Auxiliary heat dissipation type water passing cable

A water-passing cable and auxiliary heat dissipation technology, which is applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of conductor heating, cable boiling, conductor cable twisting tightness not meeting the requirements, etc., to increase the heat dissipation surface, Effect of speeding up heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

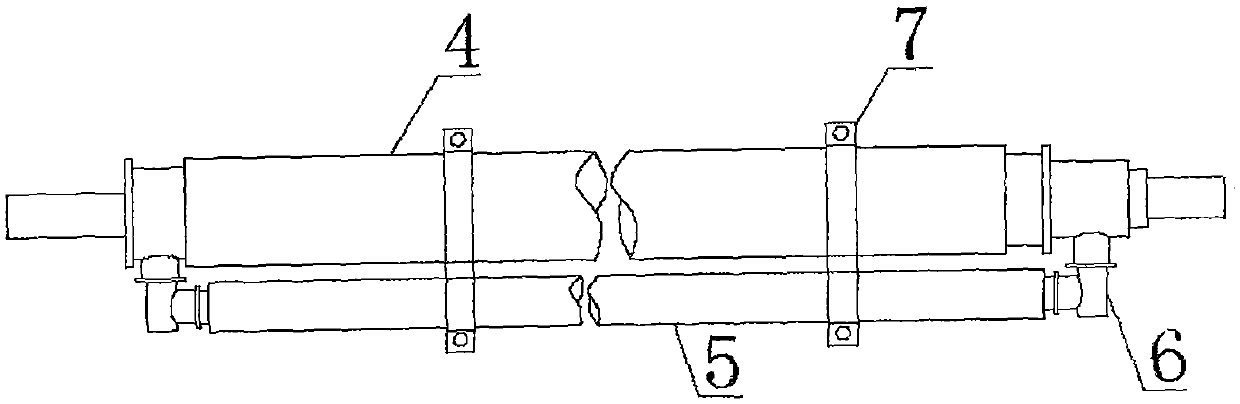

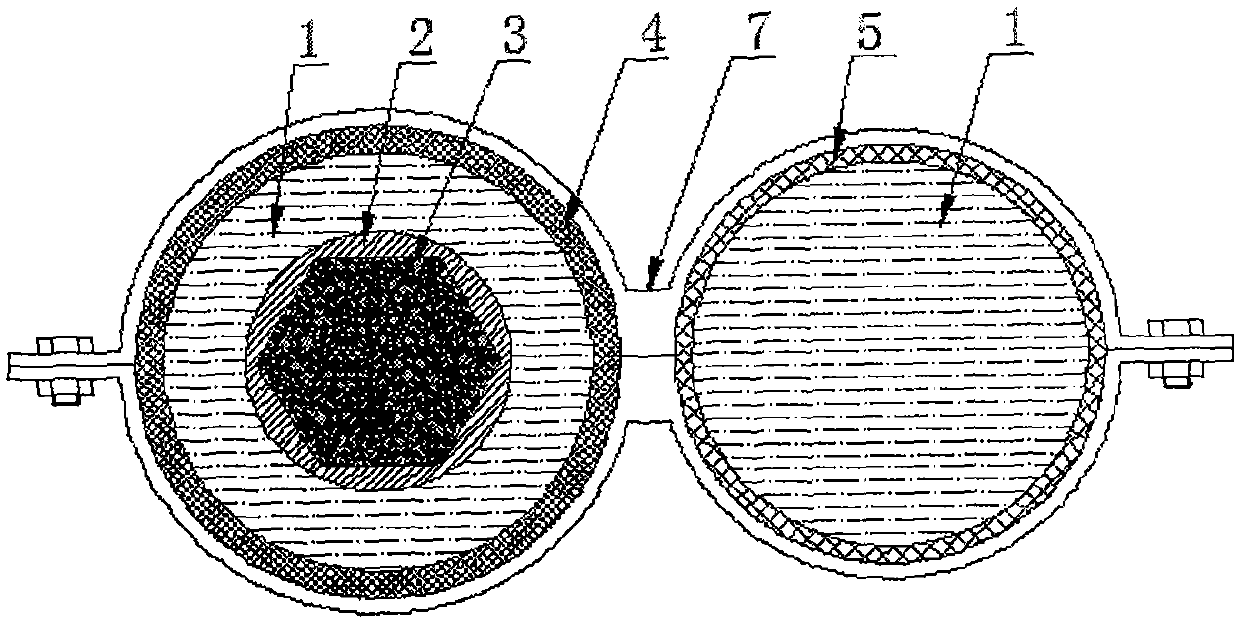

[0012] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0013] Such as figure 1 , figure 2 As shown, a kind of auxiliary heat dissipation water cable according to the present invention includes a cooling liquid 1, bundled wires 3, an insulating layer 2 and a protective sleeve 4 coated on the wires 3, the cooling liquid 1 It is filled in the cavity between the insulating layer 2 and the protective sleeve 4, and a hose 5 is arranged on the outside of the protective sleeve 4, and the two ends of the hose 5 pass through the pipe joint 6 and the inner surface of the protective sleeve 4 respectively. The cavity is connected and closed, and the cooling liquid 1 can flow freely in the cavity of the protective sleeve 4 and the hose 5 through the pipe joint 6, and several clamps 7 are arranged in the middle section of the outer wall of the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com