Floating type offshore wind power assembly platform and method using floating type offshore wind power assembly platform for assembly offshore wind turbine

A technology for offshore wind power and offshore wind turbines, which is applied in wind turbine components, wind energy power generation, wind turbines, etc., can solve problems such as difficulty in dismantling and high cost of temporary seats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

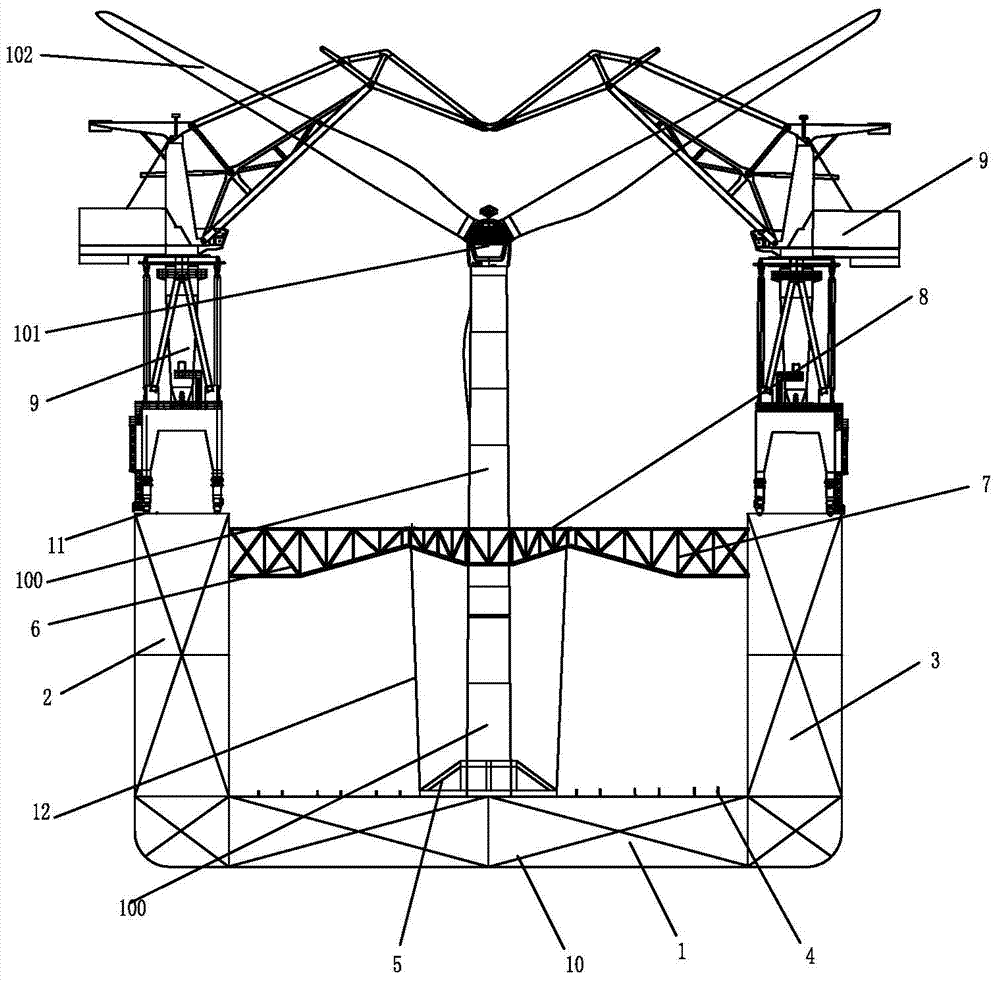

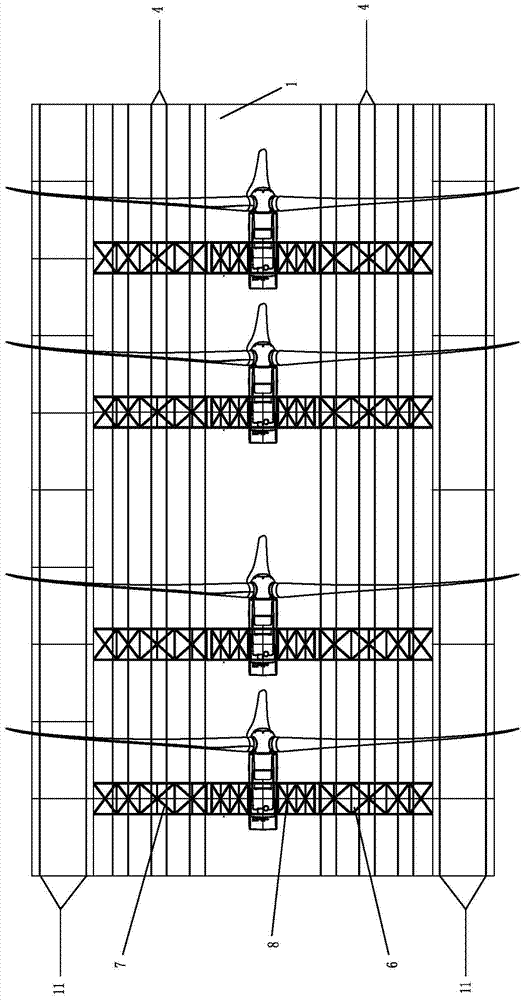

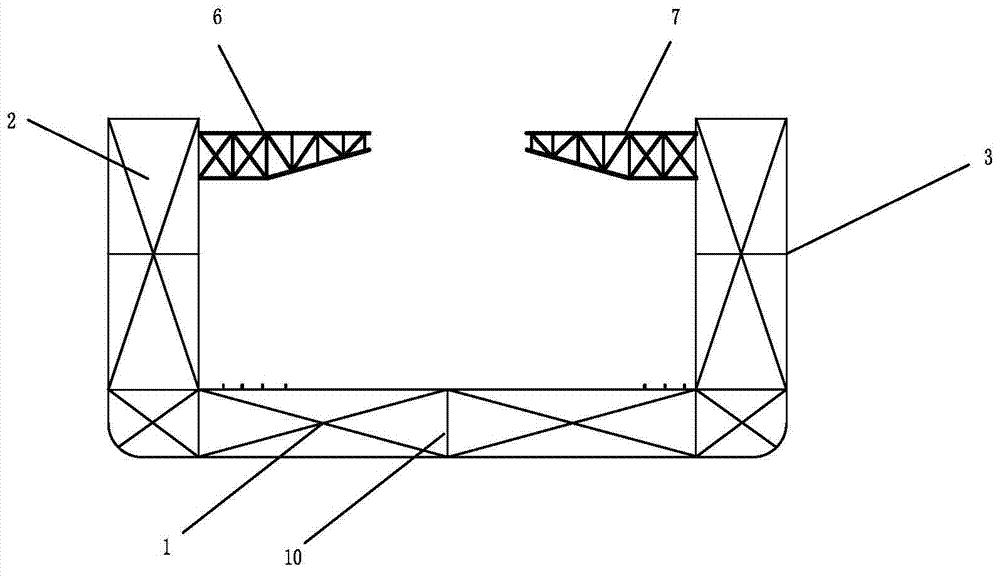

[0028] Such as figure 1 As shown, a floating offshore wind power assembly platform, wherein the wind turbine includes a tower 100, a main engine 101, blades 102, which includes a platform 1, and the left side of the platform 1 is provided with a left ballast higher than that of the platform 1 cabin 2, the right side of the platform 1 is provided with a right ballast tank 3 higher than the platform 1, the platform 1 is provided with a bottom ballast tank 10, and the platform 1 is provided with a transport guide rail 4, A fixed lifting bracket 5 for fixing the wind tower is provided between the left ballast tank 2 and the right ballast tank 3 on the platform 1, and the inner side of the upper part of the left ballast tank 2 is provided with a port side fixed Bracket 6, the upper inner side of the right ballast tank 3 is provided with a starboard side fixed bracket 7, and the middle of the side side fixed bracket 6 and the starboard side fixed bracket 7 is provided with a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com