Caisson structure and fast construction method of opencaisson

A caisson and derrick technology, which is applied in infrastructure engineering, caisson, construction, etc., can solve the problems of material and manpower waste, and achieve the effect of fast sinking, reducing on-site construction interference, and fast prefabrication and hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

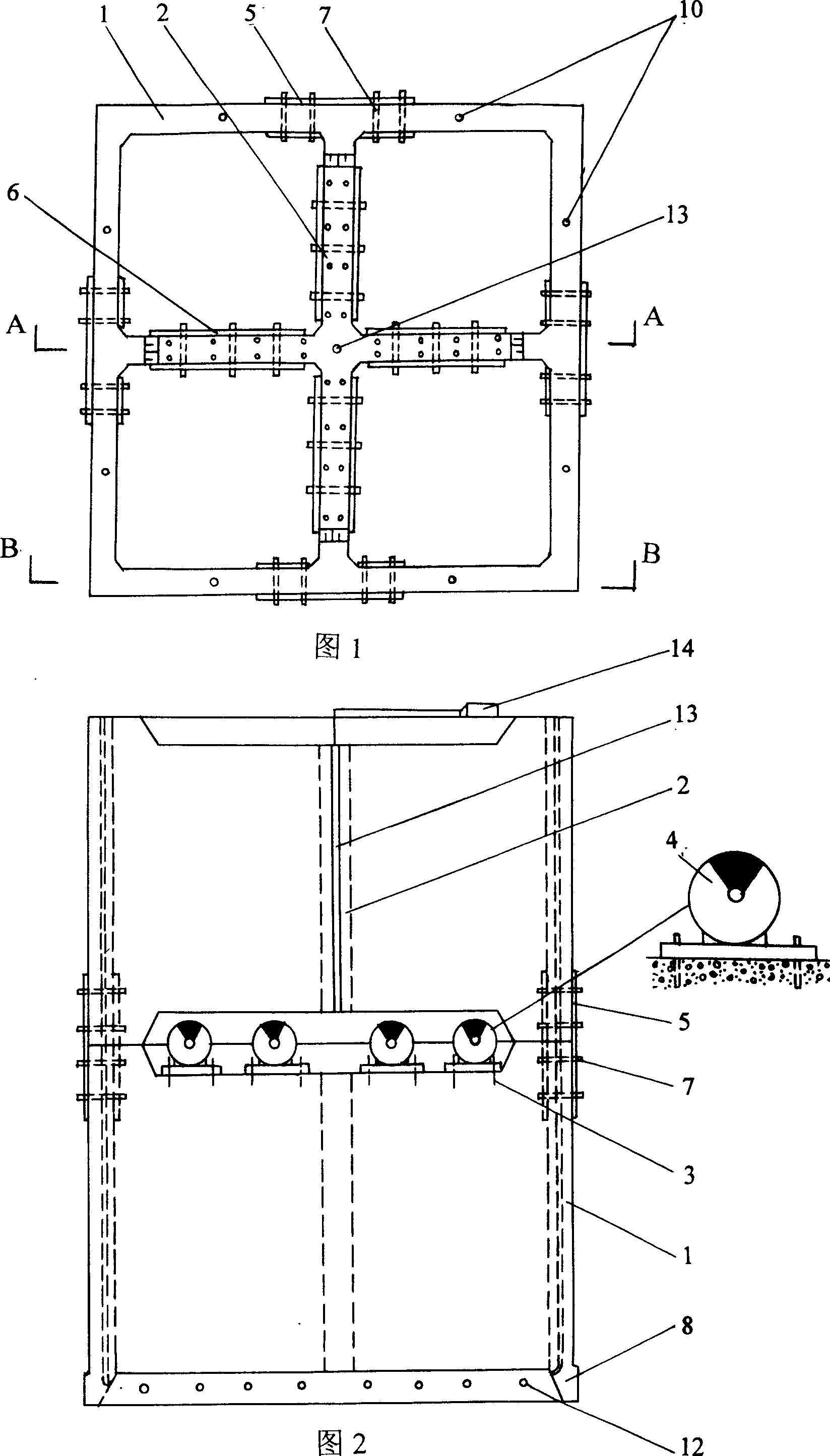

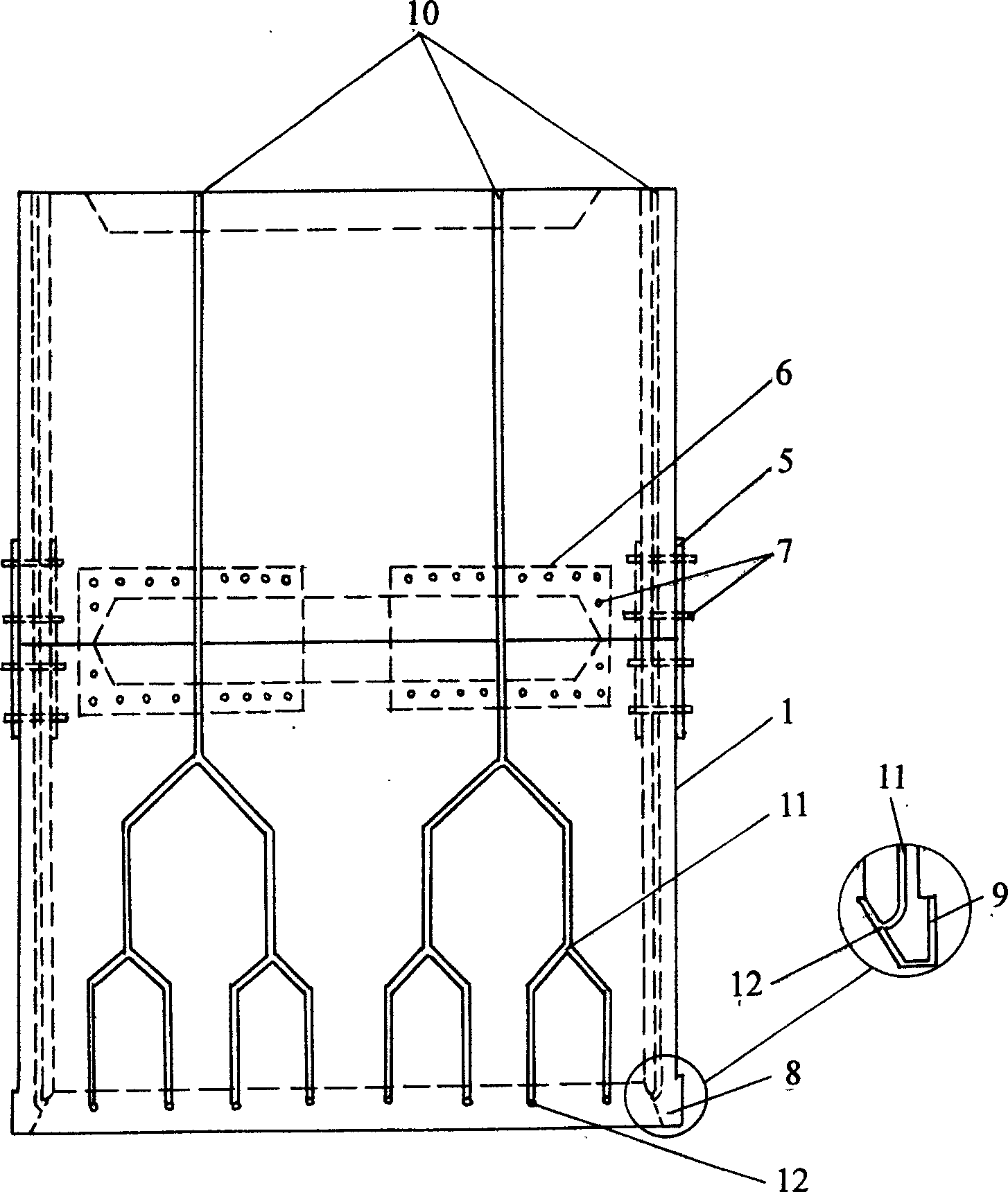

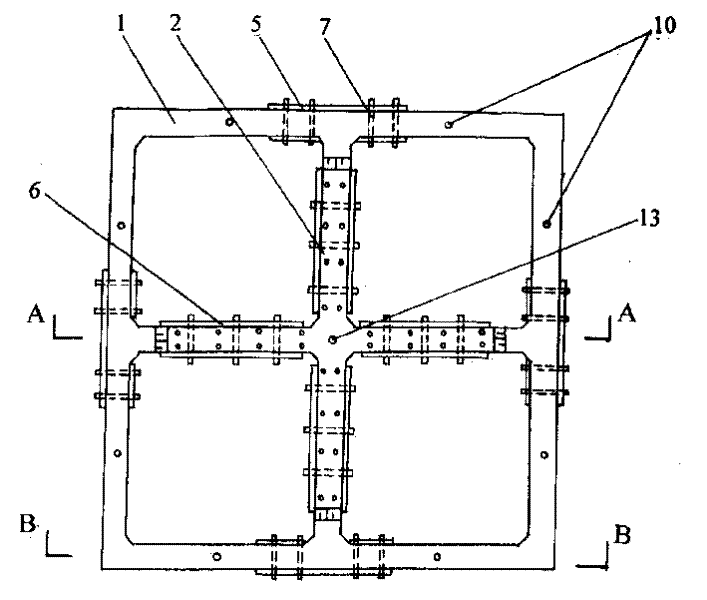

[0023] The derrick structure device of the fast caisson is shown in Figures 1 to 3. The device includes a caisson wall 1 and a caisson partition wall 2. The walls around the caisson constitute a well circle, and a connecting beam or a partition wall 2 is arranged inside the well circle. The upper and lower well circles constitute a number of well sections, the bottom of the lower well section is provided with a blade foot 8, the upper and lower steps are set on the connecting partition wall between the well sections, several shock absorbers 4 are installed in the steps, and high-pressure flushing main pipes 10 are pre-buried in the surrounding well walls. , branch pipe 11, nozzle 12, pre-buried cable pipe 13 at the intersection of the partition wall, cable pipe and shock controller 14 conduction, constitute the whole of the derrick structure device of fast caisson.

[0024] The exciter 4 and the partition wall 2 are connected by vertical anchor bolts 3, and the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com