Cooling device pertaining to an electrical machine

A cooling device and cooling system technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., to achieve the effect of improving the cooling effect and the best cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

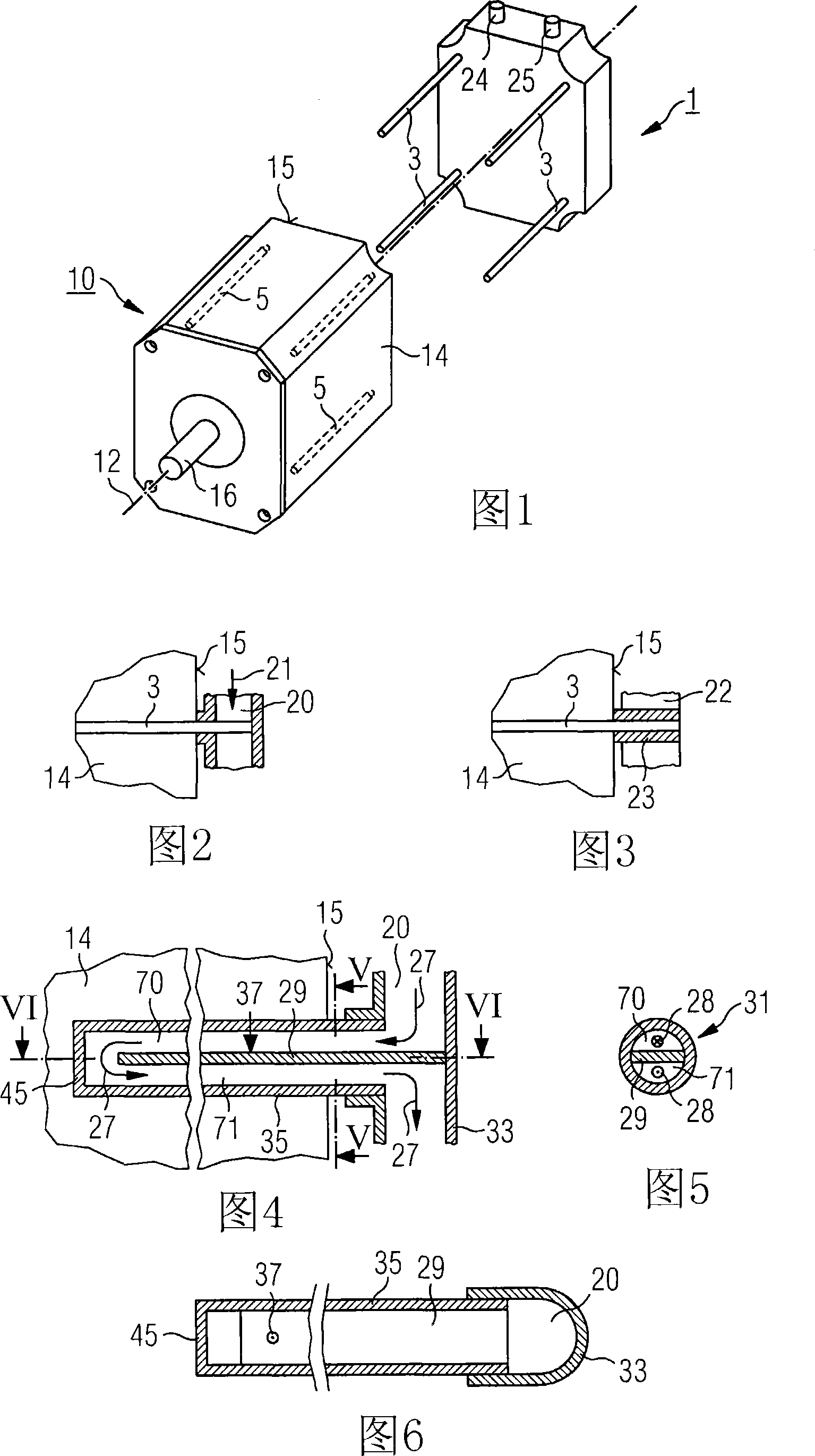

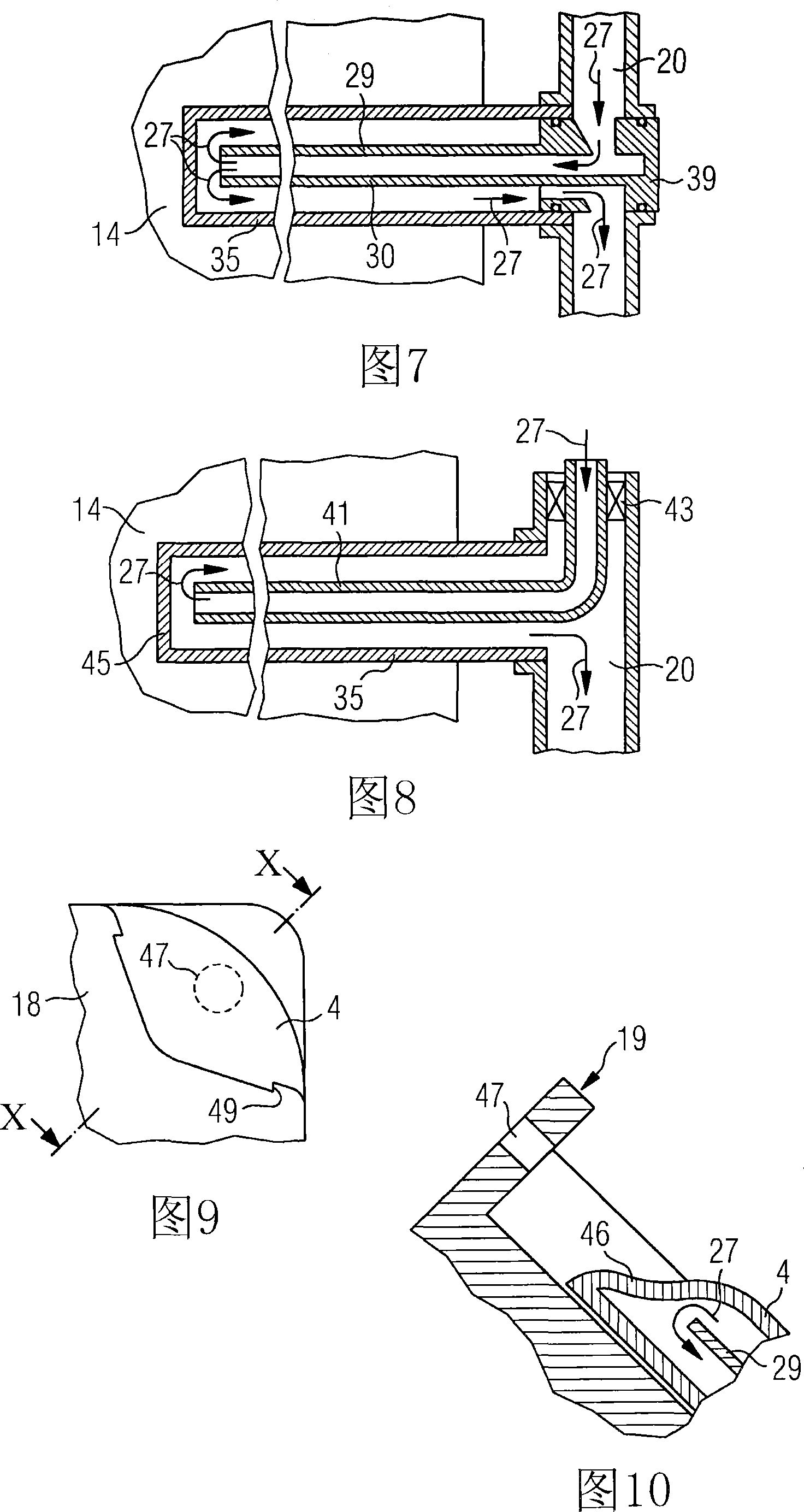

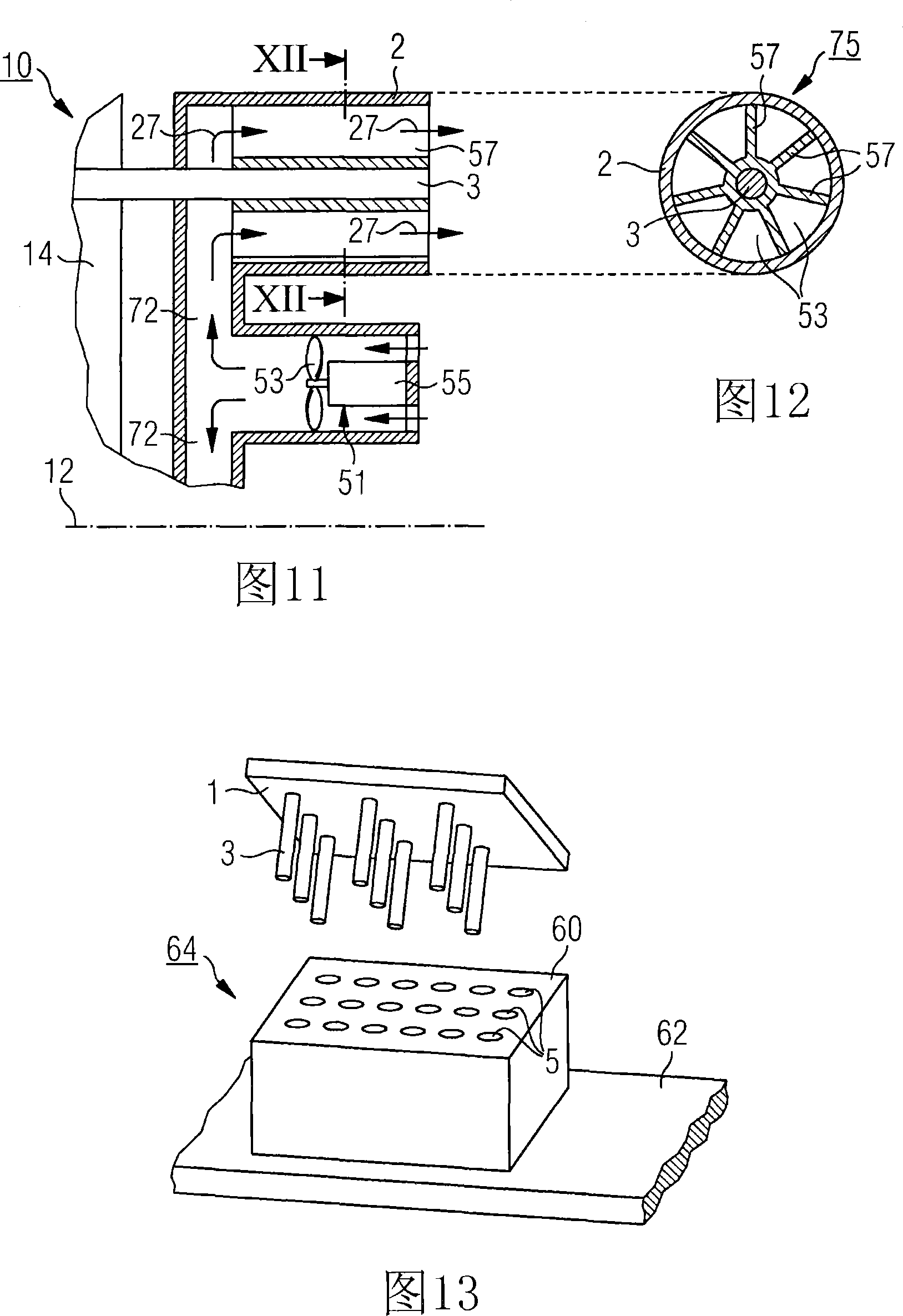

[0037] FIG. 1 shows an electric motor 10 . The electric machine 10 is a housingless rotating electric machine having an axis 12 . The electric machine 10 also has a shaft 16 and a stator 14 . A plurality of receiving channels 5 are arranged in the stator 14 . The receiving channel 5 is used to accommodate the rod-shaped heat conducting element 3 . Furthermore, FIG. 1 also shows a cooling device 1 . The cooling device 1 has connection pieces 24 and 25 . These connections are used, for example, to introduce or discharge cooling fluid or cooling air. The cooling device 1 also has a plurality of rod-shaped heat conducting elements 3 . The rod-shaped heat conducting element 3 is configured to be inserted into the receiving channel 5 . According to another design not shown in FIG. 1 , the rod-shaped heat-conducting element 3 is arranged on the stator 14 , wherein the rod-shaped heat-conducting element 3 protrudes outside an end face 15 of the motor 10 , wherein the rod-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com