Thyristor converter valve module for HVDC (High Voltage Direct Current) transmission

A thyristor converter valve, high-voltage direct current technology, applied in the direction of output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., can solve the needs of boosting and increasing capacity of direct current transmission, no application components Minimum technology, unfavorable valve module installation efficiency and other issues, to achieve the effect of ensuring long-term connection reliability, shortening the length of electrical wiring, and optimizing electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

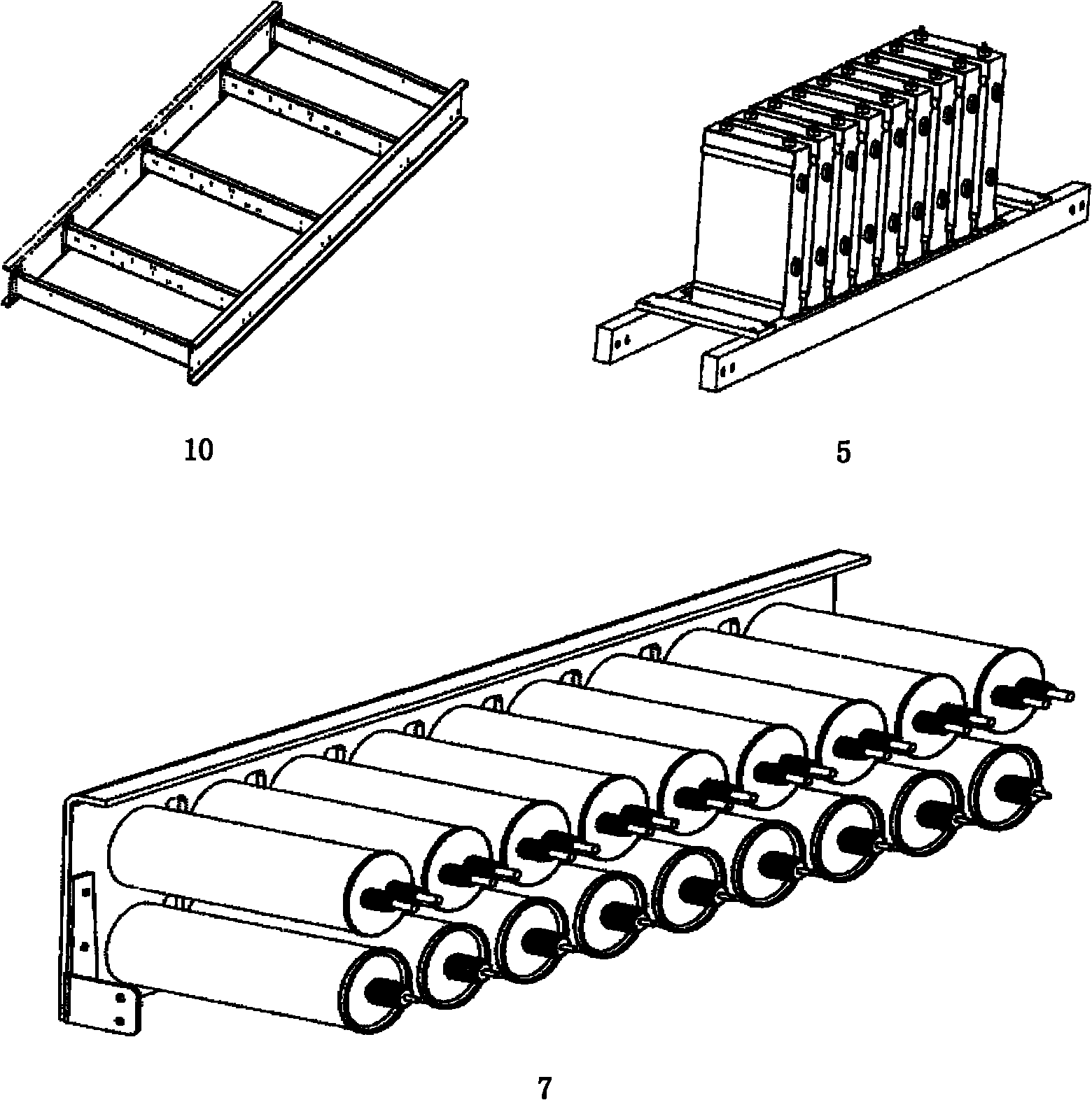

[0044] In the thyristor converter valve module used for high-voltage direct current transmission in this embodiment, the insulating material of the valve module is a flame-retardant plastic material, and the shell of the damping resistor is made of a flame-retardant plastic material, and the damping capacitor is an air-filled capacitor. : The fire-proof characteristics of the valve module are increased, so that the valve module has good flame-retardant characteristics, which can effectively reduce product loss caused by fire.

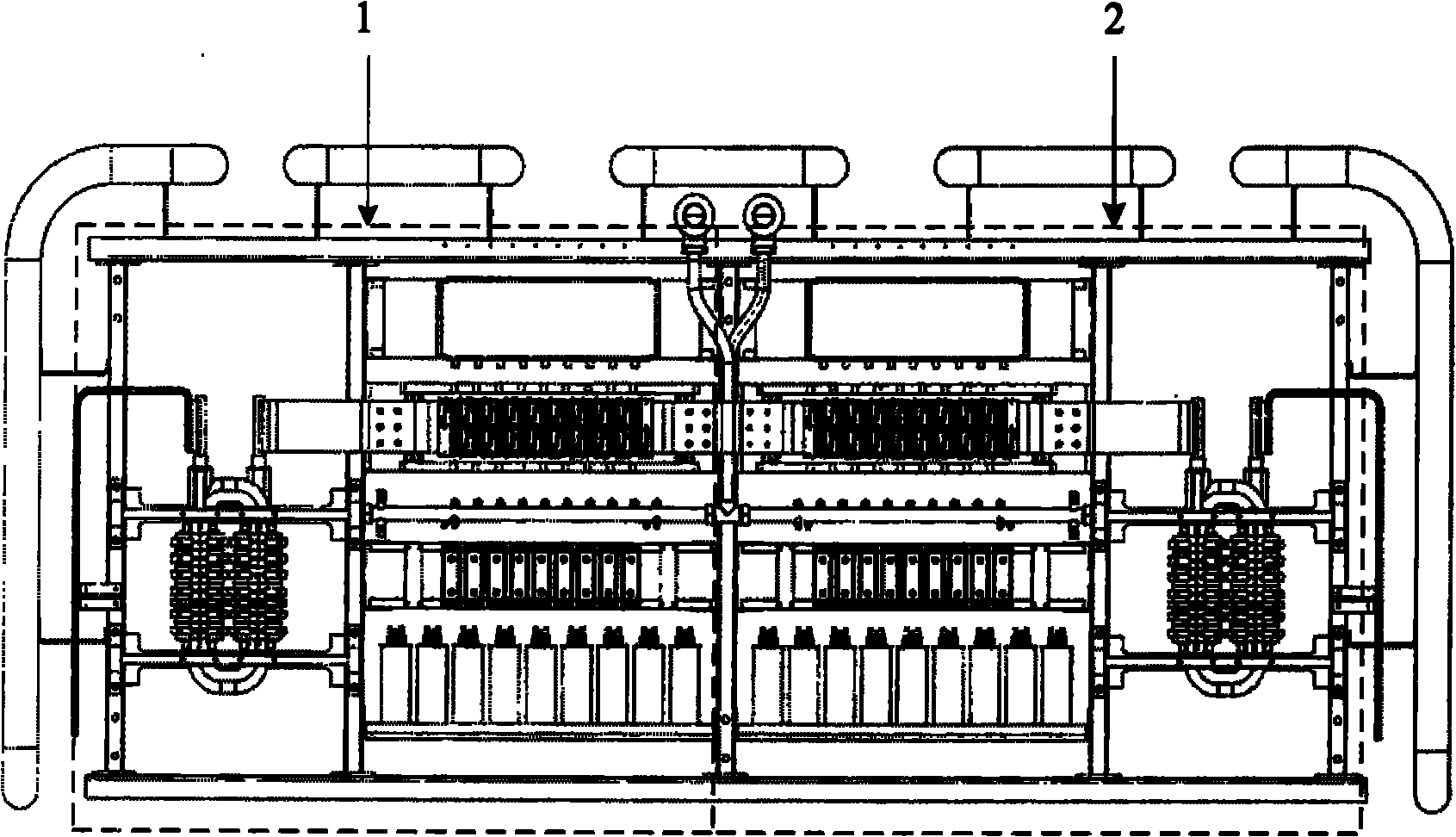

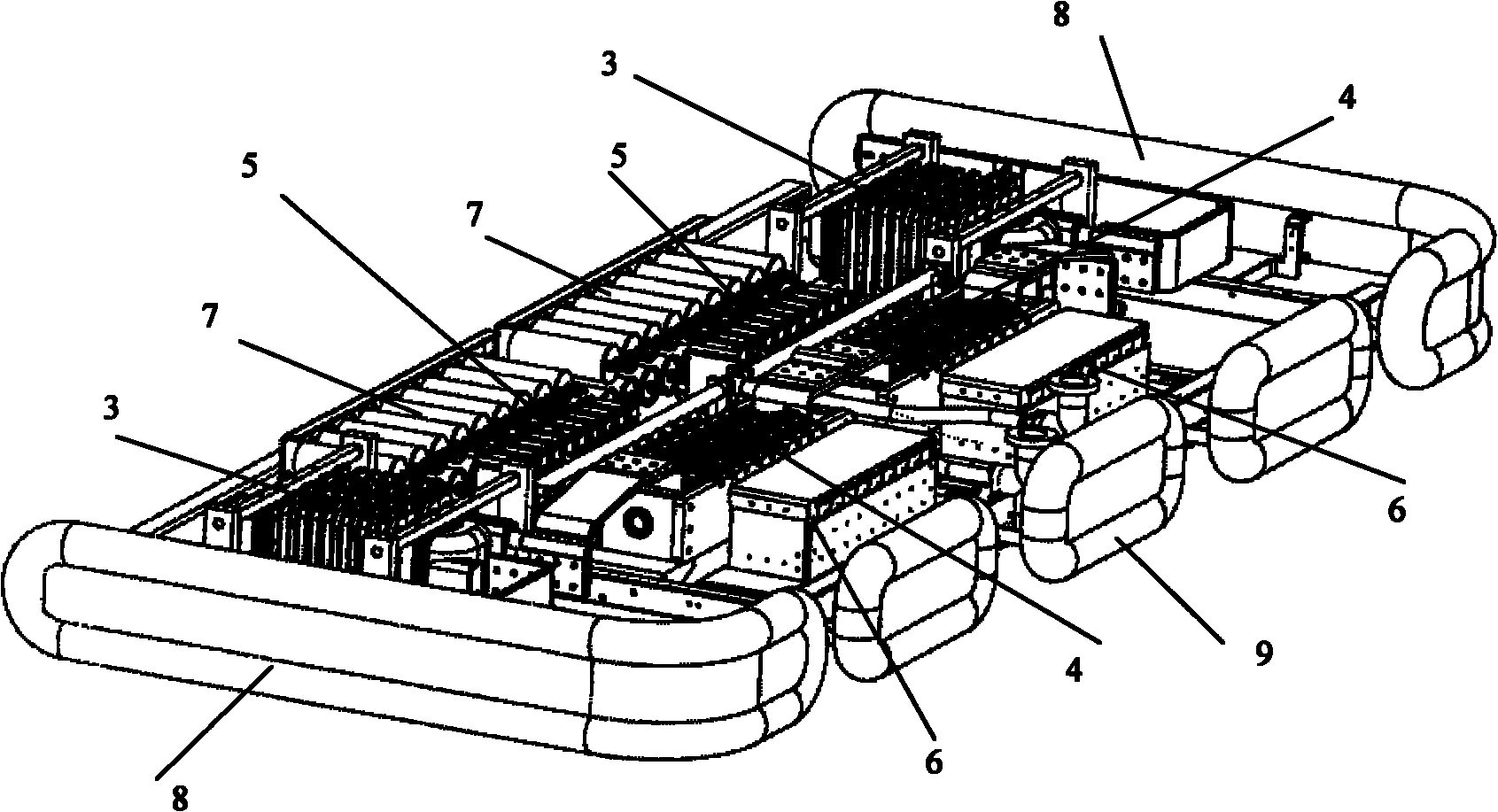

[0045] The thyristor converter valve module includes two valve sections, valve section 1 and valve section 2, and each valve section is structurally integrated: in order to effectively disperse the weight load of the valve module, a valve module The weight of the valve is distributed on the two valve sections, which reduces the requirements of the weight load of the valve module on the structural design strength, and also reduces the requirements on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com