Automatic welding-torch for ultra narrow gap and consumable electrode under gas coverage, and preparation method

An automatic technology for melting electrode gas and protection, applied in other manufacturing equipment/tools, manufacturing tools, welding equipment, etc., can solve the problems of concentricity, watertight and airtight quality of section joints, and insulators that reduce insulation reliability and disadvantages Solve problems such as metallurgical protection in the welding area, achieve reliable metallurgical protection, improve insulation reliability, and increase the effect of structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

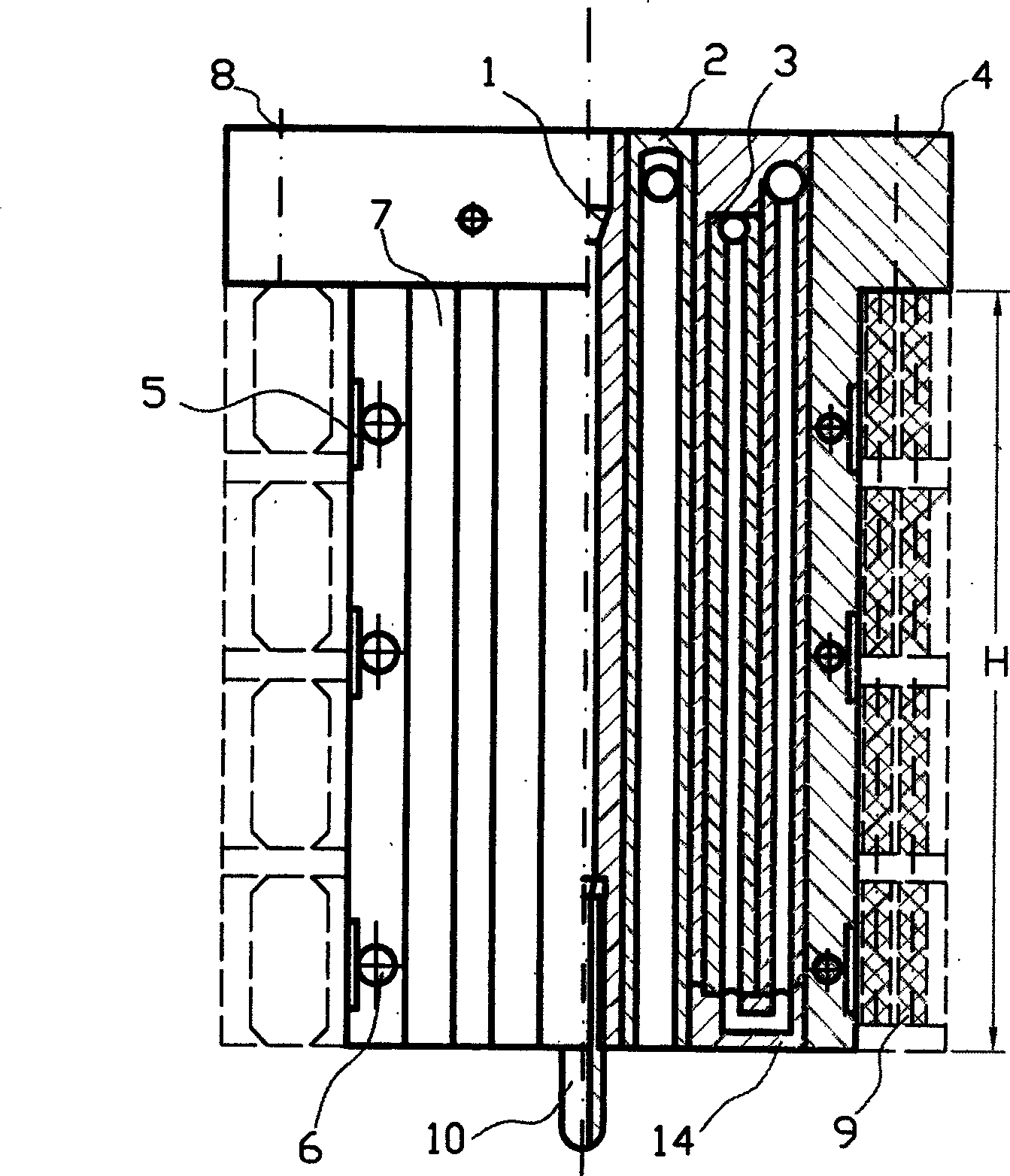

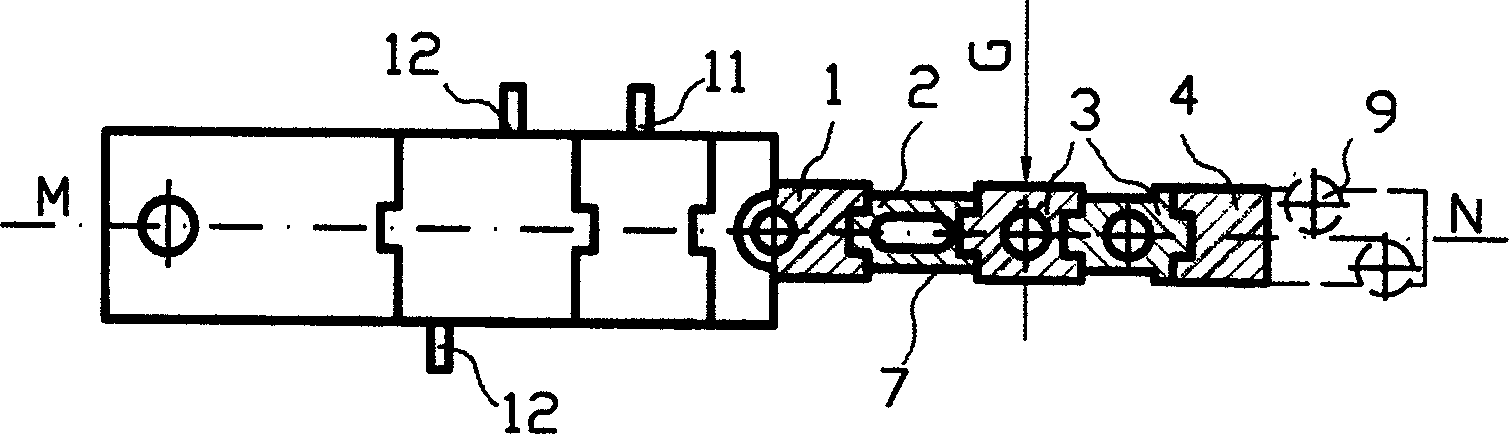

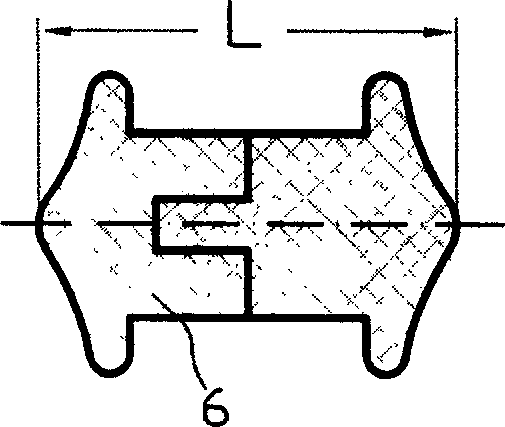

[0014] Such as Figure 1 to Figure 6 As shown, the present invention has an ultra-narrow-gap gas-shielded automatic welding torch, which consists of a guide wire assembly 1, a gas guide assembly 2, and a guide wire assembly made of thick-walled pipes without weld seams in the full height direction of fluid / solid transmission. The water component 3, the side wall component 4, the insulating component composed of the embedded insulator 6 or / and the rolling insulator 9, and the contact tip 10; The air component 2 and the side wall component 4 are adjacent to the outer side of the water guide component 3, and the insulating component is arranged on the left and right outermost sides in the width direction of the welding torch, and the maximum thickness of the welding torch working section is 7 mm; when the maximum thickness of the welding torch working section is 5 mm is An embodiment, 4 mm is also an embodiment, it can also be 3 mm; the embedded insulator 6 and the rolling insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com