Combined thermoelectric conversion device

A thermoelectric conversion device and combined technology, applied in the direction of electrical components, generators/motors, etc., can solve the problems of low thermoelectric conversion efficiency, immature application, and BASE material performance decline, so as to improve thermoelectric conversion efficiency and alleviate pneumatic heating. effect, to achieve full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

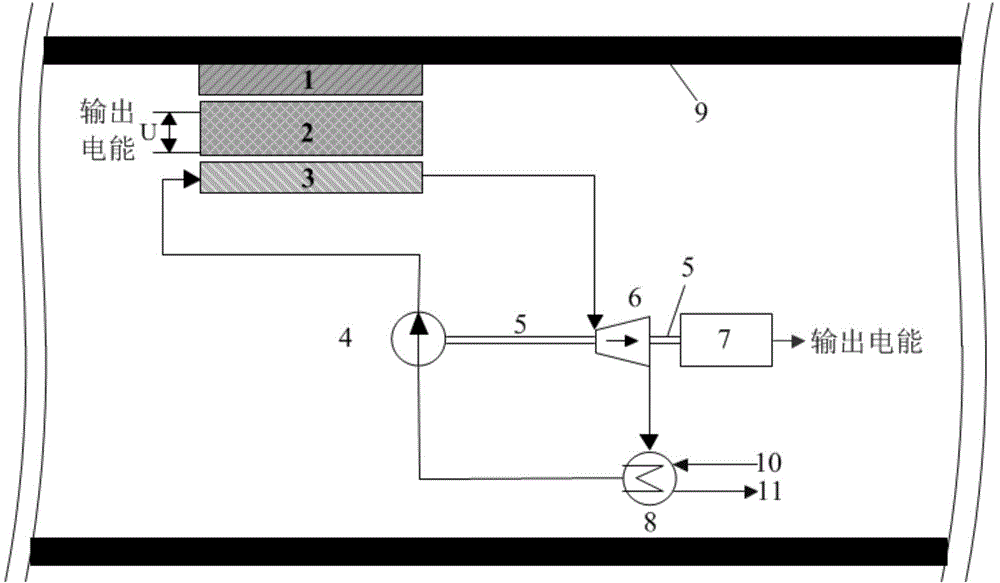

Method used

Image

Examples

Embodiment

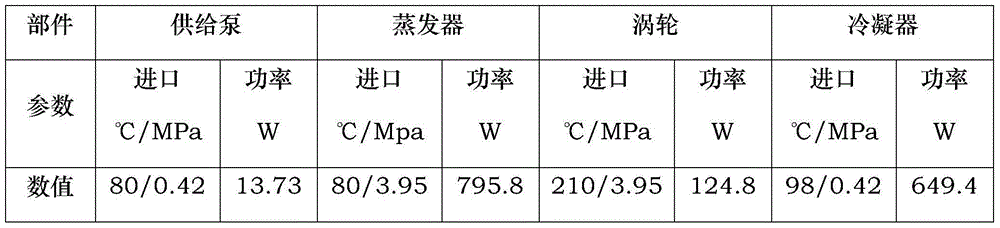

[0039]Hypersonic vehicle design conditions: flight altitude 20km, flight Mach number 5, aerodynamic heat flux 10kW / m 2 . The working fluid of the Rankine cycle is selected as R141b, the condensation temperature is 80°C, the evaporation temperature is set at 200°C, and the degree of superheat is 10°C. The operating parameters of the key components are shown in Table 1, and the flow rate of the working fluid is 3.05×10 -3 kg / s, the output electric power is 100W, and the thermoelectric conversion efficiency of the system is 12.57%.

[0040] Table 1 Operating parameters of key components of the Rankine cycle

[0041]

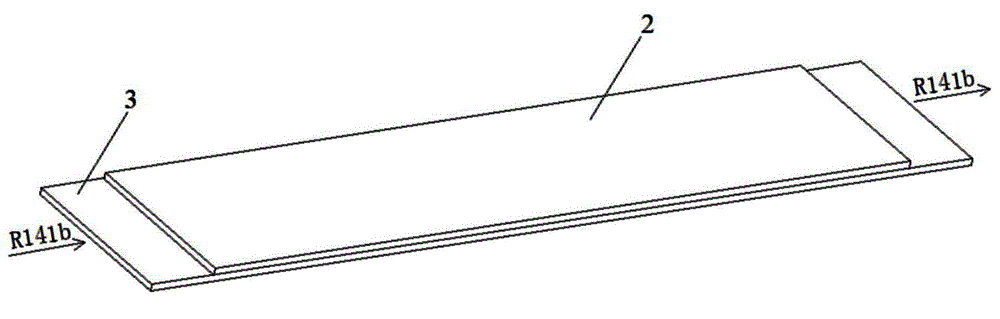

[0042] The heat absorption area of the hot end of the thermoelectric power generation module is 0.084m 2 , the hot end temperature is 300°C, the cold end temperature is 220°C, the output power is 46.1W, the voltage is 14.4V, and the current is 3.2A.

[0043] Assuming that the overall thermoelectric conversion efficiency of the device is the ratio of the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com