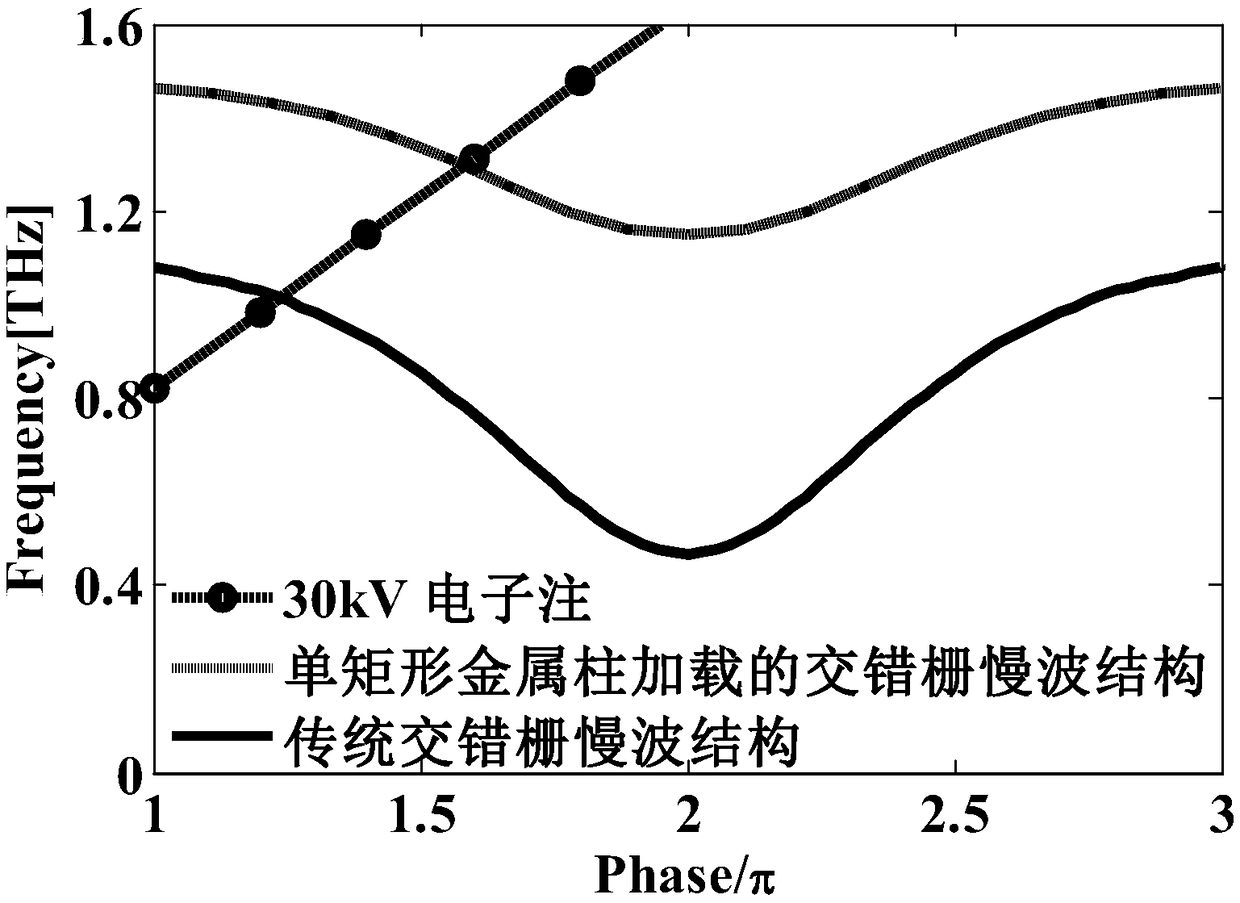

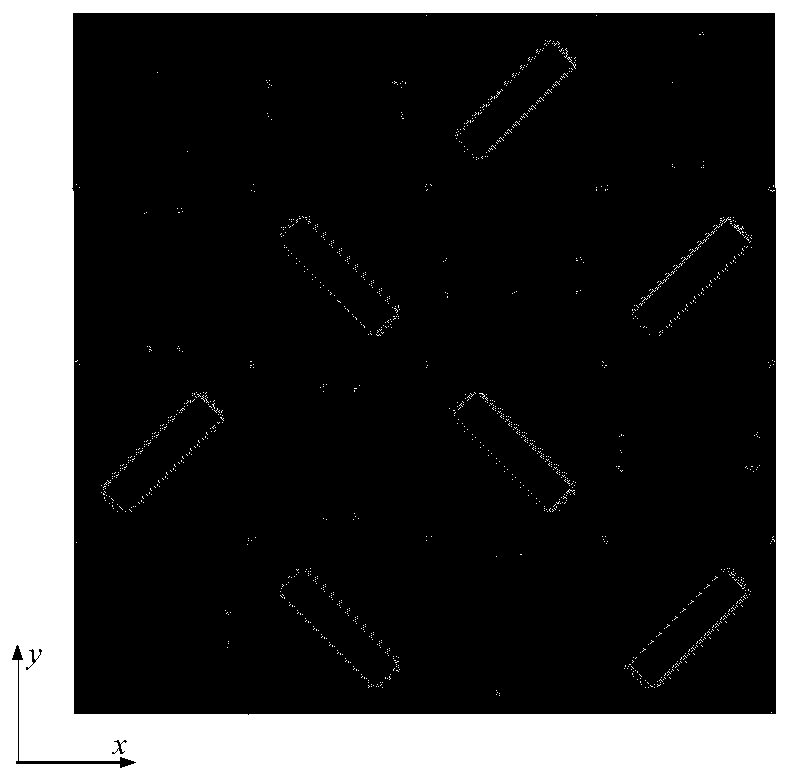

A staggered grid slow wave structure loaded by rectangular metal columns

InactiveCN108987221AIncrease working frequencyEasy processing and assemblyTransit-tube circuit elementsWave structureCommunications system

The invention discloses a staggered grid slow wave structure loaded by rectangular metal columns, which adopts a rectangular solid shell, rectangular grid teeth distributed along a longitudinal direction periodically on an upper top surface and a lower bottom surface of the shell, one or more rectangular metal columns loaded in the middle of the grid teeth and a structure composed of two band-shaped injection channels. The high-order mode operation of slow-wave structure can be realized by using the rectangular metal columns. This staggered grid slow-wave structure can effectively suppress thelow-order mode sum and work in the high-frequency band with the same structure size. The millimeter-wave terahertz traveling wave tube / backward wave tube based on this slow-wave structure has many advantages, such as compact structure, high electronic efficiency, high output power and so on. The structure has a wide application prospect in high data rate communication systems, high precision imaging systems, radar complete appliance systems and so on.

Owner:SHENZHEN UNIV

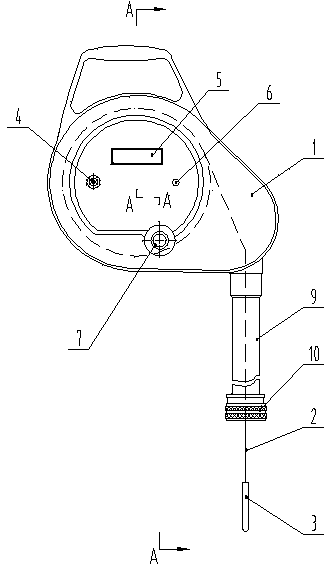

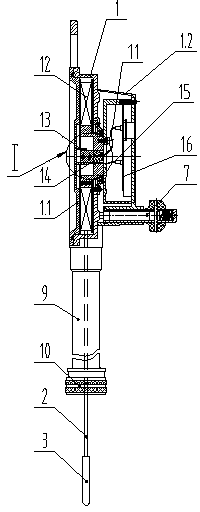

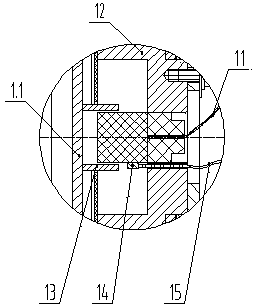

Digital display type oil-water interface detector

InactiveCN103837206AReduce labor intensityEasy to measureMachines/enginesLevel indicatorsRadial positionOil water

The invention discloses a digital display type oil-water interface detector which comprises a detector body, a measuring scale, a probe, a microprocessor, an LCD, a magnetic steel body and a rotation angle sensor. The detector body comprises a shell and a rotary disk. The measuring scale is formed by combining a flexible rule tape with scales and a guide wire. The probe is connected with the guide wire arranged in the measuring scale and extending out of the detector body. A flexible rule tape disk is arranged in the detector body. A medium sensor is arranged in the probe. The microprocessor is arranged in the rotary disk. The LCD is arranged on the front end face of the rotary disk. An output end of the microprocessor is connected with the LCD. The other end of the measuring scale in the detector body is connected with the microprocessor through the guide wire. The magnetic steel body is fixedly connected to the center of the shell. The rotation angle sensor is fixedly connected to the center of the flexible rule tape disk, and the rotation angle sensor corresponds to the magnetic steel body in radial position. The rotation angle sensor is connected with the microprocessor through the guide wire. The digital display type oil-water interface detector can obviously reduce influences of manual factors and carry out oil-water interface detection easily and accurately.

Owner:JIANGSU YUANWANG INSTR

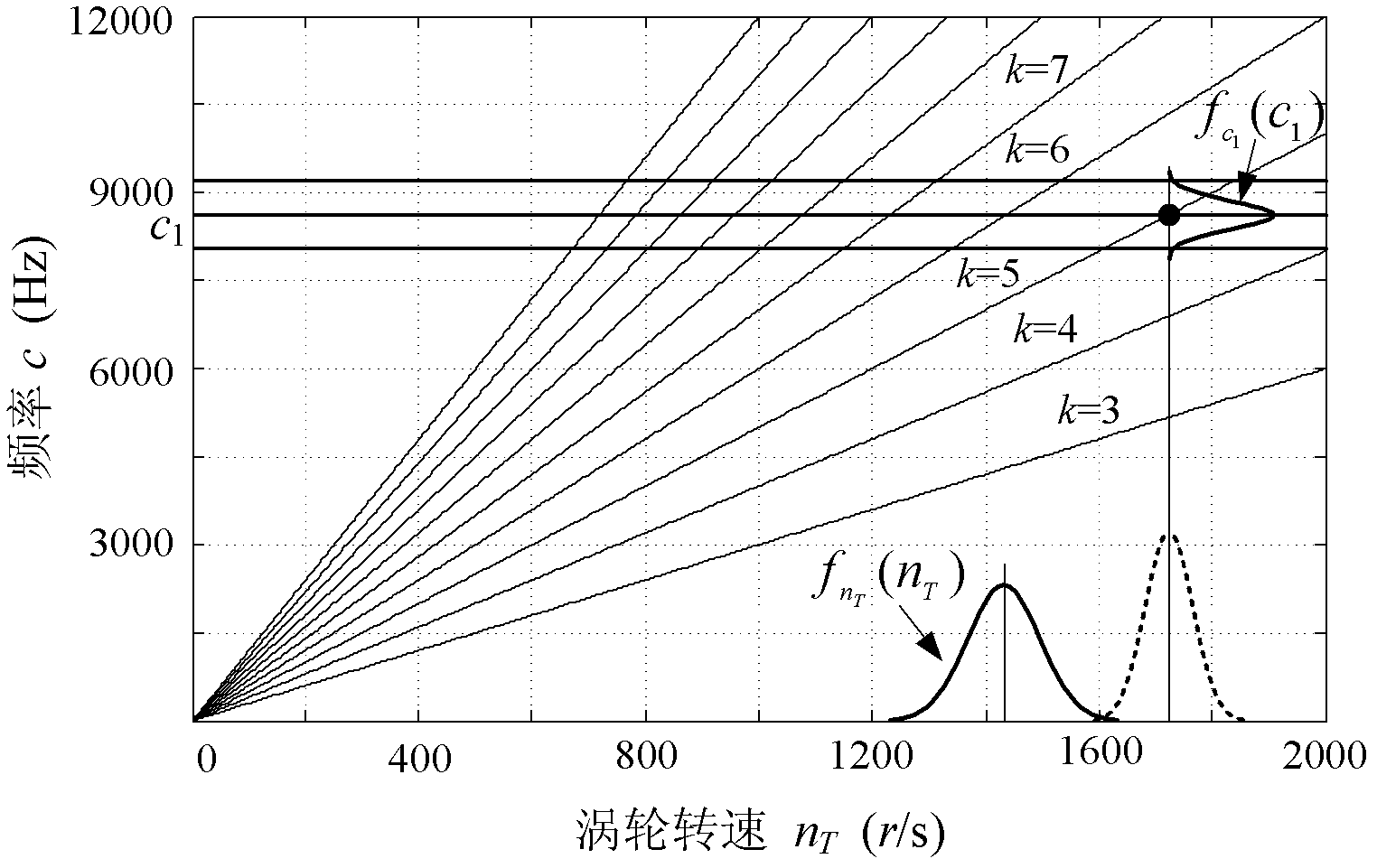

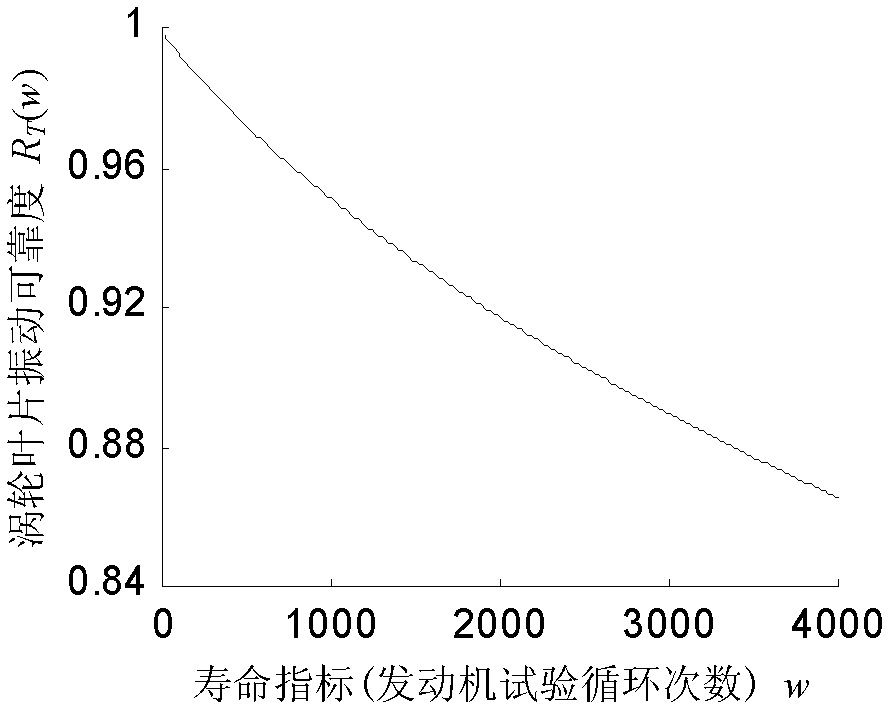

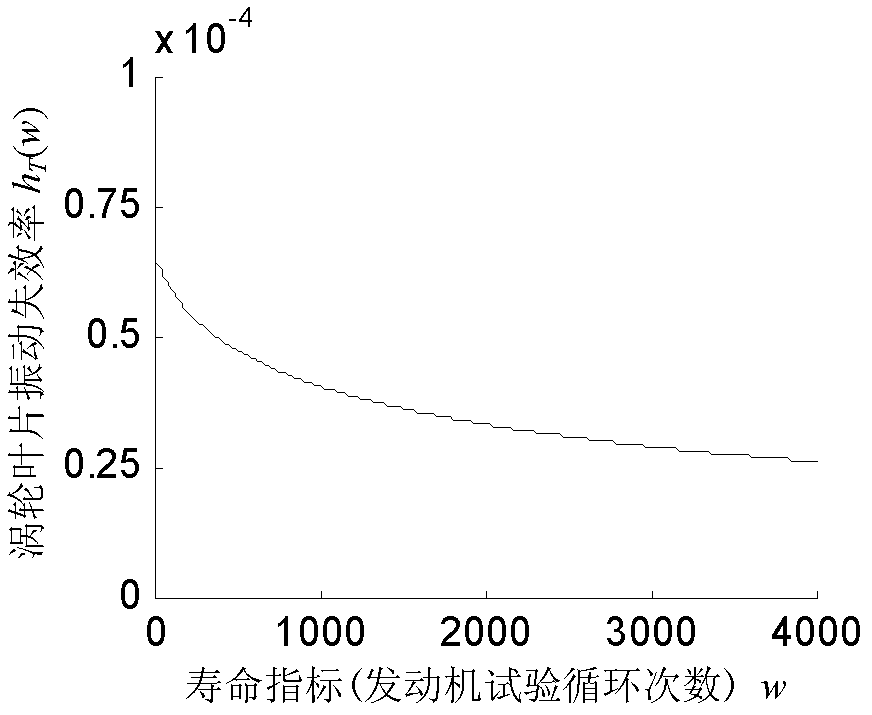

Pressurizing device turbine blade vibration reliability index evaluation method

ActiveCN103162924AVibration Reliability EvaluationLarge structure sizeVibration testingFailure rateTurbine blade

The invention relates to a pressurizing device turbine blade vibration reliability index evaluation method. Probability distribution parameters of pressurizing device turbine blade vibration first order inherent frequency are confirmed by means of finite element simulation or experimental test, the minimum resonance order corresponding to the resonance of the turbine blades is confirmed by utilizing a turbine blade vibration frequency and turbine rotating speed resonance graph, probability distribution parameters of turbine operation rotating speed are confirmed according to an engine use cross section or an experimental cross section, and a law of changing of reliability and a failure rate of turbine blade vibration along with service life index is confirmed according to parameters such as the number of turbine blades, the blade vibration first order inherent frequency, the turbine operation rotating speed and the blade resonance order. The method can confirm reliable service life of turbine blade vibration meeting given reliability requirements reasonably, can guide structural design of a turbine, avoids vibration failure of the blades due to insufficient reliability, and prevents aerodynamic performance of a turbine blade from being lowered due to aimless increase of the dimension of the turbine blade structure.

Owner:NO 70 INST OF CHINA NORTH IND GRP

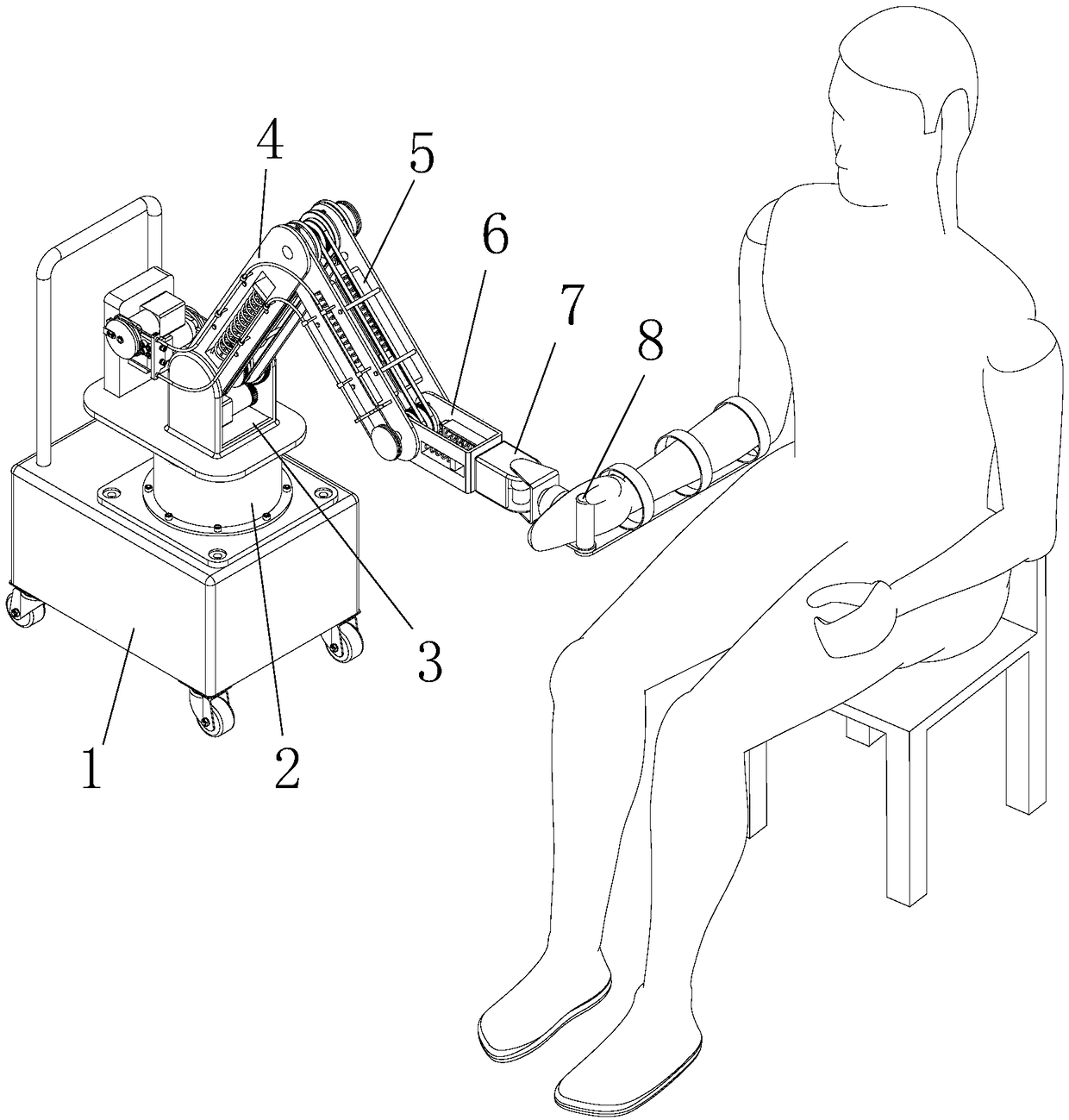

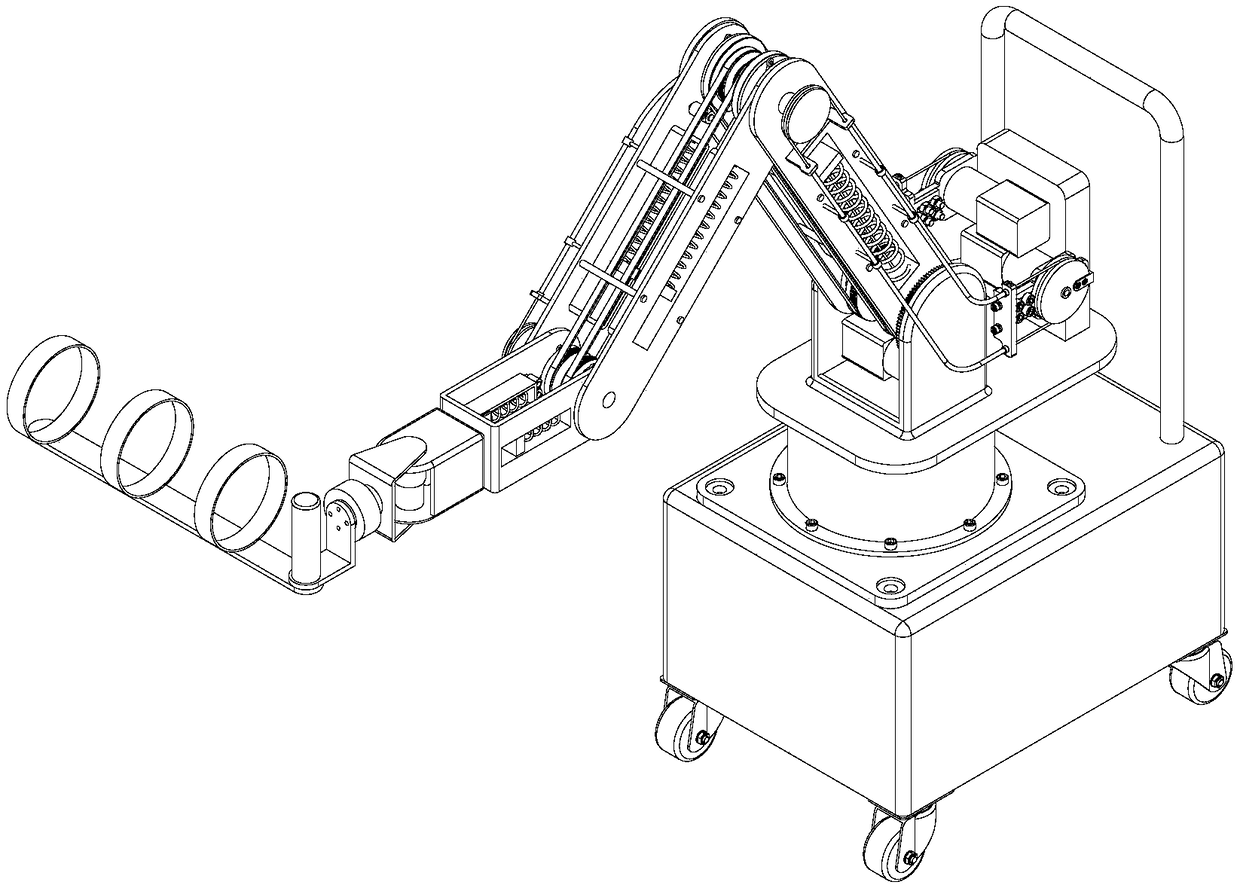

Extremity-traction type upper limb rehabilitation robot adopting gravitational equilibrium devices and working method thereof

ActiveCN108814890AReduce manufacturing costPrevent fallingChiropractic devicesDrive motorEngineering

The invention discloses an extremity-traction type upper limb rehabilitation robot adopting gravitational equilibrium devices and a working method thereof, belonging to the field of medical instruments. The robot comprises a movable frame, a robot base, a waist part, a big arm, a middle arm, a forearm, a wrist part, an extremity handle and has six degrees of freedom. The big arm, the middle arm and the forearm are internally equipped with the gravitational equilibrium devices which are used for equilibrating loading moment generated by self weight of a connecting rod of the robot. Middle arm and forearm joint driving motors are disposed at the waist part. Sleeve ropes are adopted to transfer driving moment. Encoders are arranged in all the motors and used for measuring postures of the robot. An extremity handle module is equipped with a six-dimensional force sensor used for measuring man-machine interaction force. Driving force required by the motors is reduced. The extremity load capability of the robot is improved. Cost of the rehabilitation robot is lowered. The self weight of the robot is decreased. The sleeve ropes smoothly drive joints so that safety of man-machine interaction is enhanced. Rehabilitation training of left and right upper limbs of a patient is achieved. Additionally, the extremity-traction type upper limb rehabilitation robot is not particularly applied torehabilitation training.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

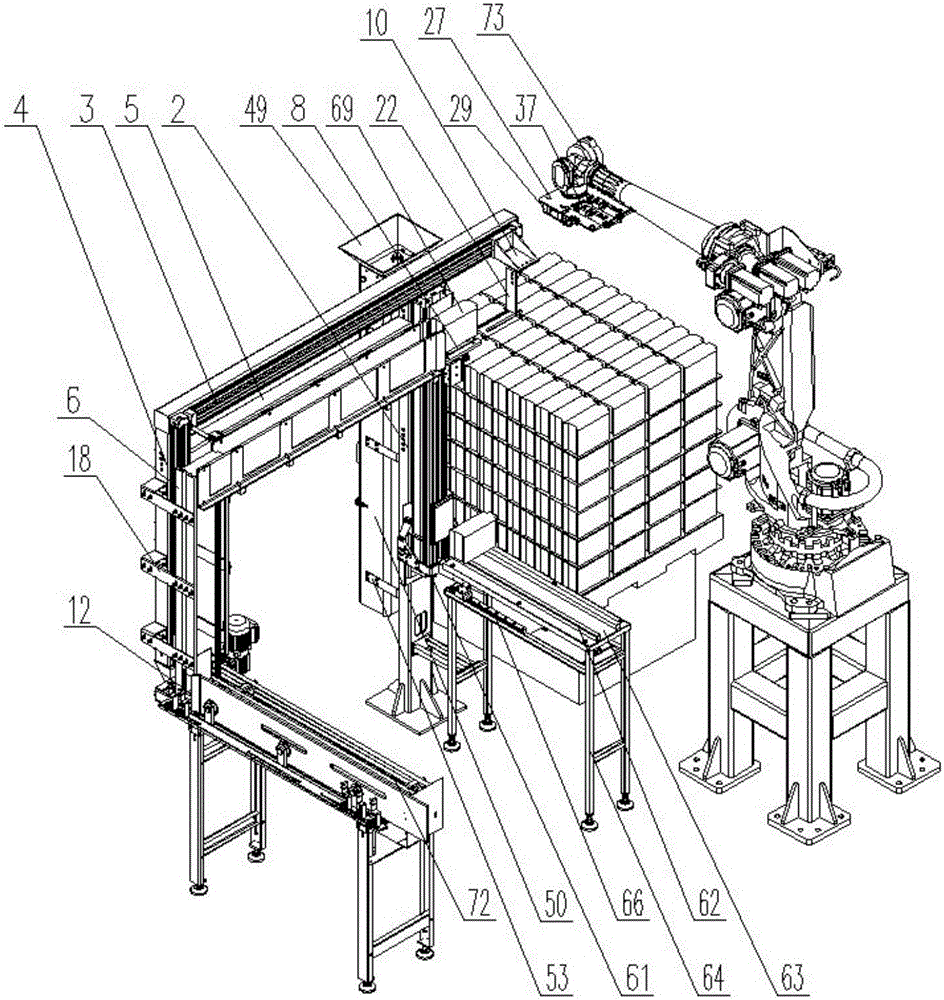

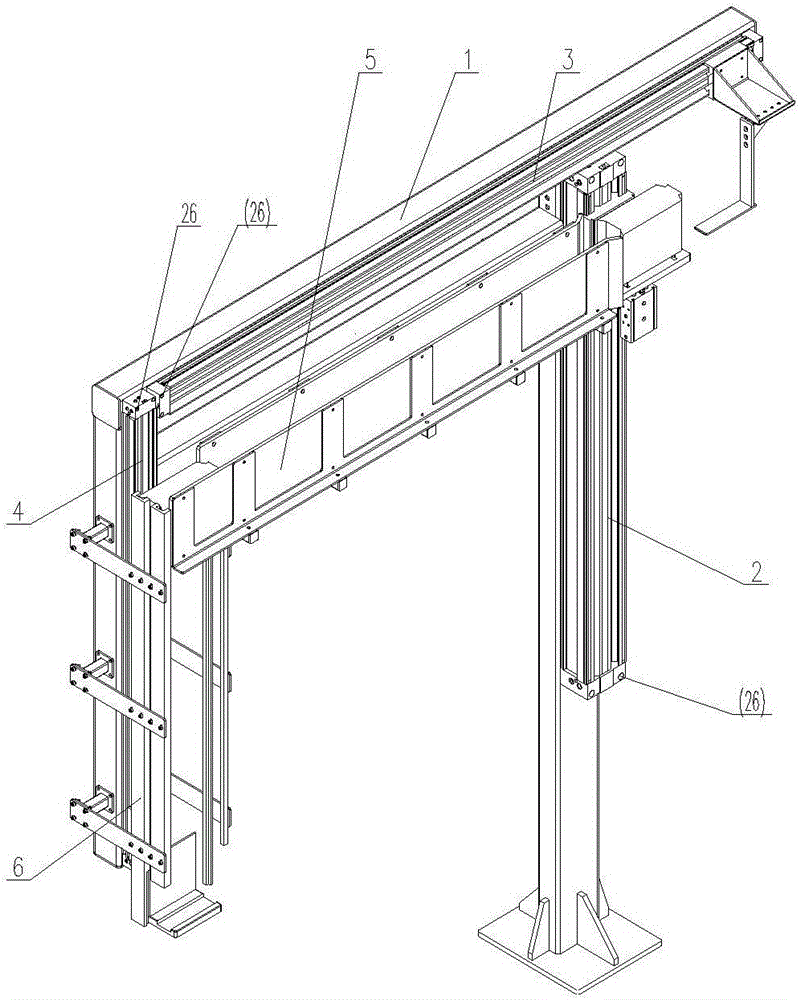

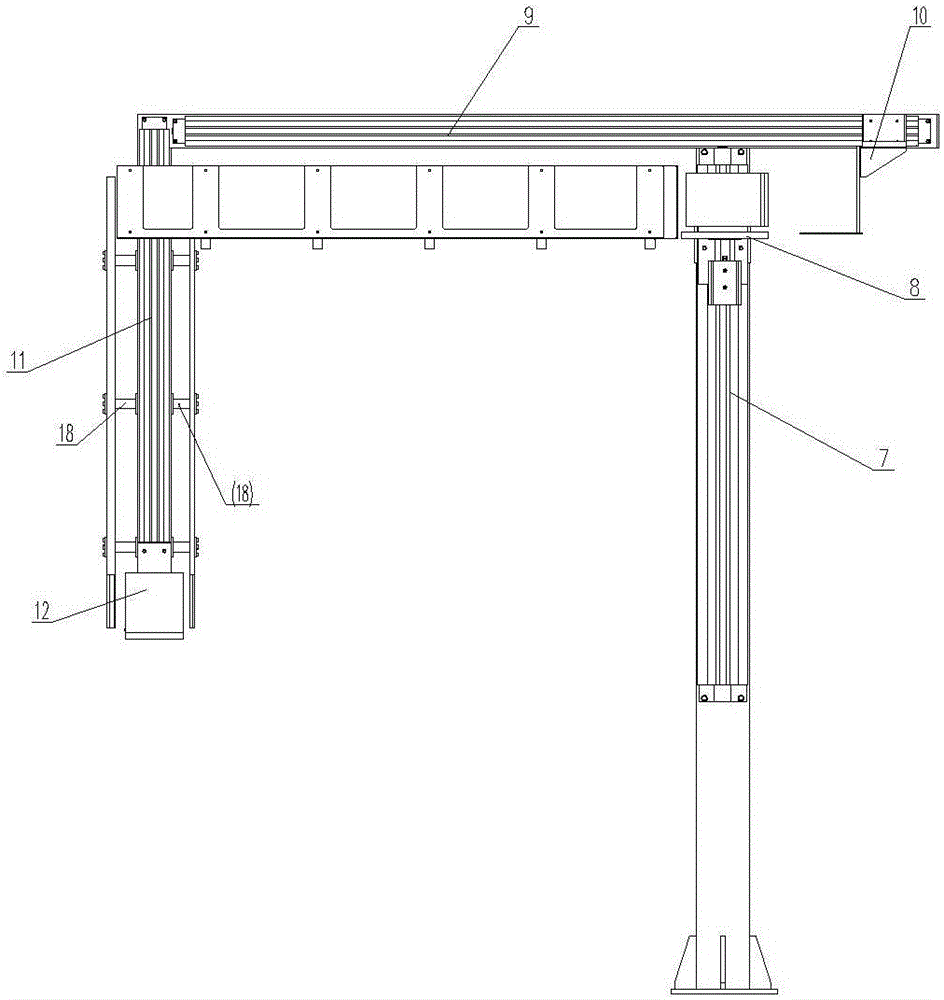

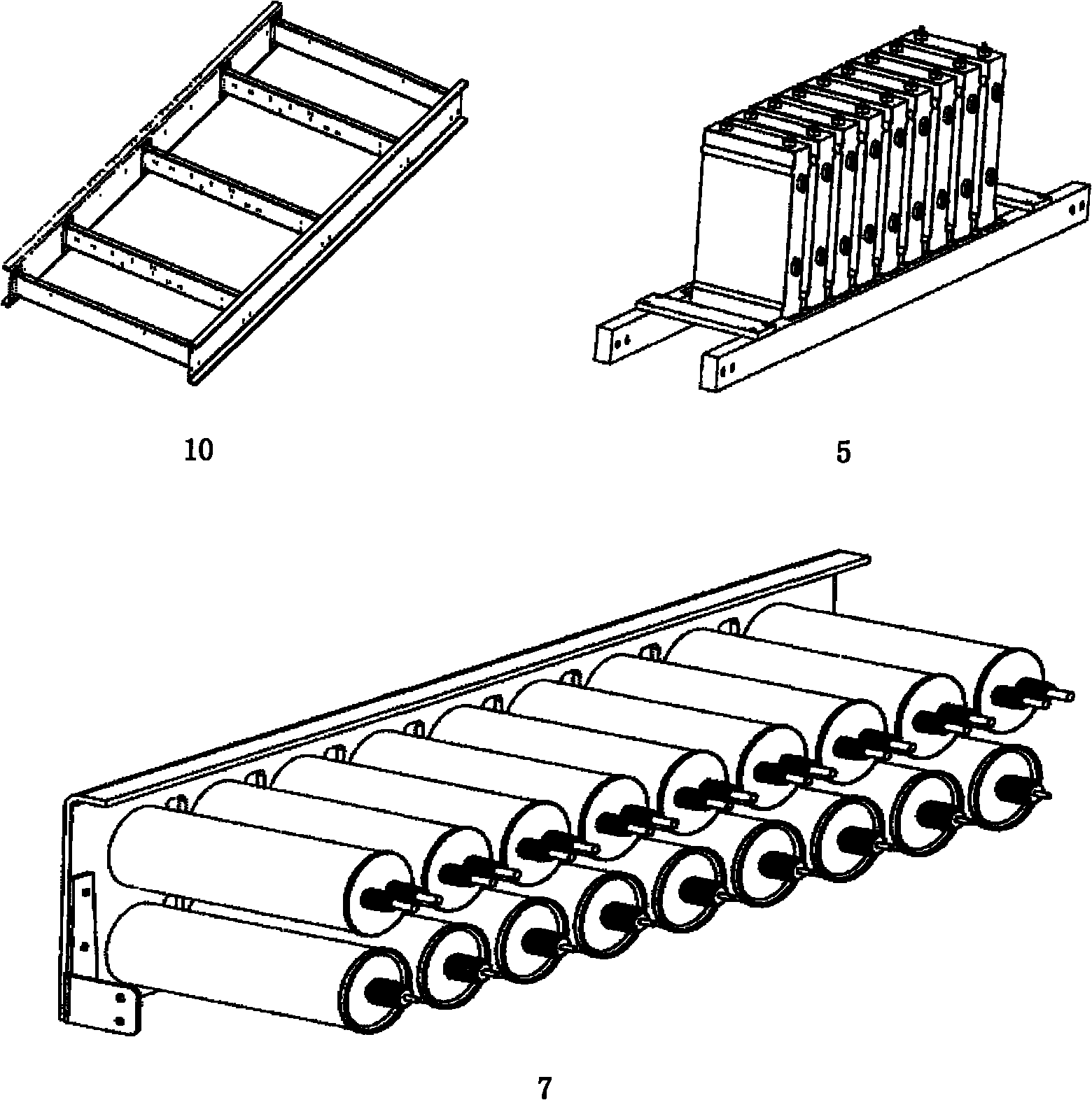

Robot-based automatic loading system for cigarette packaging square accessories

ActiveCN105883387ATimely detection of blockageIncrease falls intoConveyorsControl devices for conveyorsEngineeringAtmospheric pressure

A robot-based automatic loading system for cigarette packaging square accessories is characterized by comprising a bulk accessory conveyor system arranged on a gantry-type main support, a robot fixture close to the right side of the gantry-type main support, a bulk accessory wrapper recycling device fixed at the front end of the right side of the gantry-type main support, an automatic bulk accessory waste recycling device fixed at the rear end of the right side of the gantry-type main support, a bulk accessory wrapper withdrawal assisting mechanism arranged on a bulk accessory conveying rack, a synchronous belt conveyor connected to the left side of the gantry-type main support, and a joint robot arranged on the robot fixture, as well as a pneumatic system for providing power for a material transporting system, a material conveying system and a tool cutting system. The robot-based automatic loading system has the following beneficial effects: the production cost is effectively lowered, and the production efficiency is greatly improved; and the robot-based automatic loading system is simple in structure, good in strength and rigidity and stable and reliable in operation, and is efficient and energy-saving.

Owner:云南昆船电子设备有限公司

High-altitude float platform

InactiveCN101028863AIncrease buoyancyImprove securityLighter-than-air aircraftElectric energyFloating platform

A platform floating overhead is composed of a platform body on supporting frame, vertical tower on said platform body, several pull strings between them, several fixing cables between platform and ground, a ring air bag surrounding said platform body, several tubular air bags arranged in the cavities in platform body, the drive unit, the electric units, and several reinforcing ribs.

Owner:王旭东

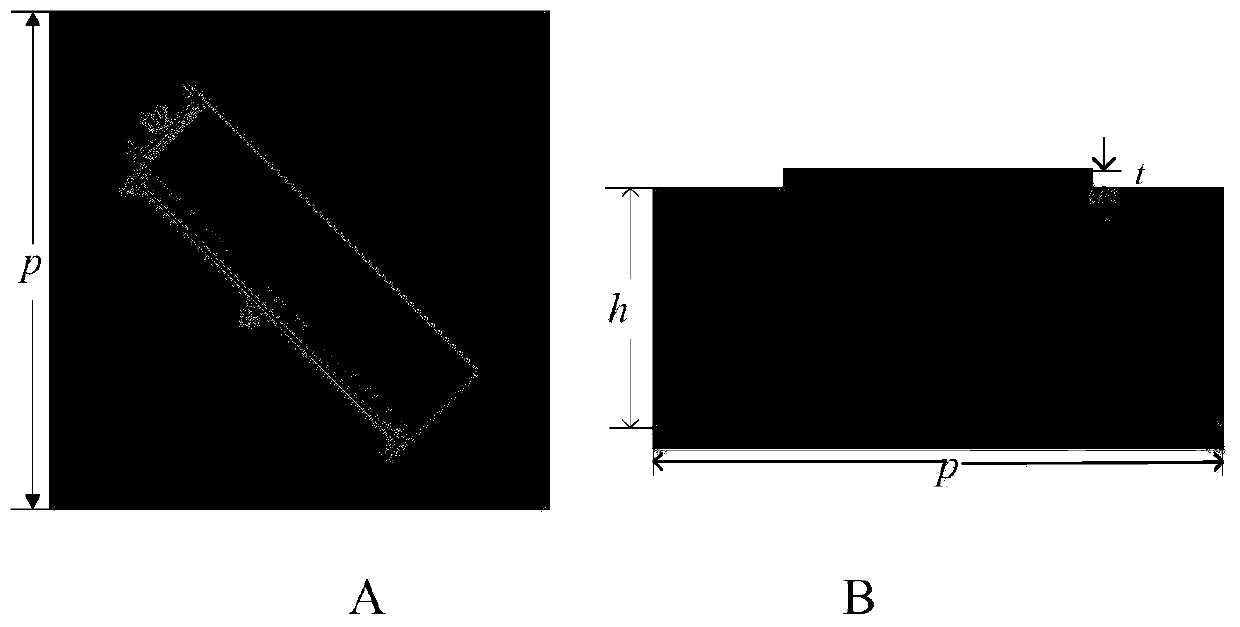

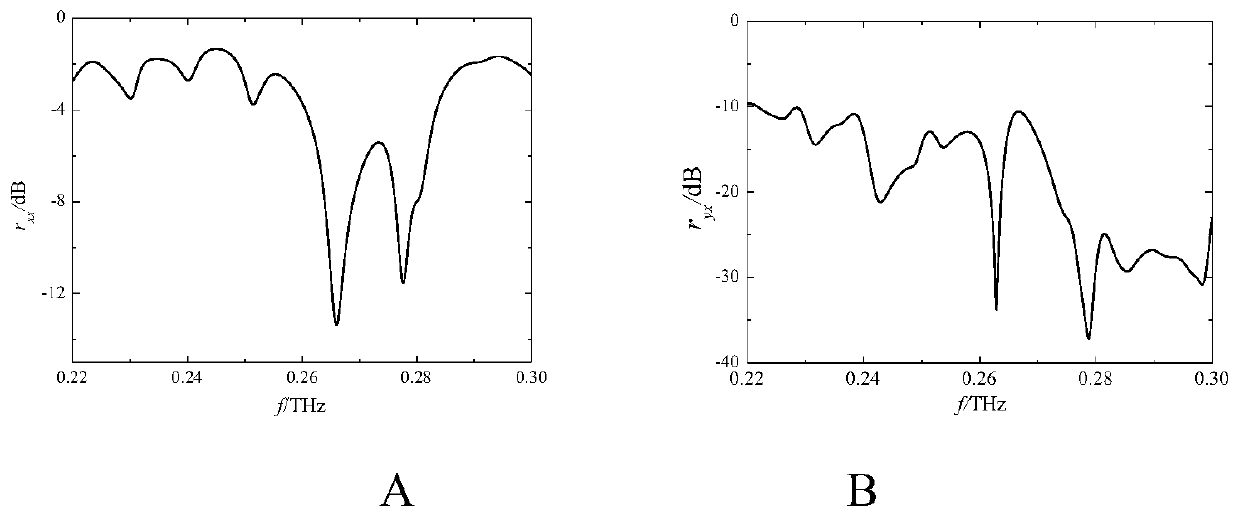

Terahertz metamaterial beam splitter

The invention relates to a terahertz metamaterial beam splitter. The unit structure of the terahertz metamaterial beam splitter is composed of a top metal strip, an intermediate dielectric layer and abottom metal plate. Four units with the rotation stepping being 45 degrees are periodically arranged to form a 4*4 phase gradient metasurface. When terahertz waves vertically enter the array surface,the electromagnetic waves are reflected into four beams of waves which are equal in energy but different in propagation direction, and the reflection angles at different frequency points are different. The beam splitter has the advantages of small volume and low cost, and can be applied to the aspects such as terahertz stealth and terahertz imaging.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

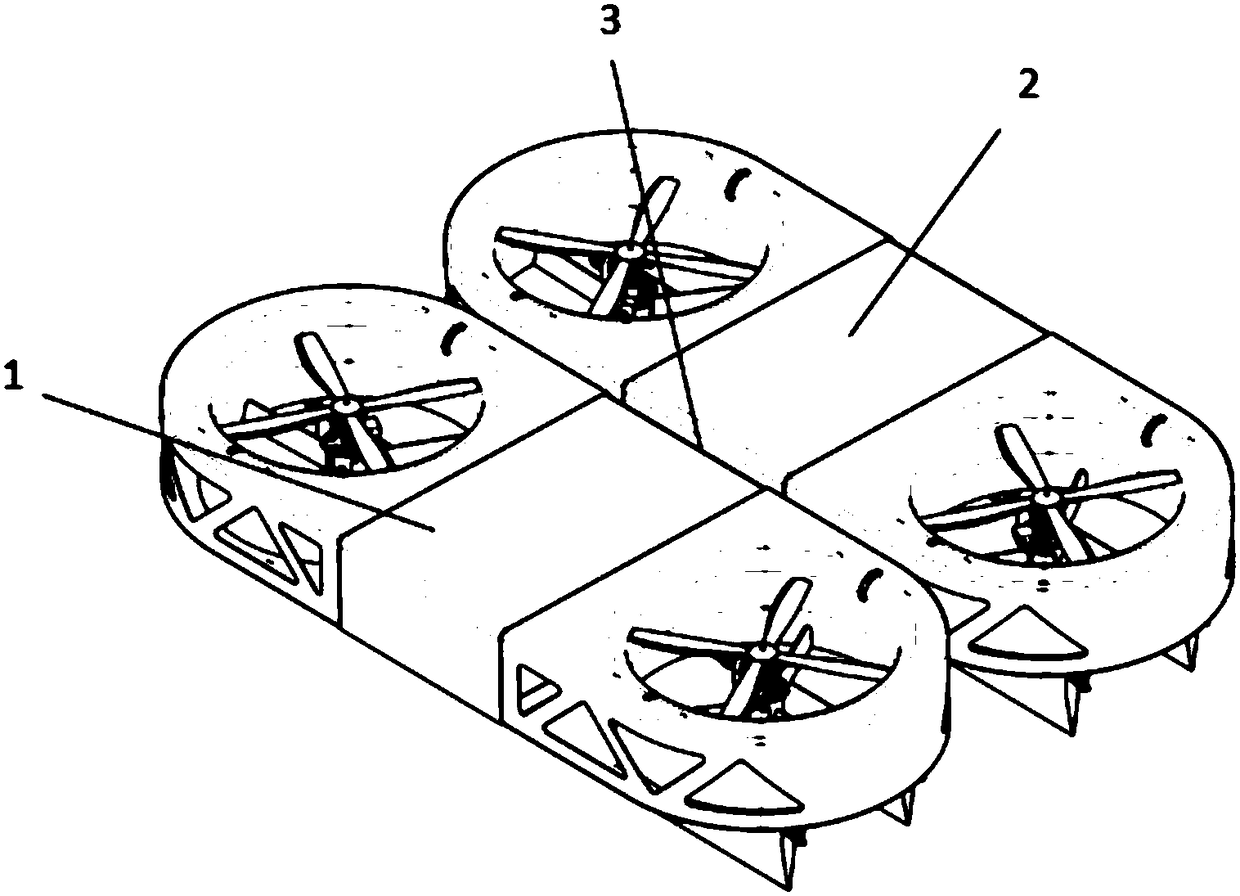

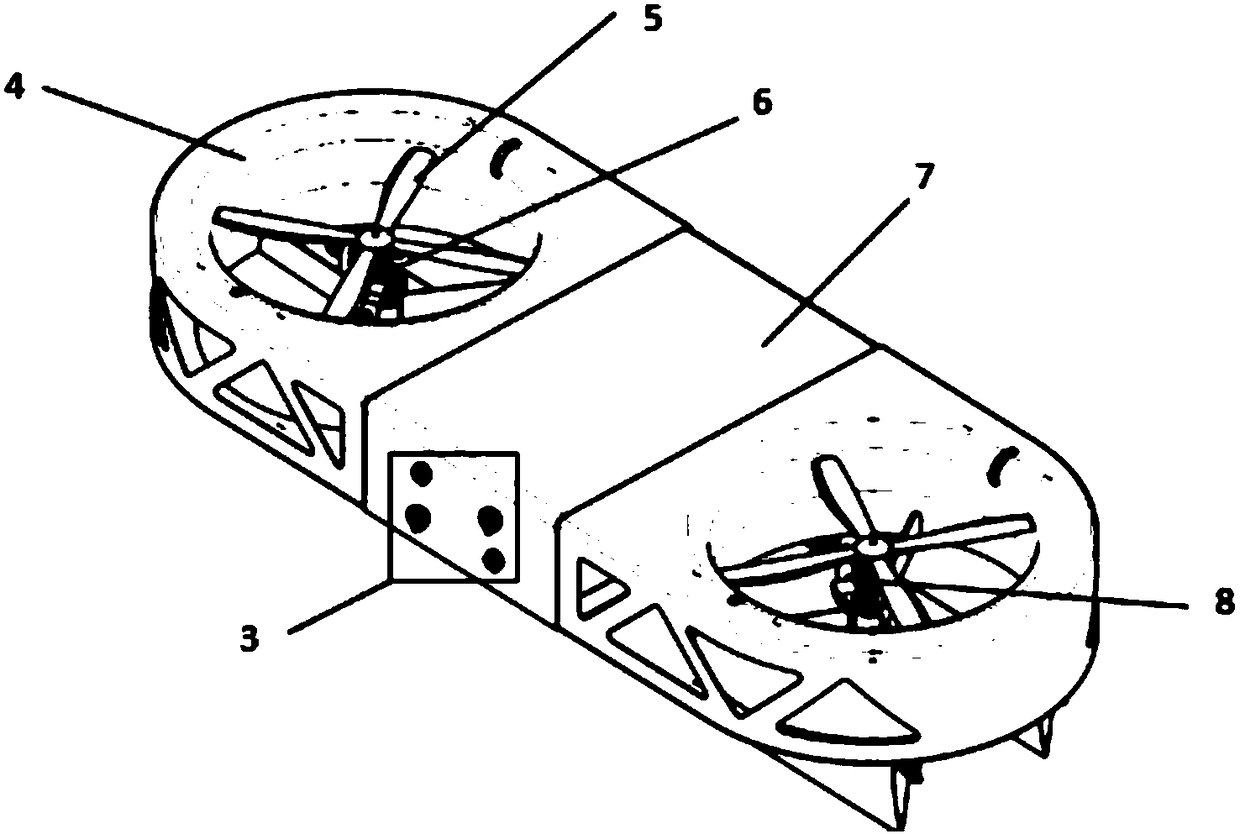

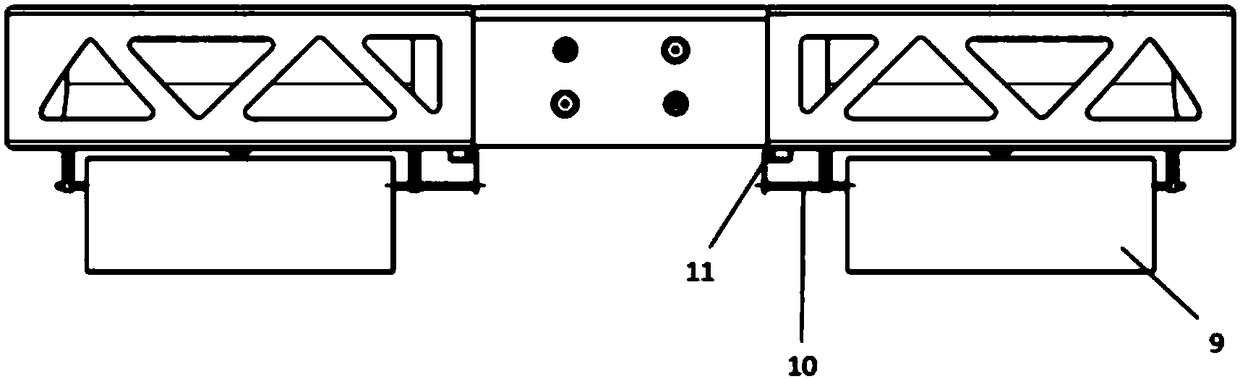

Ducted aircraft capable of being reconstructed aerially in real time, and docking separation method and system

PendingCN109334968ALarge structure sizeEasy to carryConvertible aircraftsRemote controlled aircraftFlight vehicleFlight operations

The invention provides a ducted aircraft capable of being reconstructed aerially in real time, and a docking separation method and system. The ducted aircraft comprises a first ducted aircraft body, asecond ducted aircraft body and a reconstruction controller. The first ducted aircraft body is provided with a first connecting mechanism, and the second ducted aircraft body is provided with a second connecting mechanism; and the reconstruction controller is used for controlling the first connecting mechanism and the second connecting mechanism to be docked or separated when the first ducted aircraft body and the second ducted aircraft body are in a flight state. The two independent ducted aircraft bodies have the capability of being reconstructed into an integrated mode for collaborative operation under the aerial flight operation condition. In addition, the reconstruction controller can also control the first ducted aircraft body and the second ducted aircraft body which are docked inthe flight state to be separated into the two independent ducted aircraft bodies in real time.

Owner:COOL HIGH TECH BEIJING CO LTD

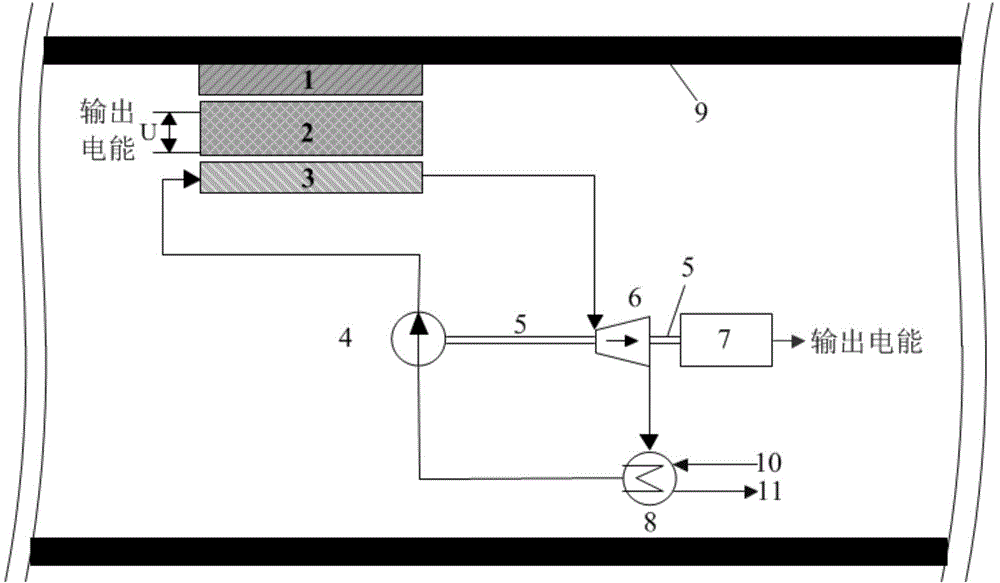

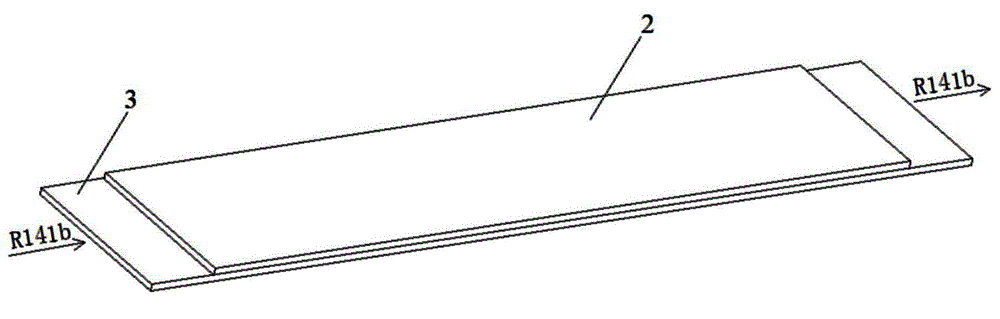

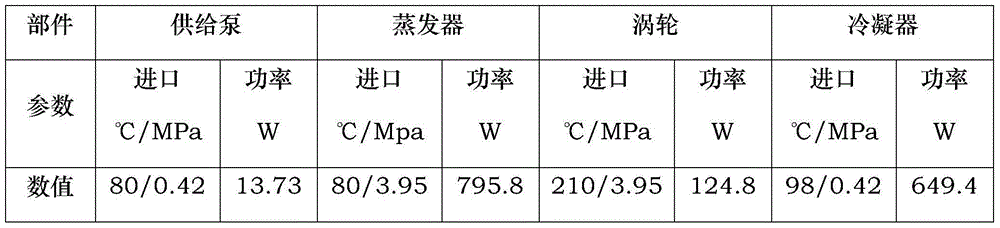

Combined thermoelectric conversion device

InactiveCN104092409AReduce surface temperatureSolve the disadvantagesGenerators/motorsThermoelectric coolingFlight vehicle

The invention discloses a combined thermoelectric conversion device suitable for heat protection and heat utilization of a hypersonic flight vehicle and combined with thermoelectric conversion and Rankine thermoelectric conversion. A hot end of the thermoelectric conversion absorbs aerodynamic heat of the skin of the flight vehicle, a cold end of the thermoelectric conversion transfers heat to an evaporator of a Rankine thermoelectric conversion system capable of adopting R141b organic working media, and heat of a condenser of the Rankine thermoelectric conversion system is taken away by a vehicle-mounted cold source of the flight vehicle. By fully utilizing the aerodynamic heat on the surface of the hypersonic flight vehicle, on one hand, the temperature on the surface of the flight vehicle is reduced, and certain heat protection on the flight vehicle is achieved; on the other hand, the thermoelectric power generation technology with a wide temperature range is combined with Rankine cycle with low operation temperature, energy is made full use of, efficiency of energy use is increased, and the whole thermoelectric conversion efficiency of the system is increased.

Owner:BEIHANG UNIV

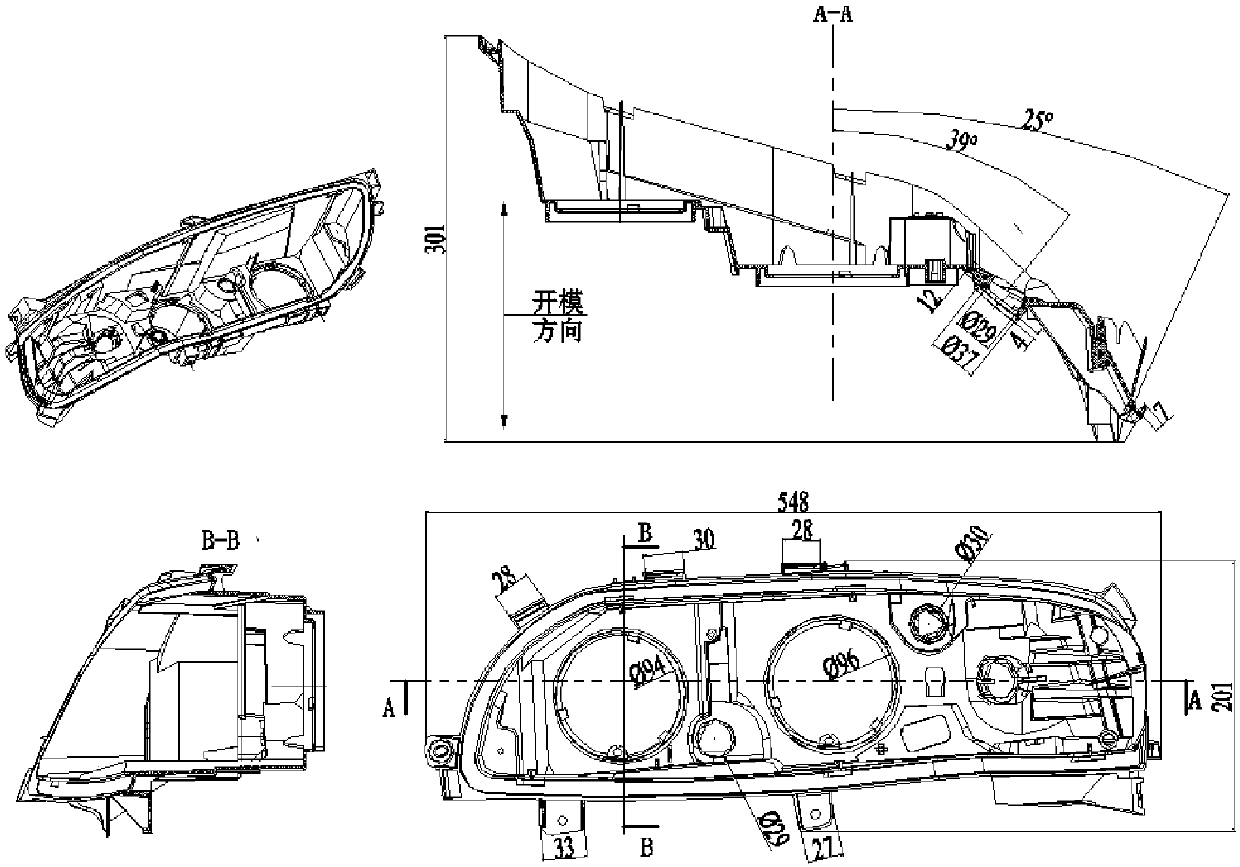

Unmanned aerial vehicle with night flight LED lamp

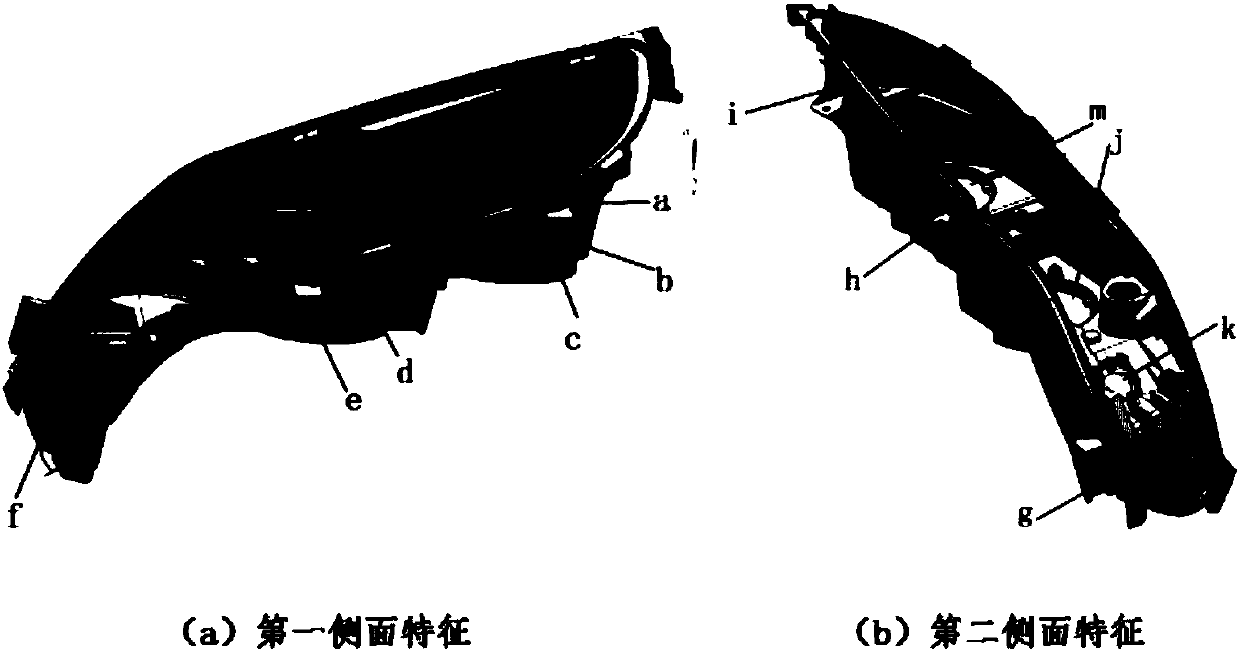

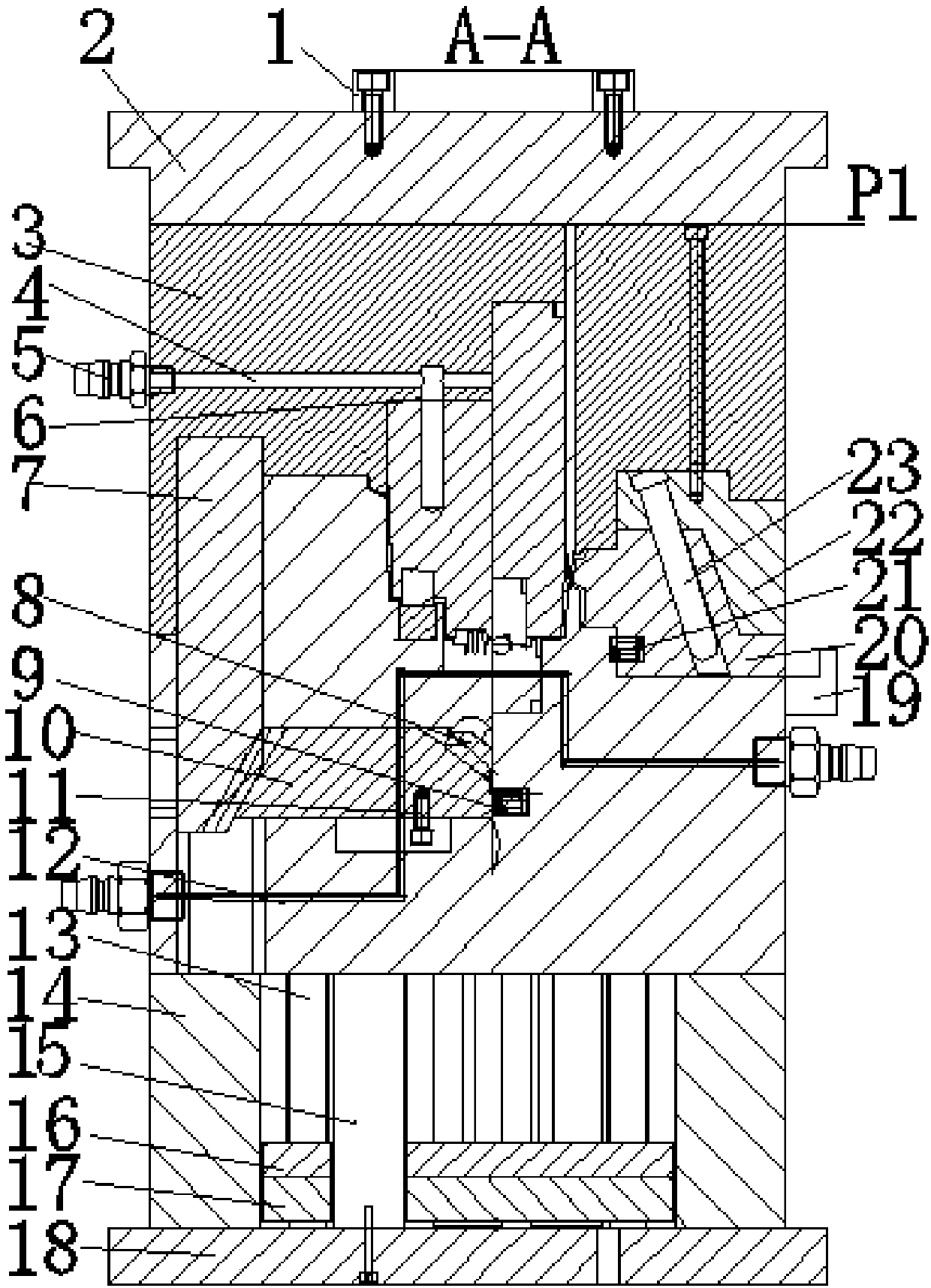

InactiveCN108015981ASolve the problems of difficult injection molding and low injection molding yieldGuarantee molding qualityAircraft componentsVehicle headlampsHot runnerShell molding

The invention provides an unmanned aerial vehicle with a night flight LED lamp. According to the unmanned aerial vehicle, a lamp holder of the LED lamp is manufactured by adopting a lamp holder injection mold, the mold structure of the injection mold adopts a two-plate mold hot runner twice parting structure, and a four-sprue subsurface type pouring mode is adopted; aiming at the machining problem, the machining difficulty can be lowered by adopting an insert splicing mode, and aiming at the problem that demolding is difficult, side core-pulling demolding mechanisms of different types are designed; and particularly aiming at demolding of a central inclined hole, the innovative design of three-time variable-direction driving of the inclined core-pulling demolding mechanisms is adopted, andtherefore the design difficulty of an inclined hole core-pulling mechanism can be lowered, the structural design size of the mold can be decreased, and the designing and manufacturing cost of the moldcan be effectively saved, the mechanism is simple and reliable, and the zero-defect automatic molding production of multi-type hole lamp holder products can be realized by using the simple mechanism.

Owner:王振环

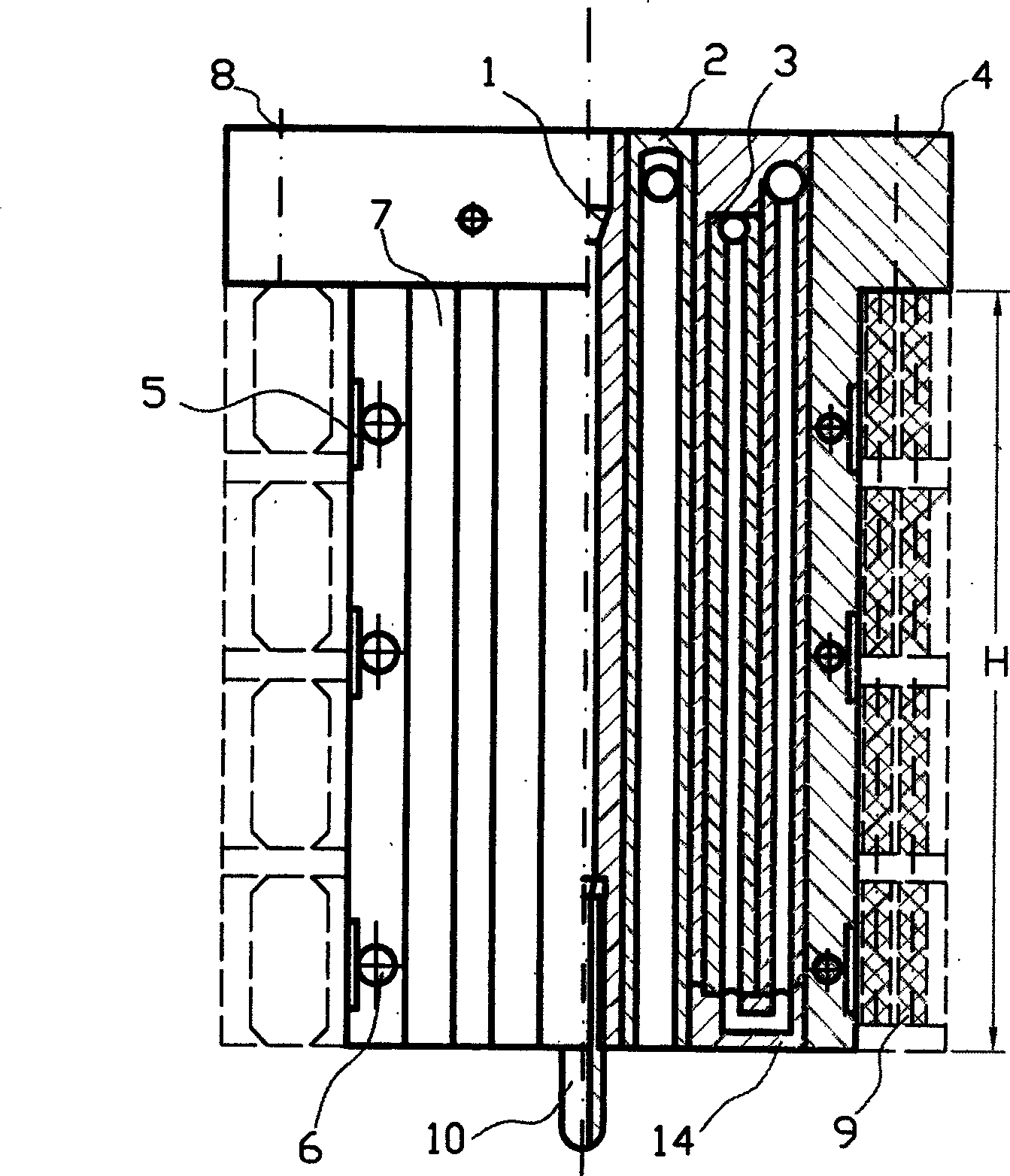

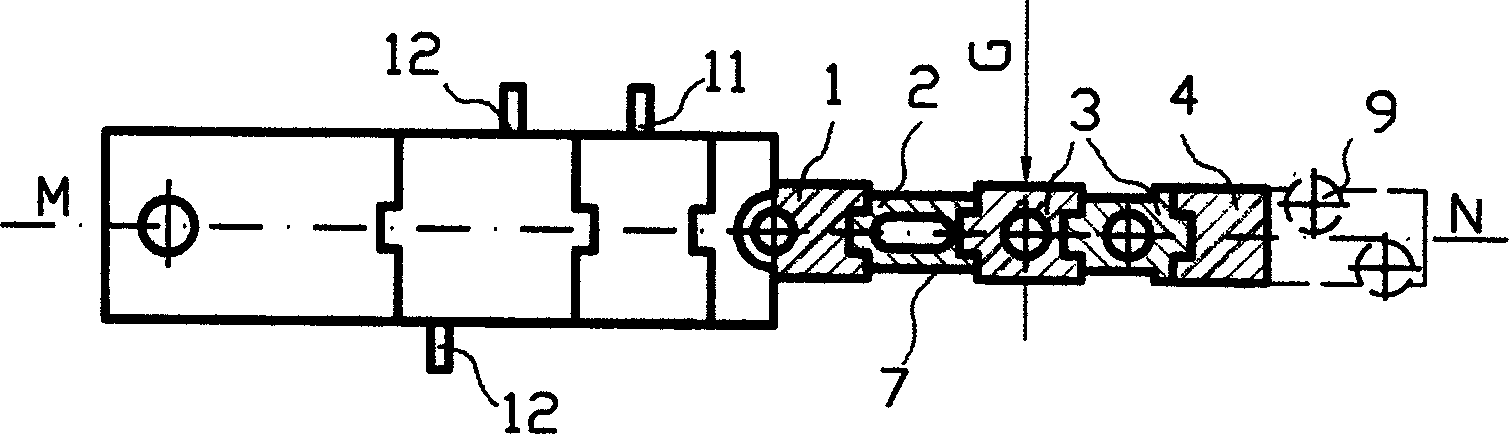

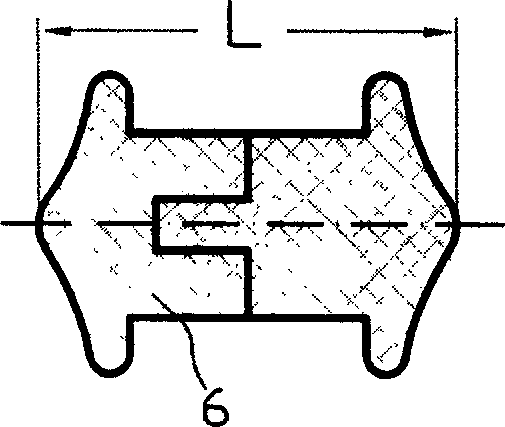

Automatic welding-torch for ultra narrow gap and consumable electrode under gas coverage, and preparation method

InactiveCN1600490AReduce the maximum thickness of the working sectionImprove protectionMolten spray coatingSoldering apparatusMaterials preparationShielding gas

An automatic welding torch for the gas shielded welding of ultranarrow gap by use of consumable welding electrode is composed of wire guiding unit, gas guiding unit, water guiding unit, side wall, insulating unit and electric conducting tip. Its making technology includes preparing raw materials, shaping each unit, soldering, treating the soldered seam, assembling, fixing, soldering in fernace, air and water tightness test, trimming, and surficial insulation treating.

Owner:武汉卓创智能设备有限公司

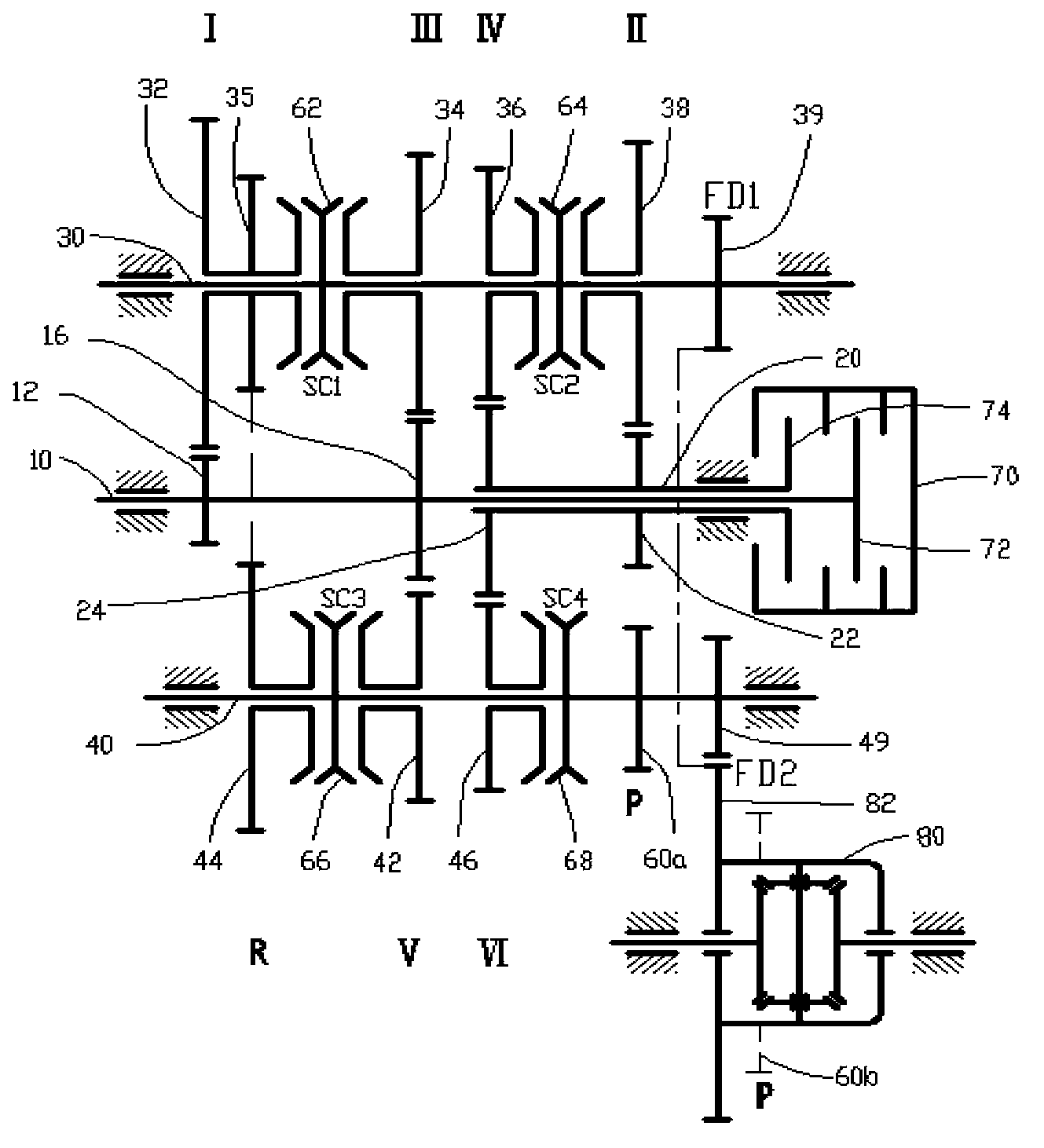

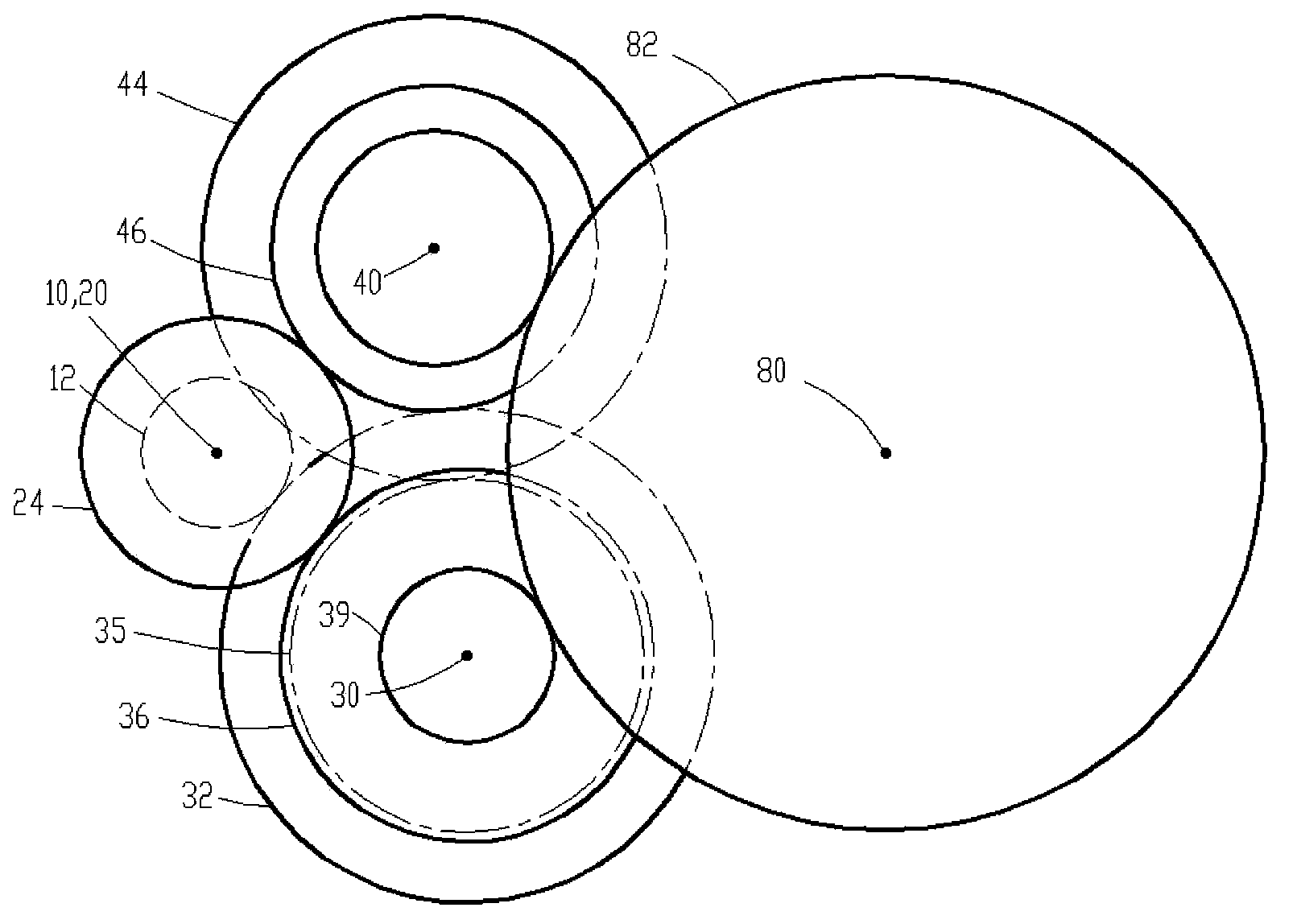

Double-clutch automatic gearbox transmission device

InactiveCN103912651AHigh reverse safetyTransmission compactToothed gearingsTransmission elementsVariatorEngineering

The invention discloses a double-clutch gearbox transmission device for a vehicle. The double-clutch automatic gearbox transmission device comprises an inner input shaft and an outer input shaft which are arranged coaxially, two auxiliary shafts parallel to the two input shafts, a double-clutch and differential assembly, multiple groups of normally engaged gears arranged on each shaft, and multiple groups of synchronizer devices for selecting gears. The double-clutch gearbox transmission device is capable of providing six forward gears and one reverse gear. A reverse gear driven gear is indirectly driven by a reverse gear driving gear connected with a first gear driven gear, the reverse gear transmission ratio is higher, so that the reverse gear safety is higher. The fourth gear and the sixth gear use the same driving gear so that the axial size of the gearbox is effectively reduced. Low gear groups are arranged at the shaft end of a gearbox shaft system, so that the shaft system has higher rigidity, smaller abrasion and longer service life. The gearbox device is featured with simple structure, small axial size, large transmission ratio freedom and so on.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

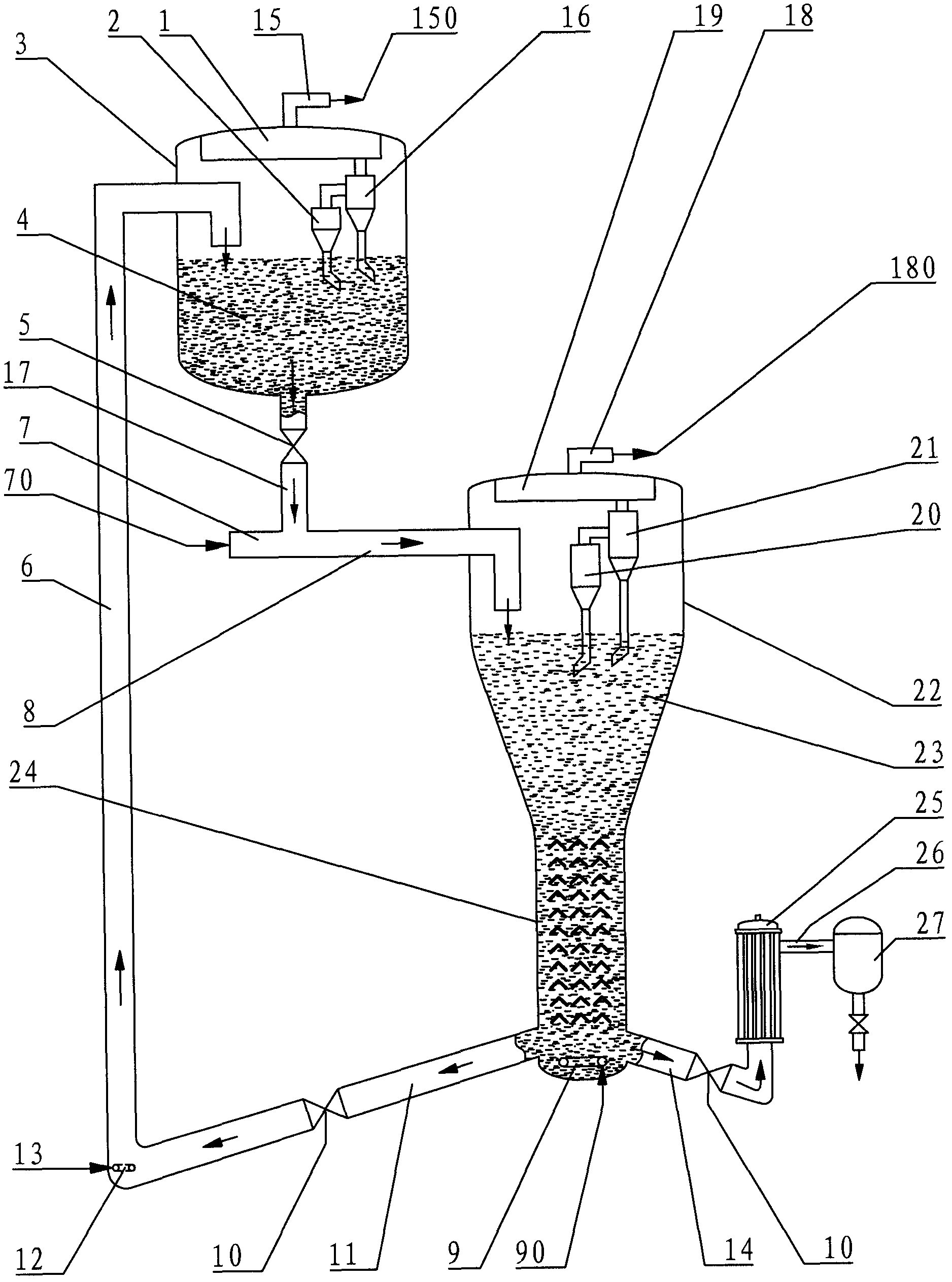

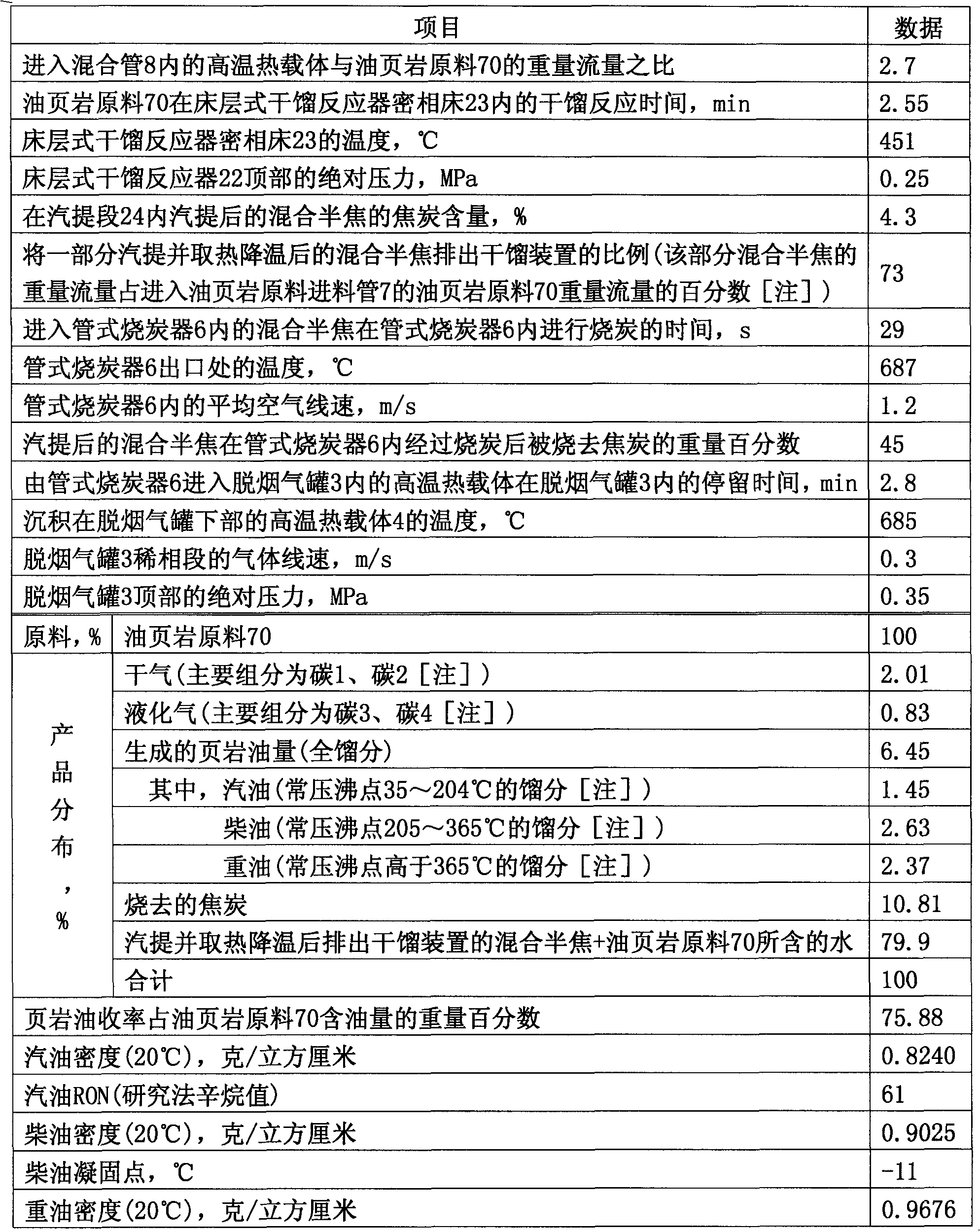

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131444APrevent overheating damageGuaranteed long-term operationDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems of high coal burning load due to the fact that all mixed carbocoal enters a coal burning device for coal burning and the like in the prior art. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that that destructive distillation reaction is carried out on oil shale raw materials and high-temperature heat carriers from a smoke removing tank (3) after the oil shale raw materials and the high-temperature heat carriers are mixed in a mixing pipe (8), and oil gas contained in the formed mixed carbocoal is extracted from a steam extracting section (24) in a steaming mode; part of the mixed carbocoal is discharged out of the destructive distillation device after the oil gas is extracted from the mixed carbocoal and the mixed carbocoal is cooled, and the other part of the mixed carbocoal enters a pipe type coal burning device (6); and coal burning is carried out on the mixed carbocoal entering a pipe type coal burning device, the high-temperature heat carriers and the smoke which are produced after the coal burning enter the smoke removing tank for separation. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

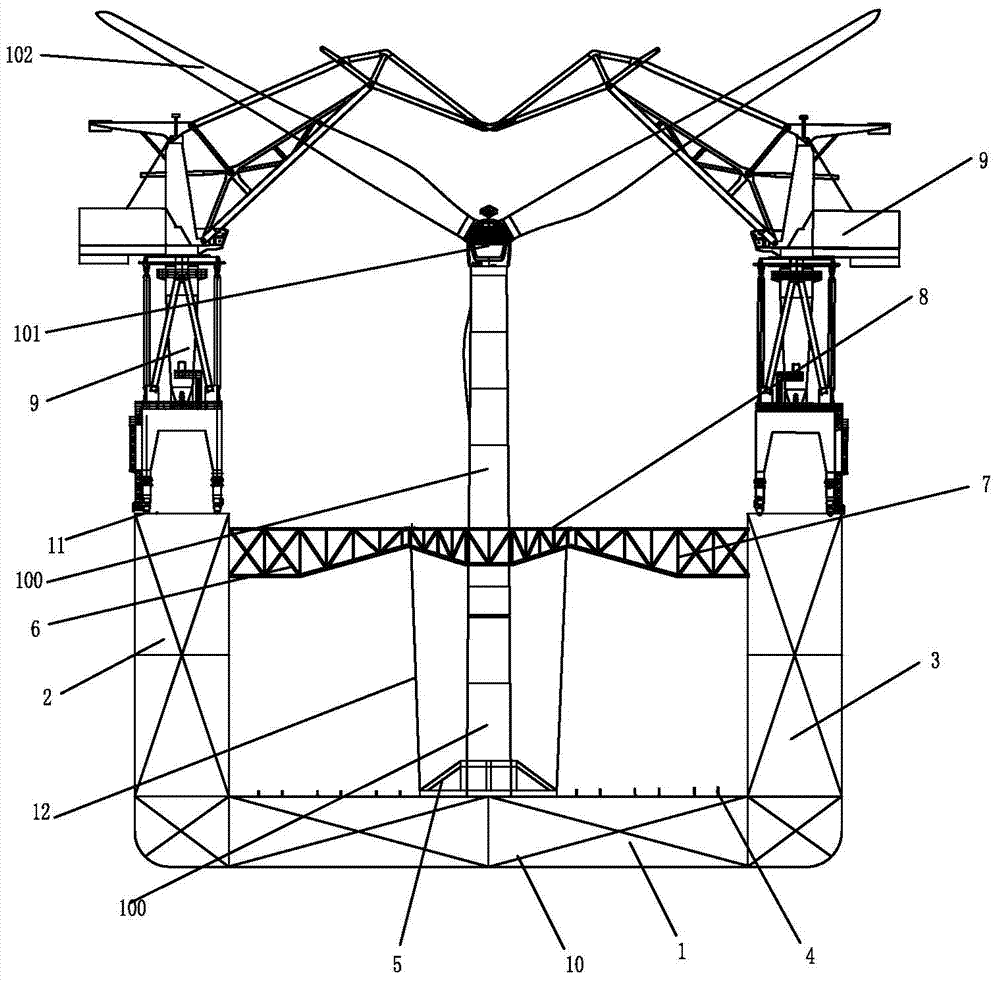

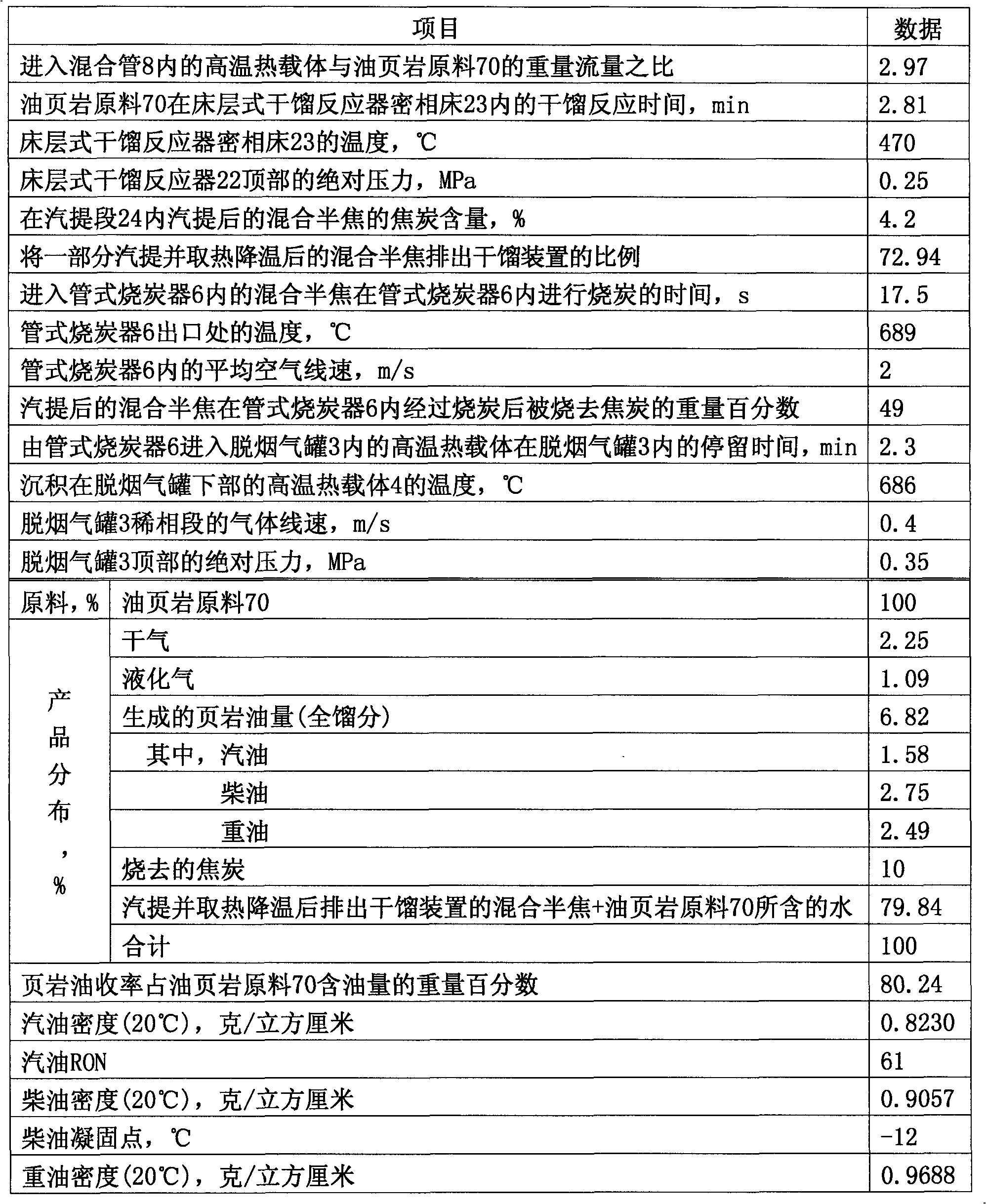

Method for cooperatively controlling multiple pollutants of flue gas by using charge adsorbent strengthened electric bag device

ActiveCN102671506ALarge structure sizeLess investmentCombination devicesAuxillary pretreatmentPollutantElectricity

The invention relates to a method for cooperatively controlling multiple pollutants of a flue gas by using a charge adsorbent strengthened electric bag device. The method comprises the steps of: pre-charging (positive charges) a mercury-removing adsorbent through an outer charge spray gun and spraying the mercury-removing adsorbent to an electric bag combined region of the electric bag compound device through an insulating conveying pipe; capturing and collecting fine particles, heavy metals (mercury and the like), congealable substances (SO3 and the like) and the like to the adsorbent to form big particles which are good for a filtering bag to capture and collect by utilizing Coulomb coagulation function caused by mutual attraction between adsorbent particles with positive charges and fine particles which are charged with negative charges while passing an electric region, but are not captured and collected; and finally, capturing and collecting the coagulated big particles by utilizing a bag-type dust collector to realize the purpose of cooperatively removing fine particles, heavy metals and congealable substance in the flue gas. Compared with the prior art, the method for cooperatively controlling multiple pollutants of the flue gas by using the charge adsorbent strengthened electric bag device, disclosed by the invention, has the advantages of high efficiency, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

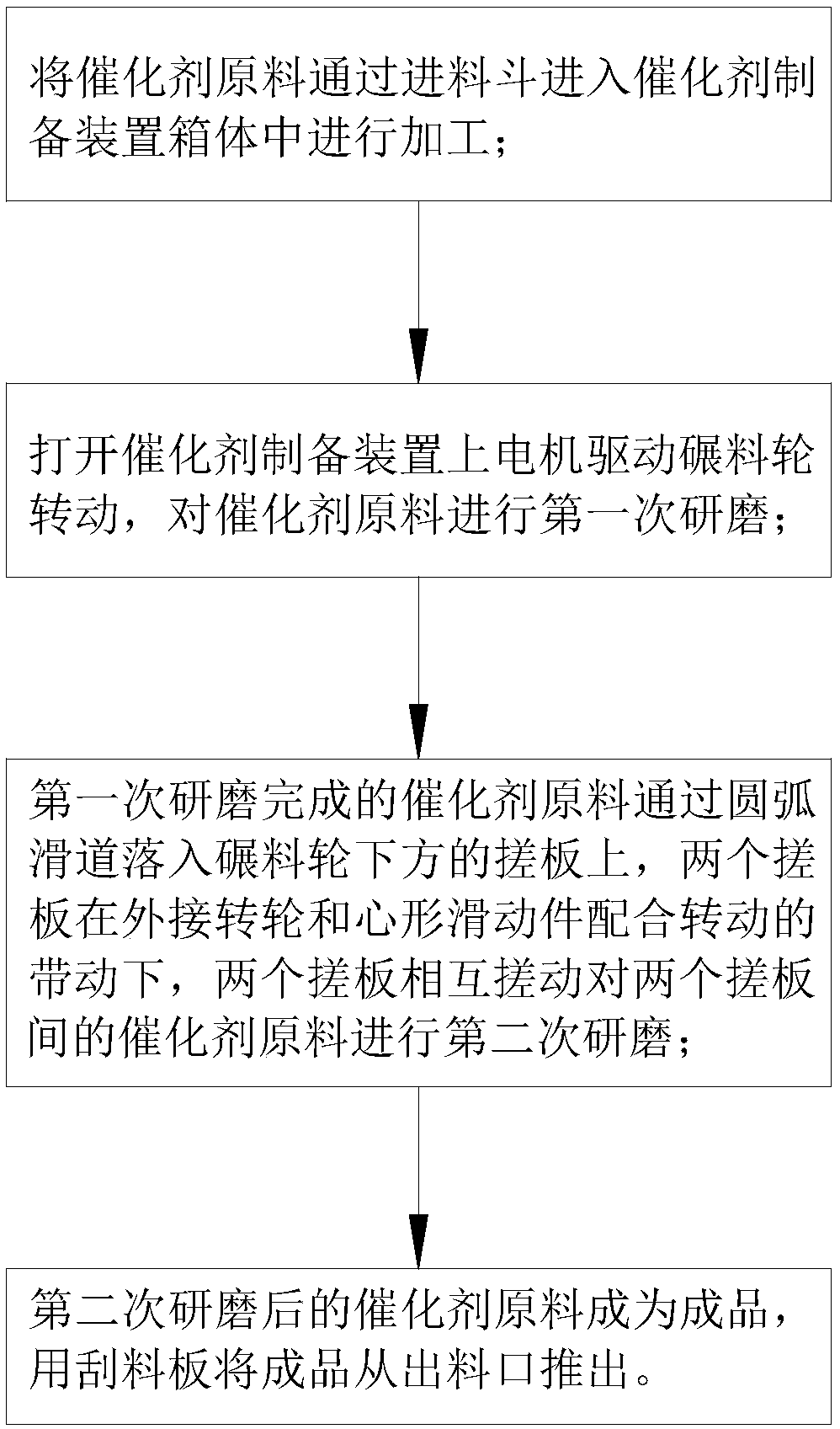

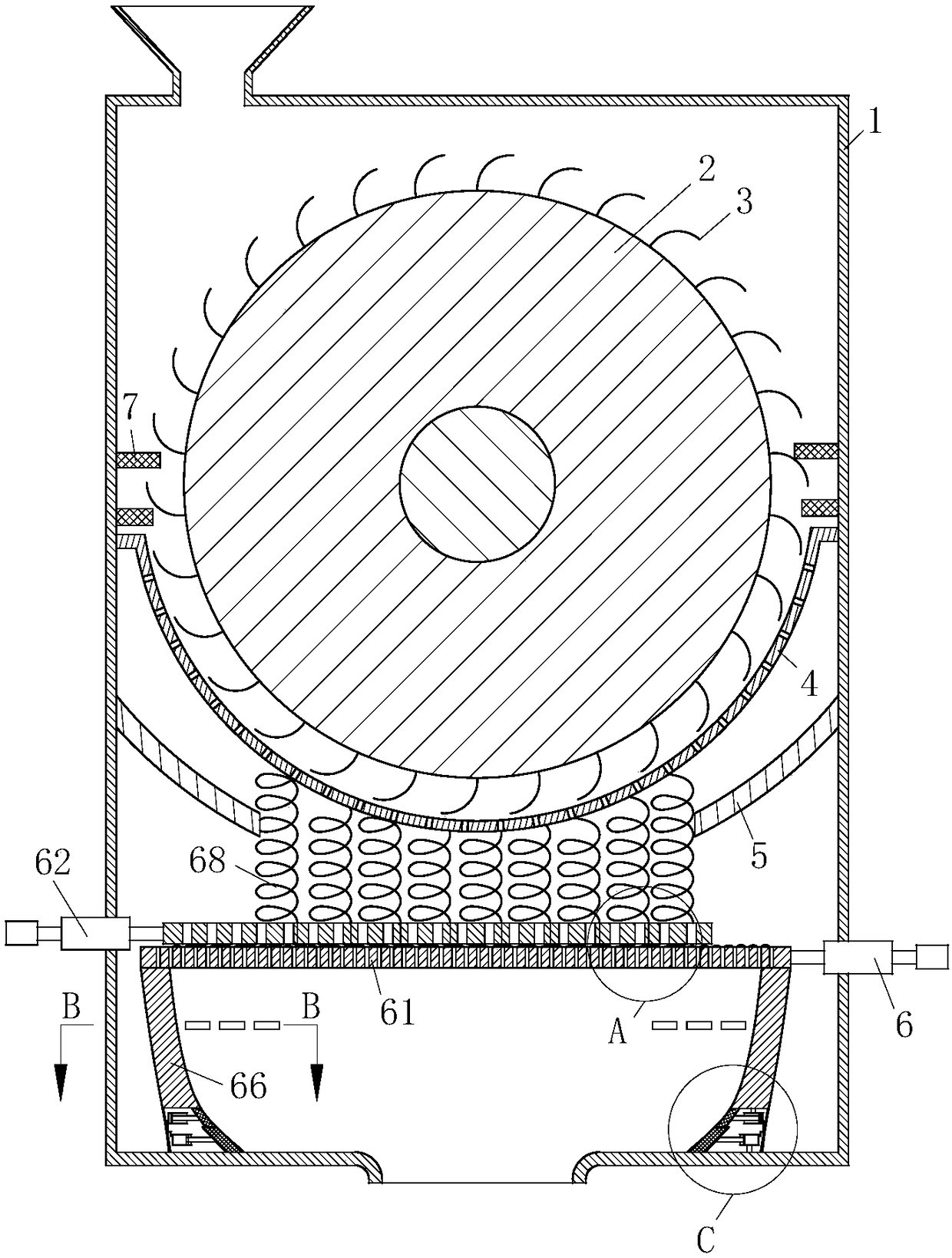

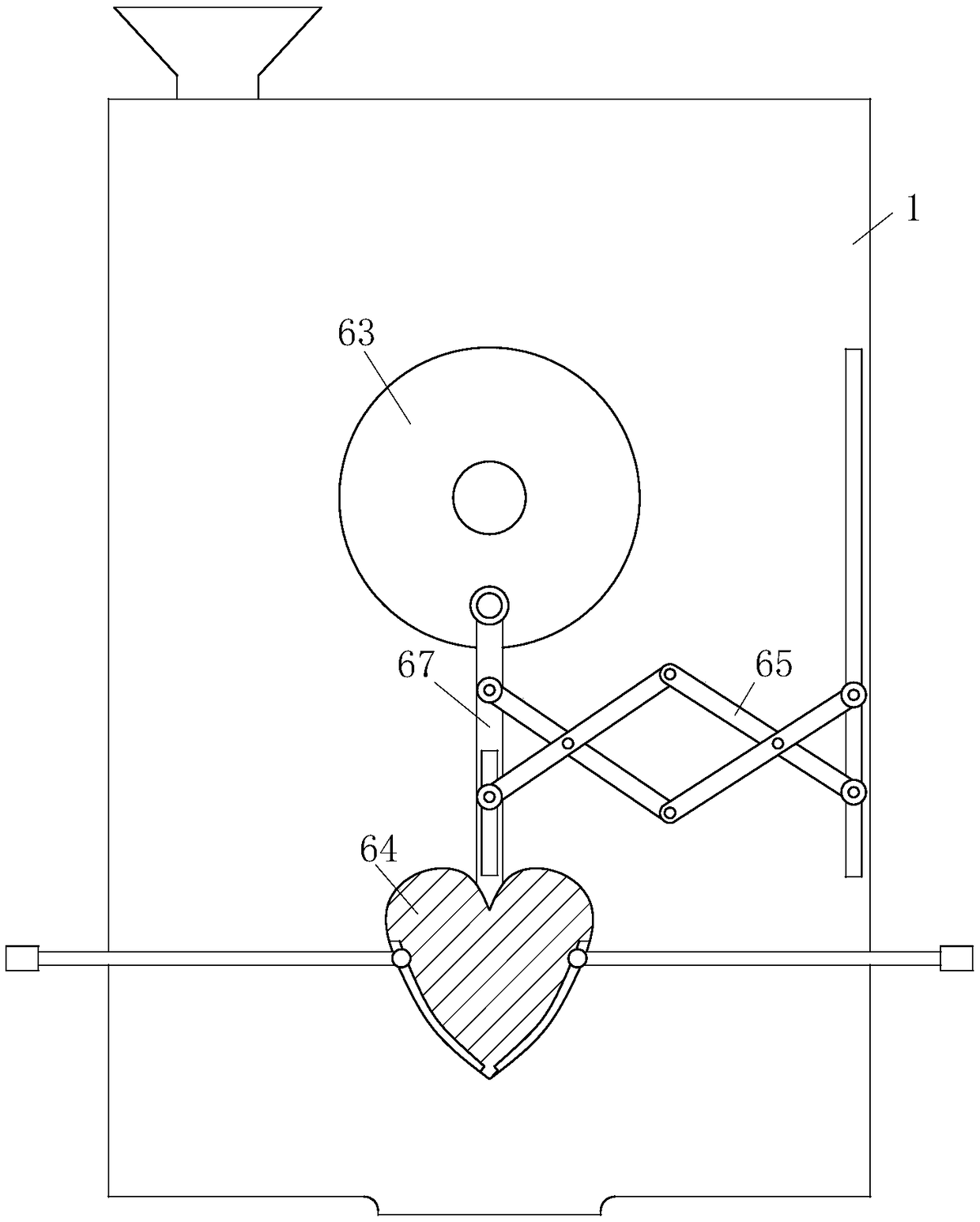

Petroleum refining catalyst preparation technology

ActiveCN109482272AIncrease productivityReduce wasteCatalyst activation/preparationGrain treatmentsGrinding wheelPetroleum

The invention belongs to the technical field of catalyst preparation technologies and particularly relates to a petroleum refining catalyst preparation technology. The technology comprises the following steps that catalyst raw materials are placed into a catalyst preparation device box for processing through a feed hopper; a motor on a catalyst preparation device is started and drives a grinding wheel to rotate, and primary grinding is performed on the catalyst raw materials; the catalyst raw materials subjected to primary grinding fall onto rubbing plates below the grinding wheel through circular-arc-shaped slideways, the two rubbing plates are driven by cooperative rotation of an external runner and a heart-shaped sliding part to rub each other so as to perform secondary grinding on thecatalyst raw materials between the two rubbing plates; and the catalyst raw materials subjected to secondary grinding are finished products, and the finished products are pushed out of a discharging outlet through scraping plates. According to the petroleum refining catalyst preparation technology, the products are pushed to the discharging outlet through push blocks on the scraping plates, the products can be gradually pushed towards the discharging outlet, operation is easy and saves labor, pushing is quick, and the production efficiency is improved.

Owner:胜星集团有限责任公司

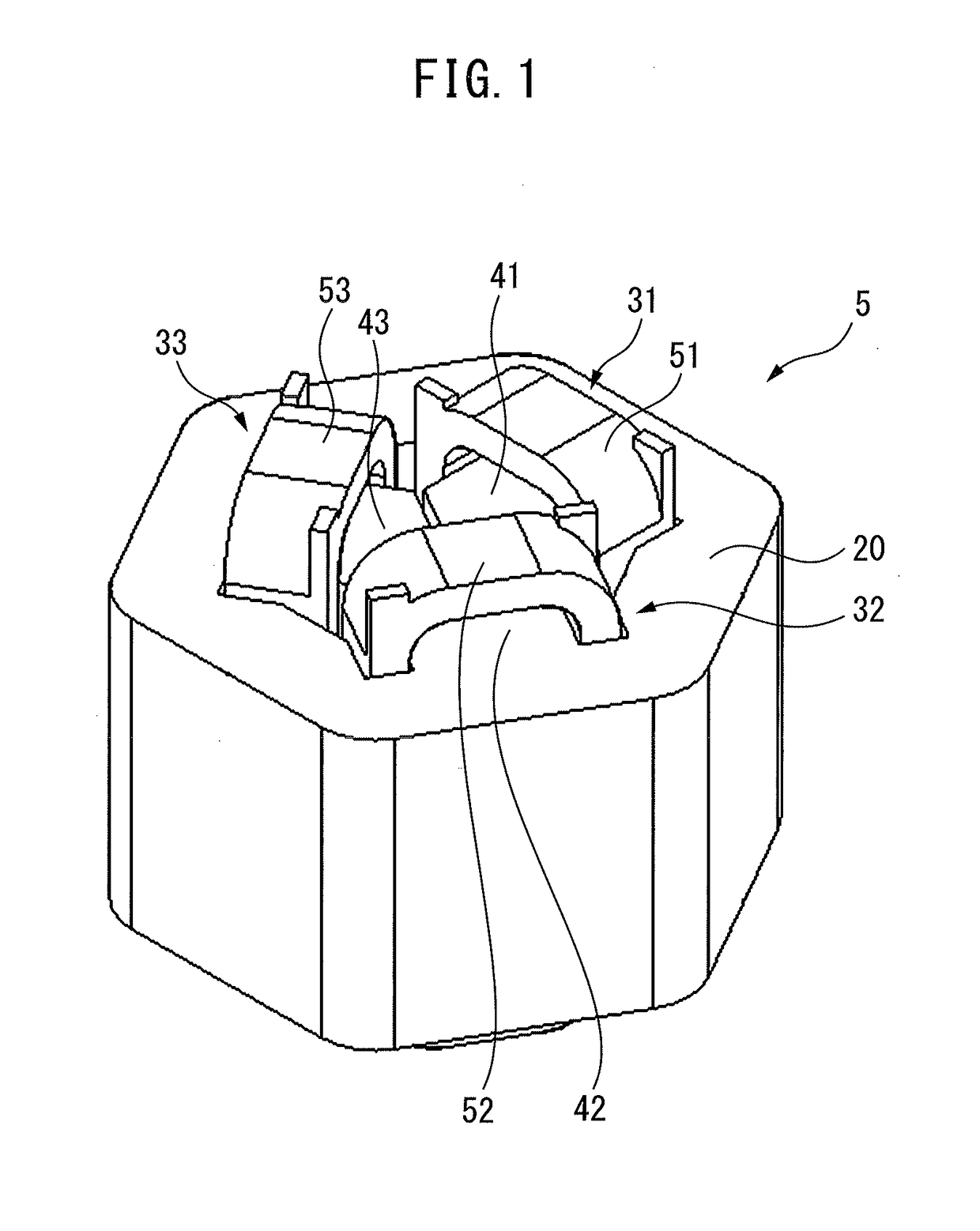

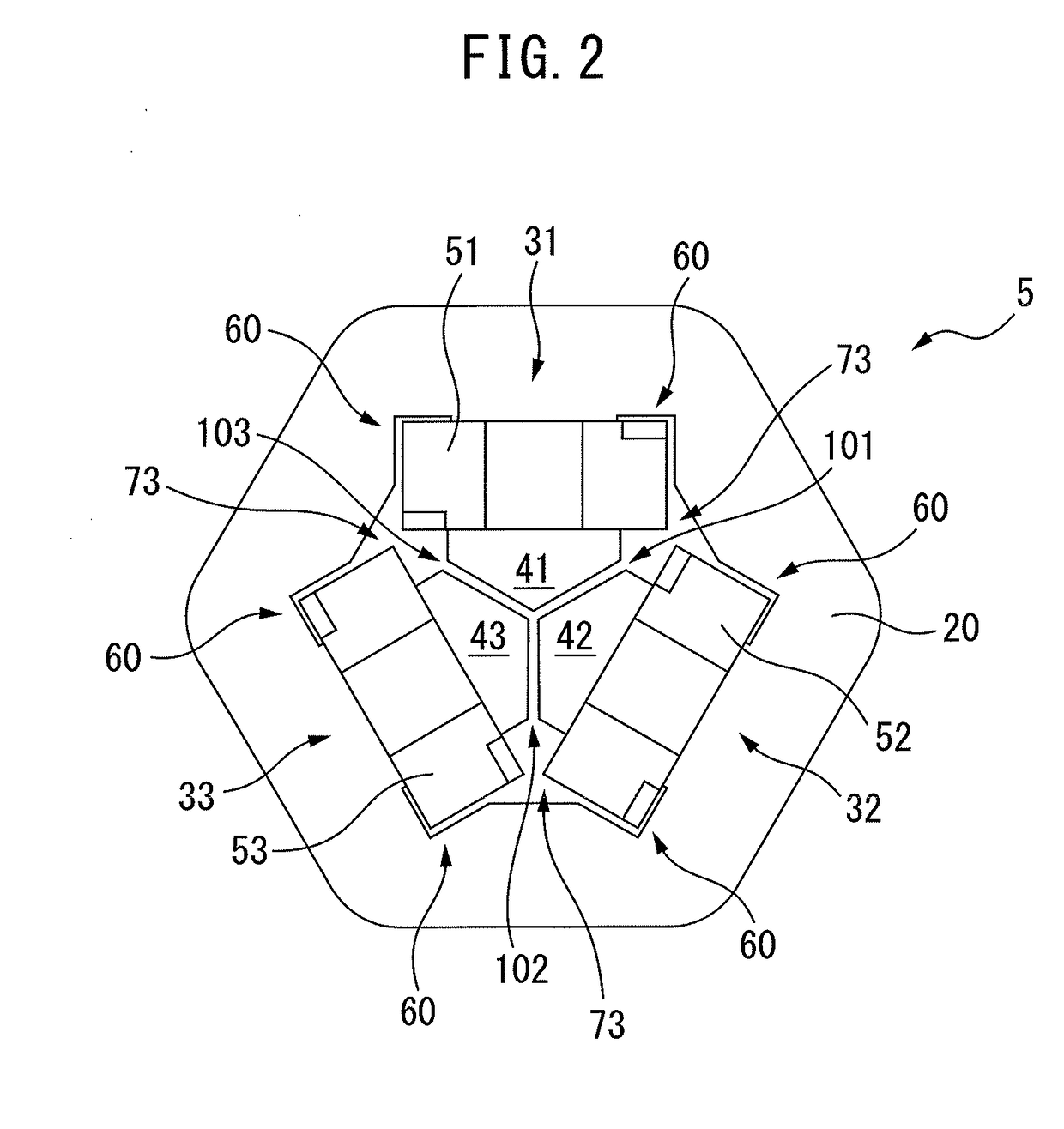

Reactor having iron core unit and coils, motor driver, power conditioner and machine

InactiveUS20180233265A1Improve cooling effectPrevents increase in temperature of coilTransformers/inductances coolingTransformers/inductances casingsPower conditionerEngineering

A reactor includes an outer peripheral iron core, and at least three iron-core coils that contact or are connected to an inner surface of the outer peripheral iron core. Each of the iron-core coils includes iron cores and coils wound onto the iron cores. A space is formed between each of the coils and the outer peripheral iron core.

Owner:FANUC CORP

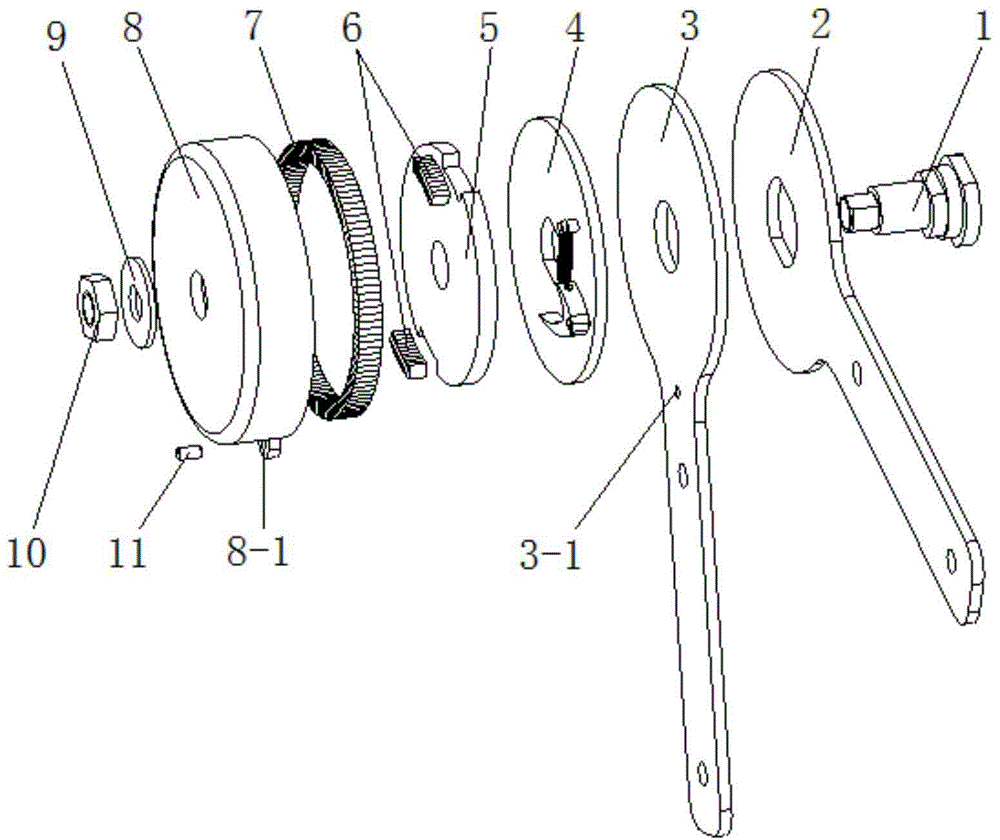

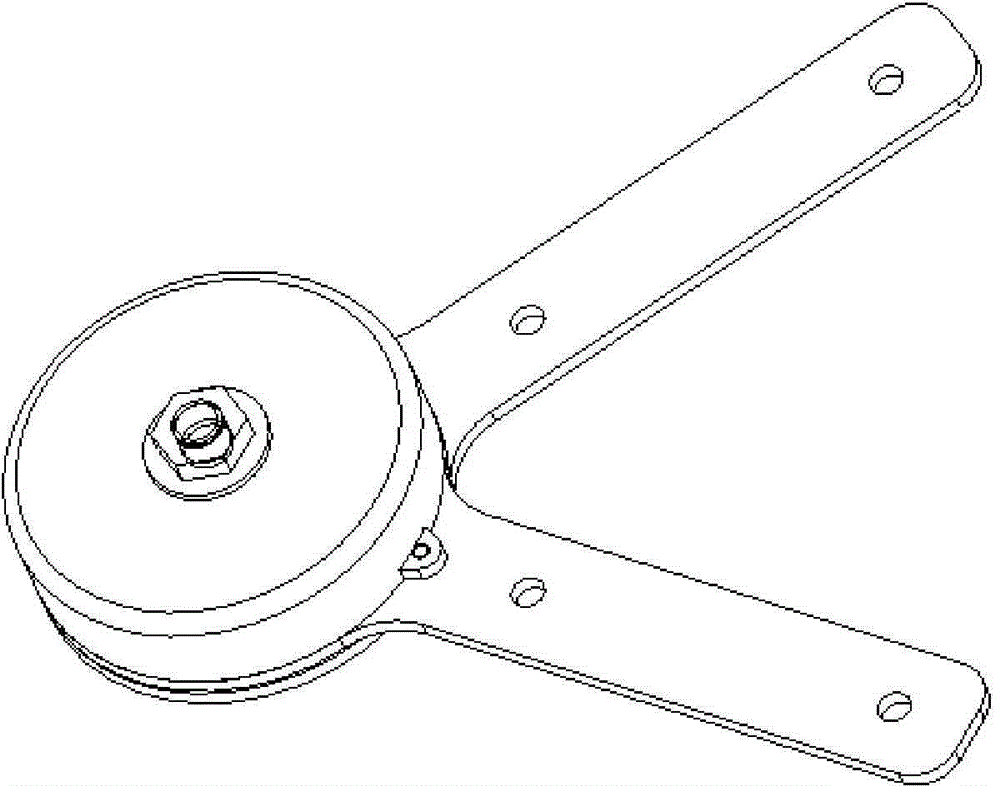

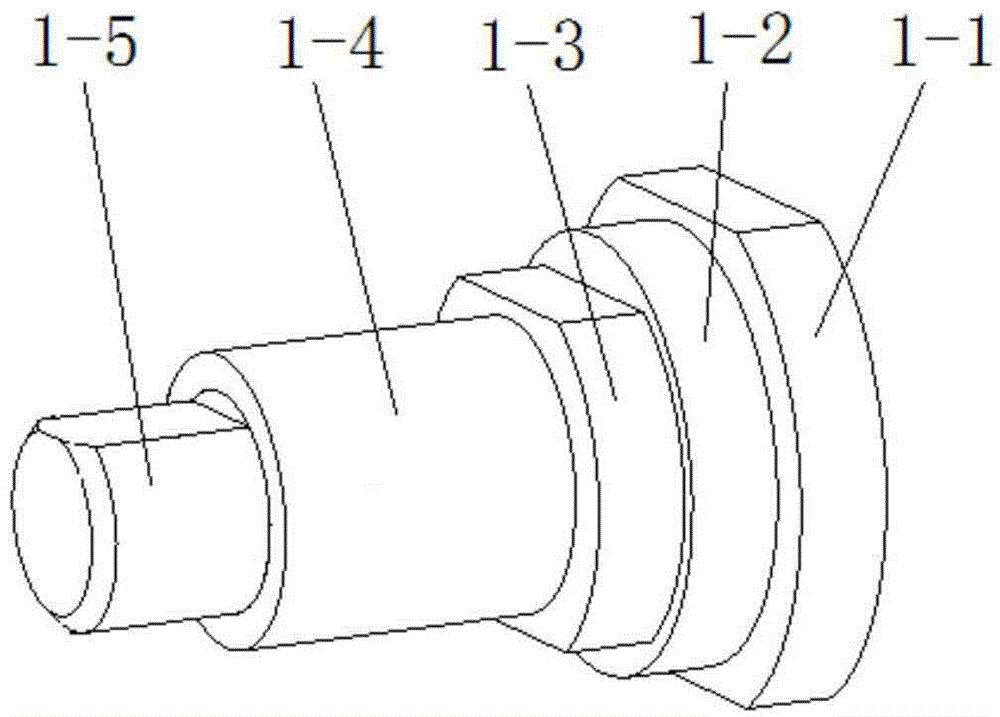

Damping hinge

ActiveCN104675242AExtended service lifeWear does not produceBuilding braking devicesPin hingesEngineeringMagnet

The invention discloses a damping hinge which comprises a rotating shaft (1), a rotating arm (2) and a fixed arm (3). The rotating shaft (1) is connected with the end of the rotating arm (2) and the end of the fixed arm (3), the rotating arm (2) and the fixed arm (3) can rotate relatively by taking the rotating shaft (1) as a center, an inner magnet mounting seat (5) is mounted on the rotating shaft (1), an inner magnet (6) is fixedly mounted on the inner magnet mounting seat (5), a ratchet wheel (5-2) is arranged on one side, close to the rotating arm (2), of the inner magnet mounting seat (5), a pawl (4-4) matched with the ratchet wheel (5-2) is fixedly connected on the rotating arm (2), an outer magnet (7) is fixedly connected on the fixed arm (3), each of the inner magnet (6) and the outer magnet (7) is in the shape of a circular arc formed by bonding two poles of multiple magnets in a staggered arrangement manner, and magnetic force between the inner magnet (6) and the outer magnet (7) is larger than resistance generated when the ratchet wheel (5-2) and the pawl (4-4) rotate forwards. The damping hinge is long in service life and small in structural size.

Owner:SHENZHEN GOLDSITE DIAGNOSTICS

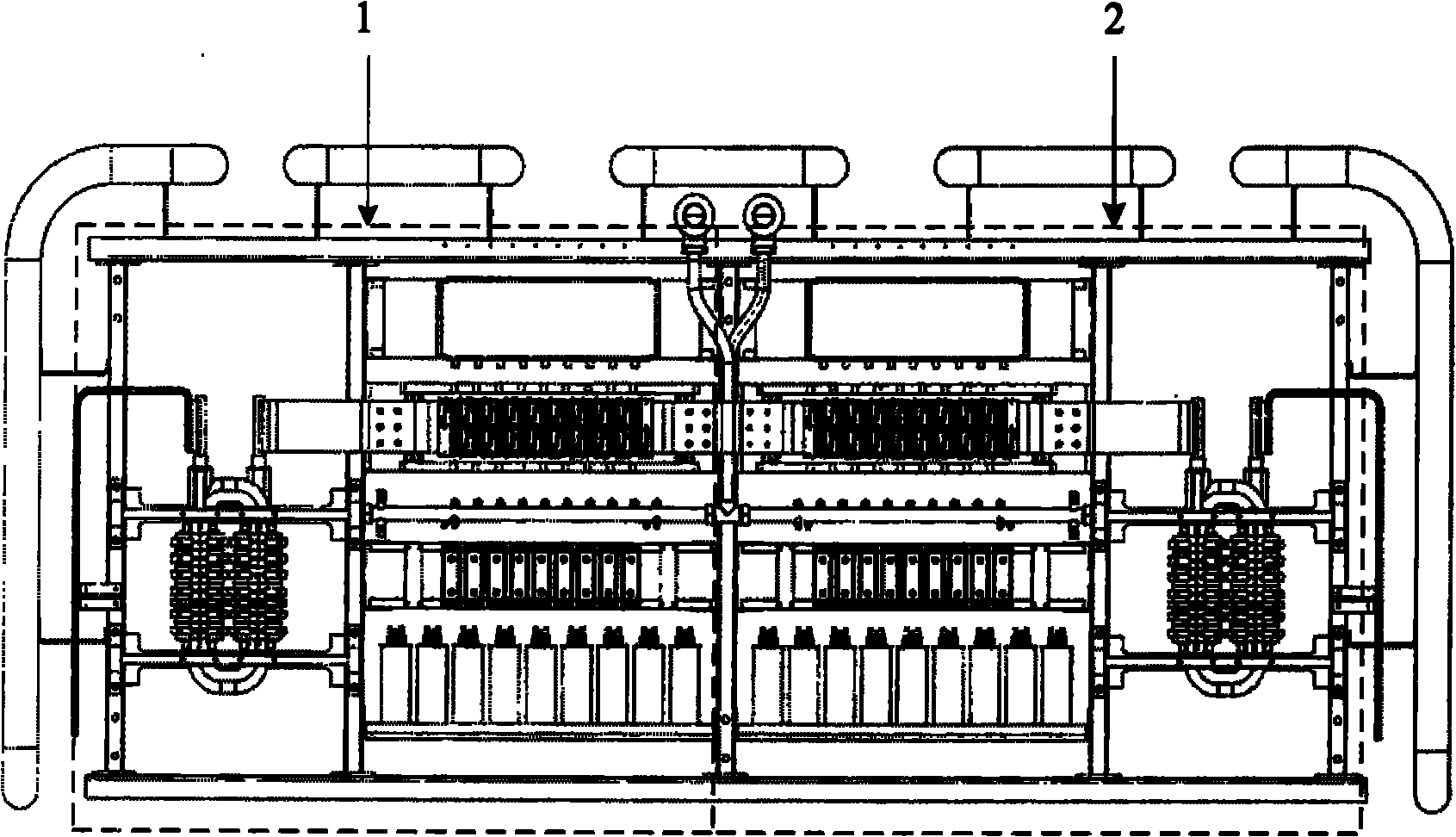

Thyristor converter valve module for HVDC (High Voltage Direct Current) transmission

ActiveCN101924454APrevent leakageSmall geometryCooling/ventilation/heating modificationsPower conversion systemsCapacitanceHigh-voltage direct current

The invention relates to a thyristor converter valve module for HVDC (High Voltage Direct Current) transmission, which is characterized by comprising two valve sections (1 and 2), wherein each valve section is an integrity in structure and comprises a saturated reactor (3), a thyristor unit (4), a DC isobarometric resistor unit, an energy-taking resistor unit, a damping resistor unit (5), a gate unit (6) and a water-cooling system; and in a thyristor-level assembly, the gate unit (6) is arranged at one side of the thyristor unit (4), and the damping resistor unit (5) and a damping capacitor unit (7) are arranged at the other side of the thyristor unit (4). The valve module is watertight, has the advantages of small geometrical size, light weight, convenient assembly and maintenance, simple technical operation and low requirements on operation skills and can effectively improve the mounting efficiency.

Owner:CHINA ELECTRIC POWER RES INST +1

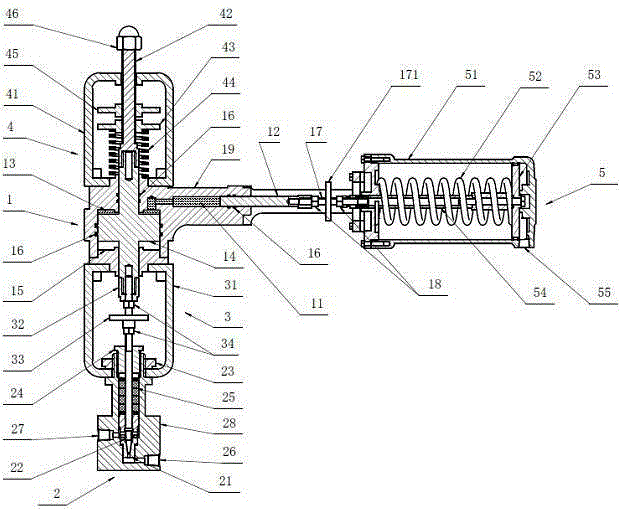

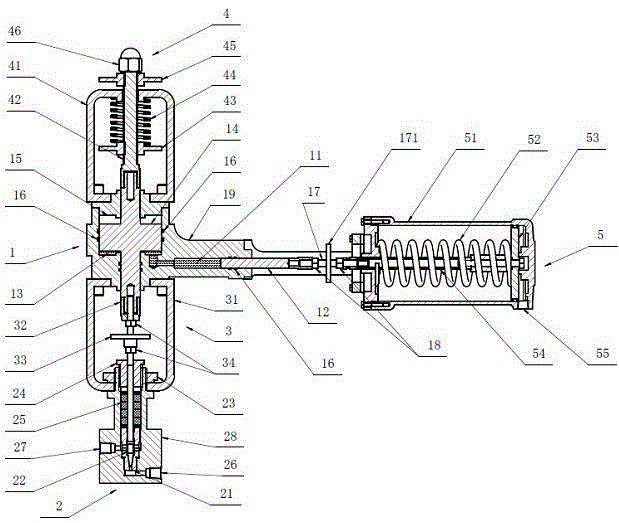

Small flow control valve

ActiveCN106763803AEfficient driveEasy to controlOperating means/releasing devices for valvesLift valveControl valvesActuator

The invention discloses a small flow control valve which can be used in rigorous conditions. The small flow control valve comprises five parts, namely a hydraulic mechanism, a reset device, a valve connecting device, a valve body and an actuator. The hydraulic mechanism is composed of a whole rack, an active piston, a slave piston and an actuator connecting device. The valve body adopts a conventional high-pressure valve structure provided with an adjusting type valve rod, and a valve element adopts a long conical valve needle and a valve seat. The actuator adopts a general piston type actuator with a long stroke. According to the flow valve, stable control over micro-flow can be realized through extremely tiny opening change, and precise control over the micro-flow under a high pressure difference is achieved. Meanwhile, the control valve further has the characteristics of open structure, flexible configuration, convenient conversion and convenient maintenance and adjustment.

Owner:CHINA PETROLEUM & CHEM CORP +1

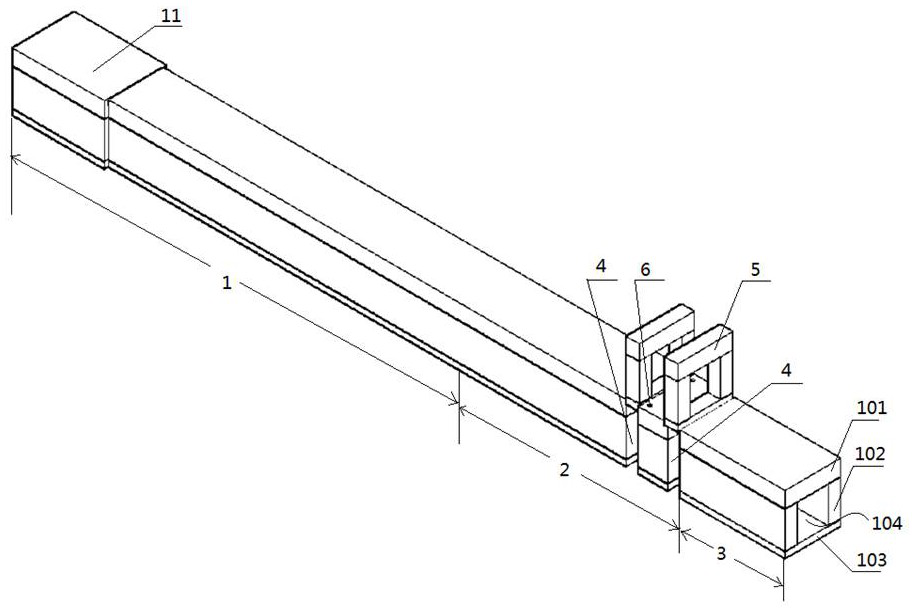

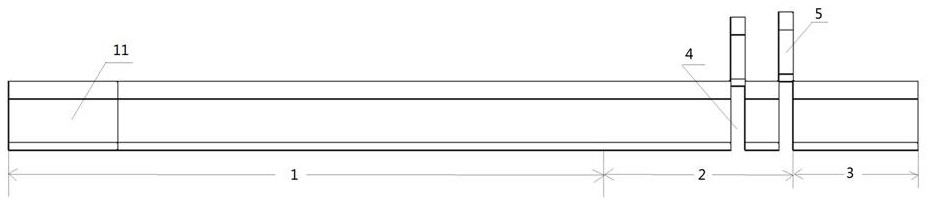

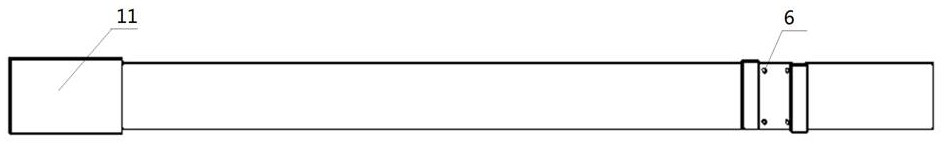

Shock wave tunnel test device and test method

ActiveCN111982451ASimple structureLarge structure sizeShock testingStrength propertiesReinforced concreteExplosive Agents

The invention discloses a shock wave tunnel test device. The shock wave tunnel test device adopts a reinforced concrete rectangular cylindrical structure, and a tunnel is formed in the structure, theshock wave tunnel test device comprises: a plane shock wave forming section, which includes a head arranged at one end of the shock wave tunnel test device and used for receiving explosive shock wavesgenerated by explosive explosion, wherein the length of the plane shock wave forming section is 30m; a tail section, which is arranged at the other end of the shock wave tunnel test device, and is anexplosive shock wave outflow section; and a test section, which is located between the plane shock wave forming section and the tail section, wherein stable planar shock waves are formed when the explosive shock waves reach the test section; and two clamping grooves are vertically formed in the tail part of the test section, are arranged at an interval, and are used for hoisting a concrete prefabricated test component or directly hoisting a movable concrete prefabricated frame. The shock wave tunnel test device is simple in structure, relatively low in manufacturing cost and capable of meeting various test requirements.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

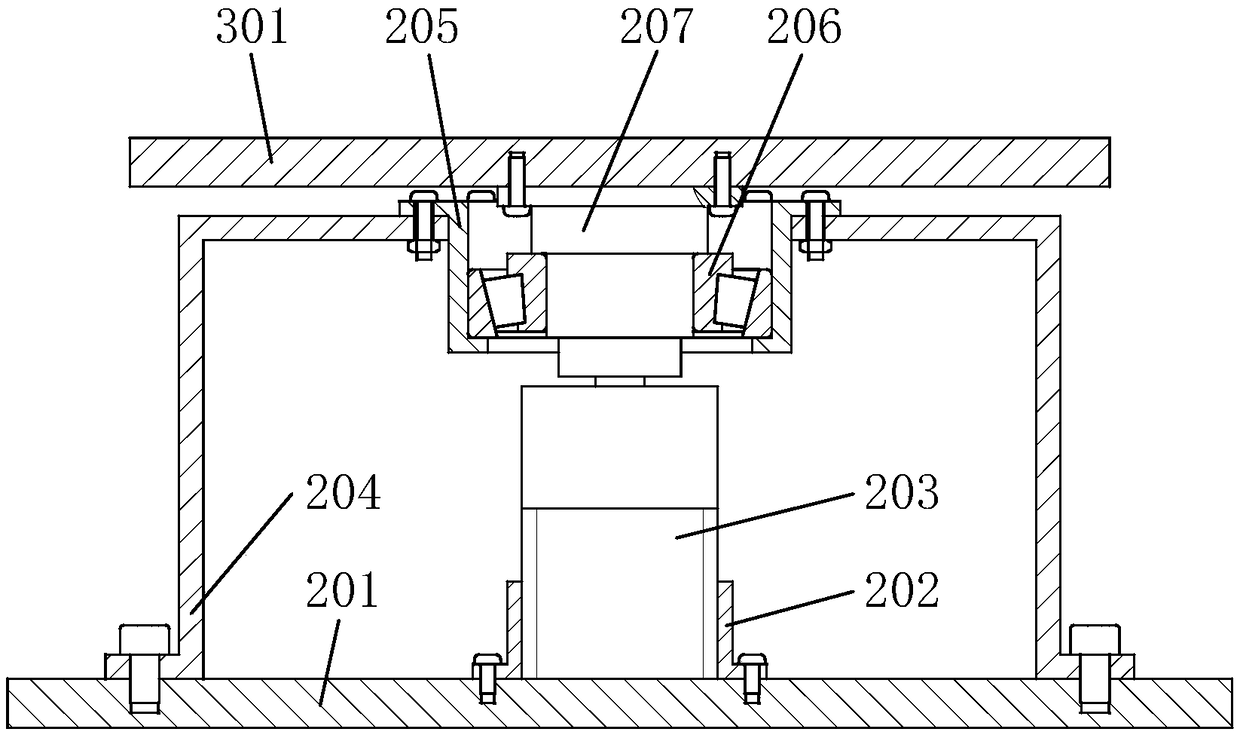

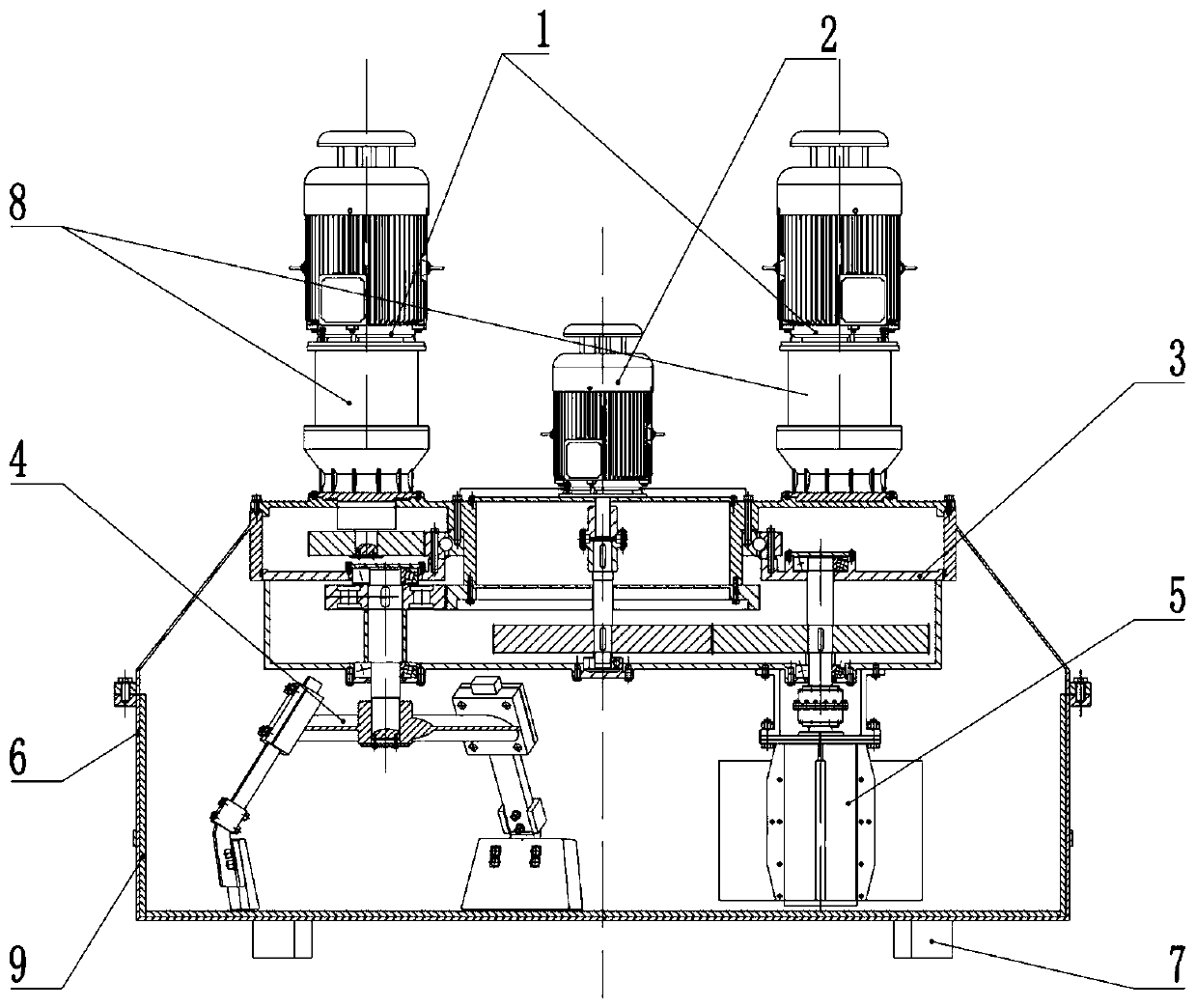

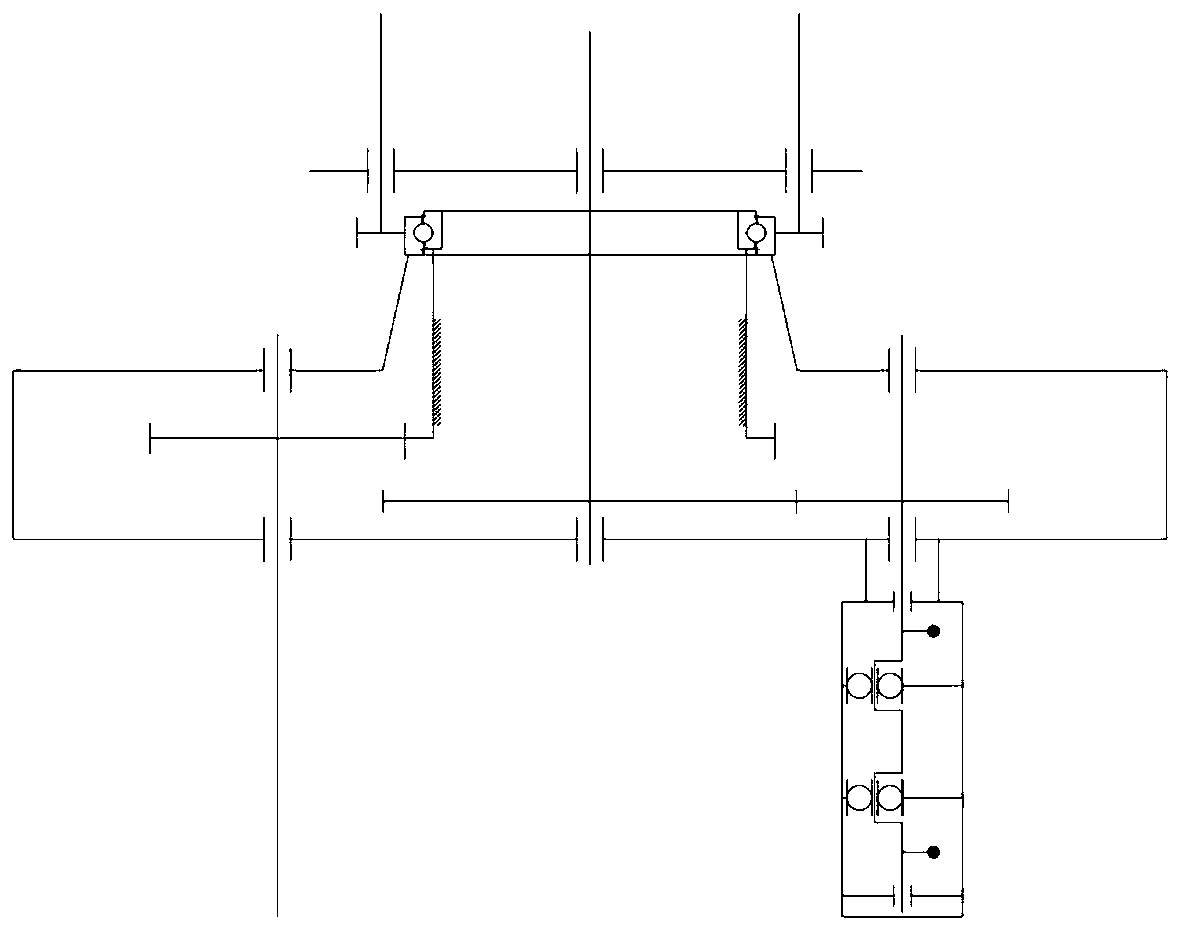

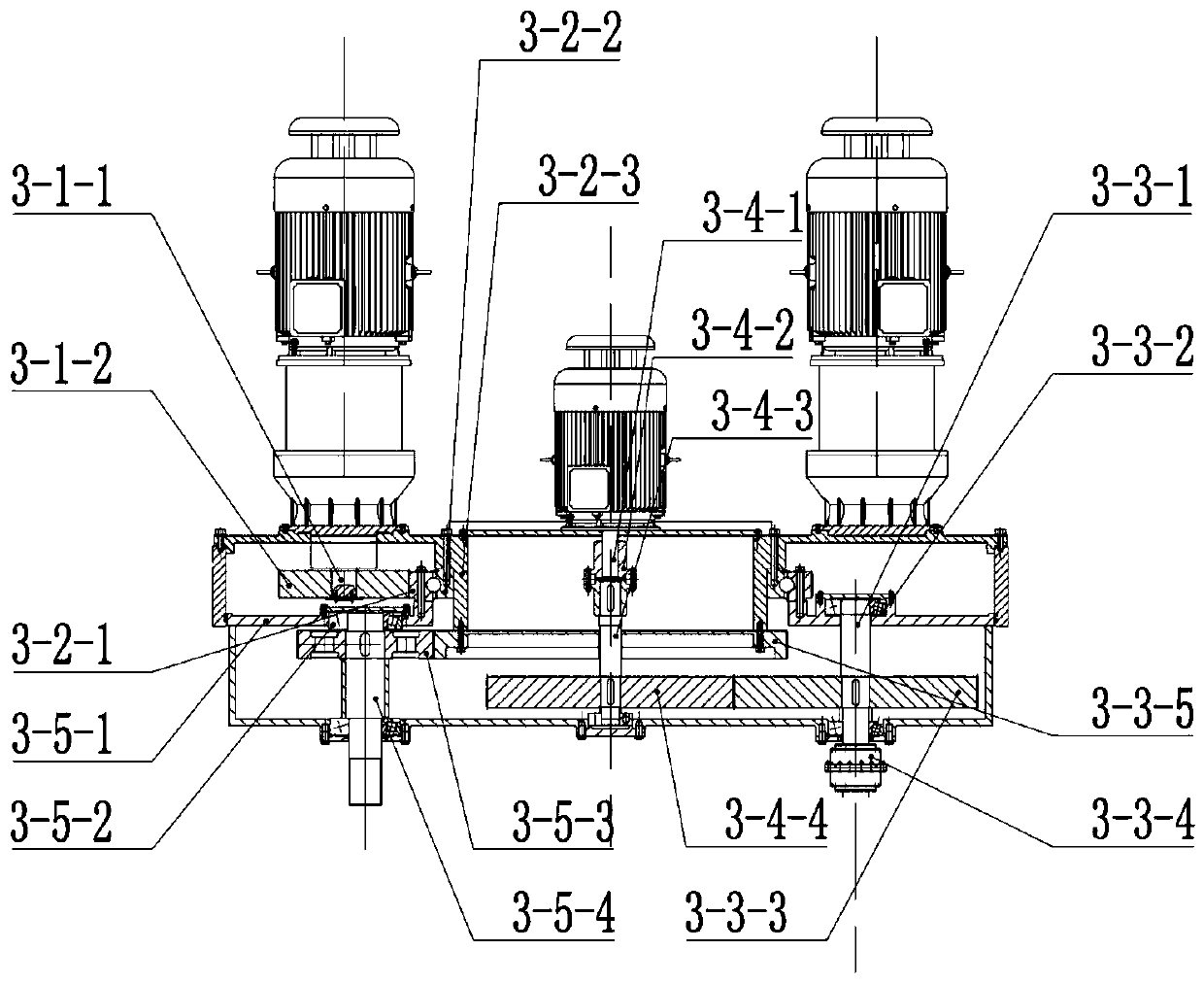

Vertical shaft planetary vibration type concrete mixer

PendingCN110900831AStir the material evenlyEasy maintenanceHollow article cleaningCement mixing apparatusClassical mechanicsElectric machinery

The invention discloses a vertical shaft planetary vibration type concrete mixer. Two mixing driving motors and a vibration driving motor are arranged on a mixing cylinder body, the mixing driving motors and the vibration driving motor are connected with a mixing device and a vibration exciter arranged in the mixing cylinder body through transmission devices respectively, the vibration driving motor is arranged between the two mixing driving motors, the mixing device rotates around the geometric center of the mixing cylinder body in the mixing cylinder body to mix concrete in a revolution rotation mode, the vibration exciter is in meshing connection with a sun wheel arranged on the vibration driving motor through a vibration exciter power transmission planetary wheel, strong vibration energy is transmitted into the concrete during revolution rotation, wear-resistant lining plates are arranged at the inner wall and the bottom of the mixing cylinder body, a discharging device is arrangedat the bottom of the mixing cylinder body, and the discharging device is connected with a hydraulic system and an electric system which are arranged outside the mixing cylinder body. The mixer is simple in structure, a gear ring required by a traditional planetary gear train does not need to be arranged, and a speed reduction mechanism is greatly simplified.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com