Petroleum refining catalyst preparation technology

A preparation process and catalyst technology, applied in the field of petroleum refining catalyst preparation technology, can solve the problems of low catalyst quality and efficiency, and achieve the effects of shortening working time, reducing production cost and refining structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

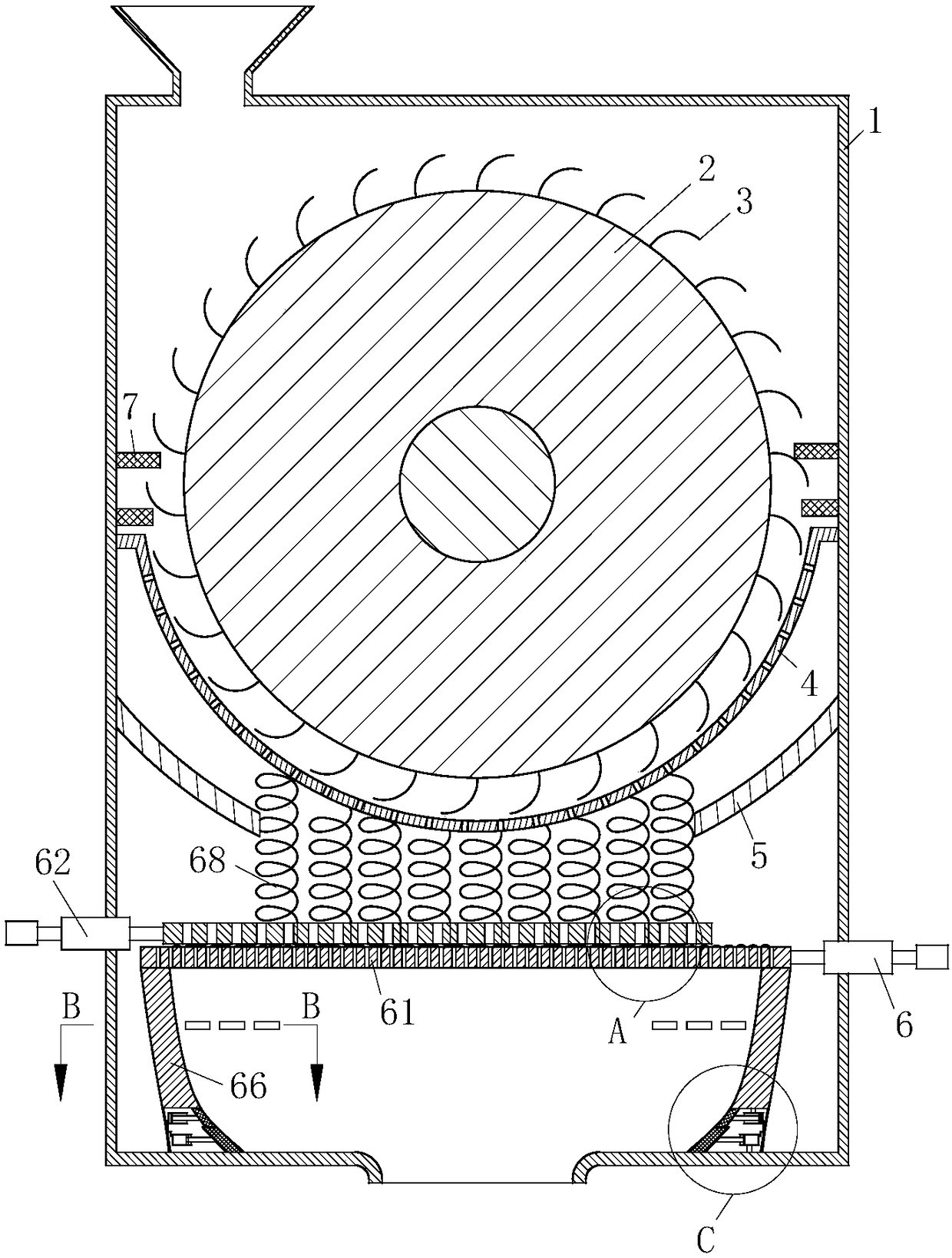

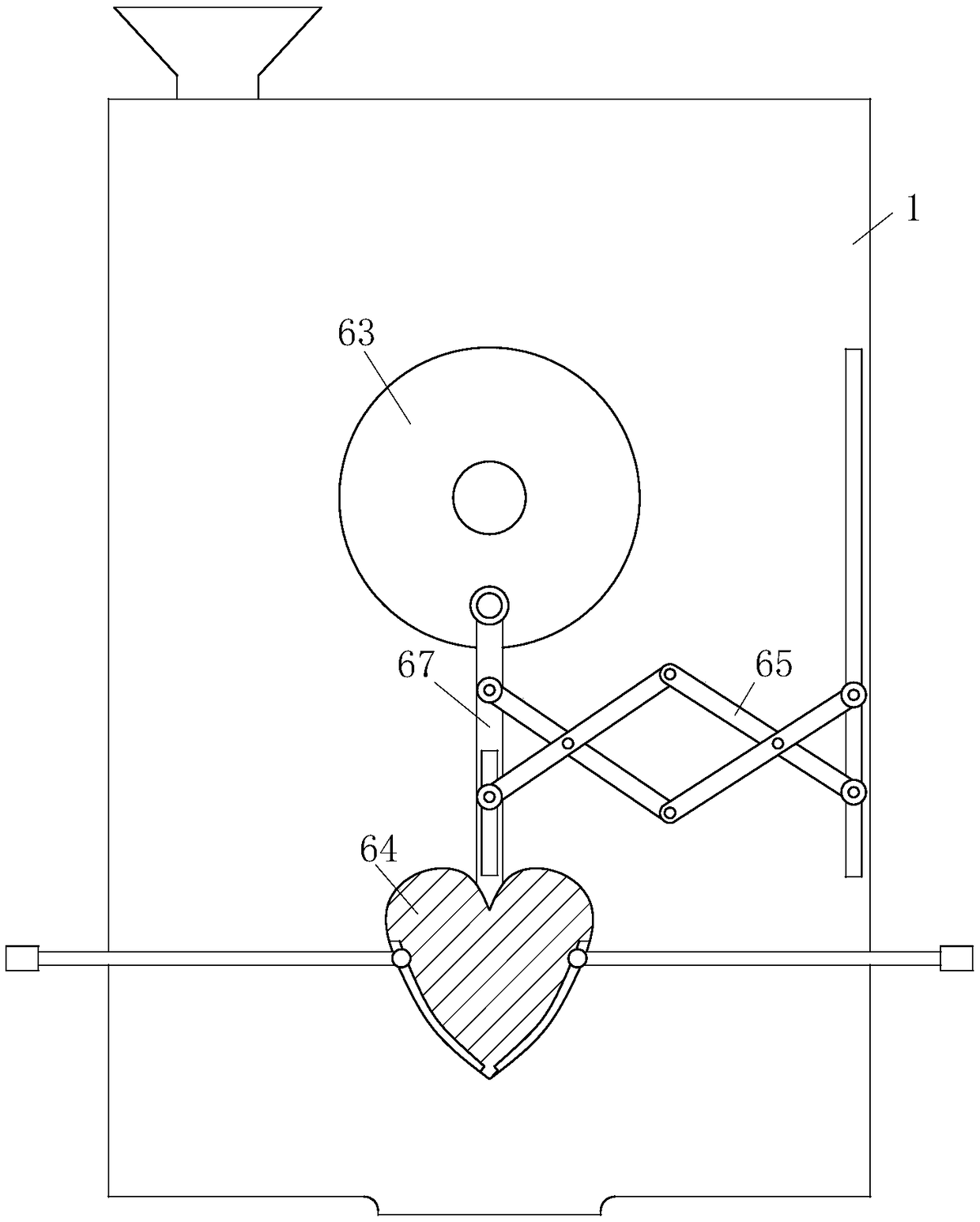

[0030] use Figure 1-Figure 8 A preparation process of a petroleum refining catalyst according to an embodiment of the present invention is described as follows.

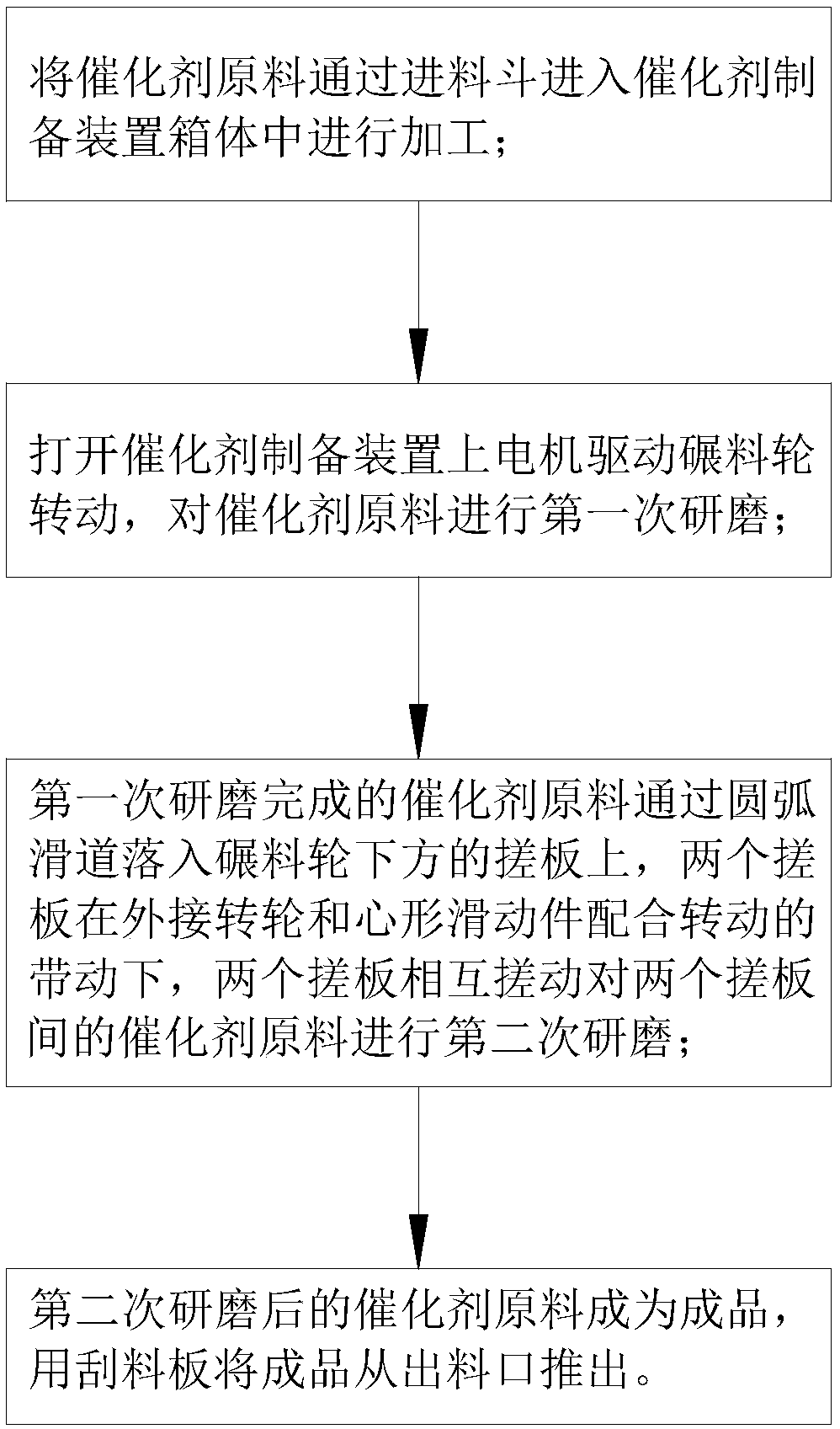

[0031] Such as figure 1 , figure 2 with image 3 Shown, a kind of petroleum refining catalyst preparation technique of the present invention, this technique comprises the steps:

[0032] S1: Put the catalyst raw material into the catalyst preparation device box through the feeding hopper for processing; this device can improve the production efficiency of the catalyst raw material, improve the quality of the product, and at the same time; can minimize the waste and loss of the catalyst raw material and reduce the production cost ; Moreover, the device has a simple structure, a small volume, and takes up less production space;

[0033] S2: Open the motor on the catalyst preparation device in S1 to drive the grinding wheel to rotate, and grind the catalyst raw material for the first time; roll and compact the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com