Multifunctional low-temperature upgrading furnace with hydrogen-source stable decomposition

A technology of compound function and upgrading furnace, which is applied in coking oven, special carbonization, petroleum industry, etc. It can solve the problems of low yield of pyrolysis tar, uneven heating, and high dust content of tar, so as to improve the yield of tar , increase air permeability, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

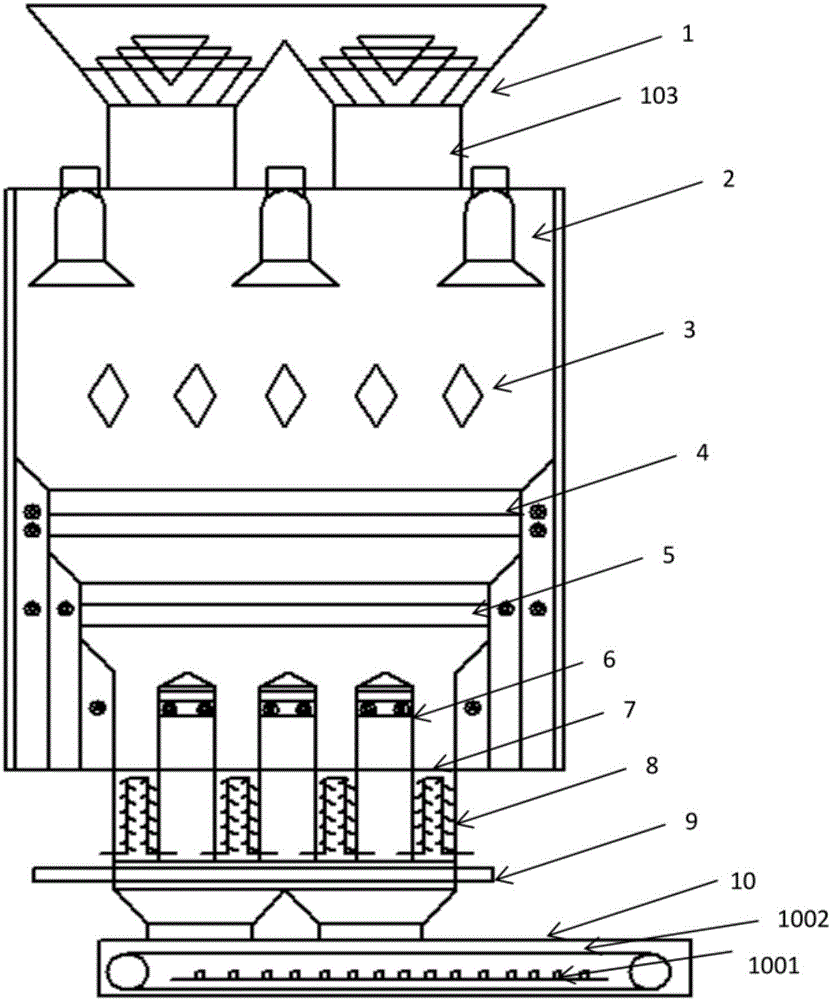

[0034] see figure 1 , for mixed coal with a particle size below 30mm, the structure of the composite function low-temperature upgrading furnace of the present invention is as follows figure 1 As shown, it includes material distribution tank 1, dust removal and drainage device 2, disturbance device 3, hydrogenation device 4, first cloth heating device 5, second cloth heating device 6, discharge channel 7, first cooling device 8, exhaust Solid device 9 and second cooling device 10.

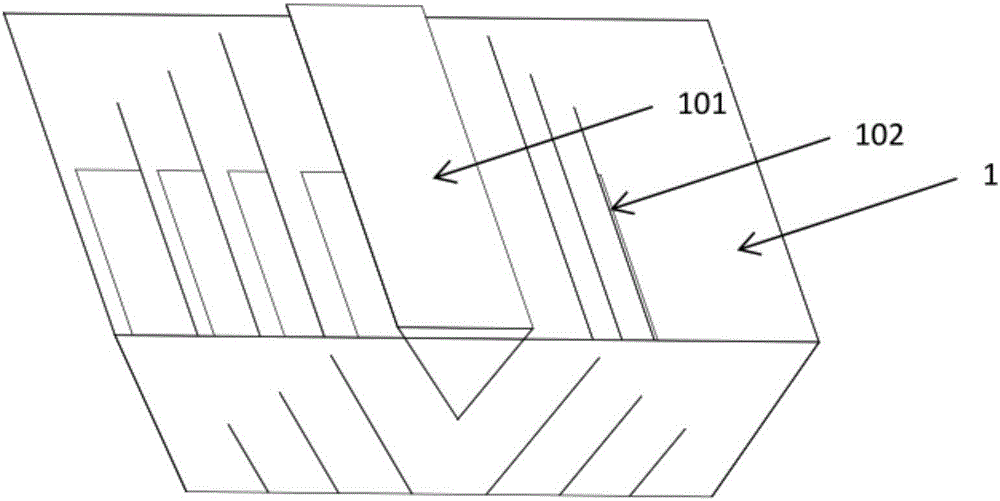

[0035] see figure 2 , in this case, there are two distributing troughs 1, and the coal is evenly arranged in the distributing trough 1 and enters the connecting pipe 103; Segregation phenomenon, the cross section of the distributing trough 1 is rectangular, the distributing trough 1 is welded by an inverted closed triangular structure 101 and several inclined walls 102, the closed triangular structure 101 is set at the uppermost end, and the inclined side walls 102 are adjacent to each other Set...

Embodiment 2

[0050] see figure 1 , for mixed coal with a particle size below 30mm, the structure of the composite function low-temperature upgrading furnace of the present invention is as follows figure 1 As shown, it includes a distribution tank 1, a dust removal and drainage device 2, a hydrogenation device 4, a first cloth heating device 5, a second cloth heating device 6, a discharge channel 7, a first cooling device 8, a solid discharge device 9, second cooling device 10;

[0051] In this case, two distributing troughs 1 are set, and the coal is evenly arranged in the distributing trough 1 and enters the connecting pipe 103;

[0052] see figure 2 The distributing trough 1 is used to distribute the raw coal transported by the power equipment so as not to cause segregation of the raw coal. The section of the distributing trough 1 is rectangular, and the distributing trough 1 is welded by a closed triangular structure 101 and several inclined walls 102 , the closed triangle 101 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com