Full-fluidized jet fluidized bed damping machine and novel damping process

A technology of jet flow and humidifier, which is applied in the petroleum industry, coke ovens, etc., can solve the problems of changing the initial particle size of coal, high operating costs, low heat transfer efficiency, etc. Density, the effect of expanding the source of coking coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

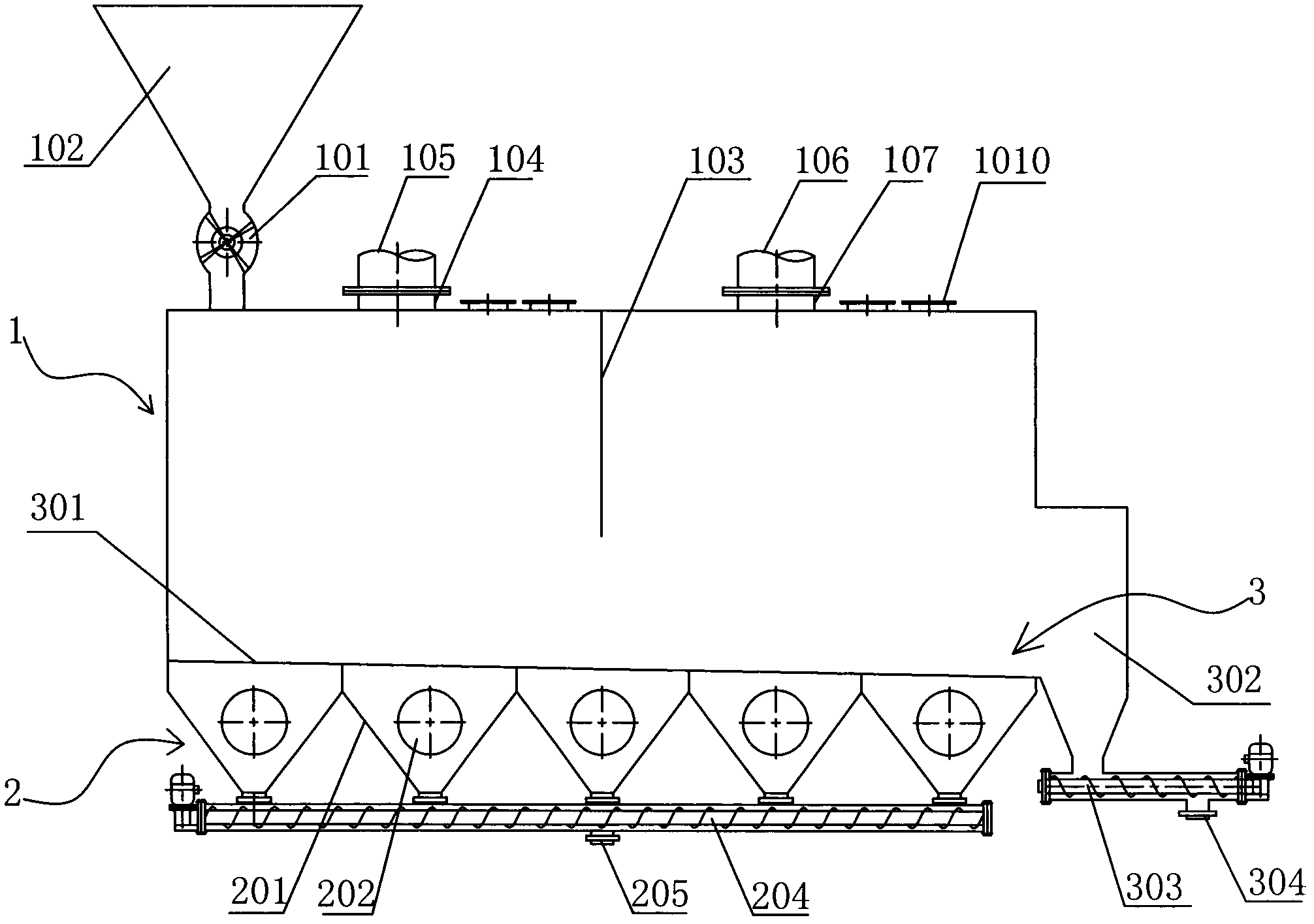

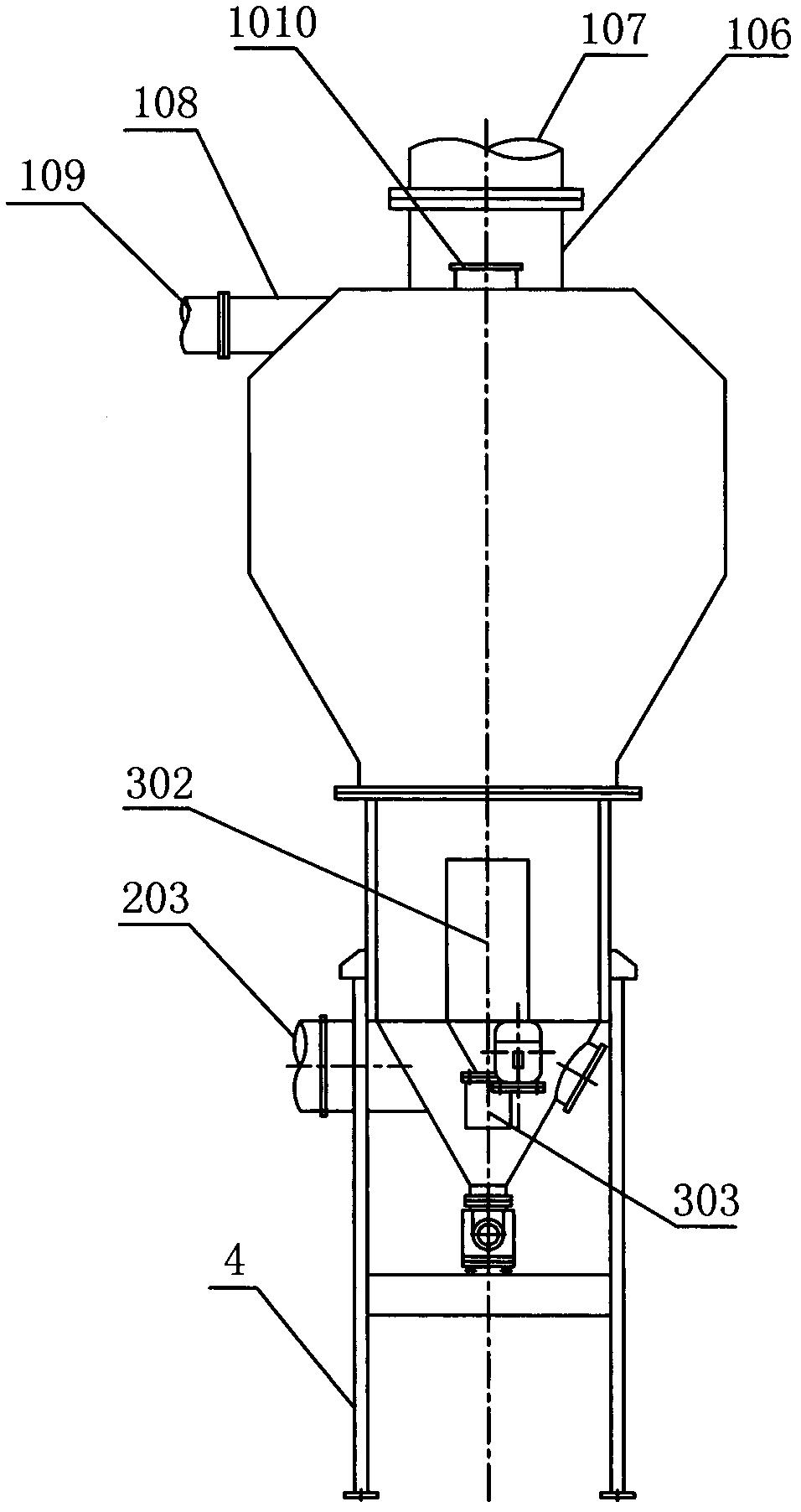

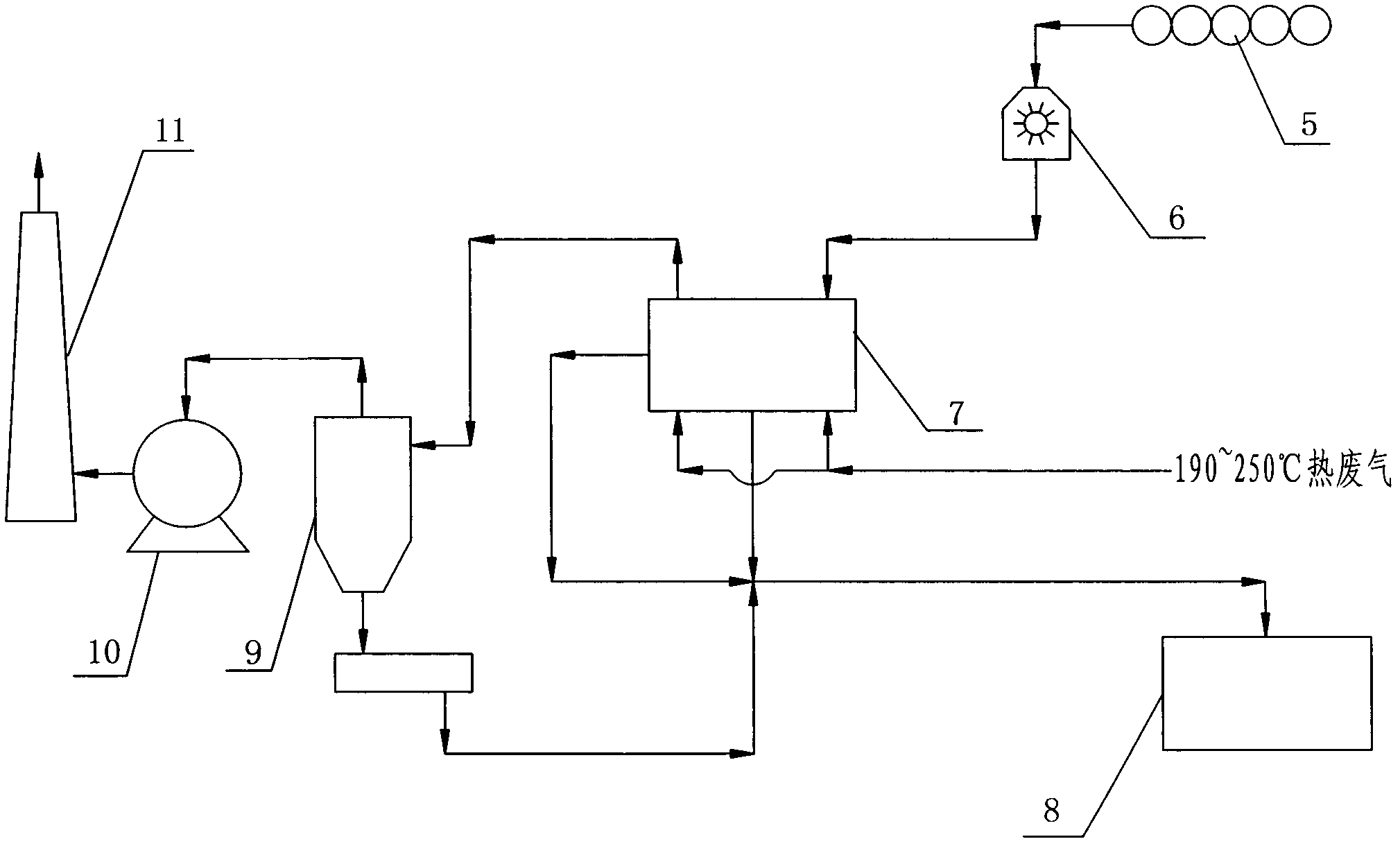

[0025] combine figure 1 , figure 2 , a full-boiling spray fluidized bed humidifier, including a shell 1 set on the upper part, a body 2 set on the lower part and a bed 3 set between the shell 1 and the body 2, the shell 1 and the bed 3. The machine body 2 and the bed body 3 are connected by flanges and assembled into one body with bolts, and the assembled body of the humidifier is installed on the concrete foundation through the bracket 4, which is a steel structure.

[0026] The top of the housing 1 is provided with a feed inlet at the left position, and a star feeder 101 is provided at the feed inlet. The star feeder 101 is used to feed the humidity conditioner body, and the Sealing, a raw material storage bin 102 is arranged above the star feeder 101 . The top of the housing 1 is also provided with an exhaust gas discharge device. The number of the exhaust gas discharge devices is set to two, and all of them communicate with the closed cavity formed between the housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com